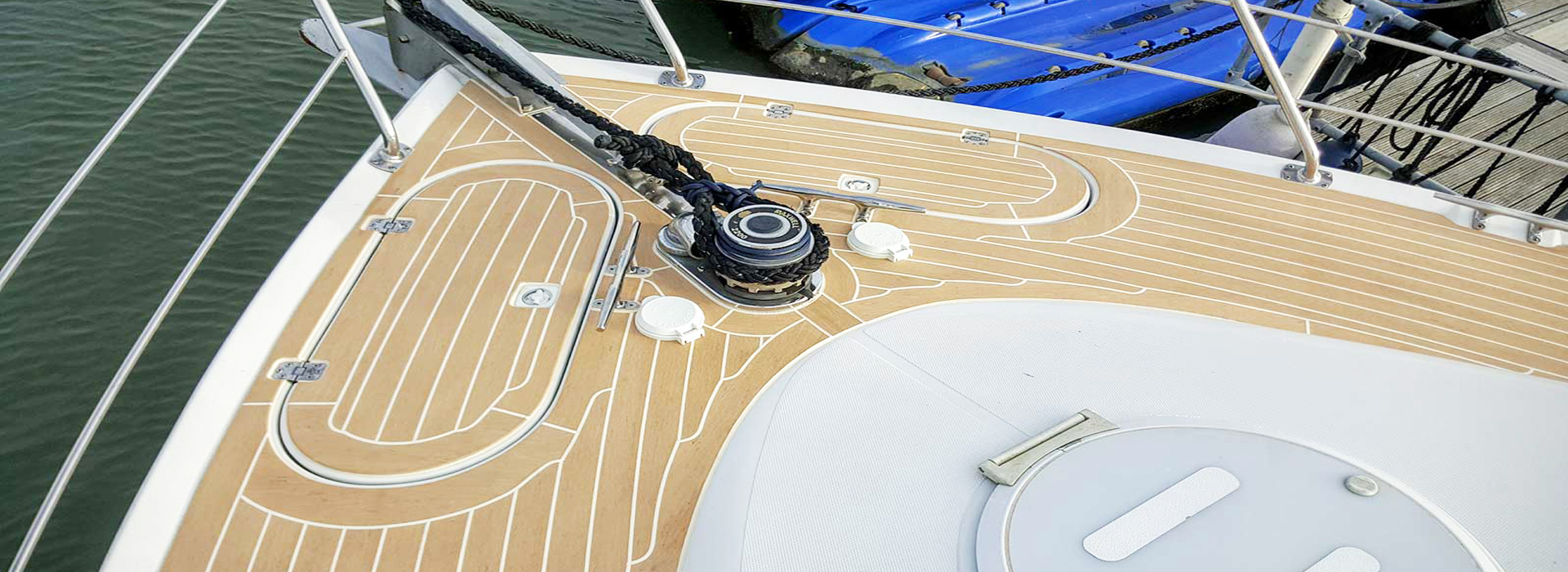

MARITIME Custom Teak Decks are made from patterns for each individual yacht.

- Deck sections are made up to 40 feet long.

- Planking can be straight-laid, or sprung to shape.

- We provide for king planks, margin boards, hatches and other deck fixtures.

- Decks of any width can be made by joining sections at caulk seams.

- The completed custom deck is delivered to your facility pre-assembled, pre-trimmed, and ready for final fitting and installation.

Maritime Wood Products consistently delivers the finest and most well thought-out deck systems. Contact us to learn more about our services.

We work closely with production boat builders to provide everything needed for the successful installation of our products. We can visit your facility and help design, engineer and pattern a custom fit deck for your application. We work within your production schedule and are responsive to time-sensitive orders and changes.

MARITIME™ Teak Deck Kits come pre-caulked and ready for installation. Maritime Wood Products supports Just In Time (JIT) inventory and delivers decking systems that improve manufacturing efficiency and quality. Contact us for more information.

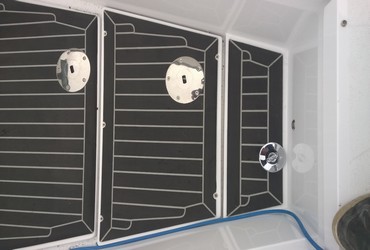

- We fabricate our custom teak decks and teak deck panels either with or without a substrate (i.e. backing material), depending on application.

- Seams are caulked to the full depth of the planking for the longest possible deck life, and the panels are then sanded to a uniform thickness.

- Our standard plank width is 1-7/8". The caulk seam is 3/16" wide. Other widths are available upon request.

- Our standard deck thicknesses are 1/4", 3/8" and 1/2". Other deck thicknesses are also available upon request.

Proudly Made in the U.S.A.

PLASDECK ECO SERIES: A Revolutionary New Boat Decking Product

Three Ways to Get PlasDECK Decking on Your Boat:

- 1. Send us a template and order easy-to-install custom panels - Available in over 20 colors.

- 2. Find a PlasDECK installer in your area to do all of the work for you.

- 3. If you're pretty handy, use our rolls of DIY shiplap material - Available in the classic teak color.

- You can also add custom inlays to personalize your deck!

- Award-winning new product! Learn more about PLASDECK ECO SERIES.

PlasDECK Colors

PlasDECK is committed to bringing you quality boat and yacht decking that looks like real teak but without the maintenance!

Sample Packs

You can see and feel PlasDECK by ordering a sample pack!

Synthetic Boat Deck, Yacht Decking, Marine Teak Decking

PlasDECK is a patented synthetic teak boat decking option that provides the elegant look of a teak deck without any of the time-consuming and costly maintenance associated with natural wood teak. Made out of flexible PVC, this material is easy to work with and maintain. It’s the perfect option to upgrade your boat and replace the dingy old carpet. PlasDECK will hold up to the sun and marine environment for years while you enjoy more of your free time.

PlasDECK is specially formulated with ingredients that will prevent the material from drying out or cracking over time. It also has the highest possible UV protection to prevent fading, antifungal inhibitors, superior adhesion… and PlasDECK is proud to say that we offer the only synthetic teak decking option that’s made in the USA! With over 20 colors to choose from, PlasDECK is the most customizable boat decking option on the market.

Support & Customer Service

- Customer Service

- Find a PlasDECK Installer

- International Orders

- Boat Decking Installation Guides

- PlasDECK Installation & Repair Videos

- Returns & Refunds

- Shipping Information

- Boat Decking In-Store Pickup

Research & Information

- PlasDECK Cleaning Guide

- Boats on File

- Boat Decking FAQs

- How Shiplap Works

- Synthetic Teak Deck Specifications/SDS Sheets

- The PlasDECK Synthetic Decking Difference

- PlasDECK Boat Deck Weathering Study

- PlasDECK 5 year Warranty

- Synthetic Teak Boat Decking Repair

Select a Language

- Yachting World

- Digital Edition

Teak alternatives: 4 options for decking that doesn’t cost the earth

- May 7, 2020

Rupert Holmes explains what’s wrong with the marine industry’s obsession with hardwood and looks at real world teak alternatives

Photo: Lignia Yacht

Everyone loves an immaculate teak deck. They look great at boat shows and at chic Mediterranean quays, as well as providing excellent non-slip properties in the most demanding of conditions.

However, teak also has drawbacks. Firstly it doesn’t last forever, especially if a modern, and likely relatively thin, teak deck is scrubbed regularly. At the extreme I’ve seen a deck lose 1mm of thickness each year through scrubbing. Given the high cost of replacement this can have a significant impact on a yacht’s resale value.

The material also easily absorbs heat from the sun, making it uncomfortable to walk on in bare feet when in the tropics or Mediterranean summer. This also contributes to heating the interior of the boat.

Ocean Cork is one of many firms to offer eco-friendly teak alternatives

Teak doesn’t look good from a sustainability perspective either. A key problem is illegal logging of rainforest in Myanmar, one of the only four countries in which the species grows. Unfortunately, a ban on importing this illegal timber into the EU hasn’t stopped the trade, as evidenced by court cases in countries including Denmark, Sweden, Germany and Holland following the discovery of illegally imported teak.

As a result, the only way to be absolutely certain a source of teak is sustainable is to use salvaged material (or to ensure that the teak can be GPS-traced back to stump).

Timber at risk

“Teak is now considered a high risk timber,” confirms Nigel Stuart, MD of Spirit Yachts . “We take our responsibility to the environment very seriously and we are not prepared to risk using unsustainable wood.”

