Revitalize Your Sailboat V-Berth: How We Replaced Our Headliner

In the video below we explore the process of replacing the worn-out and inefficient vinyl headliner in our sailboat’s v-berth. The existing headliner lacked insulation, leaving the V-berth vulnerable to temperature extremes. By removing the old one, adding insulation using closed-cell neoprene sheets, and installing a high-quality EverSoft™ Foam Backed Headliner , we achieved a visually appealing and comfortable v-berth.

Step 1: Removing the Old Headliner

To begin the transformation, the first task is to remove the existing vinyl headliner. Ours was glued to the fiberglass. Using tools like a heat gun, putty knives, and an electric multi-tool, we carefully scraped away the old one. This step requires patience and precision to ensure a smooth and clean canvas for the new installation.

Step 2: Adding Insulation

To enhance insulation and improve comfort, we incorporated 3/8 inch closed-cell neoprene sheets into the project. By creating a paper pattern to match the shape of your v-berth ceiling, we cut out the neoprene sheets accordingly. These sheets provide a barrier against heat and cold, ensuring a more comfortable environment in the v-berth.

Step 3: Gluing Neoprene Sheets and Installing EverSoft™ Foam Backed Headliner

We used contact cement to carefully adhere the neoprene sheets to the ceiling of the v-berth. Take your time to ensure proper alignment and avoid air pockets. Once the neoprene insulation is in place, it’s time to install the EverSoft™ Foam Backed Headliner. This vinyl liner, backed with foam, not only adds a touch of elegance but also enhances insulation and noise reduction within the v-berth.

Step 4: Finishing Touches with EverSoft 3/4″ Hidem Gimp

To achieve a polished and professional look, pay attention to the edges and seams of the headliner. Utilize EverSoft 3/4″ Hidem Gimp, a durable and aesthetically pleasing trim, to neatly cover the edges and create a seamless transition between panels. This finishing touch elevates the overall appearance of your new headliner installation.

By replacing the outdated vinyl headliner in our sailboat’s v-berth, we significantly enhanced insulation, improved aesthetics, and elevated our onboard comfort. The process involves removing the old one, adding closed-cell neoprene sheets for insulation, and installing the EverSoft™ Foam Backed Headliner. We now enjoy the benefits of a visually appealing and thermally efficient space, ensuring a cozy and comfortable retreat during our sailing adventures.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

- Click to share on Pinterest (Opens in new window)

- Click to email a link to a friend (Opens in new window)

- Click to share on WhatsApp (Opens in new window)

Replacing Headliner on a Boat

It's a lot of frustrating work, but doable..

When we bought our vintage ketch, one of the first big projects was replacement of the headliner in the forward compartments which had deteriorated somehow and become tacky. The surface was actually gooey to the touch and scuffed up majorly as a result. We got an estimate from a local shop and after the sticker shock, the timing issues (they were backed up for weeks) and the hassle factors, we decide to do it "ourselves" (that means moi).

We removed the headliner and brought it home for a "winter" project. I started by researching the materials online. What I found is that I could get materials inexpensively from fabric discounters locally, but they couldn't always guarantee that they would be suitable for marine use. Marine grade vinyl is treated for mold and mildew resistance, and although some other vinyls may have also been so treated, if it did not say "for marine use" I chose to pass it by. This was one job I did not want to repeat.

I chose a textured off-white lined vinyl. The lining meant I did not have to pad it, which would have added an extra layer of work and expense. I chose off white because it would reflect light and would probably be easier to match than anything else later on. I chose textured to add some visual interest.

As it turned out, the hardest part was removing the old headliner. As with most boats, the panels are cut exactly to the shape of the boat. In ours, the plywood and snap fasteners were still in reasonably good condition so I chose to reuse them. But it meant struggling to remove the old headliner which was quite stuck on well, and pulling out millions of staples and a few tacks. This was tedious. It took days. This was when I started second guessing whether I had made the right decision to DIM. If I did this ever again, I would use the old wood as a template and replace the lot.

The rest was actually easier than I expected (thank goodness). Once I had the boards cleared, I simply used them as templates. The size of the boards proved unwieldy so as soon as the weather improved I took the whole project out to the garage working across sawhorses, picnic tables and so on. Finding the right tools was the crux.

Once I had all the pieces cut. I got all my tools together - super spray adhesive, staple gun with the proper length of STAINLESS STEEL staples (anything else would rust instantly), scissors, knife and smoothing tools - and started assembling. This part was actually very rewarding. The spray adhesive was great. Be sure to wear a really good filtering mask because that stuff will glue your lungs together if inhaled. The trickiest part was getting the corners properly cut and neatly folded. Once I figured that out, I got into a groove and completed the liners in no time at all.

A final tip, store the new headliners with two tops facing together to prevent scratching then two backs facing together and so on.

Further Reading:

CoastalBoating

White Seahorse

Installing a new headliner on your boat

Replacing a boat's headliner is a crucial step in maintaining a healthy living environment and improving the appearance and functionality of your cabin.

Installing a New Headliner on Your Boat

Welcome to another informative article in our Boat Modifications and Upgrades section. Today, we will be discussing a crucial aspect of interior design and organization: installing a new headliner on your boat. A headliner is the material that covers the interior ceiling of your boat’s cabin, providing insulation, soundproofing, and a clean, finished appearance. Over time, headliners can become damaged, stained, or simply outdated, making it necessary to replace them. In this comprehensive guide, we will walk you through the process of installing a new headliner on your boat, ensuring that your living space remains comfortable, functional, and aesthetically pleasing.

Table of Contents

Why replace your headliner, choosing the right material, tools and materials needed, preparing the workspace, removing the old headliner, measuring and cutting the new headliner, installing the new headliner, finishing touches, maintenance and care.

There are several reasons why you might want to replace your boat’s headliner:

- Aesthetics : An old, stained, or sagging headliner can detract from the overall appearance of your boat’s interior. Replacing it with a fresh, new material can instantly update and improve the look of your cabin.

- Insulation : A well-insulated headliner can help regulate the temperature inside your boat, keeping it cooler in the summer and warmer in the winter. If your current headliner is not providing adequate insulation, it may be time for an upgrade.

- Soundproofing : A quality headliner can help dampen noise from outside the cabin, as well as reduce vibrations and echoes within the space. If your current headliner is not providing sufficient soundproofing, consider replacing it with a more effective material.

- Mold and Mildew : Over time, moisture can cause mold and mildew to form on your headliner, posing a health risk and creating unpleasant odors. Replacing a moldy headliner is essential for maintaining a healthy living environment on your boat.

When selecting a new headliner material, consider the following factors:

- Durability : Choose a material that is resistant to wear and tear, as well as moisture and UV damage. Vinyl and marine-grade fabrics are popular choices for their durability and ease of maintenance.

- Insulation : Look for materials with insulating properties to help regulate the temperature inside your boat. Foam-backed vinyl and carpet-like materials can provide additional insulation and soundproofing.

- Ease of Installation : Some materials are easier to work with than others. Flexible materials like vinyl and fabric are generally easier to install than rigid materials like wood or fiberglass.

- Appearance : Consider the overall look and feel you want to achieve in your boat’s interior. There are countless colors, patterns, and textures available, so choose a material that complements your existing décor and personal style.

