I’m looking for

- Something else

Boat Outfitting Skills (Carpentry) – Supported by Princess Yachts

- Qualification: Diploma

- Awarding body: City & Guilds (C&G)

- Duration: Ten weeks

- Course type: Full-time

- Time of day: Daytime

- When you'll study: Monday to Thursday, 7.00am to 5.15pm

What's it all about?

Get a headstart on your career by learning some of the key skills needed by this prestigious employer.

This ten-week course is supported by Princess Yachts and will give you the basic skills and knowledge in carpentry and boat fitting. Princess Yachts will visit the students throughout the ten-week training programme, as well as supporting site visits to Princess Yachts’ Newport Street Facilities.

At the end of the course, you will be invited to undergo a short assessment and offered an interview for a full-time position with Princess Yachts.

This course is free to those who show proof of benefits or earnings of less than £18,525.

Course information

This course is made up of the following units:

- health and safety

- principles of building – construction, information and communication

- maintenance and use carpentry and joinery hand tools

- preparation and use of carpentry and joinery portable power tools

- produce woodworking joints

- bulkhead fitting

- matrix fitting

- marine/boat terminology

You must be 19 or over to enrol on this course and you will be expected to have a good understanding of maths and English.

The following units are assessed by a GOLA online multiple choice exam:

- principles of building – construction, information and communication.

The following units are assessed via practical assessment:

- production of woodworking joints.

Upon successful completion you may progress onto the following:

- employment with Princess Yachts

- Level 2 Diploma in Site Carpentry

- Level 2 Diploma in Bench Joinery

- an Apprenticeship in carpentry.

Start date: 15 April 2024

Fee for this course: £850

Not applicable to this course

Advanced Learner Loan fee: Not applicable to this course

Please note fees are quoted for one year only.

Future careers

Plumbers and Heating and Ventilating Engineers

Carpenters and Joiners

Scaffolders, Stagers and Riggers

What you could earn:

Potential salary

Entry level salary

Average salary

Annual openings in Plymouth

Related courses

Unvented hot water systems (reassessment).

- Qualification: Certificate

- Awarding body: European Registration Scheme (ERS)

- Duration: One day

- Course type: Short course

Electrical Installation (T-Prep Foundation Programme)

- Qualification: College Certificate, T Level

- Duration: 1 year

- Course type: FREE (Eligibility Applies), Full-time

Understanding Domestic Retrofit

- Qualification: Award

- Awarding body: National Open College Network (NOCN)

- Duration: Three weeks

- Course type: Part-time

Book an open day and come visit us!

Come and visit us on one of our college open days, where you can find out more about our courses, check out our facilities and speak to current students and staff.

- CLASSIFIEDS

- NEWSLETTERS

- SUBMIT NEWS

Record number of apprentices join Princess Yachts

Related Articles

You are using an outdated browser. Please upgrade your browser to improve your experience.

Review: Princess 75 Motor Yacht

The all-new Princess 75 Motor Yacht is a trendsetter that will influence future models.

The world-wide launch for this star of the Princess lineup was at the London Boat Show earlier this year, and her first in-water display was in Asia at the Singapore Yacht Show in April.

Princess has long staked their reputation on the seaworthiness of their designs. Now, the dynamic new styling of the Princess 75 makes a good product even more elegant, and offers increased cruising efficiency. The modified deep-V hull is both efficient and stable, and allows the yacht to plane at lower speeds. The yacht comes with a choice of three different engines, and can reach speeds of up to 36 knots with twin MAN V12 1800hp engines.

The elegant exterior artfully conceals a voluminous interior, where natural light flows into the main saloon, creating an informal, calm, and relaxed atmosphere. The extended window lines, in conjunction with the unique full-height window on the port side, make this area a spectacular free standing dining space. Comfortable sofa seating is paired with a full entertainment centre featuring a 50-inch LED television, DVD player, and MP3 system with clear and crisp surround sound.

A very special custom feature in the saloon of the first Princess 75 Motor Yacht is a bespoke humidor cabinet, and a bar box designed by Linley – Princess believe that they have found “a great synergy in Linley’s sophisticated skills, craftsmanship and design, particularly their unparalleled expertise in marquetry, and selection and hand dying of veneers.” The Linley for Princess Bar Box opens to reveal an immaculately designed interior stocked with Linley Trafalgar crystal and bar accessories.

