- AROUND THE SAILING WORLD

- BOAT OF THE YEAR

- Email Newsletters

- America’s Cup

- St. Petersburg

- Caribbean Championship

- Boating Safety

Gougeon’s Everlasting Experiment

- By Dave Reed

- Updated: October 6, 2020

It’s a December night in 2015, and Matt Scharl is restless in the “guest room” set up for him in an office inside Gougeon Brothers boat shop on the bank of the Saginaw River in Bay City, Michigan. Out on the shop floor is the unmistakable white trimaran Adagio , designed and built in 1969 by the Gougeon brothers, Meade and Jan.

Earlier in the day, Scharl stood alongside Meade and Gougeon Brothers’ president and CEO, Alan Gurski, assessing Adagio ’s winter worklist. Meade’s primary concern was a 3-foot section of track that kept separating from the mast. Now, late at night and alone, Scharl can’t resist “popping a few screws,” and before long, he’s extracted the entire track. When he finally stops, the track is on the shop floor among chunks of epoxy and bits of wire.

“It’s wasn’t what they had in mind,” Scharl says, recounting the story with a chuckle, “but I did it anyway.”

He finally turned in at 3 a.m., and when he heard voices inside the shop a few hours later, he got up and walked out to the boat to find Gurski and Gougeon bewildered. “With my toothbrush hanging from my mouth,” he says, “I lean in between them and say: “Huh. That was on there when I went to bed.”

That night was the beginning of a transformation for Adagio , the most legendary craft among the tight-knit Great Lakes multihull crowd. Over 50 years of racing this unique and experimental trimaran, the Gougeons amassed a trove of trophies and accolades, but with Meade’s health declining in the years before his passing in 2017, he had handed the responsibility to son Ben and son-in-law Gurski, both of whom seized the opportunity to ensure that the boat remained competitive. Work on boats is what they do at Gougeon, especially in the winter, and they were honored to continue Meade’s great experiment.

“I knew then the boat was famous and unique and had quite a history to it,” Gurski says. “That being said, she was getting old and showing her age. Meade had a philosophy that the boat needed to last only as long as he would last. As he got older, some things on the boat went undone—or got done quickly for another day of sailing.”

For Ben Gougeon, one of 10 children, the boat was never really more than another vessel used for family outings and weeknight races in the once-thriving Bay City racing scene. As a kid, he says, he was more or less ballast. “Sailing came so naturally to my father, it was hard for him to teach others how to sail. It was more like, pull on that red line until I tell you to stop,” Gougeon says. “At the time, I never appreciated her for what she was. To me, as a kid, it was normal. I didn’t realize the vast differences between Adagio and all the other multihulls.”

Nor did he realize how fast the boat was, and still is today: “It used to drive me crazy because whenever we’d finish a race, my dad would hove to, and we’d sit there and wait for every boat to finish. We’d be around the course in like 20 minutes and then wait for what felt like hours. It wasn’t that he wanted to show everyone that he’d won; he was too humble for that. He just thought it was customary to wait for all the boats to come in, and that’s what he would do. He would talk to people as they came by and congratulate them on a good race and that kind of thing.”

Only once Gougeon, who now works for the company, and Gurski, who also considers himself a late-comer to competitive sailing, started learning how to sail the boat under the tutelage of the Gougeon brothers did they realize what they’d been bestowed. “We fell in love with it,” Gurski says. “Then came the caretaking part of it, which comes from building a relationship with the boat, sailing it and racing. It’s like your dad’s old Chevy; you develop an affection for it, and then find yourself spending an inordinate amount of time maintaining and repairing it. Part of what makes us unique as a crew—and as a family, and us as a company—is that we really like to work with our hands. It’s therapy for us in the boat shop; it keeps us closer to our customers, using our products to constantly maintain and repair our own boats.”

Initially they didn’t really know what the boat needed, but by the second season, they started to have a long-term vision of what its restoration would look like over the next 10 years, being realistic about what was most important—and having the budget to do it right.

“For example, a few years ago, a crack developed in the centerboard trunk, and every time we went over a wave, the boat would fill up with water,” Gurski says. “That winter’s job was to tear the boat in half, tear out the centerboard trunk, and then put it back in. That wasn’t fun.”

It was Meade who eventually enlisted Scharl to assist his son and Gurski himself with updating and racing the boat. “He said he was getting too old to sail Adagio , and he asked me to come to Bay City to help with the boat,” Scharl says. “I said, ‘Sure, but I’d like to sail it once to get an idea of what is involved.’ What I realized right away was that her sails were unforgiving, the lead positions were not optimal, and the hardware was aging on the boat.”

So began Adagio ’s transformation at the hands of Gougeon, Gurski and Scharl.

“Over the years, Meade would try stuff, put it on the boat, but then never take it off if it didn’t work. There was a lot of unnecessary stuff on the boat,” Scharl says. “So the primary thing was to simplify it and get a good set of modern sails. It was about making the boat easier to sail. It weighs only 2,600 pounds to begin with, so there wasn’t much room to take much weight out.”

Roughly 300 hours of labor went into the boat in the first year, 200 the next, and by the third, the work list was much smaller. That was when they finally added a traveler, engineered by Gurski and built in-house by the company’s craftsmen. “We had to do quite a bit of reinforcing to support the traveler on the transom,” Gougeon says. “It’s sort of odd the way it’s laid out because there’s a back cabin with a hatch. The traveler currently sits over that hatch, but no one goes back there anyway. It has made a huge difference on the boat. Before, we’d be blowing the sails in the gusts and have to reset them. The traveler greatly simplified the sailing of the boat.”

Adagio ’s sail number is E5, Gurski explains. The E stands for experiment: “ Adagio is Meade’s fifth experiment in boat design and construction, so I like to say there were four failures before it. It took until 1969 to get to Meade’s E5. And it just so happens that Adagio , for what she’s built do to—which is light-air sailing in the Great Lakes—holds true. She’s a light-air machine, and when it’s 8 to 10 knots, any boat in any fleet can’t hold up to her. We could make her stronger, sure, but we’d be hard-pressed to build her stronger at the same weight, or lighter. He got it right, so why change a good thing?”

Gougeon says his father was never really attached to any one particular idea, and that’s why the boat was forever evolving: “He was all for making changes for a tenth more speed and open to any changes that might allow for that. He would try to reduce the weight to make something work better, pushing it lighter and lighter until it broke, and then he’d go back to that point so it didn’t break again.”

Today, not much of his father’s tinkering remains, Gougeon says. Most of the original tiller is there, but everything’s been pretty much replaced on the boat, except the main center hull.

Scharl says Adagio is now close to perfect. “It’s crazy how fast the boat is,” he says, “but the number one thing is how quiet it is. It doesn’t make any noise going through the water. Up to 18 knots downwind, it’s absolutely quiet. Meade’s vision in 1969 is so spot-on today. I look at a lot of designs today, and I’m like, ‘Meh…they’re good, but they’re all condition-based.’ What Adagio does in all conditions is incredible. In winds less than 10 knots, no one is touching that boat. In the right conditions, Adagio would beat every boat by 15 miles—I guarantee that. It destroys TP52s and Great Lakes 70s because it’s incredibly slippery.”

