What are the pros and cons of different keels?

We all sail for different reasons, in different cruising grounds and use our yachts differently, so it makes sense that there is no one-size-fits-all keel design. At Sirius, however, we like to make the perfect yacht for each individual owner. One of the ways we serve our customers is our choice of keels – at least six different options for each model. It’s one of the ways we stand out – or should that be stand up?

We offer three styles of keel: fin, twin and lifting swing keel. All of our keels excel in many ways, but every design does have drawbacks – this is not unique to Sirius, but the keel affects the way you use the boat, so it’s important to choose the right one for you.

These are the keels we currently offer:

Standard Fin (310 DS, 35 DS, 40 DS) Performance Fin (310 DS, 35 DS, 40 DS) Medium Fin (310 DS, 35 DS, 40 DS) Shallow Fin (310 DS) Shallow Twin (310 DS, 35 DS, 40 DS) Performance Twin (35 DS, 40 DS) Lifting Swing Keel (310 DS, 35 DS, 40 DS)

Does the choice of keel compromise ocean capability?

For Sirius yachts, absolutely not. It’s important to realise that choosing one keel style over the other does not affect the yacht’s righting moment or compromise its ocean-going capabilities at all!

Whichever keel you choose, deep or shallow, twin or fin, they all have the same stability. This is achieved by putting more weight in the bulbs of the shallower keels as the shorter lever can be balanced with higher weight. Most of the blue water cruising and circumnavigations in Sirius Yachts have been made with twin-keel or reduced/shallow fin keel yachts.

Does keel choice affect performance?

As our shallow keels are heavier the weight dampens the yachts’ motion at sea, but as a downside, you have more weight to move with sails or engine. Once you’re moving there isn’t a difference but when tacking or gybing, or when not steered well, you will lose a bit in sailing performance. The shallower draught yachts also lose a few degrees to windward compared to their deeper keeled sisters, but they are still good all-round performers. Our customers with racing backgrounds always try to go for a keel as deep and light as their sailing area permits, either with a single or twin keel.

Pros and cons of fin keels

The standard keel on our yachts is a fin keel. Most sailing boats today use a fin keel because it gives a good all-round performance on all points of sail. By keeping the ballast lower it gives the most comfortable motion. The main downsides are that the draught (the depth of water required to stay afloat) is the greatest, and it’s very important to avoid running aground on a falling tide. Fin keel boats cannot dry out without additional support, either from a harbour wall or by fitting a pair of beaching legs. Some fin keel yachts are not built strongly enough to stand on their keels when out of the water, so they can’t dry out alongside a harbour wall and they need to be kept in a special cradle when stored ashore to avoid the risk of the hull deforming under its own weight. By contrast, all Sirius yachts can stand on their keels for any length of time with no problem at all.

We offer four types of fin keel. The standard fin is available on the 310 DS, 35 DS and 40 DS and is fully cast-iron. It offers the best value, good performance, and excellent responsiveness. It is the deepest of our fixed-keel options, so if you want less draught you may want to look at our other fin keels.

We also offer a performance fin keel for all our models. This uses a cast iron fin with a lead bulb at the tip (bottom). The structural strength of cast iron means the fin is the slimmest profile, but lead is denser than iron so the same volume of lead will weigh around 1.4 times more than cast iron, giving more righting moment. The heavier, softer lead down low has less volume in the bulb so achieves a slimmer profile with less drag and therefore better performance.

A lead bulb is also safer if it hits something. Lead can absorb 60% of the energy in flexing and deformation so that only 40% of the force will be transferred to the laminated structure of the keel reinforcement. A lead bulb is very forgiving and easy to reshape and will not start to rust where the coating is damaged. We can use less volume of lead than iron, and achieve better stability than a wholly cast-iron keel. We can also reduce the depth of the keel and retain excellent stability. However, lead is more expensive than cast iron and the bulb must be attached very securely to the iron fin, so this option does cost more.

If you want less draught, we also offer a medium fin. This reduces the draught of the 310 DS and 35 DS by around 40cm/1ft 4in and 55cm/1ft 9in on the 40 DS. Like the performance fin, it uses a cast iron fin with a lead bulb. To retain the keel’s grip in the water it has to have a longer chord (the distance from fore to aft). While this gives the boat better directional stability, it does make her a little less responsive and a little slower to manoeuvre.

On our 310 DS, we offer a shallow fin option – a special version for very shallow cruising grounds. This fin keel offers the least draught of any of our fixed keel options at 1.15m/3ft 9in and draws 10cm/4in less than the twin keel version. The keel has a significantly longer chord (2.24m/7ft 4in compared to 0.7m/2ft 3in of the standard keel) so she has the reassuring directional stability of a long-keeled yacht but with better manoeuvrability.

Pros and cons of twin keels

Our twin keels are the most popular option. About 70-80% of all Sirius Yachts are delivered with them – and on the 40 DS it’s 90%. Some folk still believe there is a big performance penalty with twin keels. In the past this used to be true but it’s no longer the case with modern twin keel designs, from Sirius at least. We have conducted many two-boat comparison tests, often battling for hours, by ourselves, with owners, and for sailing magazines and we have found that there may only be one or two boat lengths of difference at the end of a long windward leg, if at all. At the end of many of these comparison tests, the crews could not point out which of the boats had the twin keel.

If you cruise tidal areas, twin keels will reward you time and time again. Not only do they give you a shallower draught than the typical fin keel, they also give you the ability to dry the yacht out, whether that’s for a motion-free night’s sleep, to explore cruising grounds others cannot reach, or just for cheaper mooring and maintenance costs.

We offer two styles of twin keels; performance and shallow draught. Both options have a cast iron fin with a lead bulb. The performance keels have a deeper draught and a thinner chord so they act and feel a bit livelier when sailing and manoeuvring. The shorter keels have a longer chord, but give you the ability to navigate shallower areas. Like all keel designs, twin keels do have some downsides. They are more expensive than fin keels, and when you’re sailing fast in choppy seas at a steep angle of heel, you can occasionally get a slapping sound when an air pocket is caught and pressed out under the windward fin. Lastly, we’ve yet to meet an owner who enjoys antifouling between the keels. Thankfully it only has to be done once a year and with twin keels you might get away with doing it less frequently. A twin keel yacht can be kept on a drying mooring, where fouling is reduced because the hull spends more time out of the water. And when you’re off cruising it’s easy to give the bottom a quick scrub while the yacht is dried out.

Our yachts will happily sit on their keels on a hard surface, like a drying grid, or for winter storage but on softer surfaces we use the rudder for additional support. The rudders on our twin keel yachts are specially reinforced for this: we use a Delrin sheave to take the weight of the hull and the tip of the rudder has a wide, foil-like foot to spread the weight.