The VIP accommodation is forward, on the lower deck, with all of the three guest cabins sporting their own en suites. The guest cabins can be configured either as doubles or with twin beds – simply by pressing a button. The rooms also include specialist storage lockers, wardrobes, and stylish bedside tables.

To date, six Princess 75 motor yachts have been delivered, are in build, or on order, with a number of the units being from the original layouts presented by Princess. The company has produced a large yacht that is fast and fuel-efficient, giving a comfortable ride at high speeds up to 36 knots dependent upon the engine configuration. This package brings with it confidence on long cruises – and the fuel capacity of 1,300 gallons provides a good range. Collectively, this means a mix of performance and cruising ability that few, if any, in its class can match.

Taking the Princess 75 Motor Yacht as a whole, it is difficult to find a fault. The policy of listening to feedback from owners – coupled with attention to detail and rigorous quality control, and the production of so much of every yacht in-house – is certainly paying dividends. The 75 provides Princess with a cruising platform that meets most, if not all, the needs of a buyer, and sets a much-raised bar for future models from this UK manufacturer.

Specifications

LOA 24.25m (79ft 7in)

Beam 5.76m (18ft 11in)

Draft 1.76m (5ft 8in)

Displacement 47,700kg (105,160lbs)

Max Speed 33 – 34kts (Twin Caterpillar C32 A) 36kts (Twin MAN V12 1800)

Cruising Speed 31 – 32kts (Twin Caterpillar C32 A) 34kts (Twin MAN V12 1800)

Engines Twin Caterpillar C32 A / Twin MAN V12 1800

Fuel Capacity 6,000L / 1,585 USG

Water Capacity 1,350L Builder: Princess Yachts

This article was first published in Yacht Style. Look out for Princess Yachts at the upcoming SINGAPORE RENDEZVOUS .

RECOMMENDED FOR YOU

- The Manufacturers

- Why Work in Manufacturing?

- Early Careers Recruitment

- Careers Fairs

- News & Blogs

- Learning Resources

Back to manufacturers Back to map

Did you know?

From their beginnings in 1965, over 17,000 Princess Yachts have been manufactured. Now, they build an amazing average of 270 yachts a year. This means that every few days another yacht is completed which is incredible!

Over 21 miles of cable go into a 40 M yacht. If you laid the cable along the road, it would take you all the way from Plymouth to Totnes.

In the furniture factory, the team processes 500 sheets of wood a day. The sheets of walnut or oak are produced in Holland and the trees they are taken from are hand-chosen for Princess.

Around 7 times each month, roads in Plymouth are closed between 2.30am – 4.30am so the yachts can be pulled around the roundabouts and down streets in the wrong direction!

The biggest boat has only 13 mm height clearance under the Marsh Mills flyover and in warm weather the tyres need to be deflated to make it under and through.

Princess Yachts own 4 police cars which are driven by police officers (on non-emergency duty) to escort the boats during the early morning moves.

Princess Yachts

Princess Yachts are famous for building some of the world’s finest and most luxurious yachts, which they manufacture at their 5 different sites in Plymouth and sell all over the world. The company is extremely proud of their Plymouth heritage – their logo includes the words “Crafted in Plymouth”. 80-85% of everything you see on a Princess Yacht has been made in-house by the company’s Plymouth teams.

“Where there’s warm weather and water, you will find Princess Yachts. There’s always a carefully crafted part of Plymouth floating around some of the most beautiful places in the world” Antony Sheriff, Executive Chairman, Princess Yachts

Princess Yachts is also honoured to be the first luxury yacht manufacturer to officially partner with the Marine Conservation Society. Since 2016 they have worked together to support marine environments, preserving reefs and sea life for present and future generations.

Typical job roles include: Marine Engineering, Fabrication/Welding, Carpentry, Computer Aided Design,Composites, HR, Learning and Development and Finance

Apprenticeships: Princess Yachts has a variety of four year apprenticeship courses available each year including; Marine Engineering, Carpentry/boat building, CAD Development, Fabricating and Welding, Business Administration, HR, Finance, IT and Composites. Find out more about the company’s Apprenticeship Scheme below in the Get to Know Princess Yachts section.