Scharl’s boasts, of course, are backed by results, including a multihull division win in the 2020 Port Huron to Mackinac Race, a brutal upwind slog that saw most of its competitors retire. The previous year, the team of Scharl, Gurski and Gougeon finished second—by 14 seconds—to the 60-foot trimaran Earth Voyager . In 2016, 2017 and 2018 Adagio took home first-place honors. Countless victories beforehand with Meade and Jan and many others on board stand as a testament to its prowess.

Adagio ’s results reflect its proof of design, and its construction technique as well, Gougeon says. “It’s been around since the very beginning of the company,” he says, “so, after so many years, it stands out as a longevity thing. This boat was built with no mechanical fasteners in it—other than the stays that hold down the amas. It’s a testament to the epoxy, and certainly as she got faster in the earlier days and won a lot of races, it certainly helped promote West System to what it is today.”

As a sort of sailing shrine to the Gougeon family and the company it built more than 50 years ago, Adagio is an everlasting experiment that continues what they started when they put glue to wood. While nobody has ever tried to buy the boat, Gougeon says, it’s never been for sale anyway. Some things are not for sale, especially something this unique. There’s just not a better experience on a sailboat than Adagio going downwind, surfing waves, Gurski says. The sensation under spinnaker on this boat is magical. The quiet, the speed and the stillness are fantastic—just as Meade knew it would be.

- More: print 2020 fall , Sailboats , Trimaran

- More Sailboats

Nautor Swan Has A New Pocket Rocket

Pogo Launches its Latest Coastal Rocket

A Deeper Dive Into the Storm 18

2024 Boat of the Year Best Recreational Racer: Z24

A Guide to Tactical Risk Management

Regatta Series Returns to Detroit

Sailing’s Health Starts At Home

Luna Rossa’s New AC75 Marks Its Silver Age

- Digital Edition

- Customer Service

- Privacy Policy

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Professional BoatBuilder Magazine

Game changer: meade gougeon, 1938–2017.

By Dan Spurr , Dec 11, 2017

Meade Gougeon works on a piece of rigging for a 32 ‘ (9.8m) catamaran designed by brother Jan. In the 1960s Meade and his brothers, Joel and Jan, built DN iceboats, raced them on Michigan’s Saginaw Bay…and never really stopped.

One of the most remarkable and influential people in boatbuilding passed away last August 27 from skin cancer at the age of 78. With brothers Joel and Jan, Meade formed Gougeon Brothers Inc. in 1969 to formulate and market WEST System epoxy resins and accessories. The name WEST stands for Wood Epoxy Saturation Technique, a process he developed to improve on traditional cold-molded hulls, in which multiple layers of thin wood veneers are diag onally stapled over frames and coated with low-viscosity epoxy resin to lock the pieces into a stiff monocoque structure. Living as the boys did on Saginaw Bay, inside Michigan’s thumb, racing iceboats was a popular winter activity. Soon they began building them—200 between 1969 and 1974.

From the beginning the Gougeons were true believers in wood; its excellent physical properties confirmed their conclusions in numerous lab tests they performed. But noting that just 25% of the strength of a good mechanically fastened joint is transferred, they began an intensive search for a means to join wood parts without fasteners. As any carpenter knows, wood and glue go together like a horse and saddle. Popular glues such as resorcinol required high clamping pressures in the order of 125 psi (862 kPa), and they were not suitable as coatings. With the aid of Herbert Dow, grandson of Dow Chemical Company’s founder and an avid iceboater, the Gougeons were introduced to a chemist who helped formulate an epoxy resin that functioned as a glue and as a coating to seal in desired moisture content of the wood used in construction.

Confident of their direction, Meade quit his job as an industrial salesman, and Joel, who flew 131 combat missions in the Vietnam War, contributed some of his savings. Along with younger brother Jan they bought a building on the Saginaw River and continued building boats—more DN iceboats and then the first all-WEST System boat, the 35 ‘ (10.7m) Adagio trimaran. The year was 1970. No metal fasteners were employed in the boat’s basic structures.

In the early days all three brothers worked in the boatshop, commencing an impressive build list: the trimaran Vic tor T , which won the C-class Nationals in 1969; the Ron Holland–designed Golden Dazy , which won the 1975 Canada’s Cup; the 60 ‘ (18.3m) proa/sloop Slingshot , intended to break the world’s speed record under sail; the 60 ‘ Rogue Wave that newspaperman Phil Weld commissioned to compete in the OSTAR from Plymouth, England, to Newport, Rhode Island; and the Gary Mull–designed Hot Flash Half Tonner. All were cold-molded: lightweight, stiff, and strong. The boatbuilding world took note—not so much for the cold-molding construction process, but for their epoxy.

Word traveled locally at first, and eventually across the U.S. and to Europe and elsewhere. And not just among boat people. J.R. Watson, an early employee who spent a lot of time in customer service, recalls people calling and wanting to know if WEST System epoxy could repair a toilet tank. Indeed, GBI’s newsletter, Epoxyworks , advises readers on a very wide range of applications, many of which can be classified as home improvement.

Yellow Thing was one of Gougeon’s many small boats devised for his sailing pleasure.

By the late 1970s it was only natural that someone of Meade’s intellect desired to gather the company’s collective knowledge and share it via publication of a book. As it happened, Meade advertised for a writer/editor to join the GBI team, and I answered. My “interview” consisted of three visits to meet the brothers in Bay City, where I was given the assignment to read the book manuscript for The Gougeons on Boat Construction and offer my thoughts on how it could be improved. The last of the three visits was to the family’s Fourth of July picnic, I guess to see if I was a good fit. Meade offered me the position, which for a variety of reasons I regretfully declined. But we became friends, perhaps in a way not possible if I’d become an employee.

While GBI became a profitable business, developing new product lines such as custom PRO-SET epoxies for other industries, including aerospace, Meade was always a boatbuilder at heart. It became customary for new employees to build a boat in the shop, where there was plenty of guidance available. Current CEO Alan Gurski, Meade’s son-in-law, built a Gougeon 12.3 when he came on board in 2007.

Meade (left) and Jan Gougeon sail the first WEST System boat, the trimaran Adagio , on Saginaw Bay, in 2009, for a 40th-anniversary story in this magazine.

Meade loved to sail and he liked to keep things simple, though on my last sail aboard Adagio he admitted there were no more control lines left to add. The boat had been totally tricked out. He developed a keen interest in small wind-driven boats. He and pal Hugh Horton used to get away in the Whalesback Channel area of Lake Huron’s North Channel. Horton says Meade was always well aware that his father had died of a heart attack (on Christmas morning) when Meade was still a teenager. Taking control of his diet and fitness regime, Meade always stayed in great shape; indeed, he won the North American DN iceboat championship at age 58—a remarkable feat. And just this year he won his class in the 300-mile Everglades Challenge from Tampa to Key Largo—competing in a sailing canoe. (In his feature “First Encounter,” on page 48, Jim Brown shares Randy Smyth’s account of sailing past Meade in that race.)