A lifting swing keel

We are one of a few manufacturers to offer a lifting swing keel. There’s a lot of confusion with the term ‘lifting keel’, it seems to encompass all yachts that have centreboards, variable draught, lift-keels or swing keels. To us, a lifting keel boat should have all the ballasted weight of the boat in the keel, and that keel needs to be retracted into the hull.

Technically, a lifting keel is a keel that can be lifted or lowered and gives the boat the ability to dry out when the tide goes out. A lift-keel is a ballasted keel that raises and lowers vertically. A swing keel has a ballasted fin that has a single pivot point and the keel swings up into the boat. There are other variants of design, for example some have a lifting keel to reduce the draught of the vessel but they cannot dry out on it, others have a ballasted keel and ballasted grounding plate. All these examples have a keel that does two things: keep the boat upright and stop her sliding sideways. Our swing keel is designed with a NACA profile to give the most efficient performance.

Centreboard yachts have a centreplate to provide grip in the water and reduce leeway. The plate may carry only 15-20% of the ballast but the rest of the yacht’s ballast is within the hull and/or in the grounding plate. This is called an “integral keel” and is more common as it’s less complicated to build. The lower a yacht’s ballast is located, the better her stability, the more comfortable her motion and the better she stands up to her sail area. The most efficient place for the ballast is as low down on the deepest keel possible – this is why race boats have deep skinny keels with large torpedo-shaped bulbs on the bottom, but they don’t make practical cruising sailboats.

Our keel designs have more weight in the tip (bottom) – using a bulb on the fin and twin keel design and flaring the lower sections on our lifting swing keel yachts. You don’t have this with centreboard and integral keel yachts.

It might be surprising, but a lot of owners come to us thinking that a lifting swing keel is the best option for them. Sometimes it is, but about 98% of customers who approach us because we offer swing keels end up sailing away on a twin-keel Sirius.

The downsides of a lifting keel

A lifting swing keel does give you more cruising options. It will lift should you run into something and, of course, it gives you the shallowest draught. But that difference is only 40-50cm (1ft 4in to 1ft 8in) less draught than our shallow twin keel option. The lifting keel increases the complexity of the build and the final cost of the yacht; it also sometimes limits the internal layout and engine drive options, and you need to have twin rudders too. Twin rudders make the boat less manoeuvrable in a marina – you can opt for a third central rudder which does improve the handling, but again comes at an extra cost.

On the lifting swing keel, 40 and 310 owners are restricted to the use of a shaft drive, which is less efficient and you have to accept a bit more noise and vibration. When drying out, the drive is more vulnerable to damage, whereas it’s totally clear when taking the ground on twin keels. With twin keels, you also do not have to worry about something sticking out of the beach or stones lying around because the hull is high above the ground. With the hull up high, you do not have to dig a hole in the sand and slide down on your stomach to check or change your anodes as you would on a swing keel.

Sailors who are attracted to the idea of a lifting swing keel should carefully consider the pros and cons to compromise the least. When owners understand the repercussions of choosing a lifting keel yacht, many of them feel it restricts their options too much. They could have a lifting keel or they can sail with twin keels, dry out, have better close-quarters handling and save money in the process. Unless you need the shallowest possible draught – 0.75m (2ft 5in) on the 310 DS, 0.9m (2ft 11in) on the 35 DS or 0.95m (3ft 1in) on the 40 DS – a twin keel might well be a better option.

How are the keels attached?

The design of the keel is important but the way they are attached is just as important, if not more so. All of our fixed keels are through-bolted. Every keel has a wide flange at the root (top) of the keel and the flange sits into a reinforced recess in the hull. The flange and the recess work together to spread the loads of the keel/s into the yacht’s hull. The keels are bonded and bolted to the hull. We use up to twelve 20mm and 24mm bolts (per keel) and these go through rolled stainless steel backing plates inside the hull to spread the bolt loads evenly into the fully laminated keel grid which goes all the way up to the chainplates and also carries the mast support.

For our lifting swing keel, we laminate a substantial keel box as part of the hull to accept the keel and the hydraulic mechanism needed to retract the keel into the hull. Unlike most other boatbuilders we don’t use a grounding plate to take the weight of the yacht, our yachts sit on the length of the leading edge of the keel. Integral keels with the majority of the ballast in the grounding plates move the ballast (weight) from low down in the keel to inside the hull. This negatively affects the stability as the more weight you have lower down, the better.

We also don’t like grounding plates because they bring the hull in contact with the ground. By leaving 10-15 cm (4-6in) of the keel out of the hull when it’s retracted, most of the time the hull is kept clear of the beach and anything that could damage it.

The problem with too much form stability

With only 15-12% of their ballast in the centreboard, most lifting-keel yachts cannot rely on keel weight for stability so their hulls need to be designed with extra form stability instead. This means the hull sections have to be much wider and flatter. A flat-bottomed hull is not what you want for a comfortable ocean cruising yacht; it isn’t sea-kindly or easy to steer in waves and gusty winds conditions. We don’t make that compromise at Sirius. With all the ballast in the swinging part of our swing keel design, we can use the same seaworthy, ocean-capable hull shape designed for our yachts with fixed keels.

If you don’t know which keel would be best for your Sirius, contact us to discuss the type of sailing you intend to do, where you want to sail and what your cruising aspirations are.

General Manager – Torsten Schmidt SIRIUS-WERFT GmbH Ascheberger Straße 68 24306 Plön/Holstein

Fax: 0049 – 4522 – 744 61-29

Receive regular updates from Sirius Yachts

Subscribe to our email newsletter

Privacy Overview

Practical Boat Owner

- Digital edition

Best bilge keel yachts and twin keel yachts for drying out ashore

- Peter Poland

- April 12, 2023

Peter Poland reveals how bilge keel yachts and twin-keel designs won his respect – those that could sail well and stand on their own two feet…

Back in the late 1970s, I found myself on the horns of a dilemma. For the last decade or so I’d dismissed bilge keels and twin keels as ugly and performance sapping appendages. To my eyes, they invariably had the look of casually designed afterthoughts that had sprouted beneath nice hulls just to enable the boat to stand on its own two feet.

The boats that my company built, on the other hand, were aimed at serious sailors and I rashly assumed that anything other than a state-of-the-art fin keel or hydrodynamically efficient lifting keel would never be likely to satisfy this market.

Then my own personal boating needs underwent a change, so I had to take a flyer. Breaking my own rules and ignoring my preconceptions, I went out and spent my own hard-earned loot on a second-hand twin keeled Westerly Centaur.