Before you begin the installation process, gather the following tools and materials:

- New headliner material

- Measuring tape

- Scissors or utility knife

- Straight edge or T-square

- Adhesive (appropriate for your chosen material)

- Paint roller or brush (for applying adhesive)

- Staple gun and staples (optional, for certain materials)

- Trim or molding (for finishing edges)

- Screwdriver (for removing and reinstalling hardware)

- Protective gloves and eyewear

Before you begin removing the old headliner, take the time to properly prepare your workspace:

- Clear the Area : Remove any furniture, cushions, or other items from the cabin to create a clean, open workspace.

- Protect Surfaces : Cover the floor and any nearby surfaces with drop cloths or plastic sheeting to protect them from adhesive and debris.

- Ventilation : Ensure that your workspace is well-ventilated, as some adhesives can produce strong fumes. Open windows and doors, and consider using a fan to improve air circulation.

- Safety : Wear protective gloves and eyewear to protect yourself from potential hazards during the installation process.

Before you can install your new headliner, you’ll need to remove the old one. Follow these steps to safely and effectively remove your existing headliner:

- Remove Hardware : Carefully remove any hardware, such as lights, vents, or handrails, that may be attached to the headliner. Be sure to keep track of any screws or other small parts so you can easily reinstall them later.

- Detach the Headliner : Depending on the type of headliner you have, it may be attached with adhesive, staples, or both. Carefully peel back the material, using a scraper or putty knife if necessary to help loosen the adhesive. If your headliner is stapled, use a staple remover or flathead screwdriver to carefully pry out the staples.

- Clean the Surface : Once the headliner has been removed, thoroughly clean the ceiling surface to remove any remaining adhesive, staples, or debris. This will ensure a smooth, even surface for installing your new headliner.

With the old headliner removed and the surface cleaned, you’re ready to measure and cut your new headliner material. Follow these steps for accurate measurements and precise cuts:

- Measure the Ceiling : Using a measuring tape, measure the length and width of your boat’s ceiling, adding a few extra inches to each dimension to allow for trimming and adjustments during installation.

- Mark and Cut the Material : Lay your new headliner material out on a clean, flat surface. Using a straight edge or T-square, mark the dimensions you measured onto the material. Carefully cut along the marked lines with scissors or a utility knife, ensuring that your cuts are straight and even.

With your new headliner material cut to size, you’re ready to begin the installation process. Follow these steps for a successful installation:

- Apply Adhesive : Following the manufacturer’s instructions, apply adhesive to the back of your headliner material using a paint roller or brush. Be sure to apply an even, consistent layer of adhesive, taking care not to leave any gaps or clumps.

- Position the Material : Carefully lift the headliner material and position it on the ceiling, starting at one end and working your way across. Press the material firmly onto the surface, smoothing out any wrinkles or bubbles as you go.

- Trim Excess : Once the headliner is fully adhered to the ceiling, use a utility knife to carefully trim away any excess material along the edges.

- Secure with Staples (Optional) : If your headliner material requires additional support, use a staple gun to secure the edges of the material to the ceiling. Be sure to space the staples evenly and keep them as close to the edge as possible to ensure a clean, professional appearance.

With your new headliner installed, it’s time to add the finishing touches:

- Install Trim or Molding : To create a clean, finished edge along the perimeter of your headliner, install trim or molding. This can be attached with adhesive, nails, or screws, depending on the type of trim and your boat’s construction.

- Reinstall Hardware : Carefully reinstall any hardware that was removed during the headliner removal process, such as lights, vents, or handrails.

- Clean Up : Remove any protective coverings from your workspace and clean up any debris or adhesive residue.

To keep your new headliner looking and performing its best, follow these maintenance and care tips:

- Clean Regularly : Gently clean your headliner with a damp cloth and mild soap, taking care not to saturate the material or damage the adhesive. Be sure to address any spills or stains promptly to prevent permanent damage.

- Inspect for Damage : Periodically inspect your headliner for signs of wear, damage, or mold and mildew. Address any issues promptly to prevent further damage and maintain a healthy living environment on your boat.

- Avoid Overloading : Be mindful of the weight and distribution of items stored in your boat’s cabin, as excessive weight or uneven distribution can cause stress on the headliner and lead to sagging or damage.

Installing a new headliner on your boat is a rewarding project that can greatly improve the comfort, functionality, and appearance of your living space. By following this comprehensive guide, you can confidently tackle this project and enjoy the benefits of a fresh, updated headliner. Remember to choose a durable, high-quality material, and take the time to properly prepare your workspace and follow each step of the installation process. With a little patience and attention to detail, you’ll be well on your way to a beautiful, functional headliner that will serve you well for years to come.

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Best Day on the Water

- Books & Movies

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← Install & Repair

Boat Headliner Repairs

Advertisement

Age and abuse can discolor or rip liners in your boat. But Tom's a fan of figuring out innovative repairs. Here's a trick to cover up any eyesores.

The completed project. Who would ever know what was there?

Liners inside the cabins of boats come in many materials, but they all have one thing in common: Eventually they tear or become damaged. In older boats, even finding the same material may be impossible, and if you do, the job of replacing the entire liner or even a section may be very expensive. Patchwork may be the cheaper and easier way out, but it will probably look like patchwork — and nobody wants that. But if you incorporate another project into the lining repair, you can sometimes disguise the fact that it's patchwork AND get an additional bonus.

For example, on our boat, we had a liner that had been ripped before we owned the boat. Our solution was to cover the problem area with what is essentially patchwork. But you'd never know it because the patchwork has been transformed into a mounting for a new fan.

I purchased a sheet of StarBoard (1/4" x 6" x 12") from West Marine for around $13 (see "Technical Support," below). This material comes in several thicknesses and colors, including white and black. It will take screws (wood or better) and bear weight, depending on thickness and use. It's high-density polyethylene designed to resist saltwater, chemicals, and sunlight. It won't rot or delaminate, and is easily cut, routed, shaped, and drilled, using standard tools. It has a durable surface, which easily cleans.

Technical Support

Degree of difficulty:.

Easy to moderate

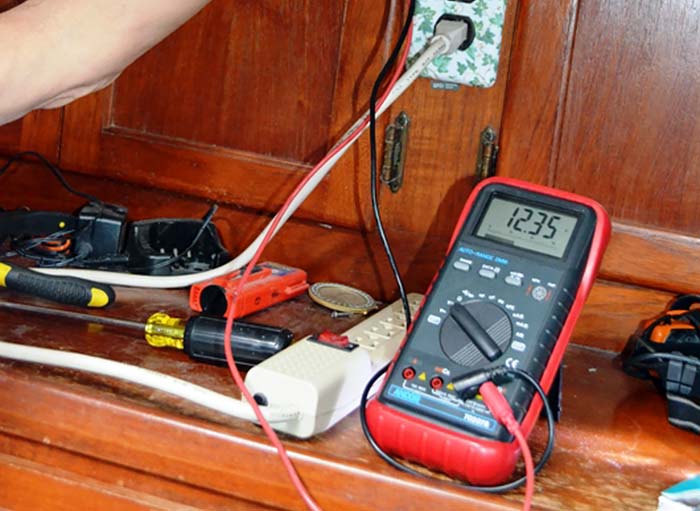

- Multi-meter

- Wire-crimping tool

- Electric drill and bits

- Butt connectors

- Screwdrivers

- Headlamp and shop lights (optional)

Materials & Cost:

- StarBoard $13

- Butt connectors and six stainless wood screws $5

Project Cost:

$98 (based on West Marine pricing)

Approximate Yard Time/Cost:

This is a straightforward job and shouldn't take a pro more than an hour or so. The national average cost for a marine electronics installer runs about $80 an hour but many have minimums, so you can plan on saving around $100 by doing the work yourself.