Teak alternatives have been available for many years and are gaining wide acceptance. In many cases they also offer multiple advantages over real teak, including better longevity. Many can be factory-made to match a template or CAD file, which significantly reduces labour and installation costs, while customisation can extend to logos and boat names.

Available products can be split into four broad categories:

- Modified softwoods

Expanded foam

Many of these don’t absorb liquids and are therefore easy to keep clean as any dirt stays on the surface.

Article continues below…

4 eco-friendly improvements to upgrade your yacht

1. Ditch the teak Teak is no longer universally popular. The price has gone up dramatically, supply is dwindling, and…

How hybrid sailing yachts finally became a feasible option

Every sailor is familiar with the wet cough of the diesel engine, and the acrid smell of its exhaust. For…

Many manufacturers offer a range of colours, with the most popular being shades close to freshly-scrubbed teak, or silvered, weathered teak. The former can look amazing at boat shows, though in the real world it can maybe look incongruous to those who understand the damage regular scrubbing does to real teak.

We’ve tried to give indicative prices for different options, but these are exceptionally difficult to pin down. Different products may need vastly different amounts of labour, which obviously affects cost, while detailing and edging is a major factor in the price of factory-made panels. The total cost for boats of similar sizes can therefore vary dramatically depending on the complexity of each of the panel shapes.

1. PVC decks

This option has historically offered some of the most convincing alternative teak products, with the grain, texture, impact resistance and non-slip properties of the real thing. As a result many of the new yachts seen at boat shows actually have simulated teak decks made of PVC.

Flexiteek decking on the SW105 Kiboko III

Despite their slightly textured surface, which replicates the grain of real wood, dirt and stains stay on the surface of PVC decking, so it can be cleaned relatively easily with a wet cloth and maybe soapy water. Unlike real teak, which has a mix of hard and very soft fibres, PVC decks can also be pressure-washed. Another bonus is that damaged areas can be sanded back to reveal fresh material that looks new.

One of the best-known brand names, Flexiteek, is celebrating its 20th anniversary and is expanding rapidly, with demand consistently growing at 20% annually. The company now produces 80,000m 2 of its decking product each year.

The 2G version, launched six years ago, is fully recyclable, while microballoons are used in place of chalk filler, which reduces heat absorption (certain PVC deck types and colours have been known to get very hot in direct sun). Flexiteek is available in a standard 5mm thickness and 11 colours, with plank widths from 45mm-200mm to replicate everything from planking to covering boards and cappings.

Flexiteek says PVC experts suggest the surface may start to crack after 25-30 years, but no problems have been observed on 20-year-old decks so far and the life span may be considerably longer. High traffic areas can become glossy, but these can be gently coarse sanded back by hand to the original matt finish.

Esthec seamless decking installed on a Princess R35

Esthec is a part of composite floor specialist Bolidt, which makes flooring in any shape for industrial applications through to decking for ships. Dutch yard Saffier has been fitting Esthec to its range of daysailers since 2008.

“We made one deck with Esthec and set this right next to a real teak deck,” managing director Dennis Hennevanger remembers, having been immediately taken by the product. “We invited all the customers who had ordered a Saffier with teak deck and gave them the choice… they instantly all went for the Esthec deck.”

Saffier has since built nearly 500 yachts with Esthec decks, “all without any problems”. Hennevanger says it is not necessarily a cheaper option to teak, but thinks it should last forever.

Saffier’s SE37 daysailer is fitted with PVC decks from Esthec

“I also like the technical side of Esthec,” he adds. “It is made completely seamless [the caulking doesn’t go right through], so it is impossible to have any leakages.” Additional benefits are that it is maintenance free, with no fading, has excellent anti-slip properties and comes with a complete freedom of design.

PlasDeck is less well known in the UK but has been established for 15 years, offering a range of PVC products in 28 shades that look and feel like wood. The company holds patents for non-migratory plasticisers that are bound to the molecular structure. The product is therefore very UV resistant and remains elastic as the oils don’t evaporate over time.

Fungus inhibitors throughout the material hold back the formation of the green mould that can all too easily grows on real teak decks, especially during persistently damp winters.

Permateek decking on a Contest 38

Permateek is another popular brand name and has recently introduced new shades that better mimic the grain of real teak. From a sustainability perspective, a big drawback with PVCs is they are plastics and will therefore remain in the environment forever. To offset this Flexiteek plants one tree for every 10m 2 of product sold. Esthec, meanwhile is formed from natural components, without the harmful ingredients commonly found in PVCs.

Prices for PVC products tend to range from €150 to €1,000 per square metre, varying according to the design and size of each panel. As a guide, in the UK Permateek costs £150-£350/m 2 depending on the complexity of the design. This compares to a material cost of around £285/m 2 for 6mm teak – but don’t forget there’s far more labour involved in laying a real teak deck.

Gisatex offers a more economic PVC product, at €69 per square metre, but in a thinner textured, non-slip material that makes no attempt to match the grain of teak. The company, which has been established for 10 years, sells matched repair kits for €10 and says a “very long lifespan is expected.” Light weight is a further advantage, but custom panels are not available.

Gisatex sits at the lower end of the PVC price bracket

There’s an increasing trend towards cork decking, according to Piet van der Staay of Marinedeck 2000, especially among younger boat owners. It’s a natural product harvested from FSC certified forests, largely in Portugal.

Common advice is to look for a product with large cork grains as these cope better with impact. In any case the material is inherently resilient and is significantly better than teak at resisting wear and abrasion.

Cork is also is a good insulator, so decks remain comfortable to walk on even in strong sun. Over a three to five year period it will slowly take a light grey hue, but this can be sanded back to reveal the original colour.

Marinedeck claims that its decking is popular among younger boaters

Marinedeck 2000 consists of cork granules with a synthetic polyurethane binder. It’s produced under high pressure, which gives the feel of high-density material, but is still flexible and absorbs knocks well. It’s supplied as individual planks, or as preformed finished pieces with a standard thickness of 9mm. The company has been in operation since 1986 and says there are still decks in good condition from its early days. As a result van der Staay quotes a 40-year expected lifespan.

Prices for Marinedeck 2000 start at €320/m 2 (ex VAT) including adhesives, while custom panels cost €520/m 2 (ex. VAT).

Another supplier, Ocean Cork, produces 8mm planks as standard, but 4mm is available if weight is critical. Given it’s one of the lightest decking materials available, at only 2.4kg/m2, for cruisers the thinner option appears to offer little benefit. Prices start at €349 (inc. VAT) for 1m 2 DIY kit (including glue and caulking) and approx €400/m 2 (inc. VAT) for larger custom made panels.

Ocean Cork is available in 8mm and 4mm thickness

This is a material with a soft cushioned feel, excellent grip underfoot and good shock-absorbing properties. SeaDek, which is made from a closed-cell PE/EVA foam is popular throughout the racing world, from sportsboats to the America’s Cup and the Ocean Race. It can be made in custom panels and in different thicknesses and is manufactured with an effective acrylic-based pressure sensitive adhesive for quick peel-and-stick application.

SeaDek’s Jason Gardner says the large range of colour, thickness, density and design options means the price range can be very wide. Whether or not there’s already a pattern for that model of boat in the company’s database also impacts pricing.

Sean Roebuck of ProCast, SeaDek’s leading UK fabricator, says prices including VAT generally work out in the range of £114-£151/m 2 .

SeaDek is popular with ocean racers. Photo: Ainhoa Sanchez/VOR

Cer-Deck, sold by Italian company Ceredi, also has a soft, slightly cushioned feel, very high resistance to degradation in sunlight and is colour stable.

It is 6-8mm thick and is available with a strong 3M self-adhesive backing to minimise labour costs when fitting. Custom panels cost around €250/m 2 (ex. VAT).

Life expectancy for expanded foam materials is around five to seven years for harsh use, and longer for less-heavily used boats. On the downside these materials are susceptible to damage from impact or pets’ claws.

Cer-Deck has a soft, cushioned feel

Modified softwood

Lignia is the latest product to be launched on the market, based on pine grown in FSC certified forests. After harvesting, the timber is impregnated with resin, before being dried in a curing process to ensure the resin is locked in at a molecular level. This gives Lignia performance and durability that can surpass tropical hardwoods.

It has a similar appearance to teak and can be worked in the same way, but has an expected lifespan of 50 years. The impregnation of resin means end of life disposal is not as easy as for untreated timber – the recommended option is to use it as fuel in biomass generating plants.