Why? Because my factory and home were on the East Coast but a lot of high-profile sailing activity took place down south. So I needed a habitable floating base that could be parked on a cheap mud mooring and be able to follow the regatta circuits on which the boats I built (Sonatas, Impalas, Deltas, Medinas etc) competed.

This boat had to provide a general all-purpose home from home. And a bit of undemanding weekend pottering would be an added bonus. With my limited budget, there was only one obvious solution at the time – a Centaur.

Article continues below…

Best cruising boats under 30 feet: Is this the ideal size for a yacht?

Cruising boats of around 30ft can often become a ‘boat for life’. Having graduated from dinghies to small cruisers, many…

Classic cruiser boats: Why GRP models are now being welcomed into the fold

Sprawled, glass in hand, in the cockpit of my friend James Stock’s beautiful Stephen Jones-designed Mystery 35, I pondered on…

I soon discovered that the Centaur’s windward performance – while adequate – was hardly stimulating, especially when compared to the close winded precision of a Sonata or Impala to which I’d become accustomed.

As a result, the Centaur’s Volvo Penta motor got a lot of use when the wind went light or ahead, whereas on a reach or a run she performed satisfactorily and got us from A to B with a minimum of fuss and at a respectable speed. And she also offered comfort down below – despite the Centaur being only 26ft long I could stand up.

Design challenge

All of which got me thinking that maybe there could be more to these twin keel things than immediately met the eye. And as the sales of our fin and lifting keel speedsters began to slow over the ensuing years, I could not help noticing that the sales of our bilge or twin keeled competitors seemed to be on an ever-rising upwards trend in the 1970s and 80s.

Around 2,500 twin-keel Westerly Centaurs were built, which means there are plenty on the second hand market. Photo: Peter Poland

If we were to continue as a viable boatbuilding business, maybe we’d have to cast aside our prejudices and take a long look at these two-legged options.

So I took courage in both hands and asked our designer whether he might be willing to consider agreeing to design us some twin keels. I hastily added that of course – being the genius that he undoubtedly was – he was bound to come up with something far better than anything that had ever graced a cruising yacht’s bilge before.

Then I stood back and awaited the inevitable broadside of shock, horror and indignation. “Well,” said David Thomas (who had never designed a slow yacht in his life), “I might. I just might.

“But first I’ll need to think about it. In case you’d not noticed, twin keels have far more variables than a fin keel. The positioning of the roots relative to the centre line, the splay, the angle of attack are all variable and important. I’ll have to think twice as hard and for twice as long.”

I took this as a ‘yes’ so left it at that. And patiently awaited developments.

Gib’Sea 76 (26ft 11in) with ‘swept’ twin keels that draw 3ft 3in. Photo: Peter Poland

History of bilge keel yachts

Of course, bilge and twin keels were not a new phenomenon. They had been around for many years. When researching an earlier article on the Westerly story, I’d been fascinated by the development work done on his twin keel and twin rudder yachts by Lord Riverdale. As had my sales manager, Andy Cunningham, who wrote an excellent treatise on twin keels.

Lord Riverdale’s first twin keel sailboat was the smaller self-designed 25ft Bluebird of Thorne , built in 1924. Later Riverdale built the bigger Bluebird of Thorne (50ft) in the early 60s that he designed in collaboration with Arthur Robb. He claimed that tank-tested models indicated a 15% improvement on his earlier twin keel designs.

Bluebird of Thorne ’s owner, Lord Riverdale, had designed and built a string of cruising yachts (all with twin keels) over a period of around 40 years prior to the culminating glory of his and Robb’s 50ft steel twin keeler.

Riverdale also liked to draw the distinction between what he called ‘bilge keelers’ (meaning boats with a ballasted or unballasted centre keel and two stabilising bilge keels) and ‘twin keelers’ (boats with twin ballasted keels).

To go further back to bilge keel basics, it was probably Maurice Griffiths who did most to put bilge keel benefits into practice and bring creek crawling and ‘upright drying out’ to numerous leisure sailors.

Built from GRP, the Golden Hind 31 is a double chine, shoal draught cruiser. Photo: sailingscenes.com

Classics such as the 1957 Eventide 24 and 26, Waterwitch and 1968 Golden Hind 31 (to name but three of his many popular designs) all came with bilge keel options – featuring a substantial central ballast keel and two supporting bilge plates. The resulting shallow draught would never provide dynamic windward performance; but that was not Maurice Griffiths’s aim.

He set out to supply honest, seagoing small yachts that would be equally at home in the rough and tumble of a hostile North Sea as they were weaving between the withies and nosing their way into peaceful and shallow backwaters.

East Coast pottering is a specialised and delightful pastime that can only be enjoyed to the full in a shallow draught yacht that is capable of drying out – whether by mistake or on purpose.

Then along came Robert Tucker and his popular twin keel plywood pocket cruisers such as the Silhouette that took off in 1954. Around the same time, a French designer began to play with twin keels.

François Sergent designed the attractive 22ft Sargue with a beam of 7ft 5in; generous for that era and with reasonable accommodation. Several of this mahogany strip planked twin keeler (drawing 2ft 4in) were built, and they not only sat happily on the Breton mud – they sailed well.

The designer said: “In passage races in the St Malo-Granville area one won two firsts and a fourth in three starts against deep keel boats and centreboarders.” It’s a pity none of them made it over to our UK shores. With pleasing performance and Gallic grace, the Sargue class looked a cut above what was available over here at that time.

Westerly Nomad’s longer coachroof offered improved accommodation to the Westerly 22. Photo: Carolyn Jenkins/Alamy

Westerly 22

Mass-produced and affordable bilge keel GRP yachts only really began to fill up our foreshores after Denys Rayner set up Westerly Marine in the early 1960s. Enthused by the tractable sailing he had enjoyed in his earlier bilge keeled designs such as the jaunty little Westcoaster, he decided that the time was right to invest in a new GRP cruiser.

And so the Westerly 22 was born in 1963. The twin keels drew just 2ft 3in and gave a ballast ratio of 33.3% while a long central ‘keel’ supported the rudder and gave a secure ‘three-point landing’.

The Westerly 22 sailed adequately, sat happily on a drying mooring, and the 22 Young Tiger was seaworthy enough to make a transatlantic crossing in 1966. The longer coachroof of the later Westerly Nomad (1967) improved accommodation.

Following on from the 22’s success and Westerly’s bursting order book, Rayner pushed ahead with 25ft and 30ft models that used the same keel recipe. The burgeoning market for family cruisers was growing fast after the post war dinghy boom.

In a remarkably short time, Westerly sold almost 1,000 of these Rayner-designed yachts and the bilge keel revolution was well and truly on its way.

