How to Build a Catamaran Boat? (Step-by-Step Guide)

Building a catamaran boat from scratch is a rewarding and challenging endeavor.

It takes a combination of skill, dedication, and hard work to craft a seaworthy vessel.

In this step-by-step guide, you’ll learn how to design and size your catamaran, gather the necessary materials, cut and assemble the pieces, lay fiberglass and apply epoxy, make finishing touches, add hardware and paint, and rig the boat.

With the right tools, planning, and patience, you can make your dream of sailing in a catamaran a reality.

Table of Contents

Short Answer

Building a catamaran boat requires a lot of patience and skill.

The first step is to choose the right materials for the hull, such as fiberglass, wood or aluminum.

Then, you will need to build the frame of the boat, which includes the crossbeams and the main hull.

After that, you will need to install the decking, the rigging, and other components.

Finally, you will need to paint and varnish the boat, as well as install the outboard motor and other accessories.

Design & Size Considerations

When it comes to building a catamaran boat from scratch, the first step is to determine the design and size of the boat.

This should take into account the intended use of the boat, such as sailing, fishing, or leisurely cruising.

The size of the boat will depend on the number of passengers and the type of activities the boat will be used for.

For instance, a larger boat may be needed if passengers will be standing or participating in watersports.

The design of the boat is also important and should be chosen based on the intended use.

If you are looking to build a sailboat, you will need a design that is optimized for sailing.

On the other hand, if you are looking to build a fishing boat, you will need a design that is optimized for fishing.

There are a wide variety of boat designs available, so it is important to research and choose the one that best suits your needs.

In addition to the design and size, you will also need to consider the materials used for construction.

The most common materials for building a catamaran boat are wood, fiberglass, and epoxy.

Each material has its own advantages and disadvantages, so it is important to research them and determine which one is best for your project.

Finally, you will need to consider the cost of the project.

Building a catamaran boat from scratch can be a costly endeavor, so it is important to have a budget in mind before you begin.

The cost will depend on the type of materials used and the complexity of the design.

It is also important to factor in the cost of any tools that may be needed for the project.

By taking into account the design and size, materials, and cost of the project, you can be sure to build a catamaran boat that meets your needs and budget.

With the right amount of patience and attention to detail, you can build your own catamaran boat in no time.

Gathering Materials

Gathering the materials needed to build a catamaran boat from scratch can be a daunting task, but it is essential for creating a sturdy and safe vessel.

Before starting the building process, it is important to have an accurate and detailed plan for the boats design and size.

Once a plan is in place, it is time to begin sourcing the necessary materials.

The most common materials used to construct a catamaran boat are wood, fiberglass, and epoxy.

When choosing wood, it is best to select a species of timber that is strong and durable, such as mahogany, teak, or cedar.

Additionally, the wood should be clear and free of knots, splits, and other defects.

Fiberglass is a lightweight fabric that is resistant to water and provides additional strength to the boats hull.

Epoxy is a waterproof adhesive that is used to seal the boat and ensure that it is watertight.

It is important to ensure that the materials are of high quality, as this will help to ensure the boats longevity.

Additionally, it is important to purchase the necessary materials in the correct amount and size.

Too little or too much of a material can be a costly and time-consuming mistake.

Finally, it is important to keep any leftover materials for future repairs or modifications.

With the right materials gathered, the next step is to cut the wood and begin the assembly process.

Cutting & Assembly

Cutting and assembly are the most important steps when it comes to building a catamaran boat from scratch.

The first step is to decide the design and size of the boat.

This will determine the type of materials you need to gather and the amount of effort that needs to be put into the project.

After deciding on the design and size, you will need to cut the wood to fit the design.

This includes cutting the wood to the desired size, as well as cutting any additional pieces that may be needed to complete the design.

It is important to ensure that all the pieces fit together correctly and securely, as any mistakes could lead to a weak boat.

Once the wood has been cut, it is time to assemble the pieces together.

This involves attaching the pieces together with glue, screws, and nails, and ensuring that the pieces fit together securely.

It is important to be careful and patient when assembling the pieces, as any mistakes could result in a weak and unstable boat.

Once the frame is ready, it is time to lay the fiberglass, and apply the epoxy to seal the boat.

This is an important step, as it will make sure that the boat is waterproof and durable.

Finally, you can add the finishing touches, such as the hardware, paint, and rigging.

With the right amount of patience and attention to detail, you can have your own custom catamaran boat in no time.

Laying Fiberglass & Applying Epoxy

When laying the fiberglass and applying epoxy, it is important to take your time and be precise.

Fiberglass and epoxy are key components of a catamaran boat, as they provide the strength and waterproofing necessary to keep the boat afloat.

Start by laying the fiberglass over the frame of the boat.

Make sure to cut the fiberglass to size and overlap the edges for a strong seal.

Once the fiberglass is in place, mix the epoxy and begin to apply it.

It is important to apply the epoxy in a thin, even layer to ensure a proper seal.

Make sure to move the epoxy around to get it into all the nooks and crannies of the boat.

Allow the epoxy to cure and then you can begin to add the finishing touches.

Finishing Touches

Once the frame of the catamaran boat is built, it is time to add the finishing touches.

This includes adding the necessary hardware, painting, and rigging the boat.

Hardware: Before adding the hardware, it is important to ensure that the frame is stable and secure.

Add the appropriate hinges, screws, and nails to the frame.

Make sure that the screws and nails are the correct size and do not exceed the recommended load capacity of the frame.

Painting: Once the hardware is added, it is time to paint the boat.

Choose a paint that is suitable for the materials used in the construction.

Make sure that the paint is applied evenly and that the frame is completely dry before applying the next coat.

Rigging: The last step is to rig the boat.

This involves attaching the sails, running rigging, and standing rigging to the masts and booms.

Make sure that the rigging is properly tensioned and secured.

Once all of these steps are complete, your catamaran boat is ready to sail.

Hardware & Paint

The last step in building a catamaran boat is to add the hardware and paint.

This step is often the most rewarding, as it is the finishing touch.

Depending on the design of your boat, there are various types of hardware you may need.

Some of the most common items are cleats, winches, fasteners, and decking.

After selecting the required hardware, you will need to install them on the boat.

It is important to use the correct type of screws and bolts, and to secure them tightly.

Once the hardware is installed, it is time to apply the paint.

The type of paint and color you choose will depend on the design of your boat.

It is important to use a high-quality marine grade paint that is designed to handle the extreme environment of the ocean.

If you are up to the challenge, you can add some custom artwork or detail to your catamaran boat.

Adding the hardware and paint is the final step in building a catamaran boat.

With patience and attention to detail, you can create a beautiful and unique boat that will last for many years.

Be sure to take your time and enjoy the process of constructing your own boat.

Once you have finished the frame, fiberglass, and epoxy of your catamaran boat, you will need to move onto the rigging.

This is a crucial step in the construction process, as it will keep your boat safe and secure on the water.

When rigging a catamaran, there are a few key components that must be taken into account.

First, you will need to determine the type of rigging you will be using.

Typically, catamarans use a combination of standing and running rigging.

Standing rigging consists of cables and lines that stay in a fixed position to provide stability and strength to the boat, while running rigging consists of lines that are used to adjust the sail and mainsheet.

Additionally, you will need to choose the right type of rope and hardware for your rigging setup.

The rope should be strong and durable, and the hardware should be made of stainless steel and be corrosion-resistant.

Once you have chosen the type of rigging and hardware, you can start assembling the rigging lines.

This process involves carefully measuring and cutting the lines to the proper lengths, and then attaching them to the mast and boom.