Anyone who saw the Spirit 50CR at last year’s Southampton Boat Show can attest that a quality yacht with Lignia decks will look stunning. It also has the benefit in being faster to dry than teak, which is handy in areas used for seating. Material costs are a little less than for teak, with typical savings around 5-20%. However, Lignia decks are just as labour intensive to lay as real teak.

Lignia, shown to great effect here on the decks of the Spirit 50CR, is a real softwood product treated to give it the appearance and longevity of teak

Price gauge

Tye Conway of UK-based decking specialist Elite-Teak says that typical installed prices in the UK are often lower than elsewhere in northern Europe, with many jobs falling into the following price ranges (ex. VAT) per square metre:

Synthetic teak: £200-£300 Foam decking: £150-£200 Cork decking: £200-£300 Real teak decking: £500-£600

Teak-effect solar panels

Italian solar panel manufacturer Solbian has a range of panels with a pigmented layer that creates different colour schemes. The teak option reduces output by only 6-8% compared to an equivalent standard panel, while custom sizes and shapes can be created without increasing prices.

The upcoming Spirit 44E will be fitted with teak-effect solar panels

The company has been working on projects with major boat manufacturers – the panels will be used, for instance, on the locker hatches of the aft deck of the Spirit 44E that’s currently in build. Solbian is also developing a version of the teak-effect panel with a non-slip finish.

Colour shades can also be matched to products of companies such as Flexiteek. Prices are typically 50% to 60% above those for the company’s standard solar panels .

First published in the April 2020 edition of Yachting World.

Teak Deck Company - Teak Decking, Maintenance, Flooring & Furniture

Teak Deck Company™ fabricates and sells ready to install teak decking and flooring products for boat manufacturers, boat owners and professional contractors. In business since 1996, we install teak decks in the United States and on mega-yachts worldwide.

All our teak decking panels are of the highest quality – a result of years of experience in boat carpentry and woodwork. We constantly invest in product development, because “this is how it was done before” doesn’t mean there isn’t a better way. We only promote new products after they have passed the toughest testing by Mother Nature.

Our prefab teak decking system was developed for production boat builders and provides great advantage for private customers and professional installers.

Fine Teak Furniture

Teak Deck Company is the U.S. distributor of fine teak furniture by EuroDesign of Sweden. Eco-friendly and FSC certified, our line of furniture is in-stock and ready to ship from our Florida warehouse. CLICK HERE to find out more.

Teak Deck Company Products Include

FREE SHIPPING!

Teak Folding Marstrand Chair w Slats

Teak Table, Square, Star Inlay

Teak Folding Chair w Armrests

Teak Folding Chair, Fredrik

Click Here to Contact Us

Or call 561.575.3732.

Everything You Need to Know About Your Boat's Teak Decking

Sep 24, 2021

There is a lot to love about teak.

Golden brown, long grain, fresh-cut teak bestows an unquestionable aesthetic elegance to any boat deck. But boat owners don’t just love teak for its looks.

TOUGHNESS AND DURABILITY

Teak is a naturally water-resistant wood from southeast Asia which has been hailed in its ability to beat many wood alternatives (like mahogany and pine) in terms of toughness and durability.

An abundance of silica in teak makes it so tough that it is known to quickly blunt the tools of expert craftsmen. Bad news for craftsmen, good news for boat owners.

Teak can withstand any weather it cruises through, and the same high silica content that dulls a tool’s edge bestows a non-skid surface that provides necessary traction on wet decks.

Teak’s high oil content also forestalls shrinking, expanding, and cracking, helping well-maintained teak decks last up to 40 years before replacement beckons.

HOW TO MAINTAIN YOUR TEAK

Here’s how to best maintain teak decking on your yacht, without too much extra effort:

Embrace Teak’s Color Changes

As teak is exposed to weather, it naturally takes on a silver-gray patina. But some boat owners prefer to luxuriate in the sun-kissed gold brown of fresh-cut teak.

Maintaining this hue long-term means using harsh brightening agents and committing to a regimen of extensive scrubbing, two things guaranteed to shorten the lifespan of your teak deck to fifteen years or less.

You can lengthen your deck’s lifespan by falling in love with the silver patina it prefers and updating accents on your boat to match.

Cleaning Teak

Though teak’s grain is hard, the soft fibers between grains are easily damaged by hard scrubbing or too-strong cleaners.

To clean your teak deck, simply rinse regularly with fresh or saltwater. Use a mop or soft-bristle brush to wipe away tough dirt, but avoid high-pressure nozzles or washers that damage the wood’s top layer.

How often should I deep-clean my teak deck? Many boat owners will want to undertake a deeper clean one to four times a year (depending on location and wear).

- Most experts advise you to steer clear of two-step cleaning solutions and choose single-part wood cleansers and soaps to limit corrosion and maximize your teak deck’s longevity.

- If a single-part cleaner is not available, use a non abrasive, powdered dishwasher detergent (like Bon Ami or Calgon). Dilute 1/4 to 1/3rd cup of the detergent in 2.5 gallons of water before applying.

- With a mop or soft scrub brush, apply the single-part cleaner or powdered detergent solution to your deck. If using a scrub brush, use care to only scrub across the teak’s grain.

- For localized stains, put a drop or two of liquid dish detergent (like Joy) on a terry cloth and rub it into the stain gently. Give the area a thorough rinse before checking your fully clean teak.

Combating Mildew

When mildew inevitably appears on the grain of your teak, softly scrub the spot with a 50/50 solution of white vinegar and water.

Resisting the urge to use bleach will benefit your deck in the long run. However, if the urge proves too strong, mix 1 cup of bleach in 1/2 bucket of water and apply it to the areas in need. Thoroughly rinse the solution away before the decks dry.

Oiling Teak

Boat owners striving to maintain the warm gold of fresh-cut teak will often reach for teak oils (usually tung or linseed) to bring out their wood’s young shine.

Teak oil “feeds” the wood, brightening its grain patterns and intensifying its rich colors. Unfortunately, oiling teak is more about aesthetics than maintenance.

Teak oils do not protect the wood, and only bring back that young color for a month or two at a time. Some experts even claim that these oils catch and hold dirt, leading to blotchy, stained wood over time.

Sealing Teak

Teak sealers are a popular method of care among boat owners looking to achieve their teak’s natural look while extending their deck’s durability.

Rather than “feeding” the wood, sealers block against moisture and dirt while sealing in its natural oils and resins.

A good teak sealer only requires reapplication once a year, making it a more practical option for most boat owners with teak decking.

UNDERTAKING (AND AVOIDING) A MAJOR REFRESH OF YOUR TEAK

When teak decking is properly cared for throughout the year, boat owners can avoid a major refresh or teak restoration project.

However, all boat owners should keep a careful eye on their deck’s caulking and be quick to repair loose strips or gaps that allow water to quickly and destructively penetrate the teak.

Do not trust what you see at first glance. To fully check your boat deck for needed repairs, wet the deck fully and make note of any area that stays wet longer than the surrounding teak. These lingering wet patches give clues to where caulk may need to be removed and reapplied.

In addition to proper cleaning, properly caring for your teak decks means sanding the deck every 12-18 months. (Regular cleaning will minimize the need for regular sanding, and sanding is not recommended for any boats less than a year old.)

Luckily, you can avoid a major restoration project and enjoy the timeless style of your teak decking for decades by putting a little time into cleaning and care now.

SIGN UP FOR EMAIL UPDATES

- Swim Platforms

- Sports Boats

- Boat Manufacturers

- Sailing Boats

- Motor boats

- Boat Dealers

- Manufacturing

- Synthetic teak Warranty

- Why Choose Nuteak?

- Nuteak vs Competition

- Motor yacht

- Sport boats

- Swim platforms

- Specialised

the new standard in synthetic teak marine decking with the most authentic natural teak look available

No matter your vessel of choice, nothing can beat the elegance and luxury that a teak deck adds to your boat. But teak is now considered a high risk timber in terms of sustainability, not to mention its cost to install and maintain. That’s why, boat owners and manufacturers around the world are turning to synthetic teak marine flooring.

Sailing Yachts

Motor yachts, production boats, commercial applications.

