I’m Arch Davis – I learned boatbuilding and design in New Zealand in the 1970s. I have been helping people to build beautiful wooden boats since 1988. You can see a few of them by clicking on Picture Gallery . My approach to design is to put into your hands the means to use modern materials – marine plywood and epoxy resin – to build a truly lovely boat with classic lines.

I believe that a boat should be beautiful, not just by virtue of her lines, but also in her construction. No material makes this possible like wood. My aim is to take advantage of wood’s unique strengths, in a structure that captivates the eye. I want you to feel that you are always doing good work in building one of these boats.

You’ll see that I have a small collection of designs. That is because I understand your need for clear, comprehensible, detailed plans and instructions. I put a lot of time into my drawings, building manuals and DVDs. I also spend a lot of time helping people through their projects, on the phone or by e-mail. I really am here to help!

If you see something that you like in my collection, please feel free to contact me with any questions. I am available on the phone at 207-930-9873, or email me at [email protected] .

Wooden Boat Plans and Boat Kits by Arch Davis

Grace's Tender - More than just a tender, this little dinghy is a fine vessel in her own right. She is a pleasure to row, and sprightly under her simple sailing rig - a great boat for youngsters to mess about in. Bay Pilot 18 - an 18 ft pilothouse cruiser for outboard power. Laughing Gull - 16 ft self-bailing sailing/rowing skiff. Ace 14 - 14 ft performance daysailer Penobscot 13 - 13 ft little sister to Penobscot 14. Penobscot 14 - 14 ft glued lapstrake sailing/rowing skiff. Penobscot 17 - big sister to the Penobscot 14 Sand Dollar - 11 ft sailing/rowing skiff. Jack Tar - 26 ft plywood lobster boat design Jiffy 9-7 - suitable for rowing or a small outboard motor Jiffy 22 - outboard powered cabin skiff Jiffv V-22 - vee-bottom sister of the Jiffy 22

About My Boat Kits

I also have epoxy kits and plywood packages for all my designs, plus sails, rigging, and numerous other items. Here's my daughter, Grace, setting up the frames for a Grace's Tender kit.

Please call or write to me at: Arch Davis Design 37 Doak Road Belfast, Maine 04915 Tel:207-930-9873

If you would like to receive a newsletter from Arch Davis Design, send me an e-mail at [email protected]

- Create New Wish List

- Description

- Materials and Notes

The POT LUCK design brings the renown New England lobster boat within the capabilities of the competent amateur builder. Our modern building methods, coupled with proven materials, make building the characteristic round bottomed hull form much easier than traditional methods more suited to professionals. These easily driven, smooth riding hulls with fine entries and long, flat running lines aft, make money saving sense in these days of increasing fuel costs and threats of fuel shortages. That's why our designers included generous sized tanks for plenty of range. For reliability, there's a long, deep skeg to protect the rudder, shaft, and propeller, while at the same time assuring good directional control. Everyone knows of the traditional beauty of these hulls, and our POT LUCK is no exception. Flaring topsides forward are not only attractive, but when coupled with spray rails, these hulls stay dry and have an easy motion when the going gets tough. Use her for a yacht, sport boat, or even commercially. That huge cockpit adapts to a wide variety of uses including sportfishing, diving, various types of specialty fishing (such as lobstering, crabbing, oystering, scalloping or gillnetting), or anywhere you might need a quick, nimble, seaworthy, and economical craft. The cockpit is self-draining and watertight, with a sub-surface drain system for hosing down, and you won't need to worry about covering it if you don't want to. Unlike some stripped-out utility boats, we made the cabin area yacht-like for comfort. Berths are provided for three, and there's plenty of seating area. The cabin features full headroom with plenty of lockers, drawers, and a hanging locker. The galley is complete and the toilet room features a shower and lavy. The control station is covered and protected, with engine and bilge access readily at hand through centerline hatches. Hull construction is either by wood or fiberglass, with separate plans available for either material. For WOOD construction, the plans show a hull built over temporary forms which do not remain in the hull. However, a series of full and partial bulkheads, floor timbers, and motor stringers later installed reinforce what amounts to a virtually frameless "monocoque" hull that is strong, but light in weight. Planking is by the conventional strip plank method (seen in numerous boatbuilding books and used for generations), or cold-molded using a combination strip planked inner core with solid wood veneers applied triple diagonally on the outside, all epoxy glued with fiberglass sheathing over. Hull thickness either way is a minimum of 1-1/8". The FIBERGLASS version details "one-off" methods, either with the fiberglass planking method (C-FLEX), PVC foam core, or Balsa core in conjunction with fiberglass laminates. Regardless of the method used to build the hull, the cabin, cockpit, and deck are made from wood and plywood in the conventional method, sheathed on the outside with fiberglass for low cost, simplicity, and durability. For those who may want to change the length of the boat, a simple method is given in the instructions to vary the length plus or minus 10%. While a Table of Offsets is provided with the plans for those who may want to loft the lines, the full size patterns provided make this tedious job unnecessary. Voluminous instructions plus hull material listings included with the plans greatly simplify the building of your own POT LUCK, giving you a custom boat at a cost far less than a comparable stock boat of this type, if there even is such a thing!

Click to open Materials PDF Click to open Notes PDF

Related Products

Pot Luck Study Plans - PDF Version

- 30, 33, 35, Slippery 38

- New 38, 40, 42, 45, 46

- 40' Yacht: Encore

- 40' Yacht: Flipper

- 45' Model: Annie L

- Slippery 38'

- New 38' Model

- Just Launched

- Work in Progress

- In the News

- Photo Gallery

- Boats for Sale

- Ship's Store

- SW Boatworks

- Calvin Beal Boats

UPDATE — Exciting News: SW Boatworks is pleased to announce that our new 42' Calvin Beal Hulls and Tops have been a huge success!! Our Mold was completed Dec 2015 and we have already constructed 47 new hulls and tops for our Customers (42'L/15'W) ! With this new level of hull and top manufacturing to meet the demand, we are reserving spots in 2023 for the 42' CB Hull and tops! If interested in reserving your spot, email Nikki at [email protected] or call the office at 207-667-7427.