Few figures in boatbuilding were more admired than Meade—for his intellect, passion, dignity, and generosity.

Read more Rovings articles

- Amphfoil marries Air Props and Hydrofoils

In the wake of the Miami International Boat Show in February, longtime builder of quality cruising sailboats Shannon Boat Company of Bristol, Rhode Island, announced the rollout of the Amphfoil… Read more »

Departures: Carl Chamberlin

Passionate, competent, considerate, modest, and thoughtful is how designer and boatbuilder Carl Chamberlin is remembered by those who knew him. He died last November at age of 75 in Port… Read more »

SAFE Boats Regains Small-Business Status with Employee Ownership

More than 20 years ago, Professional BoatBuilder ran a feature titled “God, Country and Fast Boats” (No. 85, page 64) about SAFE Boats International (SBI), a Bremerton, Washington–based manufacturer of aluminum boats…. Read more »

Recent Posts

- There was Only One Partner I’d Trust for the Refurb Project of my Life: AkzoNobel

- Citimarine Store Expands to a New State of the Art Location in Miami

- Find out how 3D printing can help your boatbuilding with MASSIVIT

- Van der Werff’s Curved Wood

- Companies (86)

- Construction (106)

- Design (162)

- Drawing Board (11)

- Education (25)

- Environment (16)

- Events (21)

- Materials (50)

- Obituary (18)

- People/Profiles (49)

- Products (16)

- Propulsion Systems (32)

- Racing (16)

- Repair (37)

- Rovings (318)

- Short Cuts (3)

- Sponsored Partner News (17)

- Systems (80)

- Task Sheet (1)

- Uncategorized (26)

- Wood to Glass (7)

ProBoat.com Archives

All Inductees > Class of 2015

Jan Clover Gougeon

August 7, 1945 - December 18, 2012

Bay City, Michigan

Jan Gougeon bio & tribute – WestSystem.com

The Gougeon Brothers on Boat Construction – PDF

Jan Gougeon obituary – Bay City

Jan Gougeon stories archive – SailingAnarchy.com

Sailing Giant Recalled – MyBayCity.com

Meade & Jan interview Aug. 8, 2008 Mackinac Race – SailingAnarchy.com – YouTube video

DN According to Jan Gougeon – IDNIYRA

Jan Gougeon profile – New England Ice Association

Meade Gougeon, the late Jan Gougeon’s older brother by seven years, says Optimist Pram designer Clark Mills saved his brother from a life of misery. Jan was not born well. “He was sickly,” Meade says, “cross-eyed, dyslexic, and so skinny we called him `rack of bones.’ The other kids teased him. He had low self-esteem. Then our local yacht club got 30 Opti kits. We’d been whacking together boats on the beach in Bay City for years, just like our ancestors, so we built an Opti in a week, paint and all. It was April, cold as hell, but Jan wanted to sail the boat. He sailed that boat 50 days in a row. He was eleven, and he never lost a race. Finally, he was not only good at something, he was gifted. He had it! It changed his life. He dominated the DN ice boat fleet from 1971 to 2000, winning eleven national championships and four Worlds. “Jan knew he was going to build boats. I didn’t have a direction, but I was hot to take a chance and said okay, let’s do it.” Jan went to Canada and apprenticed for three years under builder and pattern maker Vic Carpenter, who first introduced Jan and Meade to epoxy. Jane Pegel, who has sailed DNs beyond her 80th year, recalls the 1989 DN Worlds in Burlington, Vermont, when Jan broke his mast during a practice day. “He traveled in a small car,” Jane says. “He had no parts or repair kit with him. So we all gave him some `Gouge’ (West System), and he sat up all night in his room fixing the mast with tongue depressors. He said he worked stark naked so he wouldn’t have to wash his clothes. He got the mast fixed, and finished second in the Worlds that year.” Phil Weld’s plan to do a solo Atlantic crossing (he would set a record in 1980) in the trimaran Rogue Wave that the Gougeons were building for him, spurred Jan to sail a trimaran in the Bermuda One-Two in 1980. Sailing single-handed Bermuda to Newport, Jan got flipped over by a northeaster in the Gulf Stream. He survived four days on the overturned boat before a freighter found him. “The next four boats he built were rightable,” Meade says. “It was the first and last time any Gougeon had to be rescued. We always get back on our own steam.” – Roger Vaughan

Preserving America’s Sailing Legacy

Engaging Sailing’s Next Generation

Stay Connected to the National Sailing Hall of Fame

A brief and abridged look back on the first five decades of Gougeon history.

Our Heritage

In the late 1960s , Brothers Meade, Joel, and Jan Gougeon opened a boat shop on the west side of the Saginaw River in Bay City, Michigan. Their first product was DN Iceboats, and they would sell more than 200 of them over their initial five years in business. They also built custom racing monohulls. The boats they built were light, fast, strong, and long-lasting thanks to the brothers’ pioneering the use of epoxy for cold-molded wooden boat construction. Previously, the epoxy had been used only as an adhesive. By reformulating it with diluents that allowed the epoxy to flow, they created an unsurpassed moisture-resistant substance with excellent laminating and coating characteristics.

Eldest brother Meade elaborated on the company’s origins:

My brother Joel returned from Vietnam having flown 131 combat missions. At the time, word was traveling as to what we were doing in our shop. Other boat builders were coming around asking questions and wanting to buy some of the epoxy resin and hardeners we were formulating for our own use. We were flattered but with the frequent interruptions, it was becoming increasingly difficult to get our boats built. Joel had saved some money during his four years in the air force and arrived at exactly the right time to invest in our fledgling business and help start a new business venture selling our epoxy. “Looking Back” by Meade Gougeon, Epoxyworks 29 , Spring 2009

For images and details of the many boats the Gougeons have built over the years, visit Gougeon Boats .

WEST SYSTEM Epoxy

By 1971 , the Gougeon Brothers were selling the flagship brand, WEST SYSTEM Epoxy, to other boat builders and individuals who wanted to use it to build or repair their own boats. Back then, epoxy was brand new to the marine market.

Meade Gougeon:

We worked hard those first months, setting up production facilities and developing packaging and labels. But looking back, this was actually the easy part. Far more difficult was adequately educating our new customers on the proper metering, mixing, and applying of the various components of the new WEST SYSTEM product line. Having worked with epoxy over the previous 10 years, we’d mistakenly assumed it would be as easy for the average customer to understand as it was for us. Instead, we found ourselves spending a good portion of our time on the phone explaining how to use the products, or providing tours of our shop to visitors who wanted to see with their own eyes this revolutionary approach to using wood as an engineering material. “Looking Back” by Meade Gougeon, Epoxyworks 29 , Spring 2009

Much of WEST SYSTEM’s early success was thanks to its compatibility with wood. It was used for building new wooden boats and repairing vintage watercraft.