- Interior Flooring for Yachts

- Custom Parts for Yachts

- Photo Gallery - Teak

- Sailing & Motor Yachts

- Photo Gallery - Composite Decking

- SIS 440 Caulk

- Epoxy FFE-200

- Epoxy FE-180

- Epoxy AP-100

- Bedding & Bonding Adhesive MPS-4000

- ECO-100 Powder

- ECO-300 Liquid

- MMP-700 Mold & Mildew Preventer

- Professional Tools

- Sealer & Protector

- TDS Products Parts List

- TDS Products Dept

- Find A Product Distributor (Caulking, Adhesives, Cleaners & Tools)

- Company History

- Trust the Experts

- Digital Design

- Manufacturing

- Photo Gallery - Manufacturing

- Press Releases

Teak Decking

Performance & prestige.

Teakdecking Systems provides the yachting industry and private owners with the service and support necessary to keep modern and classic yachts looking their finest, whether new construction or refit. From the design phase, through templating and deck construction to final installation, the highly experienced Yacht Services team works with you to ensure that the teak decks not only fit and enhance your yacht, but also create the ambiance and styling you desire.

Interior Flooring For Yachts

Custom Parts For Yachts

- Photo Gallery of Teak Decking

- Request a Quote

- Read Technical Blog Articles

- Español ( Spanish )

The best decking for boat

Permateek is one of the world’s market leaders in the synthetic decking industry having many unique features which position it ahead of the competition. Permateek is an obvious choice for those seeking a high quality synthetic teak decking product.

Introducing permateek

Permateek’s quality synthetic teak flooring is highly resilient against the elements, UV-stable and looks just like real wood. With a range of 15 stunning colours and three different caulking lines, boat fitters can personalise decks with more than 45 unique options to suit any style. In addition, we have 2 ranges of multi-colours which give the natural multi-colour effect of real teak.

The Ultimate Decking System

Permateek offers an ideal solution for boat decks and flooring, suitable for boats of all sizes, from small dinghies to large super yachts.

Our decks are environmentally friendly faux teak composite boat flooring that offers the qualities and good looks of teak but with none of the hassle.

It is non-slip, wet or dry; offers low maintenance and looks like new teak season after season. Permateek teak decking for boats is cost effective, stain resistant and simple to keep clean.

With so many benefits, why would you fit anything else?

POWERING INNOVATION AROUND THE WORLD

Our network of distributors spans the globe with Permateek currently available in the UK, USA, Canada, Europe, Asia and Australasia.

Find your nearest Permateek synthetic teak decking distributor below or contact the head office. After 20 years of excellence, we have taken marine synthetic teak flooring to new heights and our fitted decks look equally at home on a 60-metre luxury yacht as they do on a small dinghy or powerboat.

The versatility of our boat decking has been proven over time in unique installations including flooring for indoor spas, balconies, car interiors and bathrooms.

The benefits of permateek

Built from planks of UV stabilised PVC

Low Maintenance

No regular wood sanding and oiling required - simply brush with soapy water

Limited Down Time

One day to pattern, and one day to fit! All other work is conducted in our workshops

Favourable pricing compared to real teak decking

Quality Craftsmanship

High quality fabrication process of thermal welding to form synthetic teak boards.

Follow the adventure

Get in touch with Permateek

Unit 3 Parkside, Ringwood, Hampshire, BH24 3SG

Practical Boat Owner

- Digital edition

The truth about teak decks

- Ben Meakins

- March 1, 2016

Shipwright Robin Benjamin says modern, thin teak decks need lots of regular care, and so it’s vital to follow his advice on how to keep them looking good

In the last 15 years I have worked on more teak decks than I care to remember, writes Robin Benjamin : I think I’ve seen every problem that exists. What you have to know straight away is that, like anything, teak decks need looking after. If you take care of your decks they may last 20 years or more, if you don’t you’ll be appalled at how awful they look after only five. Because solid teak decks have been the norm for hundreds of years they have understandably earned a serious reputation for longevity. Today’s teak decks are not the same thing at all.

In many cases modern teak decks are little more than a quick way for the manufacturer to up the ‘class’ of their product. Many are poorly fitted, the wood is too thin and the caulking gap too narrow. Because of the minimal amount of wood involved the best plug on the deck might only be 3mm deep. Likewise, the caulking, unless of adequate depth and width, will not remain glued as the wood moves. However, all these problems would amount to little if folk took care of their teak decks. The most important advice is to wash the deck every week but few people can spare the time. It’s quite simple however: if you don’t wash your deck regularly it will soon go grey and dirty.

Don’t scrub

This is how worn teak decks can become after only five years of regular scrubbing and sanding

I’ve seen it done: the owner is standing there, his trouser legs rolled up, his knees red. True, his deck looks great… from the pontoon. But if you look carefully you’ll see grooves in the planks where the softer areas of grain have simply vanished. This is how it starts. Consider that you began with a lovely smooth surface, like a CD for example. After scrubbing it looks more like an LP record, but worse, much worse. Imagine now how quickly the ‘peaks’ will wear down as you walk on them. Of course it doesn’t end here, this is only the beginning. To keep your deck clean there is only one way, and that is a gentle wash with nothing more violent than a light detergent and a large sponge or very soft brush. If you do this regularly you will not wear down the teak, but you will wash off the dirt before it gets ingrained. Dirt contributes to the wear of a teak deck. If this approach doesn’t work then you can try oxalic acid. Dissolve some crystals in warm water, do not breathe the vapours and make sure you wear gloves. It burns. Rinse well. Oxalic acid should not harm anything on the boat except your skin. There are plenty of products that do the same thing but cost a lot more. If acid doesn’t bring back the colour then there’s only one thing left to do if you want a lovely looking teak deck, and that is to sand it. But if you want my advice: continue to wash it carefully and often, with soap, and live with the deck not looking its best. For some reason no one listens to me. I gladly advise people on how to look after their decks for free, even if it means I don’t get any work. It’s better for everyone, except me, that you take my advice. Yet despite this I still see people scrubbing their teak. I shake my head in wonder. Did I not explain what would happen if they scrubbed? ‘But it looks so great!’ they say. ‘So what’s the problem?’ The problem is that the next time they see their decks they will look grey and dirty again. The only difference will be that there is less teak than there was before. If your feet don’t wear down the peaks then they’ll fill up with dirt, making it look even worse. There’s only one way to get it out – more scrubbing. This time you’ll have to scrub harder to see a result. Can you see what’s happening? There will come a point soon when you decide the decks are looking pretty rough and need a good sanding.

Sand me timbers!

New decks get sanded to make everything look nice and flush – but it’s not a good idea to repeat this too often

Boatyards are very keen to do this work for you and why not? Next time you see the boat it will look great and they know you’ll be back, because soon the caulking will start to roll out in long spaghetti-like strips and the plugs will fall out, exposing the screws and making water ingress all the more likely. Now you’ve really got a problem. The plugs are not too much trouble but there will be hundreds to do. The real problem is the caulking. Just because some of it comes out really easily does not mean that it will all be like that. No, some of it will be sticking just like the manufacturer intended. You can make a special scraper to remove it but inevitably you will slip, damage areas and, even worse, you will enlarge the groove. If you’re really lucky you might be able to use a router for about 35% of the deck, but routers are vicious and it’s all too easy to make a mistake. Even a small enlargement of the slot will look terrible. Not only that but you’ll need a curved guide to run the router along for each slot. This takes ages. Bad enough if you’re doing it yourself, but it’s unbelievable if you’re paying a yard. Specialist tools exist but they are hideously expensive and it’s only the specialist yards that are likely to have them. Unfortunately the yard will be charging by the hour and there’s always a lot of work on any teak deck. So what are the options now that your deck is worn out? You can’t just remove it, because underneath it will be horrid. If it was laid properly in the first place they will have keyed in the glued surface and that means taking to it with a grinder on a plastic boat. And you’ll still have to cover the decks to hide the mess. So I hope you can see that I’m advocating care and prevention for your lovely teak deck. To just leave it uncared for is an outrageous waste of a precious resource. If that isn’t enough to make you care for your deck, then consider the cost of replacement. Teak costs approximately £3,000 a cubic metre. But you’ll need a lot more than you think, because just cutting down a big plank to size wastes a hideous amount of wood. The cost of the teak is a large part of the final bill. Basically you can quadruple the price of the teak to take into account the cost of first measuring and photographing the original deck to ensure everything fits properly, the cleaning up of the surface underneath and finally replacing the wood. To do the job properly you may have to remove the chain plates and that means dropping the mast and completely readjusting it afterwards. Not only that, but all those deck fittings that haven’t been touched for years will need to be removed. And don’t be surprised if many of the bolts are hell to get out or break in the process. It’s possible that some of the bolts were made specially or have been glassed over. You’ll need somewhere to do all this. Perhaps it’s possible to make a good cover but even this adds to the cost. The alternative is to put the boat in a shed somewhere. Anything is possible but it always costs. Replacing a teak deck is a massive job. To replace the decks on a 9m (30ft) boat is six weeks’ work – three months for a 15m (50-footer). We are talking about many thousands of pounds and your boat out of action for a while. There are other considerations before you decide on a teak deck. They weigh more: the caulking is surprisingly heavy, not to mention the wood and the thousands of screws. Perhaps what worries me most about laid decks on glassfibre boats is that you have to make thousands of holes in an otherwise perfectly waterproof surface to hold the deck down. Many fibreglass boats’ decks are balsa cored, that is to say, the deck is made of two layers of fibreglass with a layer of balsa wood in between. Balsa wood will not last long if it gets wet, yet this strikes me as very likely. The law of averages suggests that if you make 2,000 holes in a deck the chances of them all staying waterproof for years on end is pretty slim. What happens when the balsa has rotted away? I just don’t think making thousands of holes in a deck is wise. It is possible to lay a teak deck without screws, but it takes longer and therefore costs more.