Princess look for potential apprentices with the right attitude, the right qualities and the desire to fulfil their potential – people who can stand out from the crowd and deliver the high standards of quality and service expected in the luxury yacht business. Applicants need to be dedicated, eager to learn, and keen to combine hands on work with study in their own time.

University Placements are available in the CAD department.

Graduate Programme : Princess Yachts also offers a graduate programme for those who are leaving university, with opportunities in Accountancy and Finance, Business Operational Management, Commercial, Sales, Human Resources, Naval Engineering, Naval Architecture, Marketing and Communications, Development

Princessyachts.com

3000 Employees Worldwide

5 Plymouth Manufacturing Sites at Stonehouse, Coypool, South Yard, Langage, Lee Mill.

Distributors in over 100 countries.

Get to Know Princess Yachts

Princess yachts apprenticeship scheme (section 1 of 2).

Princess works in partnership with the South Devon Marine Academy which has a dedicated Princess Yachts workshop, equipped with a V40 hull where apprentices can learn skills in all aspects of the business, offering a truly immersive experience.

The Scheme offers a mix of classroom-study with practical work and real experience and gives participants the chance to work with world-class boat-builders and other professionals who are passionate about passing on their knowledge.

The first year of the apprenticeship programme, is undertaken at South Devon College where apprentices complete additional marine qualifications such as RYA Powerboat Level 2, RYA Sea Survival, RYA VHF Radio Operators Licence and RYA First Aid as well as taking part in off water activities. SEE NEXT SECTION FOR MORE INFO…

PRINCESS YACHTS APPRENTICESHIP SCHEME (Section 2 of 2)

In the third week of an apprenticeship, the apprentices can undertake a week long residential programme at Heatree, Exeter with activities such as canoeing, rock climbing and abseiling to learn new skills including team working, self-motivation and leadership.

Apprentices’ are also taken to the Southampton Boat Show where they enjoy attending the Princess Yachts stand to really help them grasp the bigger picture and understand the exceptional global luxury brand that they are now part of.

After their first year is completed, each Apprentice is assigned to work at one of Princess Yachts’ five sites around Plymouth where they will be fully trained in their specialism.

Find out more about the Apprenticeship Scheme here

LUXURY MOTOR YACHTS AND SUPER YACHTS

Princess Yachts craft a range of highly developed luxury yachts, which are said to be the envy of the yacht manufacturing and retail community.

At 40 metres long, the Princess 40M is the company’s largest yacht to date and is classed as a super-yacht. It has the luxury price tag of £18 million! Across the yacht’s three decks, there are sunbathing hideaways, a spa bath, dining areas and even a walk-in beach club.

Click here to take a 360 tour of the Princess 40M and see the amazing craftsmanship of the Plymouth yacht building teams.

The M Class super-yachts are constructed in one of Plymouth’s most historically important areas at South Yard, which is a former naval yard dating back to the 17th century and where the city’s dockyard originally began.

CAREFULLY DESIGNED INTERIORS

As you can see here, the Y85 caters for relaxation as well as speed. The flybridge has a fantastic deck for enjoying the sights and sounds of the ocean and marinas while the saloon creates an elegant space for seating and dining.

There is a careful design process for every element of a Princess Yacht. Each newly designed yacht goes through a Mock-Up stage. This is a one-to-one scale replication of the final yacht to test exactly how the new layout works, to check head heights, door way functionality, and how the furniture and materials will feel in the space. You can watch a film about the Mock-Up Stage here.

NEW PERFORMANCE SPORTS YACHTS

The R Class is the brand new range of performance sports yachts by Princess. The R35 pictured here, is a revolutionary yacht which was designed in conjunction with Ben Ainslie Racing Technologies (yes – Ben Ainslie – one of the most successful Olympics sailors of all time!) and legendary Italian car designers, Pininfarina.

This yacht can reach a top speed of 50 knots. Only the fastest swimming fish in the world could keep up with the R Class yachts.

To confuse the eye and help conceal its design until its official launch, the prototype R35 was actually covered in dazzle camouflage which was created by Plymouth College of Art student, Katie Sheppard. Take a look at the sea trial of the prototype R35 in its dazzle camouflage design here.

SEE INSIDE PRINCESS

If you would like to see more inside Princess Yachts, watch some of their manufacturing processes, find out how the yachts are tested on water and understand the company’s amazing history and craftsmanship – visit the Princess Yachts webpage here “Inside Princess” and scroll down to watch their interesting video.