Depending on the type of rigging setup, you may also need to attach the lines to the hulls and deck.

It is important to inspect the rigging lines and hardware regularly to ensure that everything is secure and in proper working order.

Rigging a catamaran boat can seem like a daunting task, but it is essential for the safety and comfort of your vessel.

With the right tools, materials, and attention to detail, you can successfully and safely rig your catamaran boat.

Final Thoughts

Building a catamaran boat is a rewarding experience that requires patience and attention to detail.

With the right plan, materials, and steps, you can build your own boat in no time.

Now that you know the basics of how to build a catamaran boat, why not grab your tools and get started on your very own project? With the right motivation and dedication, you can make your dream of owning a catamaran boat a reality.

James Frami

At the age of 15, he and four other friends from his neighborhood constructed their first boat. He has been sailing for almost 30 years and has a wealth of knowledge that he wants to share with others.

Recent Posts

When Was Banana Boat Song Released? (HISTORICAL INSIGHTS)

The "Banana Boat Song" was released in 1956 by Harry Belafonte. This calypso-style song, also known as "Day-O," became a huge hit and remains popular to this day for its catchy tune and upbeat...

How to Make Banana Boat Smoothie King? (DELICIOUS RECIPE REVEALED)

To make a Banana Boat Smoothie King smoothie at home, start by gathering the ingredients: a ripe banana, peanut butter, chocolate protein powder, almond milk, and ice. Blend the banana, a scoop of...

- No products in the cart.

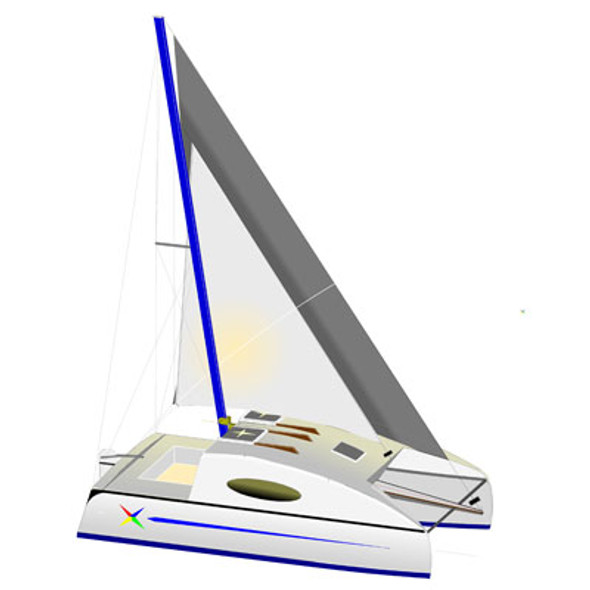

Catamarans and Trimarans

Catamaran and Trimaran Boat Plans make it a reality to build your own catamaran or trimaran. Multi-hulled sailing vessels are a special class of boat. A very different mind set is required when thinking about sailing a multi hull, let alone getting your head around building one.

There are some unique challenges building a multi-hull sail boat, the extra beam added by each hull for instance can create storage issues while under construction. Hartley boat plans make the build process straight forward for even amateur builders. However with all things considered, building a multi can be an amazing journey.

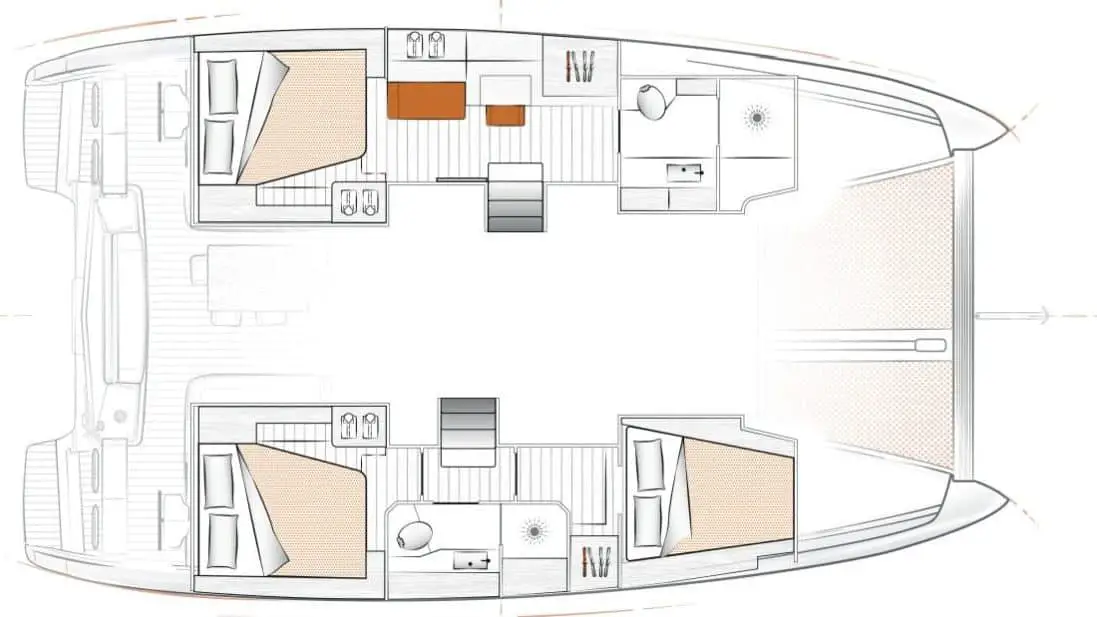

Fast Twin Catermaran

Lively 28 Cruising Trimaran

Lively 35 Cruising Trimaran

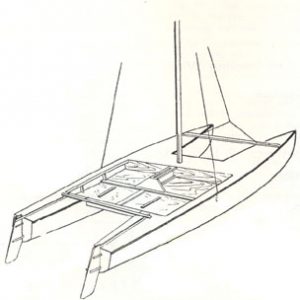

How To Create the Perfect Cruising Catamaran Layout

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

More than ever before, sailing fans are gaining an interest in catamaran layouts and designs that define performance. Many others are also looking into either buying a cruising catamaran or designing and building one. While building a catamaran is no piece of cake, this article shows you how to create the perfect cruising catamaran layout.

To create the perfect catamaran layout, carefully consider factors like a good hull design, optimal helm station placement, boat stability, and adequate load-carrying capacity. Excellent galley positioning, ease of handling, and spacious living and sleeping quarters are also crucial.

The modern cruising catamaran is a far cry from the simple Polynesian double canoe of old. That’s because structural innovations and new composite materials have resulted in multihulls with impressive cruising abilities. Keep reading to learn more about exceptional catamaran layouts.

The Changing Trends in Catamaran Designs

The early cruising catamaran designs resulted in boats that could sail much faster than traditional sailing boats. In addition, they could glide with ease in shallow waters and required less wind and crew. Unfortunately, these cruising cats were heavy, had small, cramped interiors, and boasted somewhat challenging handling abilities.

Today’s cruising catamarans are different. They boast the utmost comfort, high speeds, and the safety of a well-designed cruising yacht. They are also more exciting, visually appealing, deliver the smoothest of rides, and sport more spacious interiors.

Have a look at the below video showcasing the top ten cruising catamarans:

Features To Look Out for in Catamaran Design Layouts

Cruising catamaran designers understand what most sailors look for in a cruising vessel. They, therefore, design cruising multihulls that address these pertinent issues and more. Some of the features you might want to consider having in your dream boat include the following:

- Responsive performance. Outstanding performance allows for pleasurable cruising and ensures your safety since you have more options during difficult weather.