There are many reasons to have a Young Brothers Boat:

- Very popular and sleek design

- Seaworthy, spacious and very stable, easy sailing

- Fuel efficient

- Tested by fishermen, yacht approved

- Professionally designed by Ernest Libby in Beals, Maine

- Owned and built by SW Boatworks in Lamoine, Maine

- Experienced, high-quality custom boat construction

- Reasonably priced

- On-board licensed electrician (ABYC/NMEA certified and Qualified Marine Electronic Installer)

- Finished boats include lobster, yacht, deep sea fishing, pleasure, sport fishing, passenger and Coast Guard approved

Slippery 38

Members: Sign in Here --> Members: Sign in Here Contact Us

All Videos » Wooden Boat Building

Our concise wooden boat building videos don’t just tell you what to do, they show you how. Also be sure to check out our two in-depth wooden boat building video series: Stitch and Glue Boat Building and Plywood Lapstrake Boat Building .

Related Guide Posts

Related flotsam.

Get access to all content Join Now

Browse by Topic

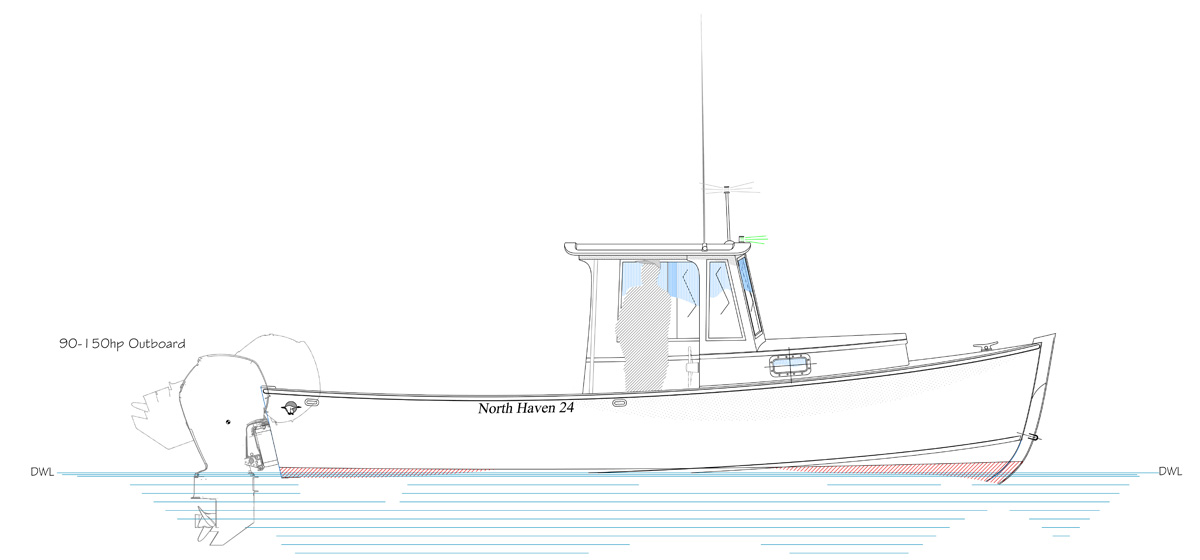

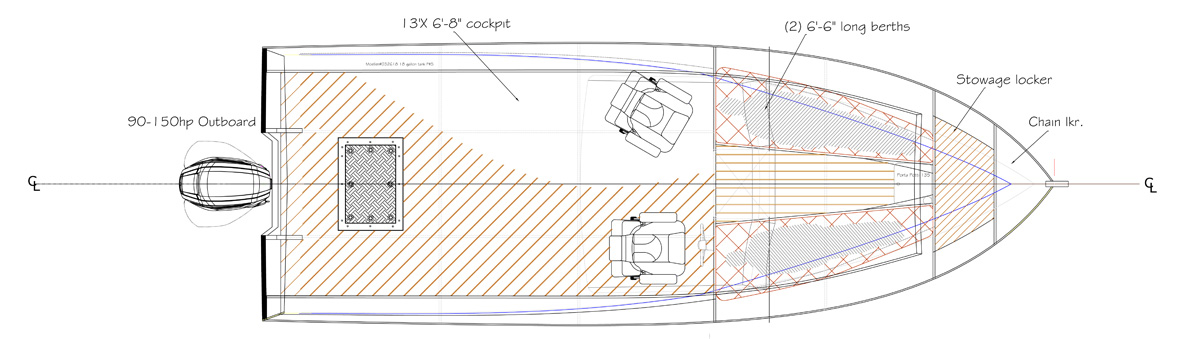

North Haven 24

Devlin Boats , Fishing Boats

The North Haven 24 is based on one of my older designs, a fishing boat called Sea Chaser . A longtime friend and collaborator of mine in Maine had always liked that hull and saw in it the makings of what’s known in the trade as a “pocket lobster boat.”

Now retired, Chris Cornell spent a decade as an editor at National Fisherman magazine before starting and editing the trade journal Professional BoatBuilder for the folks at WoodenBoat . He’s a big fan of the traditional lobster-boat configuration for both work and, especially, for pleasure. The type is known for good performance in a wide variety of sea conditions and—perhaps most important—the semi-enclosed pilothouse and the sitting-headroom trunk cabin provide shelter from the weather and greatly extend the boating season in cooler climates like that in New England.

As you might know, I am a West Coast boy, raised on heavy, slow, high- freeboard, immensely tough fishing boats built to work offshore and handle the 3,000-mile fetch from Japan that we see here. To my eye, lobster boats look almost feminine by comparison, with their low, graceful sheerlines; smaller, more refined houses; greater speed; and quicker maneuverability—all of which make them well suited to the ever-changing inshore waters of the East Coast.