Explore Other Exciting Companies

NOV Fiber Glass Systems

Babcock International

- Select Language

Master Woodworking from Princess

Wednesday 11th March 2015

Step on board any Princess yacht and there is no denying the importance a master carpenter plays in the production of our craft. From beautifully finished bulkheads and doors, to expertly crafted furnishings, down to the wooden panels hidden beneath carpets and linings. Princess Yachts’ Carpentry Manufacturing Engineer, Justin Empson, explains how we combine technology with expert craftsmanship to create some of the finest yacht interiors in the world.

”My role at Princess is to support the Carpentry Department at KitParts by identifying opportunities for continuous improvement. This can involve anything from reviewing the way an individual item of furniture is put together through to assessing the quality and efficiency of the machinery and equipment used within the department. Having worked in the woodworking industry manufacturing high quality furniture for over 20 years, I have seen how technology has helped refine carpentry processes. Historically we manually cut parts from plywood patterns which were cumbersome to store, took time to locate and became worn over time, making them less reliable. Today, through the use of technology such as CNC (Computer Numerical Control) machines we can be more accurate and efficient with the way we fabricate parts.

We operate five CNC machines within KitParts. CAD (Computer Aided Design) drawings are converted into CNC files from which the machine can precisely cut a part to shape. We are also able to use the machine to mark up the placement of fixtures and fittings helping to streamline and improve accuracy during the assembly and fit out process.

We utilise ‘nesting’ software which looks at all the parts in the schedule that are due to be run through the CNC machine, and calculates how to cut the maximum number from a single sheet of material, reducing waste.

We use special purpose machinery which help to reduce what are otherwise very manual processes for our carpenters. As we produce hundreds of thousands of parts each year this saves a huge amount of time. This includes tools such as the Weinig CUBE which produces large volumes of precisely cut wood and the Edgebander which is used to add a veneer trim to raw plywood edges.

We have a team of skilled machine operators who utilise their knowledge and experience to assess the best tools to complete a part ready to be handed over to the Carpentry team for assembly. While technological advancements have undeniably helped with more efficient and accurate production, the assembly process is still heavily reliant on the skill of the individual carpenter. Timber is a living product so will always require refinement to ensure seamless joints and a high-quality finish.

Many of the joinery skills used by our Carpenters have changed very little over the centuries however, more advanced equipment has helped make the process easier and more efficient than more traditional methods.”

Sign up to our newsletter

Sign up now to be the first to hear about our news and updates.

You can amend or withdraw consent at any time here or by emailing us . Further details regarding how we process your personal data can be found in our privacy policy .

- Name This field is for validation purposes and should be left unchanged.

Our Sister Brands

Princess Yachts’ Incredible Production Capacity

Nov 13, 2017 | Bluewater Perspective , Magazine , News , Princess Yachts | 0 comments

Waterfront Office Locations

- Baltimore 410.342.6600

- Annapolis 443.716.7965

- Ocean City 410.390.3043

- Hampton 757.723.0793

- Virginia Beach 757.937.2570

North Carolina

- Beaufort 252.728.2645

- Morehead City 252.728.2645

- Wilmington 910.256.6643

- South FL 561.845.0606

The Princess Passport

Powered by Yachting and Princess Yachts America, the Princess Passport is the ultimate resource for the inspired yachtsman. Updated with new stories and articles regularly, this hub is your place to explore, discover and enjoy.

A passport allows you to explore new places, discover new passions, and enjoy what life has to offer. As yachtsmen – that’s part of our DNA. We know that yacht ownership is more than just a hobby; it’s a lifestyle. That’s why we at Yachting have teamed up with Princess Yachts America to issue this passport to you so that you can explore, discover and enjoy with us.

Here, you won’t just find the latest information on Princess Yachts – though we can’t get enough of those stories. The Princess Passport is your hub for all things yachting. You’ll find guides on the most beautiful and interesting destinations to add to your bucket list, must-have gear and accessories to equip your yacht, tips on maintaining safety while at sea, and crowd-pleasing drink and food recipes that will impress your family and friends. So come aboard and explore, discover and enjoy.

Visit this link to learn even more about Princess Yachts: princessyachtsamerica.com

To view historical Princess Yachts America content, click here .