But even their greatest fans will admit that the sailing performance of these early models was unspectacular. Their modest draught meant that lateral resistance was minimal, so leeway when sailing to windward was considerable compared to that of a yacht with the extra bite given by deeper keels.

When buying a used twin keeler, like the Westerly Centaur or Mirage, get keel roots surveyed. Photo: Peter Poland

And the drag incurred by all that surface area on three shallow appendages cut speed through the water – especially in lighter airs. But the early Westerlys sold like hot cakes because they brought economical sailing, low cost drying moorings and carefree coastal cruising to thousands of sailors taking to the water ‘en famille’ for the first time.

As Westerly pushed remorselessly ahead, other players soon entered the twin keel market. Thames Marine set up on Canvey Island in Essex and, over many years, produced hundreds of Snapdragon cruisers. Like the early Westerlys, these boats were not – by any stretch of the imagination – racers.

While a few models offered a centreboard keel configuration, the majority were twin keelers. Accommodation was always spacious and later models had a pleasing look, thanks to their nicely proportioned coachroofs.

At the smaller end of the market, makes such as Leisures, Silhouettes, Hurleys, Tridents, Macwesters, Cobras and Alacrities – to name a few – offered twin keels as standard or as an option.

But nobody was yet putting that much thought into the designs of the keels themselves. Some builders even produced twin keels that were an integral part of the hull moulding, then filled the GRP keel cavity with iron punchings.

As a result, the keel had to be vertical (to release from the hull mould) – which is far from ideal from a performance perspective. Add a fibreglass moulding filled with iron, and it is a disaster waiting to happen if the boat dries out on rough or rocky ground.

Once the GRP keel base is worn down or punctured, saltwater can get in and rust the iron, whereupon the rest of the fibreglass keel ‘casing’ can get blown away from the rusting iron ballast inside.

Painting a Westerly Centuar while dried out. Photo: Gary Blake/Alamy

Westerly Centaur

The next real leap forward in twin keel design came courtesy of the originators of mass-produced GRP twin keel cruisers – our old friends Westerly again. As Denys Rayner’s health was fading, he enlisted the young David Sanders to take over the running of the company. Unlike Rayner, Sanders was no yacht designer. “Go to Laurent Giles,” advised Rayner.

He was aware of the bilge keel development work and tank testing that had been done by Jack Giles so reckoned design firm Laurent Giles was the most likely to take twin keel design to its next stage. It was wise advice.

When I asked Barry van Geffen (later the MD of the Laurent Giles design office) how the new generation twin keels as first used on the Centaur came into being, he said that Laurent Giles’s research and tank testing had been very revealing.

Westerly Centaur interior. Photo: sailingscenes.com

“What was learned had a significant impact on keel design, as it was discovered that through various angles of attack, heel and yaw, there was a marked change in efficiency (lift versus drag) with keels that were aligned exactly fore and aft on the hull.

The LG [Laurent Giles] team considered all the implications, along with Westerly’s insistence that for production reasons both port and starboard keel castings should come out of the same mould – and settled on a design with a 2° toe-in and veed keel base.”

Twin keel changes

So what does this tell us about Laurent Giles’s suggested changes in twin keel design? Firstly, Westerly’s insistence on symmetrical keel foils for ease of manufacture and economic considerations was fortuitous for other reasons.

Early twin keel designs were often asymmetrical – as originally advocated by the Lord Riverdale of Bluebird fame before he realised these were less effective than symmetrical keels. The theory was that the foil shape on the inside face of the leeward keel and flat shape on the outside face would generate lift (like an aeroplane’s wing) and therefore lift the boat up to windward.

Unfortunately, however, the reverse could apply to the windward keel. In addition, the water flow between the keels could produce a braking effect, thereby slowing the boat down. The effect is not unlike putting the brakes on by adopting a ‘snow plough’ stance when skiing down a mountain.

So Laurent Giles’s move to a modest 2° toe-in for maximum efficiency combined with symmetrical foils was the right way to go. The result was a marked improvement in windward performance over older bilge or twin keel yachts. And if they had gone for slightly more draught than 3ft, it would have been even better.

Westerly Griffon 22

But perhaps they continued to learn, because Centaur’s later and smaller sister – the 23ft Pageant – drew only 2in less (at 2ft 10in) despite being 3ft shorter overall. The Pageant sails well and even used to win club races in her early days. And when Ed Dubois came to design the Centaur’s successor – the 26ft Griffon – he went for 3in more draught than the Centaur and drew finer foils with less drag. So twin keel performance continued to improve.

But the early Griffon’s finer keels (with finer roots) also brought boatbuilders’ attention to the often-overlooked risks attached to bilge keels. Westerly fitted their symmetric twin keels by bolting them to small GRP ‘roots’ that formed part of the hull – rather like a GRP version of old fashioned ‘deadwood’. So the finer the keel, the finer this ‘deadwood’ stub also became.

As a result, it needed greater internal reinforcement to resist sideways movement. And the greatest ‘force’ imparted to twin keel roots – where they attach to the hull – is not necessarily encountered when the boat dries out on soft mud. It happens when the boat tries to break free from the firm grip of the mud as the tide returns and attempts to lift the hull clear of this grip. The deeper and more glutinous the mud, the harder it grips and the longer the boat’s natural buoyancy takes to lift it clear. And this is what caused damage to the early Griffon’s keel roots.

Westerly repaired the damage and reinforced subsequent models. But the lesson was there for every builder of twin keel boats to learn. It also explains why a buyer and his surveyor should inspect keel roots when assessing any possible second-hand purchase.

Hunter Horizon 26. Photo: sailingscenes.com

Hunter Horizon 26

So – to return to the request I put to David Thomas in the early 1980s for a world beating twin keel design. What did he come up with? Predictably perhaps, he took his time. We all reckoned he’d vanished into a mystical twin keel retreat. But the design that finally emerged was well worth the wait.

Thomas reckoned that the optimum angle of heel for comfortable cruising (as opposed to flat out racing) is around 15°. So he designed the keels to attach to the bilge with a 15° splay and to be slightly ‘toed in’. This way the leeward keel would be vertical when the boat was heeled 15° – thereby working at its maximum draught and presenting the biggest possible lateral area to reduce leeway.

Then he placed the keel roots as close to the centreline as was feasible while still making sure that the boat would be stable when dried out. The reasoning behind this was that the closer the keel roots are to the centreline, the less likely the windward keel is to break surface and ‘thump’ when the boat is heeled in a seaway.

The final ingredient to the new generation Thomas twin keel designs produced the most animated discussions with the builder. Any sensible designer wants as much draught as possible – to lower the centre of gravity, increase overall stability and maximise lateral resistance to reduce leeway.