- Excellent load-carrying ability . This allows you to have an extended cruising vacation or ocean crossing.

- Boat stability . Go for lightweight, robust construction, which results in a lot of buoyancy.

- A low center of gravity for smooth rides and enhanced performance. Centering weight around a low center of gravity improves the overall sailing quality, reduces pitching movement and reduces the risk of capsizing .

- Adequate bridgedeck clearance to reduce slamming and provide better performance in rough conditions. A high bridgedeck also means less noise and slapping action from the waves hitting the boat bottom, thus ensuring a quieter, smoother ride.

- Comfortable sailing. To enjoy a quality life on board, you need comfort while at sea. Thus, elements like gentle movement, no creaks or groans, no bridgedeck slamming, and minimal pitching are essential for quality, peaceful and restful sleep.

Now that you know what a cutting-edge catamaran features, let’s look at how to create the perfect cruising catamaran layout.

Build a Larger-Sized Catamaran

The early catamarans ranged between 36-42 feet (10.9-12.8m). At the time, this appeared to be a good size in terms of safety and ease of handling. However, the boats were heavy, and the additional drag and displacement adversely affected their performance and windward ability.

It’s now possible to make the new generation catamarans lighter, larger, and more spacious with excellent power-to-weight features. The current trend is larger-sized catamarans in the 45-50 feet (13.7- 15.2) range. Composite engineering and technologically advanced equipment such as furling systems, electric winches, and autopilot make it easier for a smaller crew to sail larger boats with confidence. And to do so without compromising safety or stability.

Get the Best Catamaran Hull Design

A cruising catamaran’s performance depends on three main aspects; its length, the sail area, and the boat’s weight. Long boats are generally fast. A light boat with more sail area is also faster than a heavier boat with less sail area. In other words, you can make a multihull faster by making it longer, lighter, or adding more sail.

However, there are exceptions to this rule; a boat with too much sail area is more likely to capsize if there are brisk winds. Also, if the boat’s design makes it too light, it’ll be unable to handle much punishment, while a hull design that’s too slim would make the vessel incapable of carrying any significant loads. But that’s not all; if the boat is too long or too large, it’ll become grossly exorbitant. Narrow hull shape might also mean smaller cabins.

Nonetheless, these three factors alone are not enough to determine a cruising catamaran’s performance. While faster boats boast finer hulls, the wetted surface area tends to increase as fineness increases; thus, fine hulls end up becoming less fast in low wind speeds. Also, very wide hulls mean a reduction in actual performance.

The Prismatic Coefficient (Cp), a measure of how full the ends of the hull get, is the most essential design hull shape factor for any catamaran. A high Cp equals high speeds, although you can still use a lower Cp if you have fine hulls. Nevertheless, the key to a good Catamaran design is a higher Cp for fast sailing.

To achieve a high Cp, there are several things you can do:

- Fit bulb bows . Unfortunately, the bulb bows tend to slam in a seaway when you do this.

- Have an extensive planning aft section . However, this can increase the wetted surface area, WSA and lead to additional challenges.

- Flatten out the hull rocker and add a bustle aft. This helps to add displacement aft.

Build Convertible Main Living Spaces

The open cockpit is now a thing of the past. Instead, pioneering designers for catamaran manufacturers like Nautitech, Gunboat, and Catana now replace traditional-style salons, cockpits, and cabins with spacious indoor and outdoor living spaces. The concept involves merging separate saloon and cockpit areas with duplicate lounge spaces and the use of hard-wearing composite materials.

You can also design the cabin to suit your preferences. You may decide to add a cabin or remove one, add a bathroom, have the forward berth in the hull or on the wing deck.

- The design enhancements boost usable space while opening up the living areas.

- It reduces time and costs for interior maintenance and cleaning.

- Large windows bring in more light, increasing visibility.

- Luxurious, spacious, and airy owners’ cabins provide more comfortable living space.

Bulkhead Helm Stations vs. Twin Stern Steering

Many catamaran owners have traditionally preferred bulkhead steering. This helm position remains popular, but twin stern steering positions come with more advantages since they provide greater sails visibility. The twin stern positions are also best suited for racing or day sailing since they often lack adequate protection for extended cruising.

Exposed helms are not ideal for a long ocean passage. Go for a safe, secure, and well-protected helm station that provides good visibility and comfortable space for long watches. Again, it’s best to have all control lines at the helm to establish a static control station. Also, have all push-button-controlled winches, instruments, windlass, and autopilot prominently located inside the cockpit.

- Twin stern steering positions give you a better view of the sails

- You get a better feel for overall sailing conditions.

- Twin stern steering positions lack the necessary protection for extended cruising.

Go for the Flybridge Design

The flybridge design is appealing because it offers excellent visibility, more comfort, and additional entertainment and lounging space for everyone on board. Unfortunately for smaller boats – those below 50 feet (15.24m), there is minimal protection from the elements. As such, you might want to consider adding enclosures to offer protection. The flybridge, thus the helm, remains cut off from the vessel, which makes communicating with the crew a challenge.

- It provides great visibility.

- It offers comfortable spacing.

- It might be unsafe to move from the cockpit to the flybridge in bad weather.

- It isn’t easy to communicate with the crew.

Daggerboards vs. Fixed Keels

Average cruising catamarans typically utilize fixed keels while high-performance cats have daggerboards . Fixed keels allow you to beach your catamaran easily, and your hull remains intact if a collision occurs. While you lose some angle when sailing upwind, you gain more interior space in the hulls that you can put to good use.

Daggerboards are essential in a performance cruising catamaran since they guarantee that the boat delivers good upwind sailing, including during difficult situations. During long passages, they allow you to point better upwind though the drawback is that they consume much interior space within the cruising catamaran’s hulls.

Since flying on foils ( hydrofoils ) isn’t that practical on cruising catamarans, designers of larger-sized boats have also come up with modified daggerboards. These daggerboards produce lift and prevent leeway, too, thereby improving performance significantly, as seen with the Catana 59’s curved daggerboards. These foil-like daggerboards lift the boat ever so slightly upon reaching higher speeds, making it feel less heavy and much faster.

At the end of the day, calculating the performance of a boat sailing in a wide range of varying seas and winds might not be easy – despite a daggerboard or fixed keel configuration. This is because upwind speed depends not only on the sails’ quality but also windage and the height of the bridgedeck beyond the water.

- The design innovations -curved daggerboards and hydrofoils- improve catamaran performance significantly.

- Daggerboards enable you to access otherwise inaccessible anchorages.

- Daggerboards take up hull space in the hulls of your vessel.

Galley Up vs. Galley Down

Galley layout are becoming more and more important as more people, including families, start sailing regularly. While at sea, your galley needs to be a safe place, well-ventilated, and functional. Everything should be well-thought-out for the sailor’s comfort, including handholds to make it safer to move around the boat.

While the galley location can either be up the bridgedeck or down in the hull, galley up appears to be the most popular trend. This makes the galley the focal point of both the living space and entertainment areas.

If you have a family, this placement is ideal since you make your meals from the galley and get to spend most of your time here. Many cruising families and couples prefer this arrangement and find separating the galley down the hull unappealing. Besides, carrying hot food up and down the staircase is unsafe.

Still, galley down is ideal for charter boats since it offers a private cooking area and uses up hull space efficiently.

- Having the galley on the bridgedeck is ideal for families and cruising couples.

- Placing the galley on a similar level with the serving area and cockpit is safer and less tiring.

- There’s better ventilation on the bridgedeck, making for comfortable cooking.

- There’s less kitchen privacy galley up.

- On smaller catamarans, this layout can impact the size of the saloon seating area significantly.