Preview the All New Princess Y80

The all-new Y80 features elegant refined proportions and details with a clean, timeless aesthetic.

Princess Yachts’ Y95: A Flagship Flybridge

The 23-knot Princess Yachts Y95 leads the British boatbuilder’s four-model Y Class open-flybridge series.

To Infinity…and Beyond

With the new infinity cockpit configuration making its North American debut at Miami, Princess Yachts’ Y85 demonstrates the brand’s dedication to innovation.

The Princess S65: Latest Addition to the S Class

The Princess S65 delivers exhilarating performance and expansive luxury in a sleek sports yacht package.

Princess Yachts on a Sustainability Journey to Reduce Environmental Impact

Princess Yachts partners with the Marine Conservation Society on sustainability initiatives.

Princess Yachts is Ready to Impress—Again

The new Princess Y95 and X80 are headed to the Fort Lauderdale boat show this autumn, with the Y80 up next for the Palm Beach show next spring.

Princess Yachts’ Superpowered X80

The Princess X80 is a 31-knot socializing machine with a “super flybridge.”

Preview Princess Yachts’ 2023 Fort Lauderdale International Boat Show Lineup

Explore a North American Premiere, a Show Premiere, and More.

More Princess Yachts

New Model Showcase

Princess yachts x80.

The Princess X80 is the latest addition to their X Class the “Superfly” family, a perfect compliment to the X95.

Princess Yachts F65

Princess Yachts’ F65 debuted to the North American audience at the 2023 Palm Beach International Boat Show.

Princess Yachts S72

With its U.S. Debut at the 2023 Palm Beach International Boat Show, the Princess Yachts S72 takes the S-Class to the next level.

The All-New Princess Y80

Coming in 2023, The all-new Princess Yachts Y80 realizes innovative layout solutions for an 80 foot motor yacht. Configurable cockpit options, an open or closed main deck layout with wheelhouse and a newly designed foredeck area, the Y80 offers choice without compromise.

Explore the Princess V55

The Princess Yachts V55 has a level of luxury beyond just layout or speed; it’s about the details. Underway, the Princess V55 handles like a much smaller yacht. We stuck our nose far enough offshore to prove that the deep-V hull form could easily handle the bluster of the English Channel, the Catalina Channel or the Gulf Stream.

Lifestyle/Yacht Life

Return ‘Em Right Best Release Practices Manual Now Available

Return ’Em Right, an organization dedicated improving reef fish survival, has published a guide to safe releases of deep water species for recreational anglers.

Caribbean Cruising: A Moveable Feast

In the Caribbean, colorful characters are always at play, no matter which island the party moves to next.

Exploring Key West

Unlock the rich history and culture of Key West, Florida, on your next cruise to the Conch Republic.

Cruising the Southeastern Bahamian Islands

Islands such as Conception, Rum Cay and San Salvador are off the beaten path and a visit there can feel like you have the place all to yourself.

Yacht Ownership and Safety

Raw-Water Plumbing Tips

Having mismatched seacock threads, using the wrong type of hose, or choosing the wrong alloy can lead to disaster.

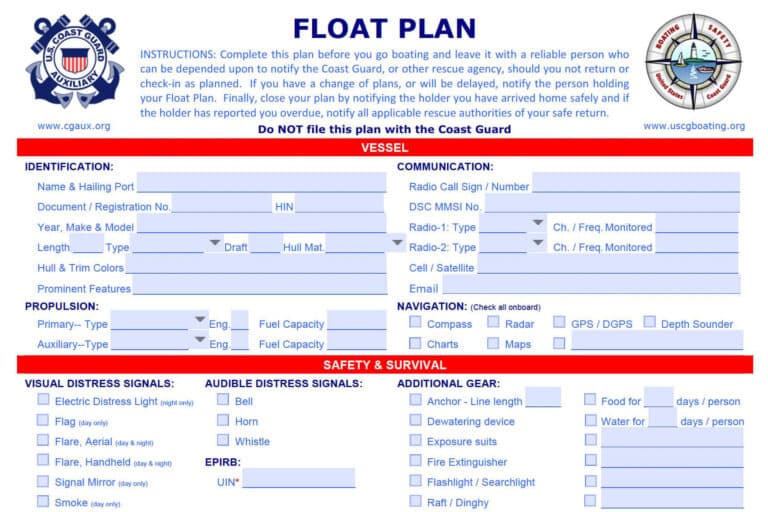

What to Include in a Float Plan & When to File One

A float plan may be your best chance of help or survival should tragedy strike out on the water.