The problem: ripped dirty headliner.

I purchased a sheet just large enough to cover the damage. All I had to do was screw it onto the strip of plywood in the overhead, to which the liner material was attached. I predrilled and used pan head screws. I could have countersunk the screw holes and used oval-head screws, but preferred to not use this slightly weakening process. The material is durable enough that washers weren't needed. When I attached the material, the tear disappeared. But the area, of course, no longer matched the surrounding areas.

We needed a fan in that area, anyway, so I purchased one for around $80 from West Marine. Prior to screwing on the StarBoard, and using the base of the fan as a template, I drilled holes appropriately sized to securely thread the mounting screws that came with the fan and drilled another hole through the StarBoard, behind the fan mount, to take the wire. I taped the fan wire ends to avoid separating the strands and carefully pulled the wires through that hole and pushed them underneath the lining, making sure they were not lying in an area where they would be compressed or where abrasion could occur.

Predrilling StarBoard.

Testing existing wire for polarity and current.

Uncrimping old butt-end connector with careful pressure from dull wire cutter.

Streamlight 3AA Haz-Lo headlamp lights tight area.

Work light floods dark area. Use quality crimping tools.

With a Volt-Ohm Meter, I tested voltage for the old 12-V DC wiring leading to the area behind the adjacent bulkhead to be sure polarity hadn't been reversed by someone in the ancient past, and then again to be sure power was indeed gone after I flipped the breaker. This wire would've been too short if I cut off the old connectors, so I removed them by carefully compressing them at the point of the crimp with a crimping tool. Next I connected the new fan wires, using tinned butt-end connectors, to that existing wire behind the bulkhead. This work was close to and inside the bulkhead, so I used a Streamlight Knucklehead worklight and a 3AA HAZ-LO headlamp for good lighting. The existing wire was of more than adequate gauge to handle the tiny load of the fan and was already protected by an appropriately sized circuit breaker. The new fan's wires were long enough to allow this work before mounting the fan — a feature I always insist upon when buying something to be installed.

I finished the job by screwing the StarBoard, with fan base attached, to the overhead, attaching the fan and snugly and securing the wire. Now the rip is covered, a smart-looking fan is mounted in its place, and the mounting looks nothing like a jury-rigged repair but a nicely thought-out and properly executed fan mount. Only you and I know it was never originally planned that way!

Plastic Or Wood?

There are several versatile synthetic products now on the market that can be used in place of wood for many boat projects. They're easy to work with, using simple woodworking tools, and easy to hand-sand. Examples include StarBoard by King Plastic , and CMG and KOMATEX by Kommerling . StarBoard and CMG are more robust for mounting purposes. CMG is claimed to also accept fiberglass. Komatex, depending on thickness, can be very flexible and easier to fit, but is less appropriate for structural or mounting purposes.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Technical Editor, BoatUS Magazine

One of the top technical experts in the marine industry, Tom Neale, BoatUS Magazine Technical Editor, has won nine first-place awards from Boating Writers International, and is author of the magazine’s popular "Ask The Experts" column. His depth of technical knowledge comes from living aboard various boats with his family for more than 30 years, cruising far and wide, and essentially learning how to install, fix, and rebuild every system onboard himself. A lawyer by training, for most of his career Tom has been an editor and columnist at national magazines such as Cruising World, PassageMaker, and Soundings. He wrote the acclaimed memoir All In The Same Boat (McGraw Hill), as well as Chesapeake Bay Cruising Guide, Vol. 1. These days, Tom and his wife Mel enjoy cruising their 2006 Camano 41 Chez Nous with their grandchildren.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

Practical Boat Owner

- Digital edition

Replacing headlinings: How to cure the droop

- Ben Meakins

- February 19, 2016

Are you coming unstuck? If your headlining is starting to part company with the deckhead, it’s time for a makeover. Jake Kavanagh follows professional upholsterer Roger Nantais as he refurbishes a Westerly Seahawk

The biggest enemy of foam-backed vinyl is water. If this leaks in through deck fittings, it can gradually rot the foam; the glue fails to grip on the crumbling mess, and eventually the vinyl will start to fall down. Many owners make valiant attempts to fix the vinyl back up, but this can often create more problems than it solves.

This article deals with linings stuck to hull sides. You can also stick them to removable plywood panels, which we followed in this article: Making Headlining Panels.

On Jane Scott and Chris Smith’s 18-year-old Westerly Seahawk 2+2, a combination of leaking deck fittings and high Mediterranean temperatures had gradually perished the foam backing, and the boat was looking decidedly scruffy inside. They decided to call in professional upholsterer Roger Nantais, who refurbished the linings from stem to stern. PBO followed his progress to learn some useful trade secrets.

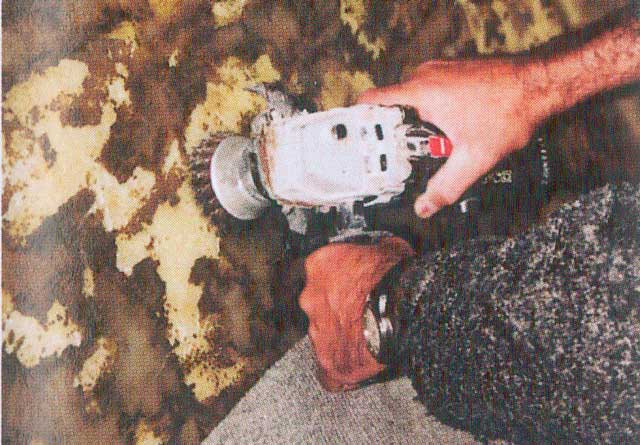

Preparation ‘You really need power,’ Roger explained. ‘It’s possible to use hand tools, but the task is made much easier if you can use a hot-air gun, a vacuum cleaner and a drill with a wire brush attachment.’

As a result, the Westerly was moved from her mooring in Poole Harbour to Davis’s boatyard in nearby Hamworthy, where Roger was able to hook up to shore power.

Depending on the state of decay, it may not be necessary to renew all the headlinings at once, but on older boats you could have trouble matching the colours. This Westerly had fairly standard white linings thoughout, complemented by plywood panels on the deckhead in the saloon. In some areas, the original linings were trapped under substantial deck fittings, such as the chain plate bases, which Roger decided to work around.

With the headlinings down, many owners use the opportunity to check hidden wiring, and get to the base of any leaking deck-fittings. These need to be re-sealed before being covered in foam again. We started with the forward cabin first, which was the most badly affected.