By the early 1970s, mass-produced fiberglass boats had eclipsed the market for wooden boats. With the aging of the fiberglass fleet came the need for a dependable repair resin. Epoxies were popular because of their superior moisture resistance and ability to bond tenaciously to various materials. By the 1980s, WEST SYSTEM had become nationwide’s trusted go-to epoxy for boat repair yards.

The Boatbuilder

In 1977 , GBI published the first edition of The Boatbuider , a newsletter to keep customers apprised of the goings-on at the company. This black and white, 8-page newsletter would eventually grow up to become Epoxyworks magazine.

1n 1978 , GBI manufactured laminated wood specimens for use in NASA’s Wind Energy Project Office. Tests were performed to determine the strength of an epoxy bond between a threaded steel rod and a laminated wood specimen. The GBI specimens were so strong they actually broke NASA’s test machine.

Employee Stock Ownership Program

In 1983 , Gougeon Brothers, Inc. began the groundwork for becoming an employee-owned company . Any full-time Gougeon employee you speak with is a part-owner of the company and has a vested interest in keeping you as a satisfied customer.

Wind Turbine Blades

It was in 1985 that production of 65′ long wind turbine blades for Westinghouse began in GBI’s Bay City plant. When erected, these wind turbines swept a 142′-diameter and could produce 600 KW of power in 28 mph winds.

Gougeon Laminating Epoxy

In 1988 , the in-house chemists at Gougeon Brothers, Inc. developed Gougeon Laminating Epoxy, or GLH/GLH. This product line would be the precursor to the company’s popular OEM epoxy brand, PRO-SET. Most notably, the brothers used GLR/GLH in cold-molding wind blades for Westinghouse, in the production of their G-32 trailerable catamarans, and in the Formula 40 racing trimaran Adrenalin which competed in Brest, France. For more on the many boats built by GBI, visit Gougeon Boats.

DN Gold Cup

Jan Gougeon took his 4th DN World Gold Cup, placing 1st overall in the 5 races of the International DN Ice Yacht Racing Association (IDNIYRA) Gold Fleet Regatta. The competition to place very close to home: on Lake Huron’s Saginaw in February 1991 .

Epoxyworks Magazine

GBI’s occasional newsletter, The Boatbuilder , became a full-fledged bi-annually published magazine in 1992 . Christened Epoxyworks , the publication deeply delves into building, restoration, and repair with epoxy. With more than 100,000 subscribers between its print and digital editions, Epoxyworks is easily the most widely read magazine on epoxy geared for the do-it-yourself audience.

PRO-SET Epoxy

The brand name Gougeon Laminating Epoxies was changed to PRO-SET in 1994 . These OEM epoxies set new standards in room-temperature cured, post-curable laminating, and infusion epoxies. They have continued to grow in popularity among high-end composite builders in the marine, automotive, and aerospace industries.

ISO Certification

In 2002 , GBI completed the arduous certification process under the ISO 9001:2000 Quality Standard . The standard represents a quality management system that pervades all elements of the business, giving structure to a whole dynamic of customer service. It’s how you know all Gougeon epoxies are manufactured with consistency and great attention to detail under the most rigorous of production standards.

G/flex Epoxies

G/flex toughened epoxies were introduced in 2007 . These innovative epoxy formulations are rubber toughened and bond tenaciously with many plastic, aluminum, and hardwood types. They resist the stress of expansion, contraction, shock, and vibration.

GBI introduced Six10 Thickened Epoxy Adhesive in 2009 . This 2-part epoxy system is packaged in a chambered, self-metering cartridge designed to be dispensed with a standard caulking gun. Its convenience and versatility made it an immediate hit with first-time and seasoned epoxy users.

Jan C. Gougeon 1945 – 2012

GBI founder Jan Gougeon was an extremely competitive sailor from age 11 until shortly before his death in late 2012 at age 67. He dominated the DN iceboat fleet from 1971 to 2000, winning 11 national championships and four Worlds. He was the only member of the 2015 National Sailing Hall of Fame class to be inducted posthumously.

National Sailing Hall of Fame

Brothers Meade and Jan Gougeon were inducted into The National Sailing Hall of Fame (NSHOF) in October 2015 . They were selected because of their pioneering work in using epoxies for boat construction and because they were accomplished, lifelong sailors.

Meade A. Gougeon 1938 – 2017

GBI founder Meade Gougeon passed away in the late summer of 2017 at age 78. He sailed competitively up until the end of his life: In the spring of 2017, he finished first in his class (sailing kayaks and canoes) in the 300-mile Everglades Challenge, a grueling race of small boats powered only by wind or muscle.

2018: Entropy Resins

Never content to rest on the laurels of their early successes, the company stays at the cutting edge of product quality, sustainability, environmental stewardship, and market growth. In 2018, they acquired Entropy Resins, a small, bio-based epoxy brand popular in the board-sports industry as well as with artisans and craftspeople.

Entropy Resins developed Super Sap® technology and manufactured the first epoxy product to be certified under the USDA Certified Biobased Product label program. Today, all Entropy Resins products meet the program criteria and are USDA Certified Biobased Products.

Through green chemistry, biobased and rapidly renewable raw materials, and efficient manufacturing, Super Sap technology is how GBI conserves energy, minimizes harmful byproducts, and reduces the greenhouse gas emissions of these epoxy products from processing. They use third-party laboratories to measure the biobased content of our products.

50th Anniversary

In honor of Gougeon Brothers, Inc.’s 50th anniversary in 2019 , Bay City’s mayor, Kathleen Newsham, made the following proclamation:

Proclamation

Whereas Gougeon Brothers, Inc., a Bay City-based epoxy company with distribution worldwide, celebrates its 50th Anniversary in business today with festivities that include hundreds of their dearest family members, coworkers, colleagues, retirees, neighbors, and friends,

Whereas founders Meade, Joel, and Jan Gougeon were born and raised in Bay City, and chose to make their homes here, and start and keep their employee-owned business here, and build cool boats here, and employ people who are smart, disciplined, and extremely good looking, and sporadically celebrate their successes by lifting a beer glass at the White Goose Inn,

Whereas the company has continuously supported the causes of quality of life, education, and the environment within this community via the Gougeon Employees Foundation,

Whereas on a beautiful Saturday evening near the Saginaw River, to the absolute delight and wonder of everyone gathered around, I, The Honorable Mayor of Bay City Kathleen Newsham, join in the reverie to proclaim that in thanks for their part in bringing five decades of economic growth, excellent employment opportunities, and really cool boats to Bay City and its bodies of water, August Third will be hereby and henceforth known as Gougeon Brothers Day .

Therefore, be it resolved that we declare today, August Third of the year Two-Thousand-and-Nineteen, as the first Gougeon Brothers Day . May this company and this community continue to grow and thrive.

USA Bobsled Team

The USA Bobsled Team ’s go-to for sled repairs throughout their 2020 season was WEST SYSTEM 105 Resin with 205 Fast Hardener. They’d complete the repairs–sometimes in a hotel lobby–let the epoxy cure, then hop into their sled and smoke the competition.

What Pandemic?