Production Catamaran vs. Custom

The choice of either a production catamaran or a custom design might seem pretty straightforward. Production catamarans from major brands come backed by proven designs, dependable construction, solid warranties, and many years of experience. The catamarans are easy to service, source for parts, and most – particularly the owner’s versions – hold on to their value, making them much easier to resell.

On their part, custom boats are fantastic in that you can tailor them to your exact needs. However, they might be more challenging to maintain or service. That’s because of parts unavailability and lack of construction knowledge.

Choose Quality Construction Materials

The best quality materials to use on your catamaran are both light and robust. While carbon fiber is great, plywood, plywood/epoxy, and strip-cedar are excellent materials too. What’s more, they are also affordable, so you don’t have to get too hung up on cutting-edge building materials. What matters is build quality; thus, a well-built plywood catamaran boat can last as long as a boat made from more high-tech materials.

Combining various materials also helps combat some of the issues that plague plywood boats in terms of resale value. At times, the design tends to make the boats appear pretty dated.

- Plywood and strip-cedar materials are affordable and provide excellent build quality.

- Plywood boats may have a lower resale value than those built with modern materials.

Consider Ease of Handling

An important factor in handling a cruising catamaran is deck layout. Most cruising catamarans sailed short-handed , so if your boat has one helm, all lines should run back here to allow for a static control station for the entire boat.

The other essential element is visibility from the helm. The 360 degrees of visibility while maneuvering, docking, or underway is crucial to your boat’s safety, as well as life and property. As such, you should be able to view both bows, or at least the pulpits and sterns, while standing at the helm. If not, you may have challenges handling the boat due to blind spots.

Consider the Load Carrying Capacity

A well-designed catamaran is enjoyable to sail in all weather conditions. It’s also much easier to handle than a monohull because of its widely spaced twin engines. But when you immerse extra hull depth, the vessel gets sluggish and moves slower, maneuvering in tight spots or when docking becomes more challenging. Furthermore, the hull submersion reduces bridge deck clearance, leading to hull slamming.

To allow for adequate load carrying capacity, you need a design that provides a generous displacement. This helps to ensure that you maintain reasonable bridge deck clearance even when fully loaded. It also allows you to avoid digging big holes in the water as you drag your transoms.

Displacement refers to the amount of buoyancy designed into the hulls, which essentially means that your boat will cruise better if its weight is less than your designed displacement.

Note that an overloaded catamaran not only loses out on performance but eventually, on safety too. To counter this, choose a lightweight catamaran with hulls bearing cored construction and interiors made of lightweight materials.

Remember, when you go cruising, you will need to carry fuel, extra water, supplies, equipment, and amenities, translating into thousands of extra pounds. Therefore, try and avoid the following design errors to ensure that your catamaran has an adequate load-carrying capacity:

- Avoid putting in place too much accommodation space.

- Avoid building a heavy boat ‐ use low-tech construction materials.

- Avoid installing inboards in a small boat.

- Lightly constructed catamarans perform faster and carry more weight.

- Cored construction makes for a strong and stiff catamaran, thus enabling good performance.

Final Thoughts

A well-designed cruising catamaran is a joy to behold. Today’s modern technological advancements mean that you can buy or build a light but strong cruising catamaran. And as you can see from this article, there are many excellent cruising catamaran layouts that you can choose from.

However, whichever layout you decide on needs to fit your sailing needs and purposes to ensure you remain comfortable and safe while at sea. Above all, ensure that you go for a vessel that you can handle with ease in all weather conditions.

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

Time For a Catamaran Adventure

Isn't Time For Yours?

Building Your Own Catamaran

Building your own catamaran is another option to getting into your own boat. In this page we will go over the advantages, considerations, and a detailed history and journal of our boat-building adventure with Light Wave . We hope this will give you a clear picture of what lies ahead if you go this route, including:

- Construction methods

- 9 essential design features

- Review of the four leading catamaran designers for home builders

- Construction times

- Budget: How much did it cost to build a basic cruising catamaran?

- Layout of our catamaran, LightWave , and lots of pictures

- Carllie’s article from September 2000 Multihulls Magazine: “The Boat Builder’s Wife “

- Equipment outfitting

- Radio and communication outfitting

- Dinghy selection and considerations

- Having a boat custom-built for you

| |

Because of the huge dollars needed to buy a new or even a used catamaran, we would never have gotten a catamaran if we hadn’t built it ourselves.

Let’s start by saying that building any type of larger boat, especially a catamaran, can be one of the most intellectually and physically challenging things you will ever do.

It has been said that building a large boat is the closest a man can come to giving birth to a baby. In other words there is going to some discomfort and pain along the way; you will question yourself on whether this was such a good idea; it’s very difficult to reverse the decision; and though friends will support you, you will be on your own most of the time with your significant other if he/she is game.

Know your boat

You will intimately know every part of your boat. You will know where every wire, hose, bolt, bulkhead, rib, and support is because you installed them!

Pride of ownership

We have often thought what it would be like to just buy a boat from a manufacturer, and know that while owners who have spent a lot of cash (or future life to pay off the lien) their often possessive and competing-with-the Joneses could not begin to compare to our quiet glow of happiness and akinship we feel with Light Wave .

Our boat is like part of the family. So much time was spent on her that we have a major emotional investment. Every time we see our vessel – from a distance at anchor or approaching her in our marina, we say, “What a pretty boat! I can’t believe we built it!” Then that sense of accomplishment settles back in and we feel we have indeed earned the privilege of all of the beautiful experiences we have had sailing, cruising, exploring the beautiful BC Coast and much further a field (or should we say “an ocean”?).

You will be able to pay for the materials as you go and “donate” your time to the cause.

Get a newer design

Many of the production boats that are out there are designs of many years ago because the manufactures have to recoup their capital investment on the mold and production setup. When you build your own you have much newer designs to draw from.

Details on Our Boat Building Adventure

We had sailed our first boat Wave Dancer for five years and had many adventures on the British Columbia coast. In May 1996, I had just returned from a little one-week solo trip in the Gulf Islands of BC when I bought the book, The Cruising Multihull by Chris White (Future link to book review on our web site).

This is the book that got me going (Carllie was not yet convinced). I must have read it a half dozen times over the next 6 months, each time becoming more convinced that this was the way to go for our next boat. It was really still pre-internet web site days so I wrote to all the designers that were listed in the back of the book. Over the next several weeks packages of information started appearing in the mailbox (there is just something about getting packages in the mail – I guess it’s the anticipation). I would pour over these preliminary printed pages with pictures and accommodation layouts. Next, I put a few dollars down to buy the information packages and study plans from the top prospects.

I waited patiently for the study plans. It was like the night before Christmas when I was kid. Oooh the wait! Finally they came, and again I carefully scrutinized the next level of detail. Things were getting a little more serious. The top contenders were:

- Richard Woods

- Chris White

- James Wharram

Click here to read my comments and reviews on their catamaran designs as well as those of Jeff Schionning.

I remember initially drooling over the Atlantic 42 by Chris White, still one of my favorite designs. It seemed to be so seaworthy (by the way if I run into about $800,000 USD any time soon, I am going to buy an Atlantic 55). The most important piece of advice that came out of the material was from Richard Woods:

“Build the smallest boat you‘d be happy with it.”

Axiom #1: The hours to build a catamaran is in almost in direct proportion to its weight.

Which brings us to Axiom #2:

Axiom #2: It takes about 1 hour to create 1 pound of finished boat.