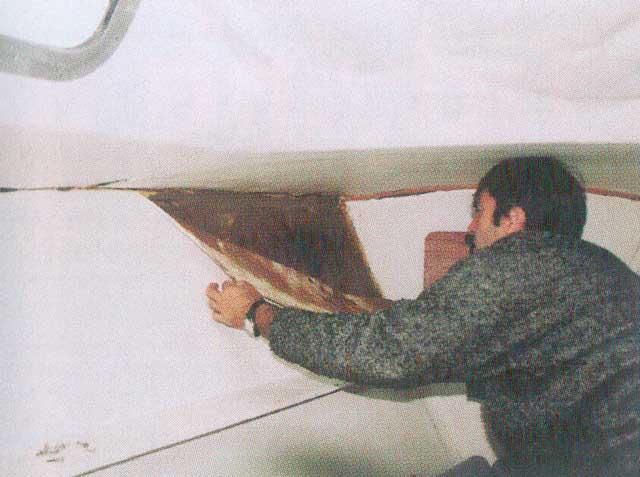

Stripping off The forecabin on this boat, as on many similar designs, has a complex headlining made of several panels of vinyl, all sewn together into a contoured piece. It may seem daunting to replace, but the procedure is quite straightforward.

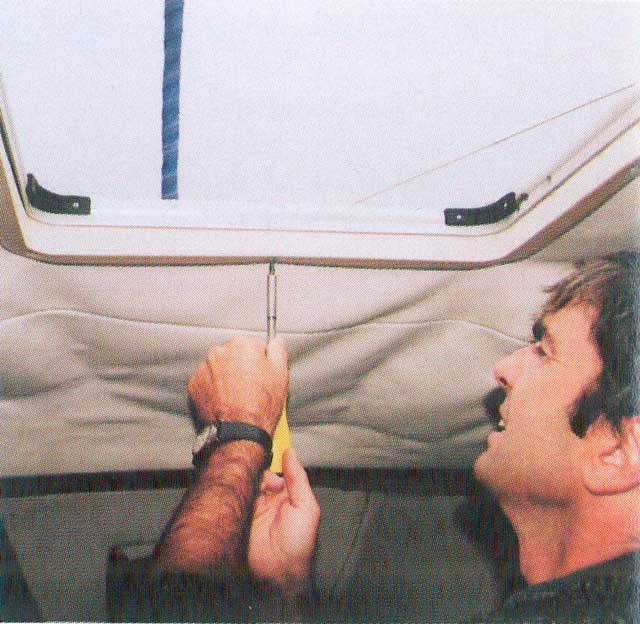

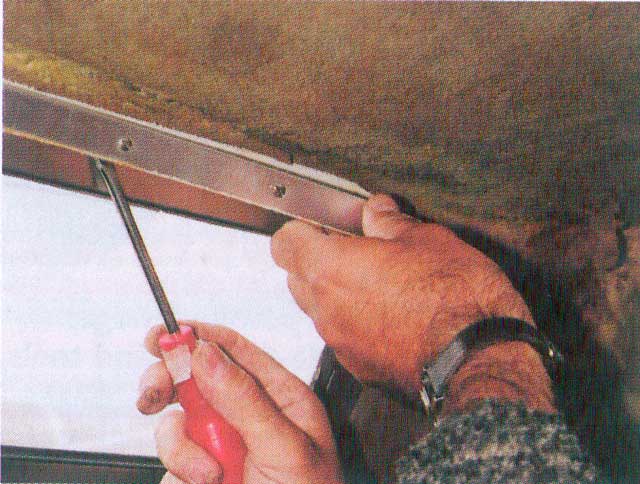

1: All the wooden trims and beadings are unscrewed. These won’t be used again, because the edges they normally hide will be made to look neater with stitching

2: The vinyl panels are peeled back carefully, while trying to keep them in one piece to use as a pattern

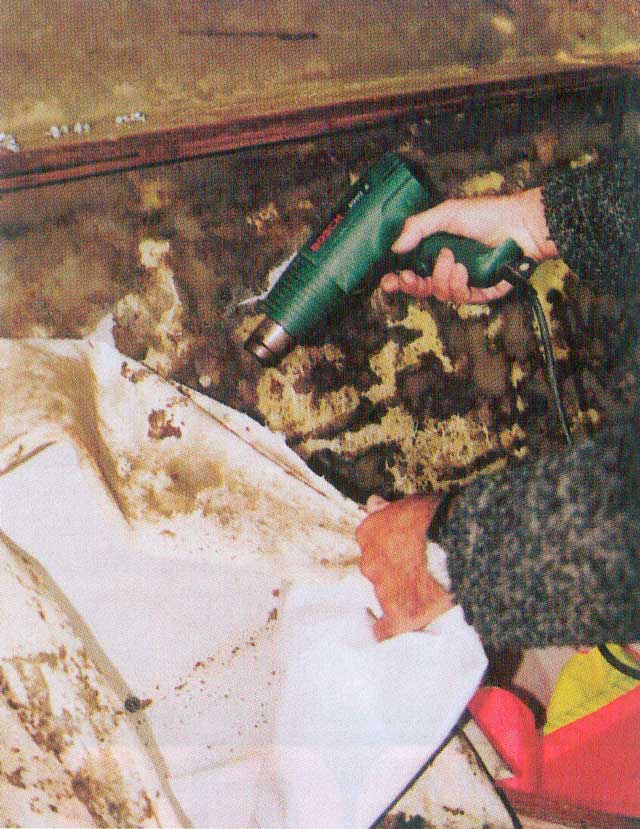

3: Any stubborn patches can be loosened with a hot-air gun

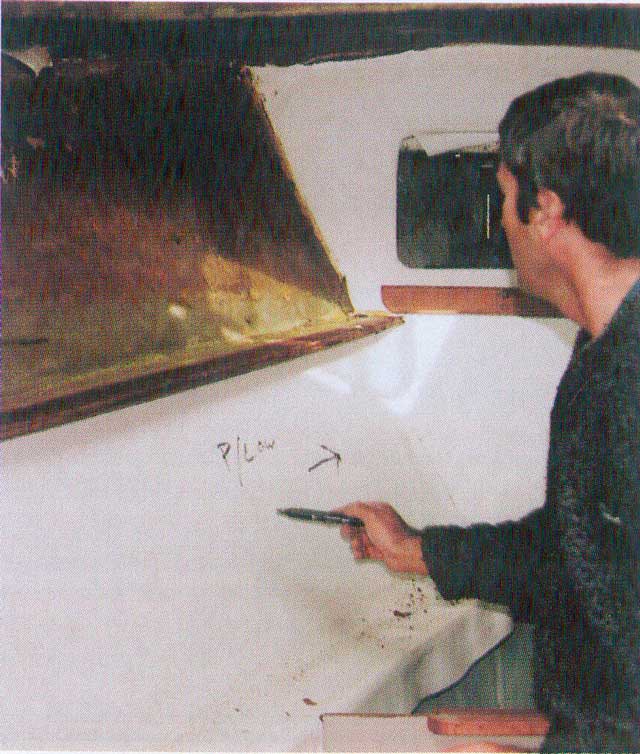

4: Before removing a panel, clearly mark its position and orientation – in this case, port lower, with the arrow pointing towards the bow