Costa Sunglasses Releases Its Second Edition: Protect Report

Costa’s latest Protect Report captures its ongoing commitment to community and conservation.

MARSS’ All-in-One Detection System

MARSS’ MOBtronic combines cameras, radar and AI to identify person-overboard emergencies.

Behind the Build

Exceptional People: Nick Smith

Nick is the Head of Product Planning at Princess Yachts.

Behind the Scenes: Princess Yachts

Yachting takes you behind the scenes at Princess Yachts.

Crafted in Plymouth, England

Princess lifts the lid on the craftsmanship, skill and passion that goes into each and every impeccably finished Princess yacht produced.

The Craftsmanship of Princess Yachts: Part 2

A further look into the production of Princess Yachts, from carpentry to metal work, loom production to infusion moulding.

Yachting Insights

A Winter’s Sail

It’s amazing how much a seasoned sailor can experience by setting a course outside the comfort zone.

Boat Owners See Things Differently

Heading out on the water in your own boat is a unique experience with unexpected rewards.

Safe Harbor’s MegaDock Is Expanding

Safe Harbor’s upgraded MegaDock in Charleston, South Carolina, is expected to accomodate up to five megayachts.

The Dos and Don’ts of Anchoring In a Tidal Zone

Anchoring in a rocky tidal zone placed my boat perilously close to destruction. Here’s what I learned.

Cruising Recipes

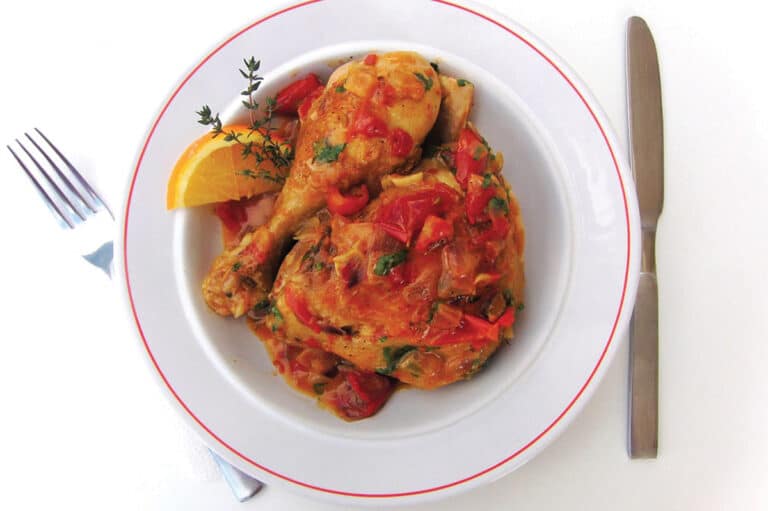

People and Food: Chicken Cioppino

A galley-friendly take on a San Francisco treat

People and Food: Offshore Banana Pancakes

Need a morale-boosting breakfast for your crew? Try this!

Sailor & Galley: A Northwest Nature’s Bounty

This rich, steaming stew from the Pacific Northwest warms chilled sailors’ bones and brings back a lifetime of memories.

Sailor & Galley: Rolled Oats Breakfast Pudding with a Tropical Twist

The coconut and mangos in this nutritious, make-ahead breakfast will transport you straight to paradise.

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- Select Language

Master Woodworking from Princess

miércoles 11 marzo 2015

Step on board any Princess yacht and there is no denying the importance a master carpenter plays in the production of our craft. From beautifully finished bulkheads and doors, to expertly crafted furnishings, down to the wooden panels hidden beneath carpets and linings. Princess Yachts’ Carpentry Manufacturing Engineer, Justin Empson, explains how we combine technology with expert craftsmanship to create some of the finest yacht interiors in the world.