So let’s sum up and cover up On the one hand I am thankful for owners and teak decks since they allow me the life I lead, but on the other I am very sad at the waste of it all. People could save themselves a lot of time, inconvenience and money if they just took care of their decks. And for some reason no one wants to spend money on ‘posh’ covers to protect their boat. Covers are initially expensive but they will repay their cost several times over. Not only will you not be required to replace your decks but you’ll be able to sell your boat for more because it has obviously been well looked after. It’s not just teak decks that will benefit from protection – plastic windows, instruments and gel coat will all last longer if kept out of the sun, wind and rain. The Grand Canyon was created by erosion from the elements. When you think like that, surely you can understand why I recommend covering up. I can only do my bit. I can’t change the world and I can’t change fashion, but I hope I can slow down the damage by telling the truth. So now you know. And remember: don’t scrub!

The good, the bad and the ugly

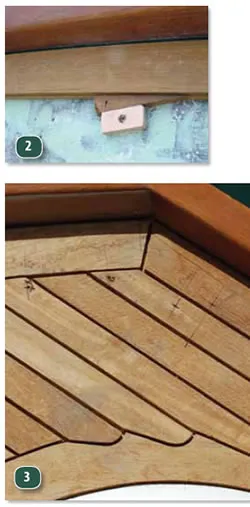

With decking that is very thin, the plugs over the fastenings are even thinner and can lift if the glue fails

This plug seems to have a problem. It could be loose and holding moisture, or the fastening is corroding

s Covers over vulnerable varnished work make sense, but a complete cover will also protect the deck

s Stains from oil and ferrous metal can be very awkward to remove from teak – try oxalic acid

Even old-style decks can have their problems. Here, to avoid butt joints, the planks had been scarfed together and, after many years, the feathered edge started to lift. The owner simply fixed it with epoxy

This thin timber decking has lost its caulking compound and the corner is starting to deteriorate

Tips for keeping teak in top condition

- Wash gently once a week

- Use a light detergent and soft sponge or very soft brush

- Tackle tough stains with oxalic acid solution

- Fit a cover over the whole deck

- Repair loose caulk and plugs promptly

- Scrub with a hard brush

- Leave decks to get really dirty

- Sand except as a last resort

This article was originally published in the June 2007 issue of PBO.

10 Teak Cleaners tested

We get scrubbing to find out what effect a variety of teak cleaners have on the woodwork of a Sigma…

Masking up teak decks

get the tape that sticks...

Cutting expensive teak-faced ply

How to get a neat edge

9 tips for using sealant

Premium bonding: some techniques for getting the most out of sealant without ending up covered in the sticky stuff!

How to stop a swing keel leak

John Taylor finds a car steering rack gaiter stops leaks from the lifting cable of his swing keel

Winterising a boat: 61 point checklist

PBO experts offer their top tips for winterising a boat, helping to keep your vessel and gear in good condition…

The great UK antifouling test for cruising yachts

20 antifouling paints tested in 13 UK locations: which works best where you keep your boat?

0,00 €

CLASSIC DESIGN

WHAT IS ISOTEAK SYNTHETIC TEAK DECKING?

Isoteak is artificial synthetic teak made of original pvc based composition. we proudly offer you new faux decking material made with a respect to design and traditions of shipbuilding..

The our faux teak looks almost like real teak, gives a boat premium look and does not require maintenance. Isoteak decking is UV stabilized, flexible but has solid structure, and doesn't loose it's great appearance over time, which is confirmed by five-year warranty. ISOTEAK panels are hot welded which prevents splitting during installation and after it. It can be combine with any surface (plastic, wood, metal, concrete). It easy to installation and doesn't need screwing. For bonding to a deck we use a special sealant with MS polymer, which is intended for nautica. It creates durable and elastic connection, resistant to salt water and UV.

CLASSIC APPEARANCE

Pleasant to touch, no maintenance, doesn't absorb, doesn't fade, anti slipping.

The our faux teak looks almost like real teak, gives a boat premium look and does not require maintenance. Isoteak decking is UV stabilized, flexible but has solid structure, and doesn't loose it's great appearance over time, which is confirmed by five-year warranty. ISOTEAK panels are hot welded which prevents splitting during installation and after it. It can be combine with any surface (plastic, wood, metal, concrete). It doesn't need screwing. For bonding to a deck we use a special sealant with MS polymer, which is intended for nautica. It creates durable and elastic connection, resistant to salt water and UV.

BE CONFIDENT with ISOTEAK under your feet

ISOTEAK PRO DECK DIY PROFILE

Price from 150 €/m2.

ISOTEAK DECK SHEETS

Price from 170 €/m2.

ISOTEAK DECK BY TEMPLATE

Price from 220 €/m2, video tutorials, check out the tutorial on how to use our panels in various situations..

Your Name (required)

Your Email (required)

Your Message

Spam check. Calculate 4 + 4 = ?

BUY SYNTHETIC TEAK FROM 150€/m2

Username or email *

Password *

Remember me Login

Lost your password?

Create an account?

Spam check. Calculate 7 - 2 = ?

- Our factory

- Our Partners

- Partnership

- Special refit

Teak Decking

DUCA Solutions offers to our respective clients a complete innovative teak decking system starting from high precision 3D laser scanning on board to fully automated advanced CNC production and vaccum gluing for installation of our highest quality teak decks all around Europe...

Esthec decking

Esthec composite decking is a valid alternative material to traditional teak decks used on mega yachts, cruise ships, powerboats and tenders for over 40 years. Given an immense freedom of colors and patterns , any imaginary design can be fulfilled by using Esthec...

Deck furniture

Quality exterior yacht deck furniture makes luxury design complete. Varnished caprails in teak, custom teak wooden tables, chairs, sunbeds, sofas, gratings, flaps, hatches, bars and bar stools next to a stunning jacuzzi lined with teak will create a miracle on your Sundeck!

Super yacht refit is a great event each super yacht faces in its life after a certain age. We offer a wide range of teak deck refit services , including deck replacement, recaulking, sanding, repairs and changing planks, renovation for decks, exterior deck furniture and capping rail refinishing and re-varnishing ...

About Duca Solutions

DUCA Solutions is a leading international super yacht carpentry and teak decking company specialized on high quality innovative teak decking services, marine exterior carpentry and joinery, deck furniture, teak decks refit & renovation. If you are looking for a deck professional you are on the right place!

Our production facility

The main teak decking factory of DUCA Solutions is strategically located in Livorno, Italy, conveniently connecting us with major shipyards in Italy and around Europe. It provides 1000 square meters of a workshop floor and is well equipped with 2 mega CNC machines and other modern woodworking machinery.

View photos of our recent works

Our Services

Being one of the best international deck covers suppliers, we at DUCA Solutions offer efficient, competent, flexible and customer oriented teak decking services and solutions for yachts and boats, super yachts and mega yachts in Italy, France, Spain, Monaco, Holland, Germany and all around Europe:

- Teak deck / composite & synthetic decking

- Inlays, logos and custom designs

- Re-caulking / re-seaming

- Sanding decks and other repairs

- Deck maintenance and restoration

- New decks & teak refit all around Europe

- Handrails / Cap rails in teak or mahogany

- Swimming pool and jacuzzi surrounds

- Shower gratings, flaps, laminates

- Marine deck stairs construction

- Exterior deck furniture / varnishing

- Carpentry & joinery on super yachts

Latest News

June 7, 2019

DUCA Solutions acquires a new CNC machine 6 meters long!