The builder, however, wants to keep the draught low to increase the boat’s appeal from a marketing perspective. So a compromise always had to be negotiated, although Thomas usually won. As a result his twin keelers invariably drew more than the equivalent sized competitors’ boats .

Hunter Horizon 26 interior. Photo: sailingscenes.com

And how did such twin keels actually perform? Extremely well. Having done initial trials on a Delta 25 hull, the Thomas keels were declared to be a success by boat testers and buyers alike. The time was ripe to introduce the first Thomas-designed spacious family cruiser that could sail well and stand on its own two feet.

The long-suffering Delta hull was dragged into the tooling shop again and given a brand new deck moulding for full standing headroom, an aft heads compartment and a spacious stern cabin. The new model was named the Horizon 26 and duly won the Best Production Yacht Award at the 1984 Southampton Boat Show .

We then walked into an unexpected marketing problem. Boat owners were so used to Thomas performance and handling that they could not believe that a twin keeler would be anywhere near as good. Some potential Hunter buyers even said that they “wouldn’t be seen dead in a bilge keel yacht”.

After a bit of head scratching a solution was found. Every demonstration boat for this and subsequent Thomas cruising Hunters had the twin keel option. Any client asking for a trial sail in a fin keel version would be politely told “I’m afraid we only have one demo boat for each model and it’s a twin keeler. So why not try that and if you aren’t impressed, we can always build you a fin keeler.”

It worked a treat. Initial scepticism invariably turned to disbelief followed by delight. Sometimes a client was taken on a trial sail without being told what sort of keel lurked beneath the waterline. When invited to have a guess after returning to the marina, it was amazing how often the client thought it had a fin rather than twin keels.

This Horizon 32 twin keeler (draught 1.3m) won a Round the Island race division. Photo: Peter Poland

Bilge keel yacht design evolution

As the years passed by, Thomas’s twin keel designs continued to evolve and performance got even better. In one memorable demolition derby Round the Island Race , a Thomas-designed twin keel Horizon 32 took the heavy winds head on and won its class and its entire division.

The twin keel Horizon 21 and Horizon 30 also excelled in the CHS divisions. Recently a twin keel Horizon 232 helped her octogenarian owner Murdoch McGregor win the Yachtsman of the Year Award for sailing solo around Britain .

Meanwhile other designers began to tweak their twin keels. Ranges such as Moody, Sadler and Westerly also moved up a gear in performance. Thomas refined his twin keel designs by adding long hydrodynamically shaped bulbs to their bases. These had the effect of throwing the centre of gravity even lower and lengthening the ‘footprint’ on which the boats stood when they dried out.

The extra weight located in bulbs lower down also meant keel foils could become finer and narrower, reducing drag. Other boatbuilders have taken note, with ranges such as the American-designed but British-built Legends displaying prominent bulbs on their twin keels.

So, as marinas get ever more expensive, will more builders offer twin keels on their smaller models? Interestingly, the answer is ‘yes’. But it’s not coming from the UK. It’s coming from France.

Django 770 twin keel yacht drying out

French bilge keel yachts

In the past there were economical marina moorings aplenty available in France, so twin keels did not feature high on the French agenda. But now things are changing. The cost of a marina berth in France is still reasonable compared to the UK: but only if you can find one.

The French Nautical Federation reckons there is now a shortage of around 50,000 marina berths. As a result, twin keels (or bi-quilles as they’re called over there) began to appear in greater numbers.

Now, with the exception of the traditional and long running Biloup Range, French twin keels are expanding the design envelope. Archambault, the builders of the Surprise range, decided that their hugely successful One Design (7.65m) cruiser-racer would have an increased market if they also offered a two-legged version.

Designer Michel Joubert went for deep (1m) twin keels with narrow chord foils and race boat bulbs on their bases. The roots are well inboard and the performance is said to be exceptional.

RM-Fora Marine specialises in multi chine plywood-epoxy hulled cruisers, invariably with twin keels. The latest models, from the pen of leading French designer Marc Lombard, are anything but conventional.

A new RM890 ready to hit the road. The twin keels draw 1.5m. Photo: RM Yachts

Draught is generous (for example the twin keel RM890 draws 1.5m) with keels that are as fine as you’ll find on a top-level racer. And the bulbs on their bases are just as sophisticated.

These RMs are exciting and versatile boats, although I wonder whether their futuristic looks and multi chine wooden hull construction will find favour with many British buyers. I hope so, because the combination of a plywood-epoxy hull with a GRP deck offers excellent insulation and a substantial strength to weight ratio.

The Django 7.70 designed by Pierre Roland and built by Marée Haute in France has also proved to be a speedy twin keel 25-footer capable of crossing many oceans. Christophe Mora and Carina Juhhova are currently in South Africa after sailing L’Envol across the Pacific and Indian oceans. Their progress reports on intothewind.fr are fascinating.

Django 7.70 L’Envol has a scrub in Brazil on her round the world cruise. An aft strut supports the stern. Photo: Christophe Mora

So far Django 7.70 L’Envol has crossed the Atlantic, cruised down the East coast of South America to Patagonia, across the Pacific and sailed the Australian coastline before moving on to South Africa.

The Django range comprises the 6.70 (lifting keel only), the 7.70 (fin or twin keel), 9.80 (fin or twin keel) and 12.70 (fin or lifting keel). The twin keel Django 7.70 that I tested was a total delight.

The future of bilge keel yachts?

So what lies ahead? With only a handful of French yards offering new twin keel boats, there is a dearth of choice in the new boat market. Of course, sailors can always buy second-hand while they await new arrivals. But be sure to get those keel roots surveyed and check rudder and keel bases for grounding damage.

I can’t help thinking that as designers come up with ever improved twin keel designs, something will soon have to give. As British marina costs move beyond the means of many boat owners and French marinas reach maximum capacity, maybe there’s a new twin keel dawn just over the horizon?

Exciting new twin keel designs might even persuade production boat builders to market new boats under 30ft again? Some may even sprout foils and try to fly!

Why not subscribe today?

This feature appeared in the April 2023 edition of Practical Boat Owner . For more articles like this, including DIY, money-saving advice, great boat projects, expert tips and ways to improve your boat’s performance, take out a magazine subscription to Britain’s best-selling boating magazine.

Subscribe, or make a gift for someone else, and you’ll always save at least 30% compared to newsstand prices.

See the latest PBO subscription deals on magazinesdirect.com

Power predictions calculate 85 h.p. to reach the maximum design speed of 14 knots with a powering efficiency of 50%.