”My role at Princess is to support the Carpentry Department at KitParts by identifying opportunities for continuous improvement. This can involve anything from reviewing the way an individual item of furniture is put together through to assessing the quality and efficiency of the machinery and equipment used within the department. Having worked in the woodworking industry manufacturing high quality furniture for over 20 years, I have seen how technology has helped refine carpentry processes. Historically we manually cut parts from plywood patterns which were cumbersome to store, took time to locate and became worn over time, making them less reliable. Today, through the use of technology such as CNC (Computer Numerical Control) machines we can be more accurate and efficient with the way we fabricate parts.

We operate five CNC machines within KitParts. CAD (Computer Aided Design) drawings are converted into CNC files from which the machine can precisely cut a part to shape. We are also able to use the machine to mark up the placement of fixtures and fittings helping to streamline and improve accuracy during the assembly and fit out process.

We utilise ‘nesting’ software which looks at all the parts in the schedule that are due to be run through the CNC machine, and calculates how to cut the maximum number from a single sheet of material, reducing waste.

We use special purpose machinery which help to reduce what are otherwise very manual processes for our carpenters. As we produce hundreds of thousands of parts each year this saves a huge amount of time. This includes tools such as the Weinig CUBE which produces large volumes of precisely cut wood and the Edgebander which is used to add a veneer trim to raw plywood edges.

We have a team of skilled machine operators who utilise their knowledge and experience to assess the best tools to complete a part ready to be handed over to the Carpentry team for assembly. While technological advancements have undeniably helped with more efficient and accurate production, the assembly process is still heavily reliant on the skill of the individual carpenter. Timber is a living product so will always require refinement to ensure seamless joints and a high-quality finish.

Many of the joinery skills used by our Carpenters have changed very little over the centuries however, more advanced equipment has helped make the process easier and more efficient than more traditional methods.»

Sign up to our newsletter

Sign up now to be the first to hear about our news and updates.

You can amend or withdraw consent at any time here or by emailing us . Further details regarding how we process your personal data can be found in our privacy policy .

- Comments Este campo es un campo de validación y debe quedar sin cambios.

Our Sister Brands

IMAGES

COMMENTS

Basic Pay (On Shift): £18.97 per hour. Overtime: £21.21 - £27.16 per hour. Hours. Various. Apply for this role. Princess Yachts are currently recruiting for skilled Carpenters/Joiners to work across their sites in Plymouth. With immediate start dates this fantastic opportunity offers employees to be part of one of the world's most ...

new career. Explore and apply for our current vacancies below. If you would like to apply for multiple vacancies, please email our Recruitment Team with your CV and state which roles you would like to be considered for. We also offer apprenticeship programmes in Engineering, Carpentry/boat building, Fabricating, Welding , Composites and etc.

APPRENTICESHIPS. At Princess Yachts, inspiring people to achieve is at the heart of what we do. We've built our success on the skills and abilities of our people, which is why we invest so much time and effort in our apprenticeship programmes. You'll be working with world-class yacht-builders and other professionals who are passionate about ...

By Princess Yachts. April 4, 2023. Martyn Hamley is one of the many skilled carpenters Princess Yachts employs to work on almost every pieces of timber aboard Princess' yachts. Princess Yachts. I'm one of more than 80 skilled carpenters in the bench carpentry section at Princess's Coypool complex, and we produce just about every piece of ...

This ten-week course is supported by Princess Yachts and will give you the basic skills and knowledge in carpentry and boat fitting. Princess Yachts will visit the students throughout the ten-week training programme, as well as supporting site visits to Princess Yachts' Newport Street Facilities. At the end of the course, you will be invited ...

Princess Yachts are thrilled to be taking on a record-number of 66 new apprentices this September 2020, after conducting 224 'zoom' interviews for the positions over the lockdown period. ... Caitlin Towriess, a first year Carpentry Apprentice joining Princess Yachts this September says: "The reason I applied for Princess Yachts is because I ...

Princess shipyards cover an area of over 1.1 million square feet, an area rich in British maritime heritage. To continue the development of our workforce... | boat, carpentry, engineering

Paul's carpentry history with Princess stretches back to well over twenty years, when he first began at the Princess Yachts International factory. Skip to content. Select Language; Princess. New Yachts. New Yachts; New Yachts Available Now; Available Now. v55; f50; v40; f45; v50; s62; s72;

Now, the dynamic new styling of the Princess 75 makes a good product even more elegant, and offers increased cruising efficiency. The modified deep-V hull is both efficient and stable, and allows the yacht to plane at lower speeds. The yacht comes with a choice of three different engines, and can reach speeds of up to 36 knots with twin MAN V12 ...