So it is that Chris had a tough time convincing me to rework Sea Chaser . I also wondered if we were to develop a new design, why would we draw so heavily on one of my older ones? But, when Chris showed me his sketches and pointed out that precious few good pocket lobster boats are being built today, I came around. I have to say that I’m pleased with the results, and Chris tells me that he is, too.

The North Haven 24 is constructed with the well-proven stitch-and-glue method, using BS-1088 Okoume marine plywood and epoxy resin. The specifications call for complete sheathing of the exterior, first with 6-ounce fiberglass cloth, then a layer of Dynel or Xynol polyester cloth over that—all set in epoxy.

Interior surfaces are saturated and sealed with epoxy resin, as well. The NH 24 can then be painted simply or fancily, with either single-part paints or two-part linear polyurethane (LPUs). This little girl can get some dirt on her hands or put the on make-up and prance about on the dance floor: it’s your choice how to finish and use her.

The result is a boat that’s strong, light, easy to maintain, and simple to repair, should that be necessary. Very solid and tough, she will be warm to the touch, not cold like an aluminum or fiberglass boat. And the NH24 will be stiff: there’ll be none of the panel flexing that increases noise in hulls built of other materials. Finally, the NH 24 will be absolutely unsinkable: epoxy-sealed wood floats .

Powered by a quiet, fuel-efficient, virtually smokeless four-stroke outboard of modest horsepower, she’ll easily and comfortably cruise in the 20- to 25-knot range. Hence, the NH 24 will be excellent for island hopping and—thanks to her keel and sheathing—even beaching, whether your goal is exploring or commuting.

She’ll shine at weekend cruising, and the huge, completely open cockpit is ideal for a flexible arrangement of folding deck chairs, a kayak or two, and/or a couple of four-legged friends. With a small cabin heater forward, the North Haven 24 will be a three-season boat on the East Coast or a four-season boat on the West Coast. And drop curtains can easily be fitted to instantly and fully enclose the pilothouse. That said, with a deep underbody and full-length spray rail, she’ll be a dry runner, and you won’t find many days when you have to throttle her back in rising seas.

I look forward to one day easing into Stonington Harbor on Deer Isle, Maine, and seeing a couple of these beauties at anchor, mixed in with their larger cousins and showing just a bit of the mix in their heritage. I think the scene will work; maybe you agree. — Sam Devlin

The North Haven 24 is available as study plans and full construction plans , or as a custom build from the guys here at Devlin Boat.

Notice to our valued Devlin Boat customers

As always, if you have any questions about orders (past or present), don’t hesitate to get in touch!

Featured Products

Artfully Designed and Crafted Boats since 1978

Shop tours on Fridays by appointment

Pin It on Pinterest

May 2015 Volume 20, No. 5

Home About Us Subscribe Advertise Archives Contact Classified Ads

Building a Wooden Lobster Boat

John’s bay boat company, part iii.

Peter Kass has had a life long interest in wooden boats. Kass still builds one boat at a time. The building methods might be called improved traditional. Some of his crew have been with him for decades.

This photo essay highlights some of the steps in an ages old building process. The work requires high level skills in engineering, intuition, architecture, materials, tools, and a lot of practice. Part III covers planking and parts of the topside. The boat is still being built.

Part IV will cover final details and the May launch. Special thanks to Walt Barrows, a photographer and admirer of Kass’s work, for granting the use of his photographs for this story. The boat in the photos was built in the winter of 2014-2015.

Jeff Hanley tracing a line on the first plank on the boat. The plank will be finish planed to the line. The stern or transom is planked first. Side planks will overlap stern planking.

The stern planked, bunged and caulked with cotton. One half the thickness of the plank is flush with its neighbor. The outer half of the upper plank edge is slightly beveled to allow cotton to be driven between the planks with a flat metal caulking iron and later filled with seam compound.

The lower garbopard plank screwed down and the second plank clamped and wedged in place ready to be fastened. Wood wedges are used to drive plank down against rabbet and garboard plank. Black metal planking dog, center, grips frame and enables wedge to be driven against top of plank. Left, planking dog an d clamp with pads to protect plank surface.

Tuck area planked and fastened. Piece along top plank is a spiling batten used to take off shape of plank below. The space between the plank edge and batten is marked on the batten, then transferred to the next plank to be cut. String on scrap,of wood that runs into shaft hole in keel is made taut to locate where center of shaft will be in order to make cut-outs in floors for the shaft.

Pulling a hot rubbery white cedar plank from the steamer. All but the butt end cut will have been made.

The widths of a single plank at each of 19 frames. Planks are narrower at the stem, wider amidship and narrow at the stern, but wider than at the stem. The distance from the keel to the rail is greatest amidship. Forward planks in a lobster boat with flare are cut to widths that produce the proper appearance. Aft of the 19th frame the planks become more equal in width. Below the turn of the bilge plank width adjustments can more easily be made.

The spiling batten on middle plank in foreground has marks used to transfer the edge shape of an installed plank to the next plank that will fit against it. The marks from the spilling batten have been transferred to the next plank to be installed. Here Peter Kass is tacking a batten to pencil marks taken from the spiling batten to draw a line for cutting the plank with a skill saw or the bandsaw before finishing with a hand plane.

Planking from keel up and rail down toward the last plank at mid-hull. That last plank is called the shutter plank.

Fairing the nearly completed planking with a jack plane. The outer edges of flat planks at the more curved areas stand proud of the curvature of the frames. Planing fairs the surface into a smooth curve.

Caulked with cotton strands, the seams primed, then payed with seam compound before priming the whole hull. Last minute cedar bungs to to be shaved flush and painted. The three forward most floors were discovered to fit better against the planks if they are installed after the molds are removed. Hence the late screwed and bunged planks.