Sailboat Keel Types: Illustrated Guide (Bilge, Fin, Full)

The keel type is one of the most important features of your boat. But the different designs can be confusing, so I've set out to create a very clear guide that will help you understand sailboat keels once and for all.

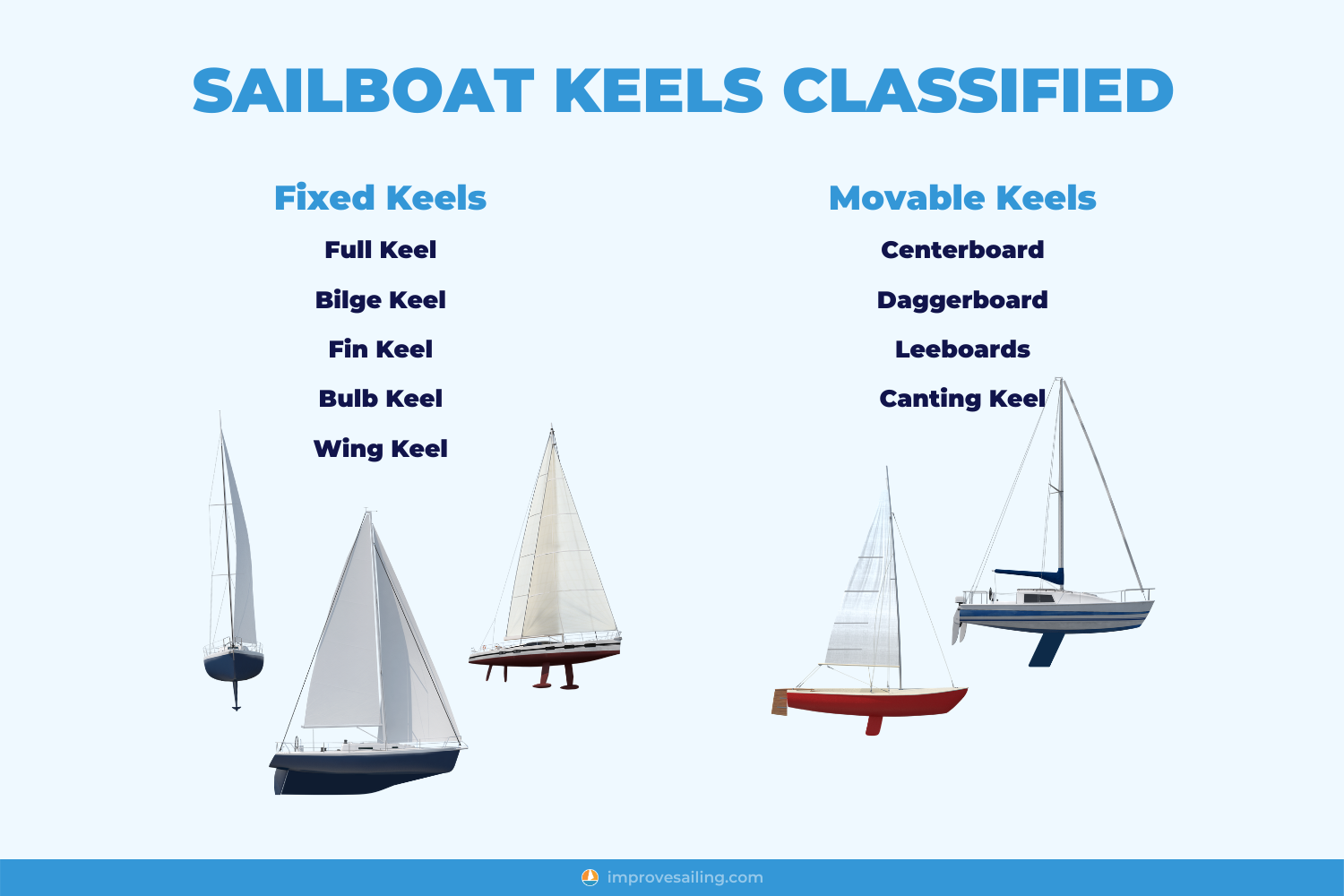

What are the most common sailboat keel types? The most common sailboat keel types are full-length keels, fin keels, bulb keels, wing keels, bilge keels, and lifting keels. Full keels are popular among cruisers, while fin keels are generally used for racing. Bilge keels and lifting keels are typically used in tidal waters, on small fishing boats for example.

In this article, we'll explore the most common keel types together. I'll use diagrams to really hit home the differences of all these keel types, and we'll discuss what keel types are best for liveaboard, ocean cruising, and lake weekend trips. After reading this article, you'll know what to choose - and why.

Sailboat Keels Explained

On this page:, overview of sailboat keel types, keel types: fundamentals, modified full keel, centerboard.

If you just want a quick overview, here's a list with the most common keel types and a short description. More detail will follow below.

The most common keel types

- Full keels run from front to aft and are the most stable keel type, making them the most popular cruising keel.

- Fin keels offer the best performance but are less comfortable. This makes them popular for racing. Fin keels are bolted on to the hull and generally run deep and thin.

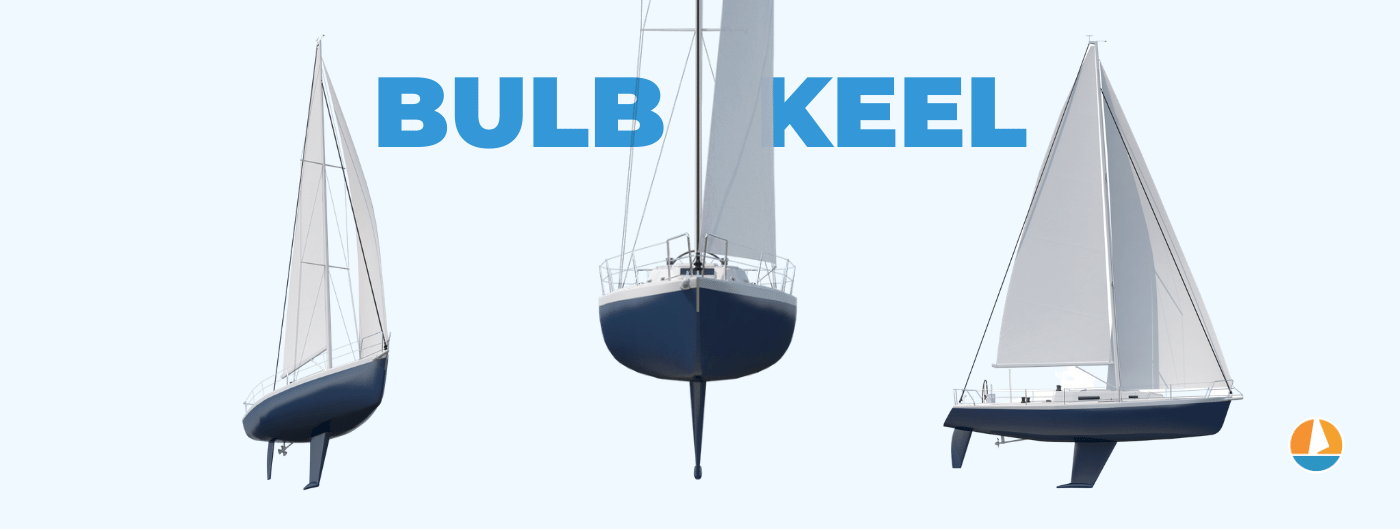

- Bulb and wing keels are both variants on the fin keel.