What are the advantages of a CNC production?

- Boosting production volume due to increased production speed

- Consistent decking quality

- Staying on a budget due to more cost effective production

- Ability to produce complex shapes with a high precision

- Environmentally friendly: reduced waste

- Increased safety for our technical personnel

- Versatility: we can create almost any design you can imagine

Follow us lang: en_US

Testimonials What our Clients say

I have to say I am very impressed with the quality of the workmanship and finish on the teak that you have achieved. Thank you for such a good job!

Captain Ben Heslop

Duca Solutions has been a marvelous partner for Esthec over the last 5 years. They have provided many years of installation expertise to customers choosing Esthec and are convinced on the long term future of our product. Duca's long years of experience, their attention to detail, full commitment and their customer service make them second to none in their craft !

Marcel van der Spek

CEO of Esthec

With the yacht being in Genoa, we had a number of good options for suppliers of our new Beach Club and Teak Table. However, Duca made the decision very easy with their professional manner, understanding of the works and although we didn't know it at the time, an on time delivery of the project. We wouldn't hesitate to recommend them to their future clients

M/Y Bash (ex Ulysses)

- Species Guide

Marine Teak Decking

ETT Fine Woods has been supplying the most prestigious yacht and boat manufacturers in the world with decking, planking and marine trim accessory parts.

Why Use Marine Teak Decking?

Marine Teak Decking is often used to build the finest boats in the world. Marine Teak Decking is functional, beautiful, and long lasting. It gives grip, warmth, and lasts in the rugged conditions that are common at sea.

We provide our Marine Teak Decking wood fully surfaced and in the lengths that you require. Marine Teak Decking is ready to install. If needed we can advise on best practices and materials to complete your build or re-decking process.

Our most popular Marine Teak Decking sizes are:

- 1/2 x 1 7/8″ Battens

- 9/16 x 1 7/8″ Battens

Ability and Benefits

Availability

- vertical or flat grain

- surfaced four sides (S4S), tongue & groove (T&G), ship lap or with caulking groover

- 1/4” to 2-1/2” thick in lengths of 3’ to 20’

- wide and long decking for renovation projects

Custom milling available to any specification. Please contact us for custom sizes or special orders.

Specifications

- Janka scale hardness is 1,155

- 42 lbs. / cu. ft., or approximately 3.5 lbs. per board foot

- Bending strength is 14,600 psi

- A golden color, with dark markings and a straight grain.

- A non-skid surface, thanks to a coarse texture that is smooth to the touch, with virtually no raised grain.

- Little maintenance needed.

- The choice of finishing the wood to a preferred shade or simply leaving it to take on a natural silver-gray patina.

What’s the Difference between Decking and Planking?

In addition to marine teak decking we can also provide marine teak planking . Planking consists of boards specifically selected for grain and straightness. They are wider and thicker than traditional teak decking. This material is produced with a meticulous attention to detail and high manufacturing quality.

Wood Species Guide

Natural woods vary in performance characteristics from one another. This wood comparison chart helps you compare hardness, weight, fungal resistance, and more. Use the wood comparison guide to help you find the right wood for your project.

Locations are strategically placed throughout the United States to serve our customers. Products stocked at each location are different based on customer needs.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Pay My Bill

- Customer Service

- Free Newsletter

- Give a Gift

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Open Transom Pros and Cons

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

Install a Standalone Sounder Without Drilling

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

How Dangerous is Your Shore Power?

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

The Scraper-only Approach to Bottom Paint Removal

Can You Recoat Dyneema?

Gonytia Hot Knife Proves its Mettle

Where Winches Dare to Go

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Rhumb Lines: Livin’ the Wharf Rat Life

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Boat Maintenance

- Sails, Rigging & Deck Gear

Replacing Teak Decks, the DIY-er’s Way

One couple's deck-refit story, a tale of trading hard labor for cutting costs..

PS contributor Joe Minick and his wife, Lee, are cruising the Mediterranean aboard their Mason 43, Southern Cross.

After 26 years, it was painful, but not surprising, to find our much-esteemed teak deck failing, irreparably. It had started life as half-inch teak planks, bedded, caulked, and fastened in the traditional manner with screws, but weather and wear had finally thinned the teak to the point where splits could often be found radiating from the bungholes.

We extended the life of the deck another season by injecting epoxy into the cracks, but a year later, many had opened again. It was time to make a decision before leaks began to play havoc with the core of the deck.

After years of cruising with a teak deck, we knew most of its pros and cons. Pros: aesthetically pleasing and a first-rate nonskid, kind to bare feet, and relatively easy to clean. Cons: hot in a warm climate, expensive, and potentially high maintenance. We began to think that maybe a change was in order.

As we explored the possibilities, we found it was almost impossible to get any kind of accurate estimate of the cost of converting to a painted deck without knowing more. Was there gelcoat with nonskid under the teak? Was there hidden water damage that would require extensive repairs before the deck could be painted after the teak was removed? A bit of work with a hammer and chisel revealed that there was only fiberglass laminate under the teak, no gelcoat or nonskid.

Damage assessment would have to wait until we removed all the teak, but other problems were apparent. The edge of the coachroof was molded to accept the edge of the teak plank, and scupper drains through the fiberglass cockpit coamings and toerail would be above the deck after the teak was removed.

Converting to a painted deck would require extensive fairing along with several layers of gelcoat and a new nonskid applied. Twice in the past, we had added nonskid coatings to an existing deck. One deck was rolled with a layer of tacky resin that was then painted; the other involved applying a course aggregate to the paint before spray-painting. There are effective paint-on nonskid options, but neither of the products or methods we used produced what I felt was a great offshore nonskid, and both were hard to clean.

The stick-on nonskid Treadmaster, while possibly not meeting everyone’s aesthetic expectations, would provide a truly nonskid surface. (See the November 2021 issue at www.practical-sailor.com for our long-term test of nonskid paints and adhesive-backed pads.)

The estimated cost of a painted deck was mounting rapidly, and I didn’t feel we were qualified to handle the job by ourselves, so we started reviewing options for a new teak deck. Although oily teak defies many kinds of glue, advanced adhesives for this task have been around long enough to establish a good track record. Bonding the teak to the deck means no more worrisome screws and their holes into the deck core. Teak was expensive, but we could handle a lot of the work ourselves, and the total cost was potentially lower than painting, if we could provide much of the labor.

The decision was made, and we arranged for a berth alongside the quay in a marina with a reputable marine carpentry shop. They recommended doing the work afloat to avoid the risk of falling and to avoid the heavy labor of hauling lengths of teak, tools, and weights up a 12-foot ladder. It was good advice.

Major Tasks

We faced several challenges that were easier said than done:

- Removing the deck hardware; virtually everything was bolted through the deck.

- Removing the old teak and preparing the deck for bonding new teak.

- Cutting, bonding, and caulking the new teak.

- Re-installing the deck hardware.

Removing the deck hardware took eight days with two people working 12 hour days. The stanchions and pulpits alone had over 120 bolts through the deck. The list went on and on, including cleats, anchor rollers, windlass, and more, but it was something we could handle. Although labor intensive, it was a good cost-cutter for us.

Removing the old deck was a long and arduous job with a chisel and hammer. We left the screws in place and drove a chisel along under a plank, breaking it off each time a screw was encountered. Unfortunately, the fiberglass laminate under the deck was occasionally nicked by the chisel.

After the teak and all associated rubble were bagged and carted away, the screws were removed with a screwdriver where possible and vise grips where not. We broke a few screws and left them in the deck to be sealed with epoxy during the next phase. A surface grinder cleaned the old caulk off before we filled the old screw holes with epoxy and applied a thin coat of epoxy to the entire deck to repair the chisel scrapes and seal the laminate. This was sanded before bonding, to provide “tooth” for the adhesive. We felt we could handle everything except preparing and bonding the new teak, so we sought the assistance of the carpenter to help with this task.

Teak decks are traditionally laid with an outer panel or frame inside the toe-rail and an inner frame around the coachroof and cockpit coamings. The outer frame may be omitted if the curvature of the rail is mild enough to allow a standard width plank to be sprung into place along the toerail, but an inner frame is almost always required to accept the end of individual planks where the curvature is more pronounced. A king plank is commonly used to join the end of the planks on the bow and at the stern.