In our case we spent 3,500 hours ( click here for full details on the construction hours ) to build a 4,000 lb. boat (just a little less than 0.9 hours per pound). If a boat’s empty weight is 8,000 lbs., it will probably take about 6,000 hours to build.

When you think about it, you can only mix and handle so much material per hour. More boat weight, more material, more hours. Sure there are some economies of scale on a bigger boat, but usually the systems become more complex and these take longer to install.

This decision process took 8 months and I figured we’d launch in 6 months. It was now January of 1997. Little did we know it would be 26 months and 3,500 hours between the two of us until we launched on June 5, 1999. We ordered the full plans and we were off and running.

We were ready to build, but where would we start the process? First of all, we live in a tiny 480 sq. ft. apartment in Vancouver. Back-yard building wasn’t exactly an option so I found a small garage nearby that we rented for 5 months.

After about 4 months in the garage, I had made all the small parts and it was time to build the hulls. This meant that we had to go larger facilities. We found space at Shelter Island Marina and Boatyard in Richmond. This is the biggest boat yard in the Vancouver area with dozens of commercial and private projects, big and small, under way.

We were out of money by then, so we sold our first boat so we could buy resin and fiberglass. It was a traumatic time as we said goodbye to our beloved Wave Dancer . We were now committed. We than had all the foam for the hull cores, barrels of resin, and huge rolls of matting and roving needed for the fiberglass skins delivered to our “domed stadium”. We kicked ourselves many times that we didn’t take a picture of this raw material stacked in one corner of the empty shed, so we could later show “before” and “after” photos. It was time to build the hulls.

Over the next several months we proceed to join the hulls with the beams I had built in the garage, and then to install the cuddy cabin, cockpit, and decks. By the spring of 1998, it was staring to look like a catamaran. Through the spring and summer of 1998, we continued with the major structural components: mini-keels, hatches, stairs, and interior. Then we went on to the very laborious work of fairing the boat before painting. Don’t under estimate that job!

By October 1998 we were ready to prime the boat and start painting. I really thought this would go quickly. I forgot that I would have to do two more complete sandings to sand off and finish the two layers of primer application. In addition we had to fill countless pinholes – a laborious process somewhat like hiking up a mountain – each time you get to what you think is the top, you see another summit!

The boat seemed to get bigger and bigger. Believe me, there is a lot of surface area on a catamaran. I clearly remember that last sanding: I had reached the end of my physical and mental endurance – I was exhausted. I was ready to move on to the next phase – any phase but more sanding!

We now started spray-painting the hulls bright yellow. It was around this time we decided on our boat name of Light Wave . The painting took over a month: the hulls being the easy part, it was the topsides, the nonskid, and all the masking and prep that seemed to take forever. Happily, the worst of the dust was gone.

By March 1999 we were in the home stretch. The center bridge deck cabin was completed so we took a week off from our paid jobs and lived on the boat in the shed so we could work all day and not waste time commuting. March, April and May were frantic months as we finished all the final touches: engine installation, rudders, windows, deck fittings, electrical, plumbing, mast, and rigging. See our outfitting page (for more details on what we picked and why, and things we would do differently now.

Initially, our electronic systems were relatively basic but included GPS and autopilot see the following link for all our electronic outfitting choices and reasoning for more details.

It was May 22, 1999 and we decided that Saturday, June 5th would be “Launch Day” so we could send invitations to all of our friends. On the Friday night before Launch Day, we still had a number of final things to do, many of them outside. Unfortunately it was pouring rain. We were tired and very wet but the boat had to go into the water next day so we persevered on till everything was ready.

The moment of truth came as Light Wave was lowered into the water. While still in the slings of the Travelift, I jumped aboard to check for leaks. Of course there weren’t any! More food and laughs and tours of the boat for all attending. It was a great day.

Emotionally drained that night, we slept in Light Wave in the water for the first time. It was another week before we actually went out for our first trip as we had to sell the shed, setup sails, and install some final deck hardware.

To sum it up, building a catamaran was a great experience. We learned a lot. Carllie and I grew closer together through it all. We had a great time doing it. We had a beautiful catamaran to show for it. Now it was time for a catamaran adventure !

| |

[email protected]

Category: Our Catamaran Build Kits

Recommended equipment.

Quality suppliers & manufacturers

The schionning team have a lot of contact with equipment suppliers and manufacturers, and hear feedback on certain brands or systems from our many customers. there are many schionnings cruising the world and testing products longevity and the customer service offered by the manufacturer., on this page we will list products and companies that we know to provide above average quality and service. it is always growing, and if your company provides equipment used on our designs and you would like to be included - please contact us., engines & drive systems.

Visit: https://oceanvolt.com

Batteries, Power Management

LITHIUM POWER (VIC)

Back in 2013 I knew that my boat batteries were reaching the end of their lives, I had been researching LiFePO4 cells for a few years and decided that I should install them. Unfortunatly I was unable to find a local supplier. So Lithium Power was established.

Technical Information

The technical information page is a collection of documents (mostly in pdf format) on the materials and systems used in schionning catamarans. including data sheets, engineering information, strength comparisons of each core material and informative articles from jeff outling the design of certain system such as engine choices and main sheet systems., detailed engineering data for your research, we understand that getting your head around the process of building your own boat, or having one built, can take a little while. to gain a greater understanding of the materials used in our designs, the below data sheets have been supplied by atl composites, and contain all of the technical data you could need regarding the composites we use. in addition are articles or documents written by jeff about certain systems used on our designs and why., all technical information and data sheets on west system/duflex/durakore provided courtesy of atl composites. for more information please see the atl composites website here., documents library.

Information Sheet – CE CERTIFICATION PROCESS

- Mainsheet Systems for Catamarans

- Motor Choices for Schionning Designs

- Weight and Weight Distribution Schionning Designs

- Schionning Designs Sailing Performance and Tips

- Hull Shapes and Performance – Power Designs

- Outboard Engines VS Diesels – Written by Ross McCombe

- An Outboard Installation That Works – Ross McCombe Follow up

- Data Sheet – DUFLEX BALSA for Catamaran Kit Builds

- Data Sheet – DUFLEX FOAM

- Data Sheet – FEATHERLIGHT Paper Honeycomb

- Data Sheet – WEST SYSTEM R105

- Data Sheet – PUMP SYSTEMS

- Data Sheet – MICROFIBRE BLEND 403

- Data Sheet – MICROLIGHT 410

- Data Sheet – MICROSPHERES 411

- Information Sheet – USING FILLERS

- Data Sheet – KINETIX RESIN Thixotropic

- Information Sheet – DURAKORE PLANKS 413

- Data Sheet – DURAKORE PLANKING 414

Kit Materials Contents

Kit materials' contents, so if you order a schionning kit, what exactly is going to arrive see an overview of the materials you will receive, and what each is used for during the build process. fibreglass cloth or tapes microspheres, microballoons or microfibers take a closer look and you can answer these questions., our schionning kits are a no nonsense, common-sense approach to building a boat. we offer great service, fast delivery and access to anything you could need for your boat straight from the supplier to your door. our construction plans and kits are sold with 100% professional boatbuilder support via phone and email, any time you're unsure or just need a second opinion, we're here..

Our kits contain all of your basic materials to build your boat to a faired shell stage, ready for painting and fit-out. We have sail-away costing estimates available for all of our standard designs, and this will give you an accurate idea of the overall cost of your project. This costing varies depending on your level of finish, as you can imagine different options vary greatly in price.

Below is a quick glance at what your Schionning Kit will include and what each item is primarily used for, we hope this is helpful and if you should require more detailed information please don’t hesitate to contact our office.

What do I actually receive?