Deck beams center and shear clamp left. Note notches in beams and tight joinery. Frame ends, frame spacers and plank edge at far right.

The engine being lowered into position. The boat's forward interior will be built around it. Lower left foreground five deep floors. Two engine beds perpendicular to the floors. Near end of the engine beds U-shaped cutouts in two floors for propeller shaft. The shaft will enter the shaft log 6" in front of the forward most deep floor and behind the floor with the cutout.

Decks and 3/4" thick mahogany plywood trunk cabin sides. The bulkhead is constructed of two layers of 1/2" mahogany plywood, glued and screwed with staggered joints.

Trimming the ends of cabin top beams for a tight fit. Jeff Hanley with knees against 3/4" mahogany trunk cabin. Bulkhead in foreground is two 1/2" layers of glued and screwed mahogany marine plywood using staggered joints.

Diversity Failing

Dave Small, Nature Photographer

Center for Sustainable Fisheries Calls for Collaborative Fish Survey

Opinion – Mr. Governor, Don’t Build That Wall

Judge Singal Slams Kennebec Salmon and Shad

Alewife Restoration on Maine Rivers Making Strides

Ecosystem-Based Management the Focus of Workshop

Short Term Leases

Lobster and Crab Bait Allowed and Not

Food & Water Watch Calls on FDA to Declare GMO Salmon Unsafe to Eat

Opinion – Maine Waters a Carbon Sink for 10,000 Cars

Always Plan for the Unexpected

Building a Wooden Lobster Boat, Part III

Don’t Keep Trade Talks Secret

2015 Maine Lobster Boat Racing Schedule

Out Here in the Real World – U-Haul Dreams

Forum Notes

Lobster Bill to Improve Lobster Licensing Voted Downstream

“Eating with the Alewives” Dinner

Capt. Mark East’s Advice to the Careworn, Confused, Lovelorn and Other Outdoor People

Lee Wilbur – Growing Up Beside the Doctor’s Office

Classifieds

The Versatile and Often Necessary Rabbet Plane

Back Then – Toothpicks and Legs

©2015 Fishermen's Voice | Website design by Lynn Pussic - e-mail

- Plans & Kits

- Plans by type

- Open Powerboats

15' Lobster Boat Plans

Write a review.

- Create New Wish List

Description

Related products.

Mia 15 Plans

15' Adirondack Guide Boat Plans

Kalostyn Plans

Kastri plans

- Help Wanted

- Submit a classified ad

- Marina listings

- Marine directory index

- View events

- Submit an event

- Search listings

- Submit a listing

- Update a listing

- Adventures and Cruises

- Animals aboard!

- Boats and boating

- Disasters and Misadventures

- Final Passages

- Food and Eating

- People and personalities

- Places and Ports

- Stormy Weather

- The editor’s page

- Christopher Birch

- David Buckman

- David Roper

- Dodge Morgan

- Jack Farrell

- Guest Columnists

- Advertising

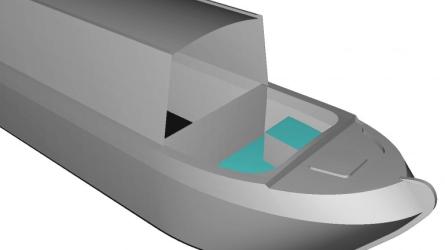

Building the perfect boat

Plans, on paper, are slowly becoming a reality. Illustration courtesy Jack Farrell

December 2021

By Jack Farrell For Points East

After more than a year of planning, and a good measure of frustration, I got word from the builder a few weeks ago that work had begun on our new Mussel Ridge 46 lobster boat for freight and passenger service to the Piscataqua region and Isles of Shoals. Albert and the crew at Hutchinson Composites in Cushing, Maine, had waxed the molds and sprayed the gelcoat, the first steps in building a fiberglass hull. The project would proceed quickly now, Albert told me on the phone. But there were some details we needed to go over. It was time for a road trip.

The route from southern Maine to Cushing on the Mid-Coast is a familiar one, never far from the water, and full of reminders of the region’s maritime roots – even when the ocean is well out of sight. It is a trip I always enjoy, but especially so this time in company with two friends and collaborators, the brain trust that will see the boat to its completion – the three of us full of excitement about the process, the new boat, and all it could be.

As with most fiberglass boats, ours was being laid up in a female mold from the outside in. (There are separate molds for each side of the boat which will be joined together after the lay-up is completed.) After the gelcoat is sprayed onto the mold-release wax, up to eight layers of carefully overlapped woven fiberglass mat are applied and impregnated with resin, along with a layer or two of chopped fibers sprayed from a gun. Additional molds shape the house top, deck and wash rails in a similar fashion. Albert’s standard mold produces a boat that is 42-feet long. Albert built the mold, along with co-designer, Tom Bernardi. A separate mold for the last four feet is added at the stern end for a 46-footer, to be tied in with more overlaps and the bilge stringers. Albert has orders for these boats, for work and pleasure, going out over two years.

My long-suffering wife and I have tried and failed five times to design and build the perfect house. We have built some very good ones, full of purpose and character, but hindsight has always revealed a mistake here and a missed opportunity there, upon which we would surely improve the next time around. After all these years, one would hope to know better, but I can’t resist approaching this new project with an eye to building the perfect boat for the job.

When the new boat idea took hold, I had two boats in service to Star Island: Hurricane, the 30-ton 1967 wooden expedition supply vessel, was easy to load and could carry the full island complement of food, fuel, luggage, and up to 49 passengers. Utopia, the 17-ton 1974 fiberglass lobster boat was more nimble and more seaworthy – safe and secure in all but the very worst conditions. But being much smaller, she could carry less freight and fewer people, and her fixed sides made loading heavy things from the float dock especially difficult.

When I was approached by a buyer for the Hurricane in the midst of the pandemic slowdown, the idea came to me to also sell Utopia, and design and build one boat that could do the whole job better. I had hoped to make the conversion before the 2021 season. At this point we have a fighting chance of making it for 2022.