The wood shop cut and milled the teak planks to half-inch thickness and three different widths to accommodate the frames, planks, and king plank. The planks were relieved along both edges to about half their thickness to provide a caulking groove, and we were ready to begin.

There is more than one way to spring planks into place for bonding, but a common trick is drill a small hole near the edge of the plank that holds a piece of scrap wood. Then a wedge is driven between it and the plank to spring it into place alongside its neighbor. Heavy weights are applied to hold it while the adhesive cures. The drilled holes should all be repaired with epoxy before installing the next plank, but some installers rely on the adhesive under the next plank to fill them and this may be equally satisfactory.

Caulking, while messy, was straight forward. As the entire deck needed a light sanding, we didn’t tape the seams and relied on sanding to remove the excess. It pays to remove, seal, or cover just about everything for this phase. The caulk dust seems to find its way into every possible opening.

It took a month to re-install the deck hardware. All the holes had disappeared under the new teak, and initially we relied heavily on our plan to re-drill them from below. This worked fairly well for the larger holes we made with hole saws and a drum sander. That changed when it came to drilling the bolt holes perpendicular to the deck and parallel to each other while standing on our heads in a locker. With backing plates on one side and hardware on the other, the holes had to be true.

Fortunately, we had taken the time to measure and mark the location of most holes, using the toerail or coachroof as our reference. In the end, drilling from the top down, where one could more accurately see the angle of the drill, proved to be the best choice, but it would have been difficult without the carefully measured and marked locations.

Considerations and Planning

I estimated the job would take two months, but it actually took us three months and a day to complete, working long hours every day in a climate where it never rained, but the summer heat was intense. Without awnings, we wouldn’t have been able to endure it, but we avoided any chance of rain with several hundred holes in the deck exposed. If rain is expected, you’ll need some means of temporarily closing all holes in the deck until the new teak is in place.

We reused almost all the hardware fasteners. Careful bagging and labeling makes this a lot easier, although a few bent screws must inevitably be replaced, arbitrarily replacing all the fasteners would add significantly to the expense of the project.

A large number of heavy weights will be needed. When planks are sprung into place, there is tendency for an edge to lift that can only be overcome with lots of downward pressure. Pieces of railroad track worked well for us but avoid using sand bags or similar approaches. The flexibility inherent with bags can allow an edge to lift, and it’s vital that the teak be pressed firmly into contact with the deck at all points.

Ends of planks can be readily cut and shaped with a fine-toothed blade in a saber saw and drum sander. If available, a carefully handled pistol grip or D-handle router works well for trimming up, but if in doubt, stick to the drum sander and a sanding block. I made good use of a Dremel tool with a smaller drum sander for shaping smaller openings cut into the new deck for fuel and water fills and the like.

Plan to prepare and lay a maximum of one plank per day per side, and even this will be a long day’s work. Reading up on patterns and layouts for traditional teak decks will help you understand the process of adding a new set of cutouts to the king plank as pairs of planks are laid up to the bow or stern. Actually bonding the king plank is done last, after everything else is in place. Photograph every inch of the deck before you start.

- Teak Decking Systems

RELATED ARTICLES MORE FROM AUTHOR

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

Island Packet 370: What You Should Know | Boat Review

How To Make Starlink Better On Your Boat | Interview

Catalina 380: What You Should Know | Boat Review

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

+1(619) 232-7900

The Only Choice For Teak Decking

Traditional & alternative decking solutions.

W elcome to Yacht Deck, specialist in both traditional teak decks and modern pvc decks. At Yacht Deck, we have highly trained craftsmen who are skilled in both traditional teak decking as well as a modern green synthetic teak decking.

Irrespective of your selection of traditional teak or alternative, we at Yacht Deck can provide you an entire turnkey installation package which includes templating, fabrication, and installation.

Traditional Teak

Alternative teak, infinity luxury woven vinyl, interior solutions, what our clients say.

I spent the day working with Marco from Yacht Deck prepping the deck for bedding hardware. This guy is amazing! He made the template for the deck installation. A relentless perfectionist! Great to have a craftsman that is so skilled and proud of his work!

Scott Wilson

Charlie created a beautiful alternative teak solution for my Duffy to replace my carpet area and also the fore deck and aft deck. It looks amazing and red wine cleans up very easy…because it’s a floating brunch location!

Jimmy Weeks

Yacht Deck worked on a few projects with our company and we heartily recommend their services. One was a complete teak replacement on a 64’ Sunseeker Manhattan that started on time, finished on time, and was on budget, very important to us.

Stuart Sitko

Unsurpassed craftsmanship.

At Yacht Deck, we have highly trained craftsmen who are skilled in both traditional teak decking as well as a modern Green synthetic teak decking. learn more >>

+1 (619) 232-7900

Information

Affiliations.

- +86-21-61182468

- [email protected]

pvc synthetic teak boat deck

Wholesalers & suppliers.

Wholesale and purchase of the highest quality synthetic teak marine decking that can last long for your boats and yachts.

Buy Waterproof Boat Deck

Custom sizes & colors.

We have many types of pvc synthetic teak boat deck, a variety of colors, a variety of styles, absolutely meet your needs.

Recruit distributors

Unlimited supply.

Our product quality and customer preference are better, more istributors are welcome to cooperate with us.

Marine Boat Yacht Synthetic PVC Teak Deck

Marine boat yacht synthetic pvc teak deck,provides the beauty look of ...

Waterproof PVC Soft Deck

Waterproof PVC soft deck,has the smooth surface on anti-fade ...

Anti-slip Synthetic Teak PVC Deck

Anti-slip synthetic teak pvc deck,look more luxurious and you can't ...

About SYNBOATEK®

Synboatek® is one of the best boat & yacht deck. it looks like teak wood, has the excellent properties of wood and plastic, and is durable and waterproof. synboatek® synthetic teak decking is seventrust's most popular boat deck product. we constantly innovate and try to produce high quality products and provide the best deck solutions for yacht manufacturer and user..

We carefully to create the best boat deck, only to give our customers a product quality protection.

Hot Products

We've recently created several new synthetic teak marine decking, different colors and different stripes to make your yacht even more glamorous.

QZ-STP Teak PVC Soft Yacht Deck

QZ-EW Anti-Slip Synthetic Teak PVC Deck

QZ-STB PVC Soft Deck Flooring For Yacht

QZG-STB Embossing And Sanding Soft PVC Boat Decking

QZG-STP Boat Soft PVC Floor

QZ-EB Synthetic Teak Pvc Soft Flooring For Yacht

QZG-STW Marine Boat Yacht Synthetic PVC Teak deck

QZ-STW Waterproof PVC Soft Boat Deck

Need to timely take care of your boat & yacht.

When you own a small boat, a yacht, or a large commercial ship, you need timely protection for your ship, soft pvc boat deck can 100% protect your hull intact.

- PRODUCT PROBLEM

Boat Deck Blog

Click here to read more about the boat deck.

SYNBOATEK® Anti-Slip Synthetic Teak PVC Deck is highly resilient, non-skid, UV stable and looks just like real wood. Teak PVC Deck is very popular to be used in custom Yachts and ...

SYNBOATEK® Synthetic Teak Pvc Soft Flooring For Yacht for boats are highly resilient, non-skid, UV stable and looks just like real wood. Pvc Soft Flooring is very popular to be us ...

SYNBOATEK® Teak PVC Soft Deck Flooring For Yacht is highly resilient, non-skid, UV stable and looks just like real wood. Soft Deck Flooring is very popular to be used in custom Ya ...

SYNBOATEK® Teak PVC Soft Yacht Deck for boats are highly resilient, non-skid, UV stable and looks just like real wood. PVC Soft Decking is very popular to be used in custom Yachts ...

Replacing a Rotten Boat Deck is an Easy Task

Although more and more ships are now made entirely of composite materials deck, the use of plywood on deck has been standard procedure in shipbuilding for decades. As a result, ov ...

How About Pvc Synthetic Boat Deck

pvc synthetic boat deck Low Maintenance Pvc Synthetic Boat Deck Pvc Synthetic Boat Deck – Best PVC Decking Products Pvc Synthetic Boat Deck has many years experience in the ...