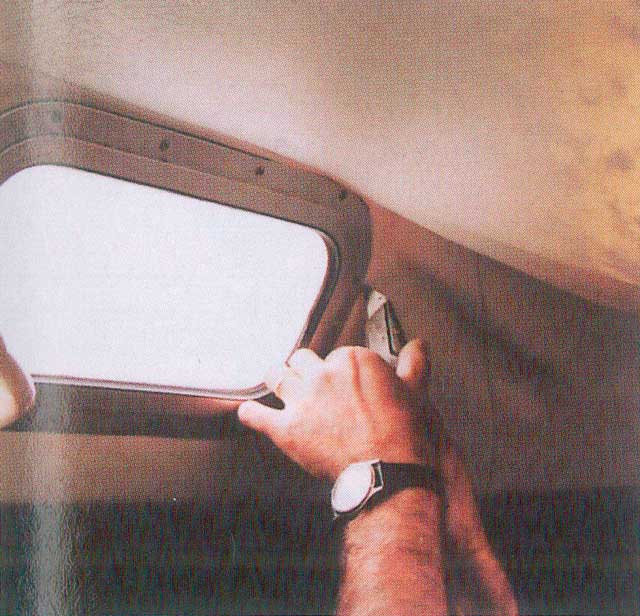

The hatch trim is unscrewed, and the side facing the bow marked with pencil so the screw holes can be relocated

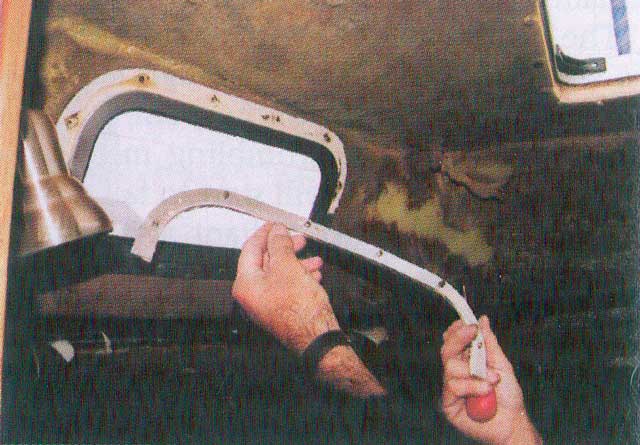

6: a blade is run around the edges of the window to free the vinyl. The window surrounds will be removed later

7: With the amount of degradation to the foam, the headlining piece comes down easily – and usefully intact

8: The upholsterer will use the old headlining as a template for sewing the panels that will make the new one

9: The window backs are held in place by flush-fitting bolts, which need to be removed from both the outside…

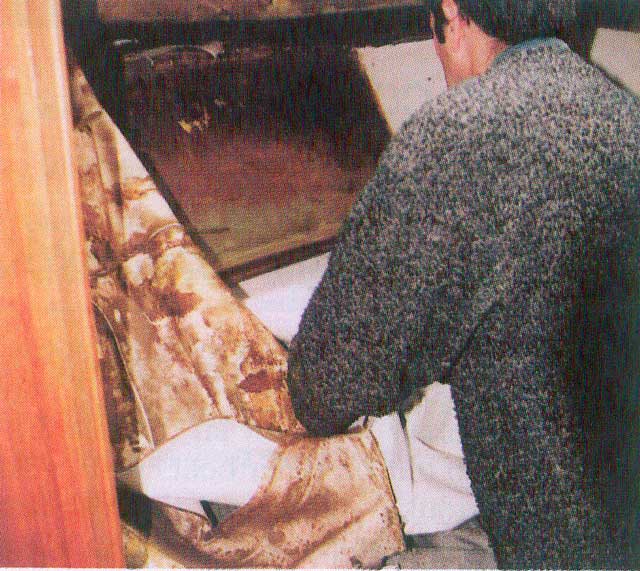

10: …and the inside. This will require two people in the more inaccessible areas. Those shown here present no problem for the solo worker

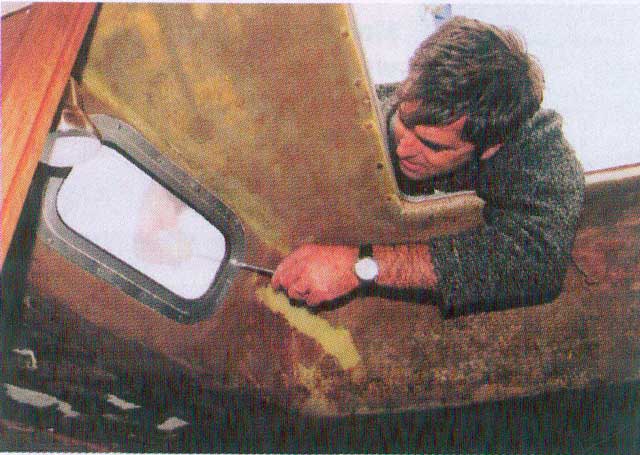

11: If the window frame is a bit stubborn, it can be prized off with a screwdriver, but be careful not to kink the metal.

12: With the inner frame removed, the vinyl beneath it can be stripped away. Remember to mark the frame in pencil to aid reassembly

13: With all the vinyl panels marked up and removed, now comes the messy bit. Use the wire brush and hot-air gun to clean off all the old glue and foam. Previous attempts at re-sticking may have resulted in hard patches of glue, which have absorbed some of the crumbling foam. The smoother you can make the inside of the hull, the neater the finish will be. Sweep up with the vacuum cleaner, and make sure you wear a dust mask.

- 1. Introduction

- 2. Relining the cabin

- 3. Tools of the trade

- Forum Listing

- Marketplace

- Advanced Search

- About The Boat

- Gear & Maintenance

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Beneteau hull liner replacement.

- Add to quote

Very nice! Have you had any moisture issues with that? It appears almost carpet like.

It is a lot like carpet but very lightweight and breathable. No moisture issues. Breathes much better than Vinyl.

Need to clarify this. That was just for the Layup of the new material. Took another 10 hours or so to strip the old stuff and remove the foam residue from the hull.

It looks good. We need to replace our vinyl head liner. It is stained and drooping in a lot of places, and hides access to the through-deck fittings. Do you remember how many yards you bought?

Not off the top of my head. I have done 3 of the jobs though. best way to do it is measure your areas and then add 10%.

I've never used that adhesive. Is it like contact cement ... don't get it right first time and you're screwed or can you slide it around a bit after contact ?

That is basically what I did but just measured in place with a regular measuring tape and a tailors measuring tape. Came out pretty well spot on though I factored 20% overage for my first one. You will use twice as much glue as you think.

Headlining Replacement That is how I did the liners in my Jeanneau with the same issue. THere is a link to the head area too. Took me a bit longer. but I replaced a lot of the flat area's with vinyl cover plywood. That took a bit of shaping and cutting. Marty

Christian, The plywood part works, "IF" and "where" you have a filler in the deck, ie balsa, foam etc. Otherwise the fiberglass is too thin to put screws in. I just used as I think the article stated some door panel plywood I got at home depot. Marty

blt2ski said: Christian, The plywood part works, "IF" and "where" you have a filler in the deck, ie balsa, foam etc. Otherwise the fiberglass is too thin to put screws in. I just used as I think the article stated some door panel plywood I got at home depot. Marty Click to expand...

thanks have you tried simple velcro before?...my decks are ply cored

You can use Kydex instead of plywood, Kydex is heat moldable plastic, with a heatgun you can form the plastic and then cover it with padding and vinyl, industrial grad velcro will hold it in place.