As a manufacturer supplying materials for essential infrastructure in the US, GBI was required to remain in continuous operation throughout the 2020-2021 COVID-19 pandemic. While many non-essential employees were set up to work remotely, critical departments such as quality control, manufacturing, and shipping continued full-time on-site, with strict COVID-safety protocols in place, and hazard pay.

G/flex Syringe

In early 2021 , perennially popular G/flex Thickened Epoxy Adhesive became available in a convenient dispensing syringe. The G/flex 655-1 syringe contains 0.42 oz. of resin and 0.42 oz. of hardener, perfect for small repair jobs.

Gougeon Brothers, Inc. is an employee-owned, family-run company located in Bay City, Michigan. We manufacture Entropy Resins ®, PRO-SET ® Epoxy, and WEST SYSTEM ® Epoxy. We also distribute PRO-VAC Vacuum Bag Consumables and publish Epoxyworks magazine. We’re ISO 9001:2015 registered , which means we manufacture all of our products to consistent and rigorous standards.

Official websites use .gov

Secure .gov websites use HTTPS

Sports Heroes Who Served: Vietnam Veteran Was Legendary Boatbuilder

You have accessed part of a historical collection on defense.gov. Some of the information contained within may be outdated and links may not function. Please contact the DOD Webmaster with any questions.

Sports Heroes Who Served is a series that highlights the accomplishments of athletes who served in the U.S. military.

Jan Clover Gougeon was in the Army during the 1960s. He rose to the rank of sergeant and served a tour in Vietnam before his honorable discharge in 1969.

Although Gougeon was a soldier, his heart was in sailing.

After returning from Vietnam and transitioning to civilian life in late 1969, he and his brothers Meade and Joel founded Gougeon Brothers Inc.

Spotlight: Commemorating the Vietnam War

The company began building sailboats and iceboats and found great success in formulating and marketing epoxy resins for boat construction and repair.

Sometimes tragedy or near-tragedy is the inspiration of invention.

On June 20, 1979, while sailing in a qualifying race for the original Single-Handed Transatlantic Race, Gougeon's self-designed and built 31-foot trimaran, "Flicka," capsized in heavy seas in the North Atlantic.

Gougeon floated on the overturned boat for four days before being rescued by a passing freighter.

It was the first and only time he had to be rescued.

Gougeon vowed to design multihull sailboats — such as catamarans and trimerans — that were self-righting, or what Gougeon called "self-rescuing."

The next boat he designed, "Splinter," was self-rescuing, as was every boat he designed afterward.

He also designed and built monohulls, including the 1975 Canada's Cup winner, "Golden Dazy."

Spotlight: Sports in the DOD

Meade Gougeon's 1979 book "The Gougeon Brothers on Boatbuilding" was celebrated by boatbuilders and wood constructionists around the world and is in its fifth edition with hundreds of thousands of copies in print.

Although the Gougeon brothers are legendary boatbuilders, Jan Gougeon is equally famous for racing boats. His first sailboat race was in 1955 at age 10.

Aboard the "Splinter," Gougeon placed first in single-handed Michigan races from Port Huron to Mackinac Island in 1981, 1982 and 1983.

While racing his trimaran "Ollie," Jan Gougeon won the single-handed Super Mac race from Chicago to Port Huron in 1987 and the Great Lakes Singlehanded Society Peter Fisher Memorial Award in 1989.

He competed in the DN Iceboat World Gold Cup Championships over the course of four decades and took the cup home in 1975, 1982, 1985 and 1991. He also won the DN Great Cup of Siberia Race in Russia in 1989, and he won his eighth North American DN Iceboat Championship in 2000.

Gougeon competed annually in the Bayview Yacht Club's Port Huron to Mackinac Race, the Chicago Yacht Club's Race to Mackinac and the 300-mile Florida Everglades Challenge.

His last competition was in a Chicago Yacht Club Race to Mackinac aboard the newly launched "Strings" in July, 2012. He died Dec. 18, 2012, in Ann Arbor, Michigan at age 67.

More Sports Heroes Who Served Sports Heroes Graphic Sports Heroes Who Served graphic - with title Share: × Share Copy Link Email Facebook X LinkedIn WhatsApp Download: Full Size ( 542.72 KB ) Photo By: DOD VIRIN: 200706-D-ZZ999-903

Subscribe to defense.gov products.

Choose which Defense.gov products you want delivered to your inbox.

Related Stories

Defense.gov, helpful links.

- Live Events

- Today in DOD

- For the Media

- DOD Resources

- DOD Careers

- Help Center

- DOD / Military Websites

- Agency Financial Report

- Value of Service

- Taking Care of Our People

- FY 2025 Defense Budget

- National Defense Strategy

The Department of Defense provides the military forces needed to deter war and ensure our nation's security.

Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

Self-Righting / Rightable Trimaran

Discussion in ' Multihulls ' started by Doug Lord , Mar 21, 2011 .

Doug Lord Flight Ready

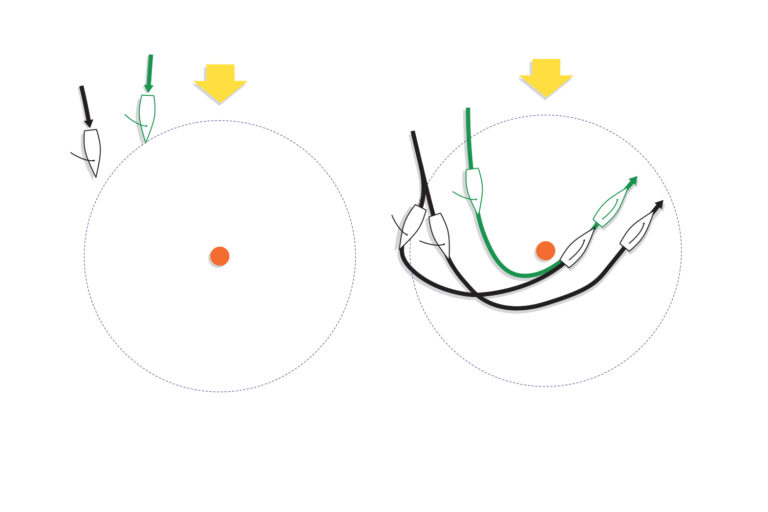

I just discovered this: " At the Gougeon shop construction also started on Flicka, another plywood cruising trimaran. Jan spent four long days on the capsized Flicka in the Atlantic Ocean during a qualifier for the next OSTAR challenge. He had plenty of time to think about rightable trimaran designs before a passing freighter rescued him. Flicka had to be abandoned at sea. In 1980 Jan designed and began to build Splinter, a developed plywood trimaran designed to be rightable after an offshore capsize. Splinter was the second boat, after Adagio, the Brothers launched with a wingmast. She is now owned and raced by Bob Struble (father of A-Cat and DN champ Matt Struble) in Saginaw Bay competes against Adagio and another noteworthy Gougeon built boat, Ollie." ---- I didn't know that the Gougeons had designed rightable trimarans-is anybody familiar with these boats or how the righting system worked? Also, I'm doing as much research as possible on "self-righting" trimarans should one exist. I'm doing a model now* to test my own concept and would appreciate any leads on other proven systems. * http://www.boatdesign.net/forums/mu...-self-righting-trimaran-test-model-36058.html Thanks, Doug

Corley epoxy coated

You might like to search up Len Surtees re: self righting trimarans. He has one available as a stock plan personally I don't agree with "smart keels" on multihulls as it's extra parasitic weight but he is a huge believer maybe they are ok on cruising boat.