DUFLEX PRE-LAMINATED PANELS

DuFlex pre-laminated panels are the main and most important material used in our kits, predominantly in the flat panel designs, however they are used in Strip-planked designs also, though to a lesser extent. These panels are 2400mm x 1200mm and are CNC routed to speed up build time on our Wildernes X Series, as well as some of our power designs. For internal furniture, a paper honeycomb core is used instead of the end-grain balsa wood core that is used for main structural areas. The use of this is purely to save weight in the shell and therefore produce a faster, more responsive catamaran.

KINETIX LAMINATING RESIN & HARDENER

WEST SYSTEM EPOXY RESINS

FIBREGLASS TAPES (DOUBLE BIAS)

CARBON FIBRE CLOTH

FIBREGLASS CLOTH

The kit process, building your own boat can be a daunting prospect, however to demonstrate each step in the kit assembly process, we've created this guide for you to study. as you can see our kits are the ultimate in building efficiency and have been streamlined over 30+ years to ensure that you're on the water faster and with less effort., how does it all go together.

The first step to building your dream catamaran begins with a strongback – this is a square frame used to position the temporary frames that will be used to form the hull shape. This frame will be set up and must be square and accurate, a string or laser level can be used to achieve this.

The forebeam is now installed along with the striker attachment fitting, as shown above. The bridgedeck is installed shortly after and taped onto the bulkheads with webs installed, this now completes what is a quite stiff and strong platform to work on.

Now that the bridgedeck is in place, the forward webs and dash will be fitted. At this stage, all furniture and internal work begins, with the main panels left off for ease of access when working.

Material Choices

Schionning material choices, solutions that work best for catamarans & why, our designs are based on cored composite construction techniques using west system epoxy resin and knitted fabrics. but given the range of today's composite technologies, which solution works best for catamarans and why written by jeff schionning, selecting the correct materials, resin choices.

It also fully protects the boat against water absorption and it can not develop the dreaded Osmosis.

We choose ATL Composite’s resin systems for their superior quality, reliability and value for money.

Having worked closely with the ATL Composites team and their products for many years, we know we can stand by their material solutions, and rely on great service should something unexpected happen.

This may not seem important but when working with a material for an extended period of time, the small things make all the difference.

CORES Which One to Use?

- End-Grain Balsa – 150kg per cubic metre

- Superlight Balsa – 94kg per cubic metre

- Western Red Cedar – 360-380kg per cubic metre

- Foam – 80kg per cubic metre

BALSA END GRAIN (150 kg/cubic metre)

Balsa has very good values and we can produce a shell using a very light laminate. It will be very stiff and very resilient to fatigue.

It has exceptional qualities including very high compression strength, extremely good sheer capabilities and fantastic sheer stiffness.

Compressive strength is the resistance to collapsing when pressure is applied perpendicular to the surface as when pushing directly onto the material with the point of your finger. Balsa is far stronger than Foam (80kg/cubic metre) in compression.

Balsa is also very strong in shear. This is when the core sample is held flat between your hands, one hand slid one way and the other slid the opposite way, when the core tears through the middle the core has failed in sheer. The amount of stretch you feel before the core shears is shear stiffness. To compensate for sheer weakness the core is made thicker. So 13mm Balsa may be equal in sheer to 19mm Foam.

(80 to 200 kg/m³)

There are many boats sailing that are built from foam as it’s mechanical properties are good for boat building.

- Initially one would expect this cat shell to be lighter as it is ½ the weight of Balsa. We do have to compensate for its weaknesses and will then add to the reinforcement the reinforcement on the outside to spread that compression load over more core and need a triaxial type weave to compensate for the veneer content that runs fore and aft on the Durakore.

- Secondly, we need to increase the Core thickness to compensate for the shear value, usually neutralizing the weight advantage.

- We only use structural foam core that is closed-cell and cross-linked.

The end result using foam core amounts to a very similar total boat weight. Professional builders can achieve a good result but usually use vacuum bagging and very good molds to achieve this.

Secondary Issues

Balsa can absorb water. It needs extreme neglect to rot (very unusual). Water soaks along the end grain quickly. It travels very slowly across the grain. We use balsa under the waterline especially because of it’s high compression strength for beaching etc. any core type must be sealed. Damage to all cores results in the same sort of repair. Notice a damp spot remaining when drying out to anti-foul… simply grind back the surface glass exposing the core, dry it out and re-glass – it’s that easy.

Timber cores are cheaper than Foam in most cases.

A light, high tech cat returns a far better (often 2 – 3 times) re-sale than lower tech materials. Often saving $10,000 on materials initially, loses $200,000 on re-sale – a serious reality.

Our boats can be built using Balsa, Foam or Western Red Cedar. Combine strength, stiffness, lightness and cost, with ease of use – it just makes good sense!

|

| | | | |

|

HOME / INDEX PAGE  James Wharram Designs Search Our SiteSelf build boats. A philosophic attitude behind the Wharram designs is that 'urban man' can, with a little financial saving and some handcraft work, create an object of beauty. This object of beauty can then, for a period of hours, days, weeks or months, carry him/her out of the urban world into a natural never-never land; the seas and oceans; to a time when the world was young; when Mankind was directly and intimately interacting with the beauty and power of nature. There are hundreds/thousands of Wharram builders or, as I prefer to call them, "Sea People", who have done or are now doing that!" - James Wharram A well built Wharram design is a 'Functional Kinetic Sculpture'" - Hanneke Boon  Everything you need to build your own sea-going catamaran: 3 steps