Christian, that was my thought, too. I considered industrial strength Velcro, but I think even the regular stuff would probably hold OK since it's not holding much weight.

The new jeanneau's are using velcro. Mine used screws. so I kept the status quo per say...... it would be worth a try. Marty

awesome guys... have been away from the boat too long...sorry for the mild hijack...awesome info and help guys keep it up christian

we took off all the ply battens on the roof....as I wanted to go smooth white paint and fully accesible hardware and backing plates...also since the boat is new to me I wanted to be able to check for leaks, modify or seal up holes and hardware not needed anymore easily etc... for the deck undersides however Im thinking either straight velcro to the underside and some simple ply and vynil covers will be fine I bought some mahogany or cherry trim for all the lines or bends that hopefully will make things look nicer another personal issue on my boat is that I have added tie rods to the hull for the aft lowers, from deck backing plate to a place on the hull sides...and I cant have anything permanent over this, maybe 1 ply panel with a hole in the middle to cover the backing plate and then panels forward and aft of said panel Im thinking velcro and panels are the way to go here since at least its flat... thanks guys

boatpoker- CALL 3M. There's a phone number on each can. Their different spray cements are each targeted to specific materials, so you need one that is good in heat (overheads get hot), permanent, and will work on the materials you have. Some work well on plywood, others won't. Some work on "impossible" plastics like polythene, others don't. It pays to call them and ask, with all the specifics at hand. 3M are great at tech support, they'll get you to an actual product engineer, not just a salesbabe, for any product, any division, any use, anywhere in the world.

I have to admit, did not think of a filler batten. Used that option for stapling the vinyl on. I usd a cedar batten about 1/4"x2" available at thelocal lumber yard. Marty

By any chance did you keep the pattern, or know where I can get one. I had someone start and he went out of business 1/3 of the way (without giving me the pattern or all the old materials back). Thanks

I have a First 375 with the same issue - my aft cabin layout is similar to your F305. How did you do the outside corners under the cockpit sole? Did you overlap the material?

- ?

- 174K members

Top Contributors this Month

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Hunter 356 Headliner Removal

- Thread starter Musetta

- Start date Sep 6, 2018

- Forums for All Owners

- Ask All Sailors

Has anyone successfully removed and reinstalled the vinyl headliner on a 2003 or 2004 Hunter 356? I need to replace the VHF cable that is above the headliner and would like to accomplish this without damaging the headliner. I have looked at the various threads on the Forum that explain a method using a putty knife to pry the vinyl loose from a groove, but the headliner on my boat does not have same configuration at the edges as is shown in the most detailed thread.

Dave Groshong

We offer a service to guide you through the process: https://shop.hunterowners.com/1to1.php

SEMPERAVANTI41

I suggest that you post some detailed pictures of your headliner. I didn't believe the putty knife instructions on mine when I first tried to remove the headliner, but after some guidance from Uncledom it worked.

Thanks -- that's a good idea. I will post photos this weekend.

I'm still finding little beige buttons and I sold the boat years ago.

shemandr, don't throw out those buttons. Can always use extras.

do post some pictures - I've never seen a 356 with a different headliner... If you use a putty knife be very careful - the sharp corners can cut the headliner. I use an automotive headliner tool, looks like a putty knife but the corners are rounded.

I modified a s/s putty knife by filing the sharp edges round. I also use a automotive interior tool kit like this on from Harbor Freight, Trim And Molding Tool Set 5 Pc. Once I open up the moulding, I grab and pull out the vinyl with a Mini Pick and Hook Set also from HF.

Aha. Thank you. It sounds like there are two steps -- opening up the moulding and then pulling the vinyl out. Is the putty knife with rounded edges used only for opening the moulding? In the earlier thread on this, it appeared the knife was used to open a c-shaped channel to release the vinyl. For opening the moulding, do you insert the knife along the outboard or inboard edge of the moulding?

insert the knife towards the outer edge to spread the channel, then pull the headliner carefully out. use the knife to push the headliner back in when you're done

chuckwayne said: insert the knife towards the outer edge to spread the channel, then pull the headliner carefully out. use the knife to push the headliner back in when you're done Click to expand

This is what I am looking at -- headliner on the left. Do those instructions still apply?

Attachments

the instructions in the original thread say to start at a corner. I cannot find a way to get knife under the edge of the headliner in these corners, where the channel holding the headliner is either not there or not visible.

yes - I sometimes use a small pair of needlenose pliers to start the headliner out

justsomeguy

How about tbe bent end of a small flatbar?

When the mast was down, took advantage to run new antenna and cable. Used RG8X which is about 1/4" instead of the original antenna wire from the factory which was about 2 times the thickness. In my boat there was a separate wire chase which was used to run the wires for the wind instrument and the masthead anchor/masthead light. The original large antenna wire was not run in this chase. There was no messenger line in the chase so the plan was to pull out the wires pulling a messenger to then pull back the same wires plus the new antenna wire. At first the wires would not budge but a generous heavy application of silicone spray shot in the chase managed to get things moving easily. This of course means running a new wire up the mast which is probably not a bad idea; replace the antenna also. By the way just abandon the original cable, cut off the ends. Run the new cable as a home run from the antenna to the radio unless your mast comes down yearly. This will most likely be easier, faster and cheaper than removing the overhead liner and also the side ABS plastic side liner behind the window frames. Not to mention that you will most likely damage the Whisperwall vinyl and have to replace it all to match. Also note here are the overhead grab rails to deal with. This vinyl is now 14 years old and delicate. As an example I put some blue masking tape on the vinyl and when it was removed it took some of the vinyl with it. Good luck.

Forgot to mention interior lights to remove also. The junction teak cover plate just drops down after you remove the screws.