The new 46-foot Shining Star design comes in at 27 gross tons – close in total load capacity to the Hurricane, and nearly half again the tonnage of Utopia. She’ll have about the same beam and cargo deck aft as the Hurricane, but her hard chines, four-foot extension and wide transom will allow weight to be carried in the stern without undue impact on her trim. She will accommodate up to 49 passengers, with warm inside seating for 24. Seating in the cargo area will fold out of the way when freight loads require. She’ll have deck-level doors port and starboard to allow freight to be wheeled aboard from the float dock. Constructed of fire-retardant resin, Shining Star will be approved to carry flammable cargoes of propane and diesel fuel along with up to 16 passengers when such cargoes are aboard. Her 575hp Tier 3 (for lower emissions) John Deere Diesel will allow comfortable cruising at up to 18 knots – although 12 knots will be the rule for increased efficiency.

By the time we arrived at Albert’s shop, the crew was already laying up the boat’s side panels. The extension molds were waxed and being readied to be joined to the main hull. We climbed down into an adjacent completed hull to check out the stringer placement and engine beds. Albert explained his method of installing the rudder tube to ensure true alignment with the engine. The scale of it all was both exciting and daunting. On the way home we stopped to celebrate what in modern day boatbuilding was the equivalent of laying the keel for yet another well-found working vessel from Maine.

With just a little luck, the hull, deck and top will be shipped down to South Berwick before Christmas. There the finishing crew, lead by boatbuilder Jonathan van Campen and marine technician Marshall Frye will take over to install the engine, systems, carpentry, electrical, plumbing, amenities and other gear.

I am so lucky to have these guys and their associates ready to jump in on this project with such enthusiasm. Frustration with the approval process is fading by the day. Will she be the perfect boat? Not likely, but she’ll be very good, and that’s OK.

Aloft out for the season

We hauled our wooden sailboat Aloft the other day and got her settled down in the boatshed. The process was complicated by the failure of the centerboard pennant which allowed the heavy board to hang vertically from its trunk, making haul out impossible. With the help of the always-willing diver Rob Love, son, James and I cranked the board aft and upward with lines wrapped forward around the board and lead aft to the cockpit winches. Part way through the hard cranking, the lines went soft, and we took up the slack, securing them to the cleats, not quite sure how that could have happened. Through the air bubbles on the starboard side, Rob surfaced with a grin. The board was all the way up. He had been able to swim below the keel where, with his tanks balanced against the rising board, he used his flotation air to complete the lift. Rob is a regular for dive tasks at Star Island, and he has bailed me out on the boats many times before this. His presence is a gift to the mariners around here, for sure.

Meanwhile out at Star Island, the unofficial capital of the Isles of Shoals, the draining, shuttering, hauling out and stowing away of close-up time have given over to the solitude of winter. The contrast is startling on the occasional late season visit: where not so long ago the islands and harbor were alive with activity, the Shoals seem now to be almost completely at rest – the silence interrupted only by wind, waves, the very occasional passing of a fisherman, and the muffled sound of Alex the caretaker’s footsteps making her rounds, feeding the wild geese, and watching the sky for the return of the snowy owls.

Jack is a USCG 100-ton master and the facilities director at Star Islands at the Isles of Shoals, where Aloft, his Ted Hood-designed wooden sloop, lives most of the summer.

More in Boats

Read our newest issue

Upcoming events

SEE ALL EVENTS

From our readers

Your format and paper choice help Points East feel like a local publication depending on local writers and local storytellers. That’s one of your strengths.

Love the focus on the New England coast, and I welcome the inclusion of both sailors and powerboaters alike. (And paddlers).

We really enjoy reading Points East. We used to just pick it up when we could find it when we were near the coast, but after missing a few issues my wife subscribed. We find it a great read.

I really like the local feel of Points East and the fact that it is not a glossy fancy pants boating magazine.

We have immensely enjoyed Points East ever since we began sailing lessons at the Boston Sailing Center… the high caliber of your magazine, and wide array of articles – from fun to serious – make it a pleasure to peruse every month.

I have been reading Points East for many years. I’ve always just picked it up at a local business (Bristol Bagels in Bristol RI), it was a morning ritual to have a bagel and read Points East. The name of your publication embodies my cruising dreams, heading to ‘points east.’

It’s like a drug, as soon as you finish one issue you’re dying to get the next one.

- Writing for us

- Cover photography

- Where to find the magazine

- Privacy policy

March / April Issue No. 297 Preview Now

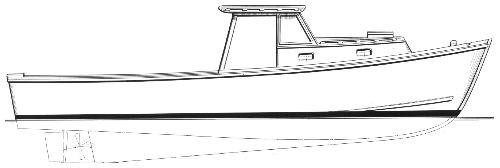

Lobster Boat 26

With seaworthy hull lines inspired by traditional lobster boats, high tech but easy to use materials and styling that isn't amateurish, this is a unique plan for amateurs. The LB26 will be equally successful as a fishing boat, day boat, or weekend cruiser. Her sharp looking hull will produce a good cruising speed and a soft ride.This boat is just right: not too big to handle and not too small to go offshore. Despite her relatively light weight, her scantlings are generous. The LB26 is not only designed to look like a seagoing vessel, she is built to be a seagoing vessel. Compared to other boats in her category, the LB26 is light and sturdy. This allows her to go fast with an economical and compact 200 HP engine.

Design Specifications

1360 SW Old Dixie hwy #103

Vero beach FL 32962 Phone:

ACCESS TO EXPERIENCE

Subscribe today.

Publishing dynamic editorial content on boat design construction, and repair for more than 40 years.

1 YEAR SUBSCRIPTION (6 ISSUES)

Print $39.95, digital $28.00, print+digital $42.95, from plans & kits.

Half Model Plan AMERICA 1/4 Scale

Optimist Club Racer

Narrowboat Semi Trad

From the community.