- Bulb keels carry additional ballast in the tip, making them more stable.

- Wing keels have two tips at the end of the keel, which reduces crossflow, improving directional stability.

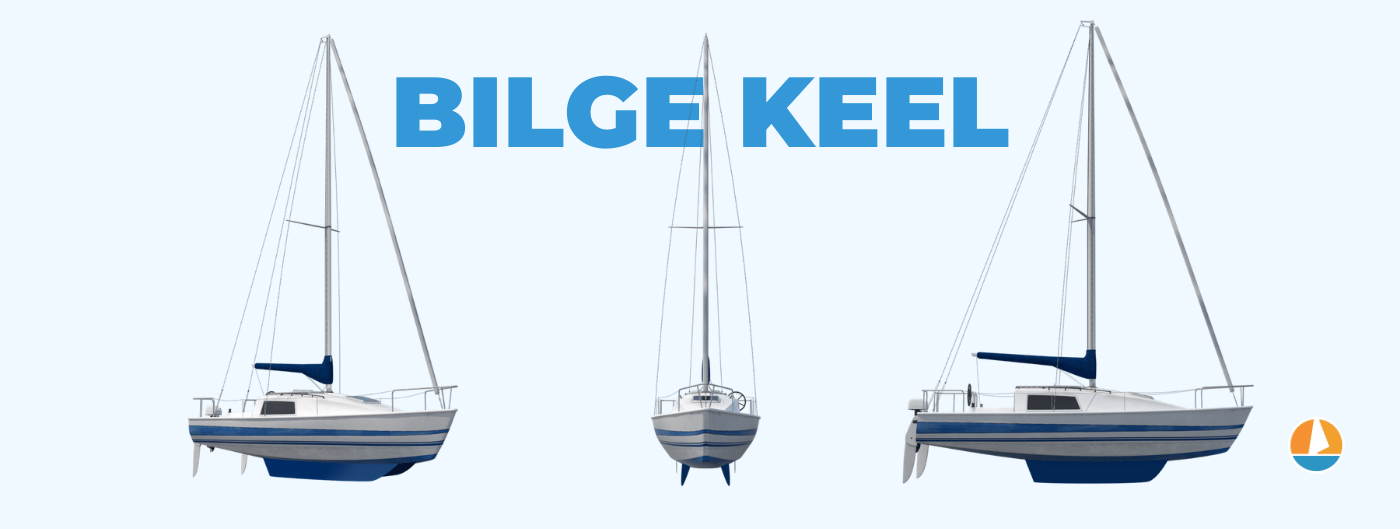

- Bilge keels are double fin or double full kees, which allows the boat to be beached, making them the most popular keel for tidal waters.

- Lifting keels are moveable keels that can be lowered and raised, allowing the boat to enter shallow waters as well.

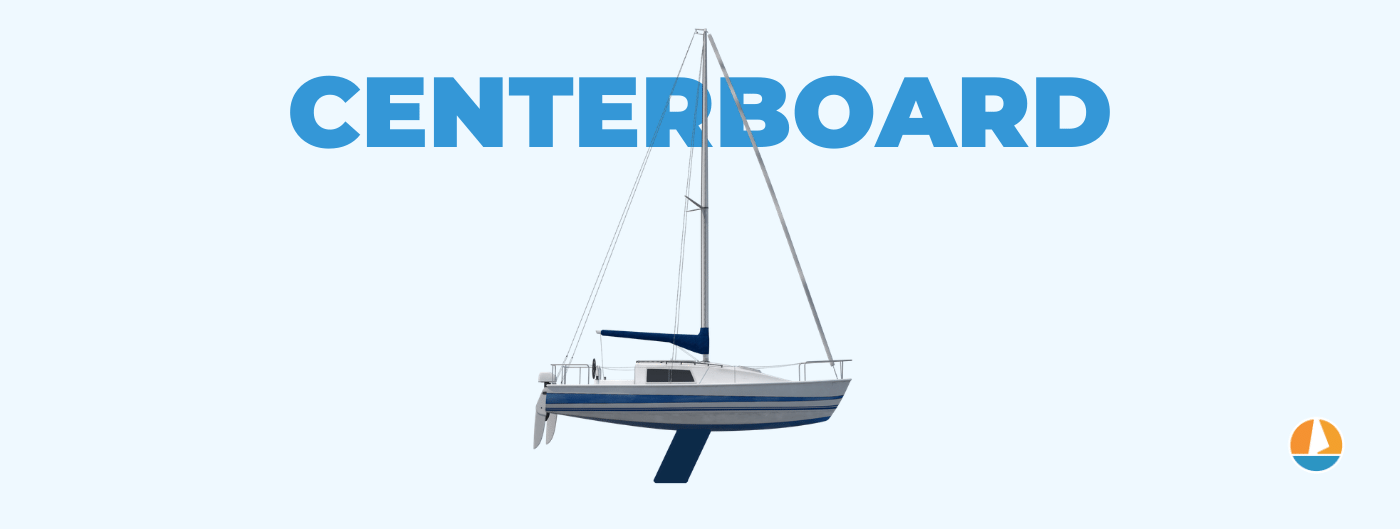

- Centerboard keels are a pivoting lifting keel, allowing to sail both coastal and inland waters.

- Leeboards are fins on the sides of flat-bottomed hulls boats, making a keel unnecessary.