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

- Popular Professionals

- Design & Planning

- Construction & Renovation

- Finishes & Fixtures

- Landscaping & Outdoor

- Systems & Appliances

- Interior Designers & Decorators

- Architects & Building Designers

- Design-Build Firms

- Kitchen & Bathroom Designers

- General Contractors

- Kitchen & Bathroom Remodelers

- Home Builders

- Roofing & Gutters

- Cabinets & Cabinetry

- Tile & Stone

- Hardwood Flooring Dealers

- Landscape Contractors

- Landscape Architects & Landscape Designers

- Home Stagers

- Swimming Pool Builders

- Lighting Designers and Suppliers

- 3D Rendering

- Sustainable Design

- Basement Design

- Architectural Design

- Universal Design

- Energy-Efficient Homes

- Multigenerational Homes

- House Plans

- Home Remodeling

- Home Additions

- Green Building

- Garage Building

- New Home Construction

- Basement Remodeling

- Stair & Railing Contractors

- Cabinetry & Cabinet Makers

- Roofing & Gutter Contractors

- Window Contractors

- Exterior & Siding Contractors

- Carpet Contractors

- Carpet Installation

- Flooring Contractors

- Wood Floor Refinishing

- Tile Installation

- Custom Countertops

- Quartz Countertops

- Cabinet Refinishing

- Custom Bathroom Vanities

- Finish Carpentry

- Cabinet Repair

- Custom Windows

- Window Treatment Services

- Window Repair

- Fireplace Contractors

- Paint & Wall Covering Dealers

- Door Contractors

- Glass & Shower Door Contractors

- Landscape Construction

- Land Clearing

- Garden & Landscape Supplies

- Deck & Patio Builders

- Deck Repair

- Patio Design

- Stone, Pavers, & Concrete

- Paver Installation

- Driveway & Paving Contractors

- Driveway Repair

- Asphalt Paving

- Garage Door Repair

- Fence Contractors

- Fence Installation

- Gate Repair

- Pergola Construction

- Spa & Pool Maintenance

- Swimming Pool Contractors

- Hot Tub Installation

- HVAC Contractors

- Electricians

- Appliance Services

- Solar Energy Contractors

- Outdoor Lighting Installation

- Landscape Lighting Installation

- Outdoor Lighting & Audio/Visual Specialists

- Home Theater & Home Automation Services

- Handyman Services

- Closet Designers

- Professional Organizers

- Furniture & Accessories Retailers

- Furniture Repair & Upholstery Services

- Specialty Contractors

- Color Consulting

- Wine Cellar Designers & Builders

- Home Inspection

- Custom Artists

- Columbus, OH Painters

- New York City, NY Landscapers

- San Diego, CA Bathroom Remodelers

- Minneapolis, MN Architects

- Portland, OR Tile Installers

- Kansas City, MO Flooring Contractors

- Denver, CO Countertop Installers

- San Francisco, CA New Home Builders

- Rugs & Decor

- Home Improvement

- Kitchen & Tabletop

- Bathroom Vanities

- Bathroom Vanity Lighting

- Bathroom Mirrors

- Bathroom Fixtures

- Nightstands & Bedside Tables

- Kitchen & Dining

- Bar Stools & Counter Stools

- Dining Chairs

- Dining Tables

- Buffets and Sideboards

- Kitchen Fixtures

- Wall Mirrors

- Living Room

- Armchairs & Accent Chairs

- Coffee & Accent Tables

- Sofas & Sectionals

- Media Storage

- Patio & Outdoor Furniture

- Outdoor Lighting

- Ceiling Lighting

- Chandeliers

- Pendant Lighting

- Wall Sconces

- Desks & Hutches

- Office Chairs

- View All Products

- Designer Picks

- Side & End Tables

- Console Tables

- Living Room Sets

- Chaise Lounges

- Ottomans & Poufs

- Bedroom Furniture

- Nightstands

- Bedroom Sets

- Dining Room Sets

- Sideboards & Buffets

- File Cabinets

- Room Dividers

- Furniture Sale

- Trending in Furniture

- View All Furniture

- Bath Vanities

- Single Vanities

- Double Vanities

- Small Vanities

- Transitional Vanities

- Modern Vanities

- Houzz Curated Vanities

- Best Selling Vanities

- Bathroom Vanity Mirrors

- Medicine Cabinets

- Bathroom Faucets

- Bathroom Sinks

- Shower Doors

- Showerheads & Body Sprays

- Bathroom Accessories

- Bathroom Storage

- Trending in Bath

- View All Bath

- Houzz x Jennifer Kizzee

- Houzz x Motivo Home

- How to Choose a Bathroom Vanity

- Patio Furniture

- Outdoor Dining Furniture

- Outdoor Lounge Furniture

- Outdoor Chairs

- Adirondack Chairs

- Outdoor Bar Furniture

- Outdoor Benches

- Wall Lights & Sconces

- Outdoor Flush-Mounts

- Landscape Lighting

- Outdoor Flood & Spot Lights

- Outdoor Decor

- Outdoor Rugs

- Outdoor Cushions & Pillows

- Patio Umbrellas

- Lawn & Garden

- Garden Statues & Yard Art

- Planters & Pots

- Outdoor Sale

- Trending in Outdoor

- View All Outdoor

- 8 x 10 Rugs

- 9 x 12 Rugs

- Hall & Stair Runners

- Home Decor & Accents

- Pillows & Throws

- Decorative Storage

- Faux Florals

- Wall Panels

- Window Treatments

- Curtain Rods

- Blackout Curtains

- Blinds & Shades

- Rugs & Decor Sale

- Trending in Rugs & Decor

- View All Rugs & Decor

- Pendant Lights

- Flush-Mounts

- Ceiling Fans

- Track Lighting

- Wall Lighting

- Swing Arm Wall Lights

- Display Lighting

- Table Lamps

- Floor Lamps

- Lamp Shades

- Lighting Sale

- Trending in Lighting

- View All Lighting

- Bathroom Remodel

- Kitchen Remodel

- Kitchen Faucets

- Kitchen Sinks

- Major Kitchen Appliances

- Cabinet Hardware

- Backsplash Tile

- Mosaic Tile

- Wall & Floor Tile

- Accent, Trim & Border Tile

- Whole House Remodel

- Heating & Cooling

- Building Materials

- Front Doors

- Interior Doors

- Home Improvement Sale

- Trending in Home Improvement

- View All Home Improvement

- Cups & Glassware

- Kitchen & Table Linens

- Kitchen Storage and Org

- Kitchen Islands & Carts

- Food Containers & Canisters

- Pantry & Cabinet Organizers

- Kitchen Appliances

- Gas & Electric Ranges

- Range Hoods & Vents

- Beer & Wine Refrigerators

- Small Kitchen Appliances

- Cookware & Bakeware

- Tools & Gadgets

- Kitchen & Tabletop Sale

- Trending in Kitchen & Tabletop

- View All Kitchen & Tabletop

- Storage & Organization

- Baby & Kids

- View all photos

- Dining Room

- Breakfast Nook

- Family Room

- Bed & Bath

- Powder Room

- Storage & Closet

- Outdoor Kitchen

- Bar & Wine

- Wine Cellar

- Home Office

- Popular Design Ideas

- Kitchen Backsplash

- Deck Railing

- Privacy Fence

- Small Closet

- Stories and Guides

- Popular Stories

- Renovation Cost Guides

- Fence Installation Cost Guide

- Window Installation Cost Guide

- Discussions

- Design Dilemmas

- Before & After

- Houzz Research

- View all pros

- View all services

- View all products

- View all sales

- Living Room Chairs

- Dining Room Furniture

- Coffee Tables

- Home Office Furniture

- Join as a Pro

- Interior Design Software

- Project Management

- Custom Website

- Lead Generation

- Invoicing & Billing

- Landscape Contractor Software

- General Contractor Software

- Remodeler Software

- Builder Software

- Roofer Software

- Architect Software

- Takeoff Software

- Lumber & Framing Takeoffs

- Steel Takeoffs

- Concrete Takeoffs

- Drywall Takeoffs

- Insulation Takeoffs

- Stories & Guides

- LATEST FROM HOUZZ

- HOUZZ DISCUSSIONS

- SHOP KITCHEN & DINING

- Kitchen & Dining Furniture

- Sinks & Faucets

- Kitchen Cabinets & Storage

- Knobs & Pulls

- Kitchen Knives

- KITCHEN PHOTOS

- FIND KITCHEN PROS

- Bath Accessories

- Bath Linens

- BATH PHOTOS

- FIND BATH PROS

- SHOP BEDROOM

- Beds & Headboards

- Bedroom Decor