The global authority in superyachting

- NEWSLETTERS

- Yachts Home

- The Superyacht Directory

- Yacht Reports

- Brokerage News

- The largest yachts in the world

- The Register

- Yacht Advice

- Yacht Design

- 12m to 24m yachts

- Monaco Yacht Show

- Builder Directory

- Designer Directory

- Interior Design Directory

- Naval Architect Directory

- Yachts for sale home

- Motor yachts

- Sailing yachts

- Explorer yachts

- Classic yachts

- Sale Broker Directory

- Charter Home

- Yachts for Charter

- Charter Destinations

- Charter Broker Directory

- Destinations Home

- Mediterranean

- South Pacific

- Rest of the World

- Boat Life Home

- Owners' Experiences

- Interiors Suppliers

- Owners' Club

- Captains' Club

- BOAT Showcase

- Boat Presents

- Events Home

- World Superyacht Awards

- Superyacht Design Festival

- Design and Innovation Awards

- Young Designer of the Year Award

- Artistry and Craft Awards

- Explorer Yachts Summit

- Ocean Talks

- The Ocean Awards

- BOAT Connect

- Between the bays

- Golf Invitational

- Boat Pro Home

- Pricing Plan

- Superyacht Insight

- Product Features

- Premium Content

- Testimonials

- Global Order Book

- Tenders & Equipment

Have we reached peak teak?

Teak decking has long been regarded a superyacht’s crowning glory, but the controversy around “conflict wood” from Myanmar forced the industry to come up with ethical and sustainable alternatives. Marilyn Mower speaks to the pioneers leading a new wave of deck innovation.

We’ve known for decades that teak decking, the golden crown of a fine private yacht, has become problematic. Particularly contentious is old-growth Myanmar (Burmese) teak, or Tectona Grandis . It may be the highest-quality, most durable teak in the world, known for its warm colour and superior water resistance, but it is also clouded in environmental and humanitarian controversy.

Rumours of mass destruction of forests and exploitation of the Burmese people began filtering west in the 1960s, about the time the country dissolved into a military dictatorship. Tumultuous years followed, then, in 2021, after a brief period of stability, things took a turn for the worse when a regime with a brutal ethnic-cleansing programme took control (it still holds a grip over the country today). Bent on financing itself, it instilled a state-controlled timber monopoly, allowing traders to indiscriminately log as long as the government got a share of the profit. At the current rate of logging, the Environmental Investigation Agency (EIA) warns that the country will lose its forests by 2035.

Over the years the US and EU have implemented various bans and regulations to prevent illegally harvested Myanmar teak from entering their markets. In June this year, the EU Timber Regulation, which sought to curb imports based on a somewhat voluntary due diligence, was replaced by a new broader and stricter methodology. Now any operator or trader who places these commodities on the EU market, or who exports from it, must prove that the products do not originate from recently deforested land or have contributed to forest degradation.

All these interruptions in sales of Burmese teak led to scarcity and rarity, resulting in a hike in prices, which simply heightened the demand for it. It also created an explosion of new teak plantations in other countries where it has always grown naturally but in smaller quantities.

Plantation teak has been touted as a solution, but it’s not quick-growing. Plant a teak tree today and it will be 30 to 50 years until it can be harvested. Even then, compared to the lumber from an 80- or 100-year-old forest tree, there are differences. While hardly noticeable in furniture, when it comes to decks, boards milled from young trees are shorter and narrower and the grain is not as tightly packed. The other issue is that the expansion of teak plantations – when not responsibly managed – can contribute to deforestation as well as the elimination of naturally biodiverse rainforest habitat and the people and animals that depend on it.

While the superyacht industry is a bit player in the global teak market, it is a high-visibility target for those who could criticise its environmental footprint. One company making a stance is UK design firm Harrison Eidsgaard , which says that teak as a deck material makes them “uncomfortable”. “While durability is paramount for all the obvious reasons, we feel owners should be involved in the thought process and discussion [of] alternatives,” says co-founder Ewa Eidsgaard.

Alternatives include ethically sourced teak, exotic woods, farmed hardwoods chemically treated to stop rot and imitation teak (man-made “composite” wood, often made up of wood fibres blended with plastic or glue) but, Eidsgaard points out, each of them has an environmental impact.

“Ethically sourced teak is scarce,” she says. The problem is that there are not enough officially audited forests to supply all the teak needed to meet demand. As Eidsgaard says, “The next batch of lots of teak trees is not going to come up any time soon.” Exotic woods or chemically treated hardwoods also trigger questions about future recycling and imitation teak is PVC based, “and that opens a different can of worms”.

Marnix Hoekstra, co-creative director of Vripack , notes that he’s surprised how “addicted” people – including himself – are to the look of teak decks on a yacht and how difficult it is proving to step away from them. “I think [decks are] one of the largest surfaces on a yacht and are very undeveloped from a design perspective. At the same time, we do have to acknowledge that it is a working surface for the crew, so it is not only aesthetics, but durability and non-skid qualities are very important,” he says. “Alternatives with those qualities are scarce. At the same time, it’s up to us as designers to make the world see how it could be different.” Farmed hardwood, for example, is perfectly usable from a technical perspective, but “global demand is so high that it is impossible for the foreseeable years that we will have enough forests to meet demand”.

For Vripack, it isn’t sufficient to just use less teak in a design proposal. Instead, they suggest a different solution. “From day one, I am not forcing the client to make a choice; I am giving them something which is greater than the original,” says Hoekstra. As an example, he cited a 60-metre Vripack explorer currently in construction where they consciously chose a synthetic decking material called Esthec. “We use it in a very innovative way. It absolutely resembles the finish you are used to, but [with the patterns we have made] it is not a copy of a teak deck.”

Esthec is a patented thermoset (heat-hardened) material that, unlike many composites, uses biomaterials and doesn’t contain PVC or wood. Marcel van der Spek co-founded Esthec in 2007. “Despite the fact that sustainability has been part of the conversation for five years, builders are finally asking about synthetics because teak isn’t available, and the ones who stockpiled teak three years ago are realising that won’t last,” he says. Esthec’s recipe is continually being refined, he says. “Our goal is to be completely bio-based by the end of 2024. We don’t import anything from India or China and our factory is not more than 350 kilometres away from where we obtain our raw materials, so that [reduces] our CO2 footprint.”

On Project Zero , currently under construction at Vitters , Vripack appeased the owner’s desire for wood differently. Following considerable research they selected Tesumo, an engineered product made from a fast-growing African tree that matures in 50 years or roughly one-third the time of premium teak. “I think we will be using it on all projects that require wood decks,” Hoekstra says. “Every board comes with a QR code on the back of it and every tree can be traced back to the source and the person who cut it. We have had it thoroughly tested in the Netherlands. It is the future of decking.”

Tesumo was developed from a research project conducted by Lürssen shipyard, German superyacht decking company Wolz Nautic and the German University of Göttingen. The wood, which comes from managed forests with Forest Stewardship Council (FSC) or Origine et Légalité des Bois (OLB) certificates, is modified with a patented process using heat, resin infusion and drying. The result has the same appearance, dimensional stability, elasticity and rot resistance as teak. “The use of easily available wood reduces the ecological risks that go along with logging a rare raw material,” says Philipp Warnecke, Tesumo’s managing director.

Another new alternative is the Dutch product Accoya, which, like Tesumo, uses an easily available certified sustainable softwood as its base material. Instead of being injected with resin, the wood is “catalysed” – a strong type of vinegar called acetic anhydride is forced into the raw timber under temperature and pressure, which changes the wood on a molecular level. It makes the wood virtually unable to absorb water, expand and rot. Accoya has a life expectancy of 25 to 50 years and can be reused, recycled or burned as biomass (fuel).

Richard Strauss, CEO of Teakdecking Systems, has been negotiating the hot potato that is Myanmar teak for seven years, with the exception of periods where the US and EU could not legally obtain it. “Teak is a bit taboo,” he admits. But, he says, what the world forgets is that ethical teak is also grown responsibly all over southeast Asia, India, Panama, Costa Rica, Brazil and central Africa, in natural forests as well as plantations. “We have four people who source wood. They go to the forests and to the sawmills to check on compliance. The FSC really has its finger on where teak is grown, and they make sure it is logged properly and the paperwork is in order.”

Most lumber importers rely on companies like DoubleHelix to oversee certifying sustainability compliance for wood stocks. “They are like the blockchain for wood,” says Strauss. “But we are taking it further; we subject our lumber stocks to a DNA test to make sure it is 100 per cent clean. In the future, all yacht builders will want this.”