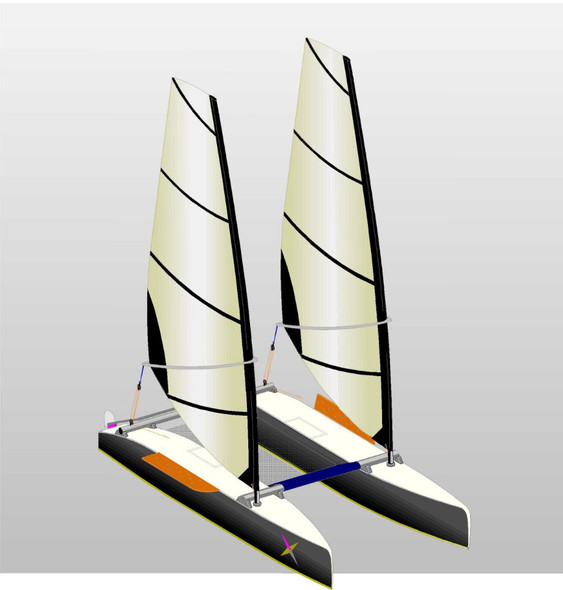

Tiki Designs Coastal Trekkers To Long Term Live AboardsFrom the car trailable Tiki 21 - winner of the 1982 Cruising World Design Competition, to the Tiki 46, a spacious ocean cruiser or charter boat, the TIKI range offers car trailable coastal trekkers to long term live aboards . Although a Tiki 21, a very popular coastal trek design, has circumnavigated, we would not recommend this for everyone! A number of Tiki 26s have also made ocean crossings, but again this is only for the experienced sailor. The larger TIKI designs of 30ft and over are craft capable of longer voyages and ocean crossings. They are designed to be less costly to build by using appropriate wood/epoxy technology and by eliminating, wherever possible, expensive metal fittings common to modern yacht design. On the larger TIKIs the 'Deckpod' offers sheltered steering and the 'Stern Ramp' provides easy access to and from the water. The TIKIs are boats you can work and live on. The Wharram approach goes beyond simple boat design - the concept of 'Flexispace' puts emphasis on not just the physical living area, but also the 'mind space' of those on board. Hitia Designs Affordable Weekend Adventure BoatsThe Hitia Designs are the perfect beach catamarans . They are 'coastal trekkers' and cater for those who do not want a craft for long distance or "blue water" sailing, but would like to be able to trail their boat to varied interesting coasts and lakes. Their easy economical construction, stability and speed makes for affordable weekend adventure boats . The Hitia 14 can be carried on the roof of your car and fits on the deck of a larger boat. The Hitia 17 has more stowage space and room for a tent on deck for longer excursions. These boats are ideal for small adventures and coastal treks. Introducing: the Mana 24 'Cat Kit' Boat In A BoxThe MANA kit is sold with all the plywood cut out by CNC cutter and pre-coated with epoxy, so building the boat at home will be a bit like assembling a flat-pack . All the parts slot together perfectly so a hull can take shape in a day. Building from such a kit takes away the worry of measuring and cutting all the boat parts , which can be quite daunting to many first time builders and saves a lot of time in the early stages of building. In designing the MANA, we looked sideways into the world of camping and have combined the innovative CNC cut "flat pack" boat-building concept with the philosophy of outdoor living to create the unique MANA camper-sailer, specifically designed for trailer sailing. The ply parts will have a first smooth coat of epoxy already applied, cutting down time in coating and sanding, so within a short time you will be able to assemble the hulls and see the boat you are building. As she is built from a pre-cut kit, we have been able to give the Mana more complex and beautiful shaping, giving her more interior volume than the Tiki designs. Pahi Designs The More Evocatively 'Female' Of The Wharram DesignsFrom the Coastal Trekking Pahi 26 to the impressive 63' flagship of the Wharram fleet 'Spirit of Gaia' - the PAHI shape is more evocatively 'Female' than the Classic Wharram designs. They are a different visual/sculptural approach to the basic design elements inherent in the Classic Designs. Constructively, they are simpler to build, using epoxy fillets instead of more difficult wood joints . They are designed to use quick growing softwood plys, coated and glassed with epoxy to achieve a durable finish. The PAHI designs were the first to use rope lashings to attach the crossbeams, giving a shock absorbing effect, without the need for metal fittings. 'Pahi' in Polynesian dialects means 'ship'. The Pahi 42 'Captain Cook' design set fresh ocean cruising standards when she was designed in 1979. The Pahi 63 was designed in 1986 and launched in 1992 to become the new ocean going flagship for the Wharram family. During the construction of 'Spirit of Gaia' many unique new solutions to plywood and epoxy building methods were developed, which were later incorporated in the larger TIKI and ISLANDER designs. Ethnic Designs Traditional Pacific Sailing CraftThe Ethnic designs have been a new development at James Wharram Designs since James and Hanneke sailed extensively in the Pacific. With everything self-made these boats are lower cost to build . They cater for those who want a "traditional" Pacific sailing craft, built using appropriate modern materials and methods, but without trying to Westernise them. These designs arose after requests from Pacific Island peoples for James to design craft to overcome shortages of "traditional" building materials, but which closely reflect the cultural and ethnic origins of these craft. Classic Designs The Early Wharrams - Sturdy and StableThe early 'Wharrams', now known as the Classic Designs, are recognised as beautiful, safe boats - easy to build, and easy to sail . Many anchorages around the world are graced by these Classic Designs, and of the seventeen drawn between 1957 and 1976, nine are still available, from the 16ft Maui to the 51ft Tehini. They were the first range of Wharram catamarans, designed in the 1960s and 70s, based on the sea experience of James Wharram's pioneering ocean crossings. They are sturdy, very stable, but relatively basic in design. They are built using simple plywood construction over a backbone and bulkhead frame . BUILD YOUR RAKU CAT WITH A DuFLEX KIT BY FOLLOWING THESE NINE BASIC STEPS Step 1. Kit DesignWork with us to finalise the details of the design you have chosen including any design options or additional modules to be included in the kit. We will determine the laminates, the number of panels required for each laminate, create the cutting files and prepare a quote for the kit if it is not already priced. Once the design details and pricing are confirmed you are ready to place your order.  Step 2. Unpacking2. The kit arrives at your workshop door, usually by container, as a stack of 1.2m x 2.4m routed composite panels ready to be joined. The shipment will normally include additional reinforcements, resins, and ancilary products as specified. Unpack the shipment and stack the panels out of the way of the space where the panels will be joined. If you have purchased a joined kit many of the panels will already be joined up to the length that can be shipped in a container (12m).  Step 3 Joining the PanelsSet up the work space where the panels are to be joined. The panels have a scarf join called a Z join that facilitate the join without needing tapes. The joining can be done with a heated Z press that cures the epoxy join quickly. Alternatively they can be joined with clamping pressure. If the panel are are being joined with the Z press you will need an elevated work bench the full length of the longest panels you are using. (image below). If you are joining them with a clamping technique the space can be on the factory floor. A nesting booklet is provided with the kit to show how the panels are joined (right)  Joining the panels with clamping pressure Panels are being joined into a single long panel by painting the surfaces of the scarf join with epoxy screwing through plywood battens that have a release film applied to one side. Joining the panels with the Z Press  Step 4 Stacking Joined PanelsOnce the joins are cured the panels are stacked to one side until they are needed for the job. The inividual parts should not be cut free of the panels until they are required. Bulkhead and floor panels will be needed before the hull sides and cabin top so they should be left to the front of the stack wherever possible.  Step 5. Separating the PartsWhen assembly is ready to begin the individual parts are separated from the panels by cutting the joining tabs. It is likely you will be building onto moulded hull bottoms that have been built from strip planking or another method of building moulded components. The process for building moulded components is described in another article.  Step 6. ASSEMBLYAs the joined panels are assembled onto the job you will need to apply glass tapes to the joins as specified in your plans. Panels can be surfaced and coated inside and out with high build while they are on the workshop floor to minimise fairing time once they are assembled to the boat. The paint on the panels shown here has been kept back from the edges to provide a good bond for the tapes.  Smaller items such as steps, seats and dagger cases are nested into the kit and for the more complex parts diagrams are provided to assist with the assembly process.  Step 7. InteriorInterior kits can be ordered with the primary kit, or they can be ordered later when final decisions have been made about the interior arrangement. A compromise solution is to order the interior as a set of plain planels that can be cut to shape on site after finalising the layout.  Step 8 Fairing, Painting, Hardware Installation8. The DuFLEX construction process goes a long way to minising the amount of fairing that has to be done, but inevitably any boat that has not come out of a female mould will require some level of fairing and surface preparation prior to painting. The fillers and resin systems required for the fairing work are normally supplied as part of the kit. Hardware installation is the same as for any other form of construction using high density core inserts or consolidated laminate in way of fittings.  Step 9. SailingGo Sailing. This Barefoot 40 Catamaran was built entirely with a Duflex kit in Foam/Glass and Epoxy resin systems from ATL Composites  DuFLEX Kits are manufactured and supplied world wide by ATL Composites atlcomposites.com.au And in Europe by VDL Composites www.vonderlinden.de/her/28/vdL-Composites-GmbH For more information on DuFLEX and associated Products atlcomposites.com.au/category/27/DuFLEX