L.H.F. HERRESHOFF DIDDIKAI BUILT IN 1980 GREAT CONDITION

36' 6" L.H.F. ketch that's a joy to sail and beautiful from all angles.

Free sailboat rigging

Complete wooden sailboat rigging from 24′ Al Mason design sloop.

1928 16' Restored Anderson Catboat.

New hull, cockpit, rudder and centerboard. Restored deck, cabin, mast and rigging.

Original 1954 Herreshoff ARAMINTA For Sale

ARAMINTA is L Francis Herreshoff’s clipper bow ketch (Design No.

- Classifieds

- Remember Me Forgot Password?

- Boats Scale Boats Discussion Scale Lobster Boat build

- Electric Flight

- Advertising

- Our Sponsors

- Review Policies

- Terms of Service

- Privacy Policy

- Site History

- Mark Forums Read

- Member Search

- Upcoming Articles

- Do Not Sell My Data

- Manage Consent

- Back to Top

Banksy tree artwork defaced days after appearing, prompting temporary security measures

A new mural by British street artist Banksy has been defaced within days of appearing prompting a London council to impose "temporary measures" around it.

Islington Council, in north London, said it had erected fencing, camera surveillance and ordered visits by community officers to manage on-lookers to help protect the artwork.

The stencilled mural of a person having spray painted tree foliage onto a white wall behind a leafless tree, appeared on a street near Finsbury Park this week.

The enigmatic artist appeared to confirm his role in the creation, posting before and after pictures of the transformed wall on Instagram on Monday.

But following a flurry of media reports and public attention, it had by early Wednesday been defaced.

Images shared on social media showed two streaks of white paint strewn across the bright green artwork.

"It's sad to see the piece has been defaced," an Islington Council spokesperson said.

"We are discussing future solutions with the homeowner, to enable everyone to enjoy the artwork while protecting it, the tree, and the surrounding area.

"We're also in the process of installing a CCTV camera."

"This is a really powerful piece, and we really hope it's left alone."

Vandalism not deterring crowd

Despite the white paint splashed across and the added security, people taking photos of the mural appeared philosophical about the vandalism.

"The whole art of Banksy is kind of ruining itself over time, it's temporary art," noted a visitor who said he had travelled from Germany to view the mural in person.

"And if it's ruined after one day or after three days or three years, the wall is old and will be ruined itself anyway one day.

"So it's that the act is maybe more important."

On the day the mural appeared some passers-by peered into the future and saw the chance of vandalism, but thought it would not affect it much.

"It's good to see it before it gets vandalised," said Geoff Gardner, who stopped by on his way to work on Monday.

"I suppose if someone comes and sprays red paint over it, you could call that art as well."

Alex Georgiou, whose company owns the building, said "it's quite mad to be honest, to come down here and just to see all the crowds of people looking at the building."

"I definitely plan on keeping it on there and letting people enjoy it," he said on Monday.

"Everyone's loving it, which is great."

Possible environmental message

The artwork covers the wall of a four-storey residential building and shows a small figure holding a pressure hose beside a large cherry tree.

Green paint has been sprayed across the wall, replicating the absent leaves of the tree, which has been severely pruned in a technique known as pollarding.

Many onlookers discerned an environmental message in the vibrant green artwork, which appeared on Sunday — St. Patrick's Day.

"The tree looks very sad without branches and without greenery," said Pura Lawler, on her way to a gym class.

She felt Banksy was saying something about "destroying the forests, destroying the greenery."

Former UK Labour Party leader Jeremy Corbyn, who represents the area in parliament, said the work "makes people stop and think, 'Hang on. We live in one world. We live in one environment. It is vulnerable and on the cusp of serious damage being done to it.'"

"Environmental politics is about densely populated urban areas like this, just as much as it is about farmland and woodland and hedges," he added.

History of defacing

Banksy, who has never confirmed his full identity, began his career spray-painting buildings in Bristol, England, and has become one of the world's best-known artists.

His mischievous and often satirical images include two policemen kissing, armed riot police with yellow smiley faces, and a chimpanzee with a sign bearing the words, "Laugh now, but one day I'll be in charge."

Banksy's work has sold for millions of dollars at auction, and past murals on outdoor sites have often been stolen or removed by building owners soon after going up.

In December, hours after Banksy stencilled military drones on a stop sign in south London, a man was photographed taking down the sign with bolt cutters.

Police later arrested two men on suspicion of theft and criminal damage.

The latest work would be harder to take down since the piece relies on the tree for its impact.

The artist himself is also known to have destroyed some of his works in the past, rendering them more valuable.

In 2018, Banksy's Girl With Balloon artwork shred itself into pieces the moment it was sold for more than 1 million pounds at a London auction.

- X (formerly Twitter)

Related Stories

Banksy artwork taken from london street less than an hour after it was revealed.

- Community and Society

- Contemporary Art

- United Kingdom

- Urban Development and Planning

- Election 2024

- Entertainment

- Newsletters

- Photography

- AP Buyline Personal Finance

- Press Releases

- Israel-Hamas War

- Russia-Ukraine War

- Global elections

- Asia Pacific

- Latin America

- Middle East

- March Madness

- AP Top 25 Poll

- Movie reviews

- Book reviews

- Personal finance

- Financial Markets

- Business Highlights

- Financial wellness

- Artificial Intelligence

- Social Media

US Army boats head out on a mission to build a floating pier off Gaza’s shore for food deliveries

Soldiers of LLV Monterrey from 7th Transportation Brigade (Expeditionary) prepare to deploy to the Gaza Strip on Tuesday, March 12, 2024, at Joint Base Langley-Eustis in Hampton, Va. (AP Photo/John C. Clark)

A group of soldiers from 7th Transportation Brigade (Expeditionary) wave to the crew of LLV Monterey as it pulls out from port on a humanitarian mission to Gaza, on Tuesday, March 12, 2024, at Joint Base Langley-Eustis in Hampton, Va. (AP Photo/John C. Clark)