Corley said: ↑ You might like to search up Len Surtees re: self righting trimarans. He has one available as a stock plan personally I don't agree with "smart keels" on multihulls as it's extra parasitic weight but he is a huge believer maybe they are ok on cruising boat. Click to expand...

Self-righting Trimaran Corley said: ↑ You might like to search up Len Surtees re: self righting trimarans. He has one available as a stock plan personally I don't agree with "smart keels" on multihulls as it's extra parasitic weight but he is a huge believer maybe they are ok on cruising boat. Click to expand...

catsketcher Senior Member

Get the old book - the Capsize Bugaboo published by Multihulls mag. It has a few self righting designs in it. I think that they often need compromises in capsize prevention to make it work though. cheers Phil

Thanks, Phil.

Gary Baigent Senior Member

Splinter is Jan Gougeon's great looking little trimaran (whereas Splinter and Ollie look a bit boxy/clunky to my eye) and Splinter's rigging stays are block and tackle with the high block maybe a couple of metres up. The mast is a wing and the main hull is flush decked and guessing, Jan designed the boat so that the buoyant wing mast would halt the platform going much past 100 degrees - then the rigging would be slackened/tightened so the platform came upright; then the mast would be winched vertical again. Doesn't look like a self righting design; such a beast would be as rare as rocking horse defecation. Horrible Misty Miller would be one but the keeled cat has bad trade offs: double keel weight and draggy buoyancy bag at mast top. Splinter looks almost square beam to length so the boat has to be a powerful performer, unlike MM. There is a neat photograph of Splinter in the Gougeons' book.

DaveJ Senior Member

I don't know if this helps, But Ian Farrier does talk about righting his tri's on his web page.

DaveJ said: ↑ I don't know if this helps, But Ian Farrier does talk about righting his tri's on his web page. Click to expand...

luckystrike Power Kraut

Hello to everyone, look at this, not a tri, but a workable system on a firebird catamaran. May be helpful. http://www.youtube.com/watch?v=655COFngiQA&feature=mfu_in_order&list=UL Ceck out the other videos from haryeybowden, there is one where the system is explained. Cheers Michel

Self-righting Trimaran luckystrike said: ↑ Hello to everyone, look at this, not a tri, but a workable system on a firebird catamaran. May be helpful. http://www.youtube.com/watch?v=655COFngiQA&feature=mfu_in_order&list=UL Ceck out the other videos from haryeybowden, there is one where the system is explained. Cheers Michel Click to expand...

different ways of capsizing Doug one of the methods in the Bugaboo book relies on the floats being submersible and the boat going over sideways. It seems to me that this is a little bit cute as the mechanism could not work if the boat went over its nose. This method is probably more useful for older narrow tris. As tris got wider pitchpoling became a more common way of falling over. Splinter is one of these go over sideways tris. She would probably not self right from a pitchpole. I think this is a bit like the quest for the holy grail and without trying to be disrespectful, probably as futile. The huge flurry of re-righting ideas propounded in the 70s and 80s died out when the boats stopped capsizing as much. Monos need self righting because they can get laid over even in a nice day by a bunch of gorillas with too big a kite up. Then everyone giggles as the boat pulls up and sails away. As multis are so stable they don't often capsize, therefore they don't need to self right. cheers Phil

Self-righting Trimaran catsketcher said: ↑ I think this is a bit like the quest for the holy grail and without trying to be disrespectful, probably as futile . cheers Phil Click to expand...

Okay then Doug here are my quick ideas You have to include a wing mast, maybe even some kind of thickened inflatable head to the main like kitesurfers have. Say it is there to stop tip vortices - get it to do something else as well. Then inverted buoyancy will be the killer. Upside down is stable with normal boats. So maybe some trick where the back half of the float and main hull will fill up with water and the big wing mast pulls itself up to the surface. Then you need a very cleverly thought out amount of buoyancy low in the floats and main hull to clear the water out. The floats could look like normal floats but just have a watertight self bailing floor - just self bailing. Of course they would have a normal deck for normal sailing but they would bleed water if needed. The cockpit in the main hull will do the same. The mast and main have to overcome this floor buoyancy and then the floor buoyancy has to rotate the platform from nose up in the air to flat. Mast rake, flotation and CB and CG are all very tricky. In terms of energy you have to make the upright state a lower energy state than upside down. That will be hard. have fun Phil

- Advertisement:

Thanks, Phil. I think on an 18 footer with buoyancy at the masthead and a sealed mast you don't have to consider the upside down case(for self righting). The boat would be nearly vertical-with the mast close to parallel to the water post pitchpole. The dihedral of the cross arms could be such that the buoyancy of the ama bow would actually become RM. The ama+ crossarm buoyancy would be just a bit less than the total weight of the boat: in the unlikely event that the boat were to capsize-it would be only momentarily because the buoyancy of the whole ama+ cross arms would be acting to right the boat along with the keel ballast. The pitchpole case is more difficult which is why I'm building a test model. That, coupled with the keel may do the trick. The system would rely on the rigs' integrity post pitchpole/capsize. My interest is in a self-righting system from a capsize or pitchpole of 90 to about 110 degrees only. I have no interest in a system that "self-rights" from a turtled position. The design I'm interested in would not be able to turtle in the conditions in which it would be designed to be used.

Self righting multihull?

Foiling ballasted self-righting trimaran, another autonomous self righting multihull drone, ballast on self-righting trimarans, high performance mpx foil/self-righting trimaran-the test model, movable ballast for small multihulls / self-righting.

Proa Self Steering? AD-Scull? Sheet to Tiller? Lets see...

Self tacking jib options

Self tacking jib system question

Alternative catamaran rigs for self build? Becoming more self sufficient

- No, create an account now.

- Yes, my password is:

- Forgot your password?

Building, restoration, and repair with epoxy

Decades of Epoxy Technology

By tim atkinson — senior chemist.

Cover Photo: The Formula 40 trimaran ADRENALIN is just one of the high-end epoxy composite structures built during Gougeon Brothers first 25 years.

Editors note: Our head chemist Tim Atkinson penned this piece on some of the history of Gougeon Brothers, Inc. on the occasion of our 25th anniversary, back in 1994.