Log in or Sign upYou are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser . Open Source 13-15m Catamaran PlansDiscussion in ' Projects & Proposals ' started by archie1492 , Jan 3, 2018 . archie1492 Junior MemberDear all, I want to create a detailed building information model for a 13 - 15 meter catamaran that is capable of being CNC cut and assembled. I need some help finding plans I can use as a basis of design. Specifically, I need the hull profile information. Section cuts through the hull will give me the ideal contours for a boat of this size. Can someone help? After weeks of searching, I still cannot find these online. For now, this is merely an exercise in my 3d modeling capability. I'd like to share my drawing work with the forum if I can get some assistance to start off. There are future possibilities I am also considering. I'm an experienced Architect & construction designer with a strong background in computer aided design. Once I've modeled the boat in 3d, I would like to flatten the various parts and create plans for the individual boat parts to be CNC cut. I would like to build a small scale model first (1:2o or perhaps 1:10) with the ultimate goal of building the boat full scale. TANSL Senior MemberThis is a very simple catamaran which, if you are interested, I can give you a lot of information. It is not a spectacular boat but it can help you in your first steps with boats. LOA = 16 m, Lbp = 14.6 m Thanks I really appreciate it. The hull lines for the motor cat you've provided are not quite what i'm looking for. I'm specifically looking for the hull lines for a 14m catamaran sail boat. I guess there is some standard for these contours especially the area below the waterline. Check the attached document as well if anyone is interested in this. Attached Files:catdimension.pdfI'm sorry, you never specified that it was a sailing catamaran. I thought that to carry out your purposes, " For now, this is merely an exercise in my 3d modeling capability ", any model was valid. Apparently, you have different purposes than, in addition to, to practice with 3D models. The better you clarify what you are really looking for, the better someone can help you. Hi all, Here's an example of what kind of information I need to get started. Optimising Hull Lines for Performance https://www.graingerdesigns.net/the-lab/optimising-hull-lines-for-performance/ The boat shown here is a 8.5m cat sailboat. I'm looking for something a bit larger in the 14m range. Also, the images only show one of the hull profiles. I'd like profile lines for the entire boat. I will post some other images I've found online showing profile lines for smaller boats. I still cannot find any 14m hull lines. Can anyone help? grainger_1488019480.jpgGrainger_1488019410.jpg, grainger_1488019333.jpg, grainger_1488019265.jpg, grainger_1488019219.jpg. Here are some other hull lines I've found online. Hope this is useful to anyone else looking for this information. Thanks! Evergreen Lines small.jpgHull-lines.jpg, shark-20.jpg. You could take any of those boats and scaleb the lines to get the desired length. Since it is only a 3D modeling exercise, you do not have to worry about anything else. You could even make a mix of 2 or 3 of those models to get the one you are looking for. Thanks Tansl, I'd like to make the boat drawings accurate for the 14m size. Perhaps one day I will develop this into something worth building full scale. The more accurate I can draw the boat, the more I will learn about the boat design. Maybe it does not look like it but I would like to help you. If you do not find what you want on the Internet I could draw a lines plan, strictly following your instructions, which would help you to make the 3D model. Or, if you find something similar on the internet I can adapt it to your needs and fill in the information that you indicate you need for your work. I insist that starting from the shapes of a 10 m boat you can get the shapes of a boat of 14 m, with total accuracy. Dolfiman Senior Memberarchie1492 said: ↑ I'd like to make the boat drawings accurate for the 14m size. Perhaps one day I will develop this into something worth building full scale. The more accurate I can draw the boat, the more I will learn about the boat design. Click to expand... Cata 14m with Gene-Hull UE Catamaran 2.3_2018 01 15.odsGene-Hull Catamaran 2.3 User Guide_2018 01 16.pdfHull for cata 14m with Gene-Hull UE Catamaran 2.3_2018 01 16.pdfDolfiman, thanks so much! This is exactly what I was looking for. It's very interesting and probably a bit over my head at this point. I think this should work for modeling the basic hull shape. For the bridge deck and all of the stuff above the hull I can model this with a bit more creativity. Although, I'd like to learn more about understanding the center of gravity for the boat and the proper location of the mast. Are there any rules of thumb about this? Thanks again! archie1492 said: ↑ I think this should work for modeling the basic hull shape. Click to expand... Cata 14m V2 with Gene-Hull UE Catamaran 2.3_2018 01 15.odsIn complement to illustrate this first approach, my good friend Alain did some 3D views here attached of the hull V2 version with Multisurf (using fit for purpose ouput data in section 5. of the above file). To inspire you , some other examples of cata, more sport/day sailer oriented than the Saona 47 : - R/P 45 (Reichel-Pugh) : multihull http://reichel-pugh.com/tag/multihull/ - Dazcat 1295 : in this video, from 1:45 the launch, you can see the hulls from various angles https://www.youtube.com/watch?v=0BZF4Udda5E - SIG 45 (VPLP design) : from 1:20 you can see the winward hull fully lifted dean 1962 New Memberarchie1492 said: ↑ Dear all, I want to create a detailed building information model for a 13 - 15 meter catamaran that is capable of being CNC cut and assembled. I need some help finding plans I can use as a basis of design. Specifically, I need the hull profile information. Section cuts through the hull will give me the ideal contours for a boat of this size. Can someone help? After weeks of searching, I still cannot find these online. For now, this is merely an exercise in my 3d modeling capability. I'd like to share my drawing work with the forum if I can get some assistance to start off. There are future possibilities I am also considering. I'm an experienced Architect & construction designer with a strong background in computer aided design. Once I've modeled the boat in 3d, I would like to flatten the various parts and create plans for the individual boat parts to be CNC cut. I would like to build a small scale model first (1:2o or perhaps 1:10) with the ultimate goal of building the boat full scale. Click to expand...

Archie, I have been looking to do the same thing. Where are you at on the project? Very interested in hearing all about it. Thanks. The Open Trawler Project!

DUO 800 Study Plans DUO 800 Assymetrical Plans DUO 480 Adventure DUO 900 Study Plans DUO 900 Plans Wizard Study Plans Download Wizard Plans Download Strike 20 racing trimaran using a F18 beach cat for hulls and rig Strike 16 Main Hull Only Plans Download Wingmaran 15 Study Plans Download Wingmaran 15 Plans and Templates Download ECO 520 PDF

Adding your products to cart

Plans and Kits for Catamarans and Proas and other MultihullsCheck out my page on Advantages and disadvantages of multihulls If you're planning a boatbuilding project you might like to check my boatbuilding resources. These are articles from my website and some outside links and build diaries. Multihull plans in no particular orderEmail me if a link is broken or if I've missed a boat. I try to keep my links good but things change quickly on the web. I try to include most plans that I run across. I only exclude the ones that seem to be dubious, some are plagiarized or some just seem to be of terrible quality, or a website that includes pop-ups or other nasty things, that I don't dare include them. I have not personally checked all plans. Before building, do your homework.

Too Much ChoiceThere are a great number of large cruising catamaran and other multihull plans out there. I think one of the reason is that building a large catamaran is easier than building a cruising size keelboat. Many designers feel confident that the home builder has a good chance of success in putting together quite a competent multihull. I have not included all the large multihull plans and kits I have found, nor have I included many of the home made single effort catamarans that are out there.

I try to be accurate and check my information, but mistakes happen. ALSO keep in mind that not all boat plans are well designed. Old Banks Dories are particularly tricky because they were notoriously unsteady until they had some weight in them. Check the boat forums, many people have built dories. I have not built these boats and I can't recommend or proscribe any.  Boatbuilding ArticlesSmall print. This information is for general knowledge and entertainment. If you plan to build a boat be careful. If you don't know how to use powertools get help. Did You Know That We Offer Contract to Closing Services? Click Here to Find Out More. Need Marine Financing? Apply Here With Our Partner, First Approval Source

Catamaran Construction – Hulls, Laminates, and Composites