From their beginnings in 1965, over 17,000 Princess Yachts have been manufactured. Now, they build an amazing average of 270 yachts a year. This means that every few days another yacht is completed which is incredible! ... Carpentry/boat building, CAD Development, Fabricating and Welding, Business Administration, HR, Finance, IT and Composites.

As a Boat Builder at Princess Yachts, I apply my NVQ Level 2 and 3 skills in site carpentry to create high-quality and bespoke luxury yachts. I work with a team of experienced and passionate boat builders who share a commitment to excellence and innovation.<br><br>In the past 6 years, I have contributed to the successful delivery of multiple projects, such as the V50 sports yacht, the Y72 ...

MEET the team. We invite you to meet some of the people inside Princess Yachts to discover more about the craftsmanship, skill and passion that goes into each and every Princess yacht produced. Staff Portrait - Zach Tiddy. Staff Portrait - Alan Jenvey. Staff Portrait - Killian Scott. Staff Portrait - Steven Hobbs. 14.

Read more about the master woodworking techniques that go into Princess Yachts design, including high quality materials and more. Skip to content. Select Language; Princess. New Yachts. New Yachts; New Yachts Available Now; Available Now. f50; f45; v50; x80; s72; v40; Available for 2024 Season. x95 vista; y72; X Class Superyachts.

Today, that legacy lives on through Princess Yachts' facilities and workforce. Princess has spread their operations throughout the area, taking care to retain the rich heritage of the town while occupying centuries-old buildings for carpentry, electrical loom assembly, metalwork and more. The former naval shipyard that constructed iconic tall ...

Princess lifts the lid on the craftsmanship, skill and passion that goes into each and every impeccably finished Princess yacht produced. The Craftsmanship of Princess Yachts: Part 2 A further look into the production of Princess Yachts, from carpentry to metal work, loom production to infusion moulding.

Full job description. Princess Yachts are currently recruiting for skilled Carpenters/Joiners to work across their sites in Plymouth. With immediate start dates this fantastic opportunity offers employees to be part of one of the world's most luxurious yacht brands. Our ideal candidates will have experience in performing high standard Carpentry ...

Like all the best dreams, ours started small - in a rented shed which sits opposite our current Newport Street site, where we built our first boat in 1965. Since then we have built and shipped tens of thousands of craft across the globe from the yacht that started it all, Project 31, to the new X Class super-flybridge yachts. Explore Princess ...

Princess Yachts' Carpentry Manufacturing Engineer, Justin Empson, explains how we combine technology with expert craftsmanship to create some of the finest yacht interiors in the world. "My role at Princess is to support the Carpentry Department at KitParts by identifying opportunities for continuous improvement. This can involve anything ...

Moscow Yacht Show 2017 — the afloat exhibition of yachts and boats show in Moscow — June 22-24, Royal Yacht Club (Leningradskoe sh., 39/6) ... Princess, Sanlorenzo, Sunseeker, Galeon, Cranchi etc. Smaller motor boats will be represented by domestic manufacturers among which Velvette Marine, VBoats, Popilov Yachts, Pacifico Yachts. In terms ...

Princess Yachts was acquired by L Capital 2 FCPR, an investment group co-sponsored by LVMH (Moët Hennessy Louis Vuitton) and Groupe Arnault in 2008. In January 2016, L Capital merged with ...

Yacht prices in Philippines. Prices for yachts in Philippines start at $49,995 for the lowest priced boats, up to $7,900,000 for the most luxurious, opulent superyachts and megayachts, with an average overall yacht value of $714,500. When exploring what type of boat or yacht to buy on YachtWorld, remember to consider carefully a number of ...

Our L&D team aim to offer something for everyone. Employees can benefit from a number of training courses available within Princess Yachts to support both personal and professional development. Training is delivered through a combination of e-learning, classroom instruction, blended learning and hands-on training in our workshops.

Pals Prosper from Proximity to Putin's Power. Nikolay Tokarev, a major general in the Russian secret service, is a long-time associate of Vladimir Putin. Tokarev, 65, and Putin served as KGB agents together in Dresden, East Germany, in the 1980s. Skyscraper in the Moscow-city business district. (Photo by: KRO)