In 1969, Meade Gougeon and his younger brother Jan founded Gougeon Brothers’ Boatworks to build iceboats. These lightweight, sail-powered vessels were built of wood laminated with epoxy. By 1973, the company was the largest builder of iceboats in the country. The company rapidly expanded its business into other boat-building efforts. Using epoxy to build the iceboats was a natural choice since they had been using epoxy as an adhesive on many boat projects for the previous 10 years. Meade and Jan were first introduced to epoxy resins in 1958, by Vic Carpenter of Superior Sailboats in Montrose, Michigan. Vic was one of the earliest users of epoxy resins as a structural adhesive for wooden boats. He learned about epoxy resins from a pattern maker. At that time, epoxy had just made an entrance into the pattern-making industry, where it was used to bond patterns together. Frequently, boat builders who wanted to experiment with epoxy resins would go to a pattern shop and decant a bucket of resin and a bucket of hardener and take it back to their shop. The Gougeons were quite intrigued with the possibilities of epoxy resins for boat building.

In 1960, while stationed with a large corporation in Kansas City, Meade built two boats using an epoxy as the adhesive. After being transferred to Erie, Pennsylvania, in the early 1960’s, Meade and Jan built their first trimarans using epoxy from a nearby chemical company. Up to this time they had mixed results with the different epoxies they had used. However, they were very impressed that epoxy could bond to many different kinds of wood, metal, and fiber reinforcement, and that it appeared to be very moisture resistant as well. The commercially available epoxies of that time had many advantages over the other adhesive options, such as resorcinol and WELDWOOD™ (a urea-formaldehyde powder which was dissolved in water before use), but they still had some limitations.

After returning to their hometown of Bay City, Michigan in the later 1960s, Jan and Meade established their new business on the former site of the Ben Huskins Boatworks on the Saginaw River. With the help of friends who worked at Dow Chemical, they formulated their own epoxy system which was ideally suited for their application. Modifying the epoxy system so it was suitable as a coating was a major breakthrough. It had long been known that the epoxy resins had very good moisture resistance but they were so difficult to apply that they weren’t used as a moisture barrier coating. With the new formulation, the epoxy could easily be applied as a moisture barrier over wood or fiberglass surfaces.

Many people who saw the iceboats were interested in using Gougeon Brothers’ resin system for their own projects. By 1971, Gougeon Brothers was selling WEST SYSTEM® Epoxy to other builders and to customers who wanted to use the epoxy for building and repairing their own boats. Brother Joel Gougeon joined the company in 1971 and was very involved with developing the epoxy business during his years with the company. In 1975, the original iceboat business was sold to Joe Norton of Norton Boatworks in Green Lake, Wisconsin, so that the company could concentrate on the epoxy business and building larger custom boats. Today, our epoxy systems are sold across the United States and in a dozen foreign countries.

Much of the early success of WEST SYSTEM epoxy was due to its compatibility with wood. The epoxy was used for construction of new craft and repair of old. By the early 1970s, mass-produced fiberglass boats had essentially replaced the traditionally built wooden boat. But with the aging of the fiberglass fleet came the need for a dependable repair resin. Epoxy resins became a popular choice because of their superior moisture resistance and their ability to bond to a wide variety of substrates. However, because of the nostalgic value and beauty of wooden boats, the wooden boat market did not completely disappear.

The construction technique based on laminating wood veneers together with epoxy, which the Gougeon Brothers developed for building the iceboats, was also used to build a few high-profile racing sailboats. The first complete boat built incorporating WEST SYSTEM epoxy and composite construction techniques was Adagio . This 35-foot trimaran was designed and built by the Gougeons and launched in 1970. Another notable boat built in this manner was the Holland- designed Golden Dazy, which won the Canada’s Cup Regatta in 1975. The success of these wood/epoxy composite boats led to a “mini-revolution” amongst builders and designers. They realized that they could build stiffer and stronger hulls with wood and epoxy than they could with fiberglass, and do so without increasing the weight. Many custom builders continue to choose wood and epoxy as their construction materials today.

Other important boats built by Gougeon Brothers include Accolade , a Bruce Kirby-designed 30′ half-ton monohull in 1974; Hotflash , a Gary Mull-designed 32′ half-ton monohull in 1976; Phil Weld’s Rogue Wave , a Dick Newick-designed 60′ Trimaran, in 1977; and Slingshot , a Georg Thomas-designed 60-foot proa in 1978. Slingshot recorded the second-fastest time at the World Speed Trials in 1979. Gougeon Brothers developed a production version of the Olympic Class Tornado catamaran, which they built in 1975 and 1976. A Gougeon-built Tornado was sailed to win a Silver Medal in the 1976 Olympics. Patient Lady , a C-Class catamaran built by Gougeon Brothers, won the 1977 Little America’s Cup. Adrenalin , a Formula 40 Trimaran, was built for Bill Piper of Ossineke, Michigan in 1987. This boat amazed the sailboat racing world by taking an extremely close second place during her first regatta in the Formula 40 Grand Prix circuit in Brest, France, in April of 1988. But later Adrenalin was legislated out of contention when the Formula 40 class rules were changed.

The manufacturing experience and research and development associated with the use of wood/epoxy composites in the construction of wind turbine blades has also largely influenced our company. In 1979, the Gougeons’ reputation for excellence and innovation in wood/epoxy composite construction captured the attention of NASA researchers who contacted the company to build experimental wind turbine blades for use on wind energy machines. The success of the wood/epoxy blades led to multi-million dollar contracts with General Electric, Westinghouse, and Bendix. 4,300 blades, from 10 to 70 feet long, were produced between 1979 and 1993. The wind turbine business allowed the company to fund an extensive research program, the results of which have been instrumental in developing extremely lightweight structures, both on and off the water. Data collected was also used to improve the performance of WEST SYSTEM Epoxy and to test new construction methods.

In 1990, Gougeon Brothers built the prototype for the Gougeon 32 catamaran, Wildcard . The G-32 was markedly different than previous Gougeon-built boats because it used foam-cored composite construction and the new Gougeon Laminating Epoxy and only minimal amounts of wood. As far as we know, it was the first female-molded production boat built with epoxy. Wildcard enjoyed a very successful racing career and, to date, fourteen G-32’s have been built.

Today, we still sell primarily into the marine market, but our epoxy formulations find their way into a wide variety of other applications. This diverse customer base requires a large customer service effort. Our technical staff fields more than 10,000 technical questions annually. Gougeon Brothers has always worked closely with its customers and has built its business as an epoxy formulator based on interactive customer service, extensive research and development, and manufacturing experience. Gougeon Brothers strives to support its customers by sharing its knowledge and experience through books, instructional manuals, and other publications, videos, seminars, and workshops.

Gougeon Brothers, Inc. has always been a privately-held company but in 1983, set the groundwork to become an employee-owned company. In effect, any Gougeon employee you speak with is a part-owner of the company and has a vested interest in keeping you as a satisfied customer.

In 1992, Gougeon Brothers developed a mission statement affirming our purpose. That is to provide safe, high-quality, cost-effective products and comprehensive technical information supported by continual research and development.

Official Board

Registration

1925 Course

Division iii, division ii, results archive.

- Shop Official Race Apparel Custom Merchandise & Specialty Items

Media & Press

IMAGES

VIDEO

COMMENTS

Adagio. Launched in 1970 and pictured here in 2018, Meade Gougeon's 35′ trimaran Adagio was the first large, all epoxy bonded and sealed wooden boat built without the use of fasteners. Meade and Jan Gougeon constructed her in just six months. She's been sailing on the Great Lakes ever since and continues to be a serious contender in the Mackinac races.