- Closet Storage

- Bedroom Vanities

- BEDROOM PHOTOS

- Kids' Room

- FIND DESIGN PROS

- SHOP LIVING

- Fireplaces & Accessories

- LIVING PHOTOS

- SHOP OUTDOOR

- Pool & Spa

- Backyard Play

- OUTDOOR PHOTOS

- FIND LANDSCAPING PROS

- SHOP LIGHTING

- Bathroom & Vanity

- Flush Mounts

- Kitchen & Cabinet

- Outdoor Wall Lights

- Outdoor Hanging Lights

- Kids' Lighting

- Decorative Accents

- Artificial Flowers & Plants

- Decorative Objects

- Screens & Room Dividers

- Wall Shelves

- About Houzz

- Houzz Credit Cards

- Privacy & Notice

- Cookie Policy

- Your Privacy Choices

- Mobile Apps

- Copyright & Trademark

- For Professionals

- Houzz vs. Houzz Pro

- Houzz Pro vs. Ivy

- Houzz Pro Advertising Reviews

- Houzz Pro 3D Floor Planner Reviews

- Trade Program

- Buttons & Badges

- Your Orders

- Shipping & Delivery

- Return Policy

- Houzz Canada

- Review Professionals

- Suggested Professionals

- Accessibility

- Houzz Support

- COUNTRY COUNTRY

A/C Repair & HVAC Contractors in Elektrostal'

Location (1).

- Use My Current Location

Popular Locations

- Albuquerque

- Cedar Rapids

- Grand Rapids

- Indianapolis

- Jacksonville

- Kansas City

- Little Rock

- Los Angeles

- Minneapolis

- New Orleans

- Oklahoma City

- Orange County

- Philadelphia

- Portland Maine

- Salt Lake City

- San Francisco

- San Luis Obispo

- Santa Barbara

- Washington D.C.

- Elektrostal', Moscow Oblast, Russia

Professional Category (1)

- Accessory Dwelling Units (ADU)

Featured Reviews for A/C Repair & HVAC Contractors in Elektrostal'

When should you hire local hvac companies, ask hvac contractors about these residential heating and cooling technologies:, business services, connect with us.

IMAGES

VIDEO

COMMENTS

DetailsReplacing the headliner in your boat, RV, automobile or other vehicle is a great way to update the look and feel of your boat or automotive interior. This simple fabric refresh can help to modernize and update your boat cabin. There's not a lot of natural light in a boat cabin or RV interior. Removing and replacing dingy, worn-out headliner can also greatly increase the brightness and ...

Jan 25, 2007. 287. Cal Cal 33-2 cape cod. Nov 10, 2020. #8. Best things about project, 1) Access to stuff underneath (check bolts, through deck stuff) 2) Easy to upgrade lights 3) Change color/upgrade look. The project took a couple of days, you'll need good templates, jig-saw, and patience. Very doable.

http://www.sailrite.com/Installing-Removable-Cabin-Headliner-in-a-Boat-VideoInstalling Removable Cabin Headliner in a Boat Video is a great how-to video on r...

In this vlog we finally get the new headliner in the salon area of our sailboat. We used a tongue and groove style vinyl beadboard found at Home Depot. It's ...

The primary goal when installing new headliner is to first insulate between each plywood furing strip and then cover the insulation with vinyl for a beautiful cabin interior. We're using Nauga Soft vinyl fabric to wrap our panels. Nauga Soft is a great choice for boat cabins. It offers great durability with the look and feel of real leather.

Back in the 1970s and 1980s, many sailboats were finished with foam-backed vinyl headliners glued directly to the underside of the deck and coachroof molding. If you own such a boat, you're likely to be well acquainted with the problem of the headliner coming adrift as the glue and foam interface breaks down.

In the video below we explore the process of replacing the worn-out and inefficient vinyl headliner in our sailboat's v-berth. The existing headliner lacked insulation, leaving the V-berth vulnerable to temperature extremes. By removing the old one, adding insulation using closed-cell neoprene sheets, and installing a high-quality EverSoft ...

Step 1: Remove headliner panels from the boat. Some times they are fastened in place with wood trim, other times with snaps, and more recently with velcro. Step 2: Remove old vinyl from the form - ours was plywood. Wear heavy gloves to protect your hands from the glues as well as piercing by corroded staples and tacks.

This aft cabin has was stripped of its headliner / hull liner because it was out of date, too dark, stained and no longer sticking well. All that's left now ...

Installing the New Headliner. With your new headliner material cut to size, you're ready to begin the installation process. Follow these steps for a successful installation: Apply Adhesive: Following the manufacturer's instructions, apply adhesive to the back of your headliner material using a paint roller or brush.

4% back on purchases from West Marine stores or online at WestMarine.com. Discounts on fuel, transient slips, repairs and more at over 1,200 businesses. Deals on cruises, charters, car rentals, hotel stays and more…. All for only $25/year! Age and abuse can discolor or rip liners in your boat. Here's a trick to cover up any eyesores.

3: Any stubborn patches can be loosened with a hot-air gun. 4: Before removing a panel, clearly mark its position and orientation - in this case, port lower, with the arrow pointing towards the bow. The hatch trim is unscrewed, and the side facing the bow marked with pencil so the screw holes can be relocated.

http://search.sailrite.com/?freeText=headliner How to install carpet style headliner or hull liner in your boat. This video will show you the steps needed to...

Beneteau hull liner replacement. I forgot to post on this headliner replacement. Was on a Beneteau first 305. I did it a few years back but just now getting to adding it here. The 80's Bene's used a foam backed vinyl for the liner and in short order the foam would separate from the vinyl and start sagging.

Before work begins on a new or replacement driveway, your professional should create plans based on your needs and material choices, as well as your property grade, soil and other Moscow Oblast landscape factors. When it comes to the actual driveway construction, driveway contractors are responsible for preparing the site, obtaining the ...

Search 151 Elektrostal' custom fireplace contractors & installers to find the best fireplace contractor for your project. See the top reviewed local fireplace services and installers in Elektrostal', Moscow Oblast, Russia on Houzz.

How to install a foam backed vinyl headliner in a boat will give you all the steps needed to remove an old headliner and prepare the surface for new foam bac...

Door dealers are responsible for a variety of services, including door installation, door replacement, door repair and custom door design. If you need a new door, Elektrostal', Moscow Oblast, Russia door dealers will help you determine what kind you need, as well as shape, color, size and more. From barn doors to French doors to front doors ...

Mar 20, 2004. 1,729. Hunter 356 and 216 Portland, ME. Sep 7, 2018. #10. insert the knife towards the outer edge to spread the channel, then pull the headliner carefully out. use the knife to push the headliner back in when you're done.

Generally, Elektrostal' HVAC contractors or HVAC installers work with or run companies that repair or install heating systems and a/c services for homes. Local air conditioning companies can help with a wide variety of air conditioning services, including both a/c installation and a/c repair. Air conditioning contractors, also known as a/c ...