Soldiers from 7th Transportation Brigade (Expeditionary), 3rd Expeditionary Sustainment Command, make final preparations on LSV SP/4 James A. Loux before deploying to the Gaza Strip on Tuesday, March 12, 2024, at Joint Base Langley-Eustis in Hampton, Va. The Loux will be supporting the construction of a floating pier off the coast of Gaza for delivery of humanitarian aid. (AP Photo/John C. Clark)

BG John “Brad” Hinson, commander of 3rd Expedition Sustainment Command and Assistant Commanding General (Supply) of XVIII Airborne Corps, speaks during a press conference pertaining to four army watercraft deploying to Gaza for delivery of humanitarian aid on Tuesday, March 12, 2024, at Joint Base Langley-Eustis in Hampton, Va. (AP Photo/John C. Clark)

CW3 Jason West, left, skipper for LSV SP/4 James A. Loux, 7th Transportation Brigade (Expeditionary), stands with his family before deploying on Tuesday, March 12, 2024, at Joint Base Langley-Eustis in Hampton, Va. (AP Photo/John C. Clark)

LSV SP/4 James A. Loux heads down the James River for a deployment to the Gaza Strip on Tuesday, March 12, 2024, at Joint Base Langley-Eustis in Hampton, Va. The watercraft will build and operate a floating pier in support of a humanitarian mission to Gaza. (AP Photo/John C. Clark)

Soldiers from 7th Transportation Brigade (Expeditionary), 3rd Expeditionary Sustainment Command, enter the mess galley on Large Land Craft Monterey on Tuesday, March 12, 2024, at Joint Base Langley-Eustis in Hampton, Va. The Monterey was one of four army watercraft deploying to Gaza for a humanitarian aid mission. (AP Photo/John C. Clark)

Col. Sam Miller, commander of 7th Transportation Brigade (Expeditionary), speaks to media before units from his brigade deploy to Gaza in support of a humanitarian mission on Tuesday, March 12, 2024, at Joint Base Langley-Eustis in Hampton, Va. (AP Photo/John C. Clark)

Soldiers give the crew of the LLV Monterey a box of snack bars before the Monterey leaves for deployment to the Gaza Strip for a humanitarian mission on Tuesday, March 12, 2024, at Joint Base Langley-Eustis in Hampton, Va. (AP Photo/John C. Clark)

- Copy Link copied

WASHINGTON (AP) — Four U.S. Army boats, loaded with tons of equipment and steel pier segments, left Virginia on Tuesday, heading to Gaza as part of the U.S. effort to expand the delivery of food and other supplies to starving Palestinians as Israel’s war against Hamas drags on.

The ships pulled out of docks at Joint Base Langley-Eustis and headed down the James River toward the Atlantic Ocean for what could be a month-long voyage to the Mediterranean Sea. There, at a yet-to-be-announced location along the Gaza shore, they will build and begin to operate a floating dock to receive the aid.

Since Hamas militants attacked Israel on Oct. 7, Israel’s military has battered the territory, killing more than 30,000 Palestinians, according to the Gaza Health Ministry, and creating a humanitarian catastrophe . The U.N. says virtually all of Gaza’s 2.3 million people are struggling to find food. But getting humanitarian aid to the area has been difficult, due to the ongoing hostilities and struggles to coordinate with the Israeli military, which has blocked routes and slowed deliveries due to inspections.

The latest Pentagon plan calls for the U.S. military to build what is called a modular causeway system. Off shore, the Army will build a large floating platform where ships can unload large containers of aid. Then the aid will be transferred by the Army to a motorized string of steel causeway sections that have been pushed to the shore.

That pier is expected to be as much as 1,800 feet (550 meters) long, with two lanes, and the Pentagon has said it could accommodate the delivery of more than 2 million meals a day for Gaza residents. Officials have not said who will be unloading the containers and taking the aid ashore. President Joe Biden has said there will be no U.S. troops on the ground in Gaza.

On Tuesday, as family members and senior Army commanders watched, about 70 soldiers with the 7th Transportation Brigade (Expeditionary) pulled away from the docks in four U.S. Army vessels: the USAV Wilson Wharf, USAV Matamoros and USAV Monterrey, all Army landing crafts, and the larger USAV SP4 James A. Loux, a logistics support watercraft.

The brigade’s commander, Army Col. Sam Miller, said about 500 of his soldiers will participate in the mission. All together, Pentagon officials have said about 1,000 U.S. troops will be involved.

Calling it a complicated mission, Miller said the transit will take about a month, but it will depend on weather and any possible high seas. The actual construction, he said, will take about a week, but that also could be hampered by weather. Then it will take additional time to get the delivery process coordinated with those providing the aid and the system up and running. Defense officials have said it will take about two months to get the deliveries started.

The Army’s vessels and maritime capabilities are unique and not as well known as the Navy’s. The last time the 7th Transportation Brigade did a similar mission to construct a large pier was in Haiti in 2010. But it has participated in a number of major military exercises.

“The soldiers here are energized, they’re motivated, they’re excited,” Miller said, adding that the new humanitarian mission “gives them purpose and meaning” and highlights the Army’s watercraft. He noted that just 36 hours after Biden ordered the operation, the first Army vessel — the USAV General Frank S. Besson logistics ship — left Joint Base Langley-Eustis on Saturday.

Miller said a larger Maritime Sealift Command ship will also be leaving Virginia in the coming days, and will be carrying some of the bigger equipment and more of the steel pier segments.

IMAGES

VIDEO

COMMENTS

Please call or write to me at:Arch Davis Design37 Doak RoadBelfast, Maine 04915Tel:207-930-9873. If you would like to receive a newsletter from Arch Davis Design, send me an e-mail at [email protected]. Arch Davis Design - Offering Boat Plans, Kits, Videos and DVDs For The Amateur Boat Builder including sail boats, row boats and power boats.