Gougeon Brothers released its West System epoxy products in 1971. The next year, they launched E5, named Adagio, which would cement their reputation. Built to Meade's own design, the 35-foot trimaran, his fifth, was the first large, all epoxy bonded and sealed wooden boat built without the use of fasteners.

OLLIE Sailboat Cruise By On Way To 2021 Mackinac Race - Gougeon 35 TrimaranOther YouTubehttp://www.youtube.com/carwarz/http://www.youtube.com/c/carwarzrc/htt...

The previous year, the team of Scharl, Gurski and Gougeon finished second—by 14 seconds—to the 60-foot trimaran Earth Voyager. In 2016, 2017 and 2018 Adagio took home first-place honors.

By Meade Gougeon — GBI Founder It was after eight months of building that we originally launched Adagio, our 35-foot cruising trimaran. It was on July 6, 1970, and she was then a unique boat in three respects. First, she was the first large wooden boat entirely bonded together with epoxy using no permanent fastenings.

Above: Adagio, Meade Gougeon's 35′ trimaran in the Chicago to Mackinac Race. This boat is a testament to how many decades wood epoxy structures can last. The 35′ trimaran Adagio, designed and built by Meade and Jan Gougeon in 1969, survived the harrowing conditions at the finish of the 2002 Chicago to Mackinac race this past year. The old ...

Meade Gougeon works on a piece of rigging for a 32 ... the 35' (10.7m) Adagio trimaran. The year was 1970. No metal fasteners were employed in the boat's basic structures. ... Meade (left) and Jan Gougeon sail the first WEST System boat, the trimaran Adagio, on Saginaw Bay, in 2009, for a 40th-anniversary story in this magazine.

Jan went on to design and build the 35′ trimaran OLLIE; the trailerable GOUGEON 32 catamaran; and the folding, trailerable 40' catamaran STRINGS. After FLICKA's capsize, every sailboat Jan designed featured self-righting capabilities. All of Jan's sailboats continue to compete on the Great Lakes today.

Winning this year's race 204-mile "Shore Course" division aboard their Declercq 36 Flying Buffalo were Al and Bob Declercq. Winning the longer 259-mile "Cove Island" course, which includes a turning mark over on the Canadian side of Lake Huron, was Matthew Schaedler's J/122 Blitzkrieg.Taking first in the multihull division were Ben Gougeon and Alan Gurski's Gougeon 35 trimaran ...

September 25, 1938-August 27, 2017 "The wind is coming up. Tell the boys they can commence with the race." Fittingly, these would be the last words of Meade A. Gougeon as he watched a fleet of sailboats, including his trimaran Adagio, assembling for the Great Lakes Multihull Regatta in front of his home on the Saginaw Bay.Gougeon died Sunday, August 27, 2017, peacefully at home ...

2022 Gougeon Brothers Great Lakes Multihull Championship Regatta Preliminary Scratch Sheet: Class Specific Report: ... Trimaran: 35: 1.1304 4. Usa 25411: Hardly Tri-ing: Martin Foster Viking Multihull Sail Club: Chesterfield, MI, USA: Corsair F31 R: 31: 1.0433 5. USA 51618: Isosceles:

Meade Gougeon, the late Jan Gougeon's older brother by seven years, says Optimist Pram designer Clark Mills saved his brother from a life of misery. Jan was not born well. ... (he would set a record in 1980) in the trimaran Rogue Wave that the Gougeons were building for him, spurred Jan to sail a trimaran in the Bermuda One-Two in 1980 ...

In 1969, Jan and Meade founded Gougeon Brothers Boatworks, and in 1970, they launched their E5, Adagio. It was a 35-foot trimaran and was the first large, all-epoxy bonded and sealed wooden boat built without the use of fasteners. The boat was not just revolutionary in its construction, but it was fast, too, dominating races around the Great Lakes.

By Ben Gougeon. Adagio, our beloved trimaran, was designed and built by Meade and Jan Gougeon in 1969 and launched in the summer of 1970. After undergoing a minor refit this past winter, she still has what it takes to win. ... Of course, Lake Huron had to throw 35-knot winds, rapidly shifting direction, at us about 40 miles from the finish line ...

"Ollie," a 35-foot trimaran designed and built by Jan Gougeon, sails on the water in 1985.

Gougeon Laminating Epoxy. In 1988, the in-house chemists at Gougeon Brothers, Inc. developed Gougeon Laminating Epoxy, or GLH/GLH.This product line would be the precursor to the company's popular OEM epoxy brand, PRO-SET. Most notably, the brothers used GLR/GLH in cold-molding wind blades for Westinghouse, in the production of their G-32 trailerable catamarans, and in the Formula 40 racing ...

While racing his trimaran "Ollie," Jan Gougeon won the single-handed Super Mac race from Chicago to Port Huron in 1987 and the Great Lakes Singlehanded Society Peter Fisher Memorial Award in 1989.

" At the Gougeon shop construction also started on Flicka, another plywood cruising trimaran. Jan spent four long days on the capsized Flicka in the Atlantic Ocean during a qualifier for the next OSTAR challenge. He had plenty of time to think about rightable trimaran designs before a passing freighter rescued him. Flicka had to be abandoned at ...

Yacht Scoring is a web based regatta management, regatta administration and regatta scoring system that simplifies the task of competitor registration, event management, competitor and media communications while providing results in near-real time to competitors and the World following your event on the internet.

The Gougeon Brothers were pioneers of speed sailing, relying on great design and lightweight wood/epoxy engineering to break speed records. ... The design was trademarked as a Stressform™ 35 along with Stressform wing mast plans. ... ADRENALIN, a Formula 40 trimaran built by Gougeon Brothers for Bill Piper of Osseneke, Michigan.

2023 Bayview Mackinac Race Overall Finishes - All Divisions Official FINAL Results Division I - Cove Island Sail Boat Owner / Skipper Design Finish Time Elapsed Time Corrected Class Div. USA 15004 Fast Tango Tim Prophit NA 40 Monday - 12:36:30 48:26:30 46:19:46 Class F 1 USA 93272 Janine Kevin Lemonds J/109 Monday […]

Decades of Epoxy Technology. Cover Photo: The Formula 40 trimaran ADRENALIN is just one of the high-end epoxy composite structures built during Gougeon Brothers first 25 years. Editors note: Our head chemist Tim Atkinson penned this piece on some of the history of Gougeon Brothers, Inc. on the occasion of our 25th anniversary, back in 1994.

2022 Bayview Mackinac Race Overall Finishes - All Divisions Division I - Cove Island Sail Boat Owner / Skipper Design Finish Time Elapsed Time Corrected Class Div. USA 998 DeTour Chuck Stormes Italia 9.98 Monday - 20:37:24 55:17:24 52:10:37 Class E 1 CA 51725 Huzzah Greg Chamberlain Beneteau First 36.7 Monday - 19:31:53 […]