Description. SPECS. Materials and Notes. The POT LUCK design brings the renown New England lobster boat within the capabilities of the competent amateur builder. Our modern building methods, coupled with proven materials, make building the characteristic round bottomed hull form much easier than traditional methods more suited to professionals.

Downeast Maine boat builder, Young Brothers Boats, creates custom lobster boats, sportfishing boats and yachts. Economical to operate. World's fastest lobster boats. Made in Maine. • 207-667-7427 Nine Easy Sailing Models: 30, 33, 35, 38, 40, 42, 45, 46 & Slippery 38. About Us;

The 30" boat will run really well on a 540 motor in direct drive, giving enough power to get it moving at a good clip. The real boats are no slouches when it comes to get-up-and-go---. Jun 13, 2007 , 09:00 AM

I will show you how build my RC Lobster boat (lobster yacht) step by step, which covering last two years, from cutting the first piece to safely floating. I ...

Get Part 2 and more of this ongoing series here: https://www.offcenterharbor.com/lobster-boat-yt/ Off Center Harbor has several comprehensive wooden boatbuil...

The first video! I recently purchased a 1977, 21 foot repco lobster boat. This series will be a FULL rebuild of this classic boat. She's currently set up as ...

The Lobster Boat 26 (LB26) is a plan for an amateur like no other. We made it possible for an amateur to produce a boat that will look better than most production boats and have the resale value of a custom-built boat. With seaworthy hull lines inspired by traditional lobster boats, high tech but easy to use materials and styling that isn't ...

John's Bay builds working fishing boats and pleasure boats. The building methods might be called improved traditional. From use of the half model to bronze keel bolts to custom hardware to the seventh coat of spar varnish, it's all about the details. Kass still builds one boat at a time. As much to continue enjoying the building process ...

Our concise wooden boat building videos don't just tell you what to do, they show you how. Also be sure to check out our two in-depth wooden boat building video series: Stitch and Glue Boat Building and Plywood Lapstrake Boat Building. Title. Re-Sheathing the Deck on a Wooden Boat, Part 4 - Fiberglass and Dynel: Eric gives us the run down ...

The North Haven 24 is constructed with the well-proven stitch-and-glue method, using BS-1088 Okoume marine plywood and epoxy resin. The specifications call for complete sheathing of the exterior, first with 6-ounce fiberglass cloth, then a layer of Dynel or Xynol polyester cloth over that—all set in epoxy. Interior surfaces are saturated and ...

The Outer Fall was built by the John's Bay Boat Company for James R. Tripp from Spruce Head, Maine. The boat is a 47-footer. Work began in July 2014. The launch took place on May 16, 2015. This photo essay has highlighted some of the steps in an ages-old building process. The work requires high level skills in engineering, intuition ...

Building a Wooden Lobster Boat John's Bay Boat Company, Part III . Peter Kass has had a life long interest in wooden boats. Kass still builds one boat at a time. The building methods might be called improved traditional. Some of his crew have been with him for decades. This photo essay highlights some of the steps in an ages old building process.

Strip plank. Major strip wood requirements for hull. 2460' of 3/8" x 3/4" (750m of 10x19mm) WRC. Guidance Use. 4-6 adults - estuary/coastal. Drawing/Design Package. 5 x A1 drawings + 4 x A4 instruction/spec sheets. Additions and alterations included with the plans. 15' Lobster Boat Plans.

The Lobster Boat 26 (LB26) is a plan for amateur like no other. We made it possible for an amateur to produce a boat that will look better than most production boats and have the resale value of a custom built boat. With seaworthy hull lines inspired by traditional lobster boats, high tech but easy to use materials and styling that

After John's Bay Boat Co. launched the 45' x 15' 10" wooden lobster boat Lori Jane for Ed Munsey of Cundys Harbor, Maine, on Aug. 17, 2019, Peter Kass and his crew set about building the next boat, the Never Better, a 42-foot pleasure boat. Kass wasn't optimistic about building another lobster boat in the near future. In fact, he didn't ...

Each of the Beals Island builders had his own signature when building a lobster boat (say, using four panes instead of three in the windshield), but the skeg-built hull was the constant. To the casual observer, all the Beals Island lobster boats looked alike above the waterline. "The general look was a high bow, a low stern, a long, graceful ...

Albert's standard mold produces a boat that is 42-feet long. Albert built the mold, along with co-designer, Tom Bernardi. A separate mold for the last four feet is added at the stern end for a 46-footer, to be tied in with more overlaps and the bilge stringers. Albert has orders for these boats, for work and pleasure, going out over two years.

Lobster Boat 26. With seaworthy hull lines inspired by traditional lobster boats, high tech but easy to use materials and styling that isn't amateurish, this is a unique plan for amateurs. The LB26 will be equally successful as a fishing boat, day boat, or weekend cruiser. Her sharp looking hull will produce a good cruising speed and a soft ...

To do this we are building a 1/5.5 scale model of a 38' lobster boat. This boat will be used to compare our model against at a later time. For our testing we will be using Radio control on the model in the harbor with instruments on board to record the data. What i need help with is figuring out where would be a good place to get the equipment ...

Fears oil and gas exploration will damage $240m lobster industry in WA 14m ago 14 minutes ago Thu 21 Mar 2024 at 12:32am Cattle dying from mosquito-borne disease spreading south with warmer ...

Well here's the rub. I really messed up. Like really messed up. I had to completely remove almost all the work I did in the previous video. This took a long ...

WASHINGTON (AP) — Four U.S. Army boats, loaded with tons of equipment and steel pier segments, left Virginia on Tuesday, heading to Gaza as part of the U.S. effort to expand the delivery of food and other supplies to starving Palestinians as Israel's war against Hamas drags on.. The ships pulled out of docks at Joint Base Langley-Eustis and headed down the James River toward the Atlantic ...