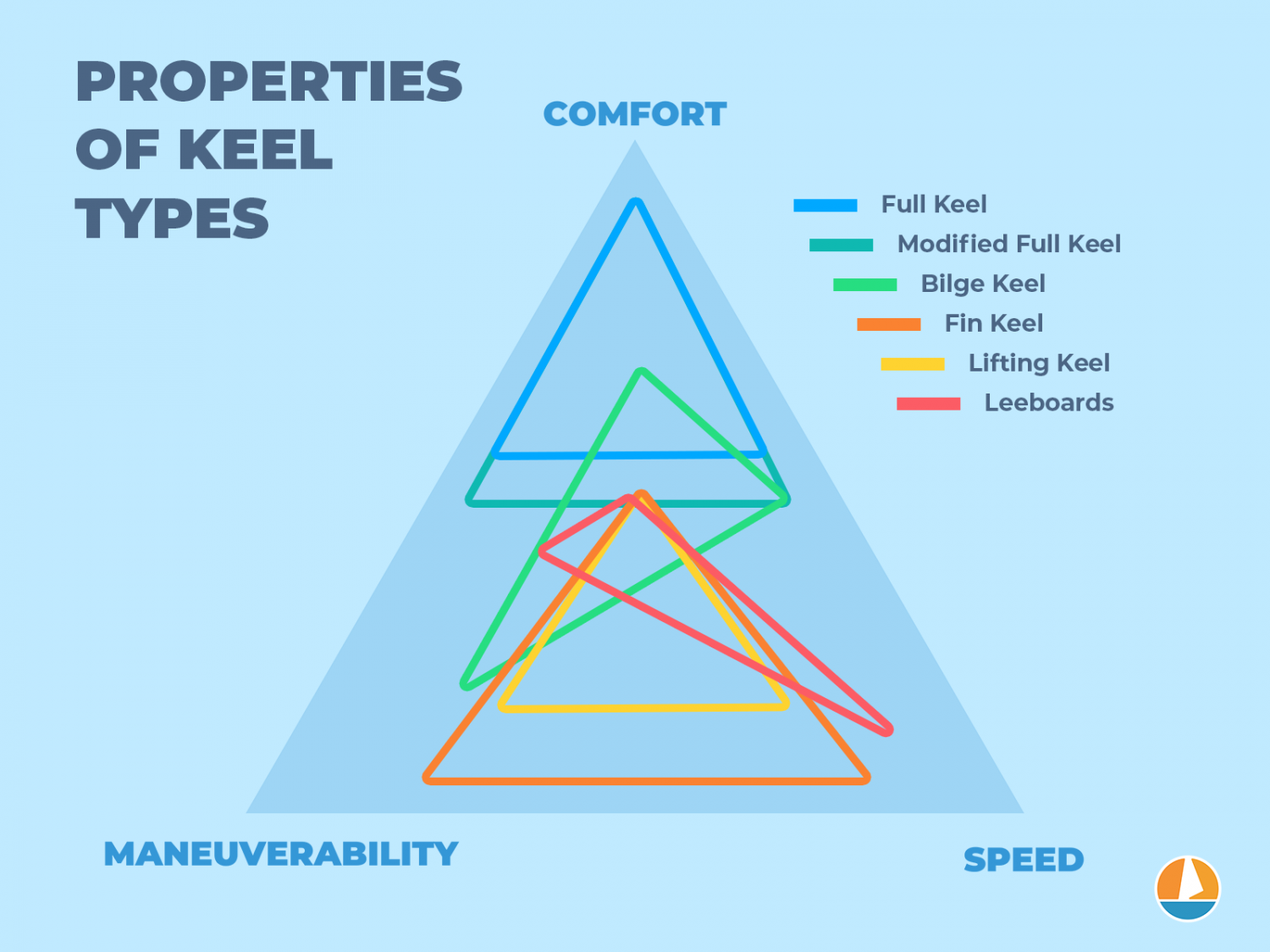

Properties of each keel type

What does a keel do?

What does the keel do? A keel is a vertical blade running down from the hull. It is weighted and acts as a ballast, countering the boat's tendency to heel and preventing it from tipping over. The wetted surface under the waterline reduces slippage to leeward by creating a track, which counters the sideway force of the wind on the sails.

The reason sailboats don't tip over is that the weight of the keel counters the buoyancy of the hull, which means it will pull the boat downward. This downward force reduces heel and prevents the boat from rolling.

A canoe doesn't have a keel. Try stepping into that: it will want to roll.

It counters the horizontal force the wind puts on the sails. Whenever the force on the sails increases, the resistance of the water on the keel increases proportionally.

The heavier the keel, the less heel you'll get.

A keel reduces slippage to leeward. Slippage is simply the amount you fall off course because of the direction of the wind and current. Leeward is the side of the boat behind the wind.

So if you don't have a keel, you will fall off course quite a lot because the wind will push you over the water surface.

You will also heel quite a lot since there is nothing beneath the water surface to counter the force of the wind high up in your sails.

A keel fixes both of these issues and makes sailboats one of the most reliable boats in heavy winds and storms.

You can read on about how keels work here.

Keels can be classified by multiple dimensions. You can look at them from the side or the front. You can also classify them based on properties.

Before I dive into each keel type in-depth and show examples, let's make sure we have the same starting point.

There are essentially two sorts of keels:

Fixed keels

Movable keels.

Fixed keels are keels that are integrated into the hull or bolted on. They can't be moved or lifted.

When looking at fixed keels, you can divide them up further based on the side view. There are three main categories:

Bilge keels

Full keels are more comfortable, provide better stability and protection, but are also slower than fin keels.

Fin keels are less comfortable, provide less stability, are more vulnerable, but they're also a lot faster than full keels.

Bilge keels are double keels: one on each side of the hull. This allows them to be beached, which comes in handy in tidal waters. They are generally a lot slower and less maneuverable compared to fin keels.

Movable keels can be lifted from the water, creating a shoal (shallow) draft, allowing the boat to enter both shallow waters and coastal waters. This makes it a very versatile keel type. There are two main designs:

Lifting keels

Lifting keels can be lowered and raised through a slit in the hull. Examples of lifting keels are the daggerboard and centerboard.

Leeboards are wooden swords attached to the side of the hull and prevent slippage to leeward, but they don't stabilize the boat, nor counter heel by adding ballast.

With fin keels, there are different tip designs available. The most common two tip designs are:

These are both variants of the fin keel. Generally, these keel designs are mentioned in one breath with full keels and fin keels, creating confusion on what kind of keel they are. But it's important to understand that they are a sub-category of fin keels.

Rudder design

As with the tip of the fin, there are different rudder designs that may apply to both fin and full keels. The two most common rudder designs are:

Skeg rudder

Spade rudder.

A skeg is a structural part of the keel in front of the rudder that protects the rudder. The keel encompasses the rudder, preventing any rogue ropes, weeds, or rocks from damaging the rudder.

A spade rudder is an unprotected rudder: it doesn't have any structural protection from the keel design. It is simply attached to the hull. This design is very common.

Alright, we understand the big picture. Let's dive into more detail for each keel type and discuss the pros and cons.

Fixed keel Good for cruising and liveaboards Comfortable

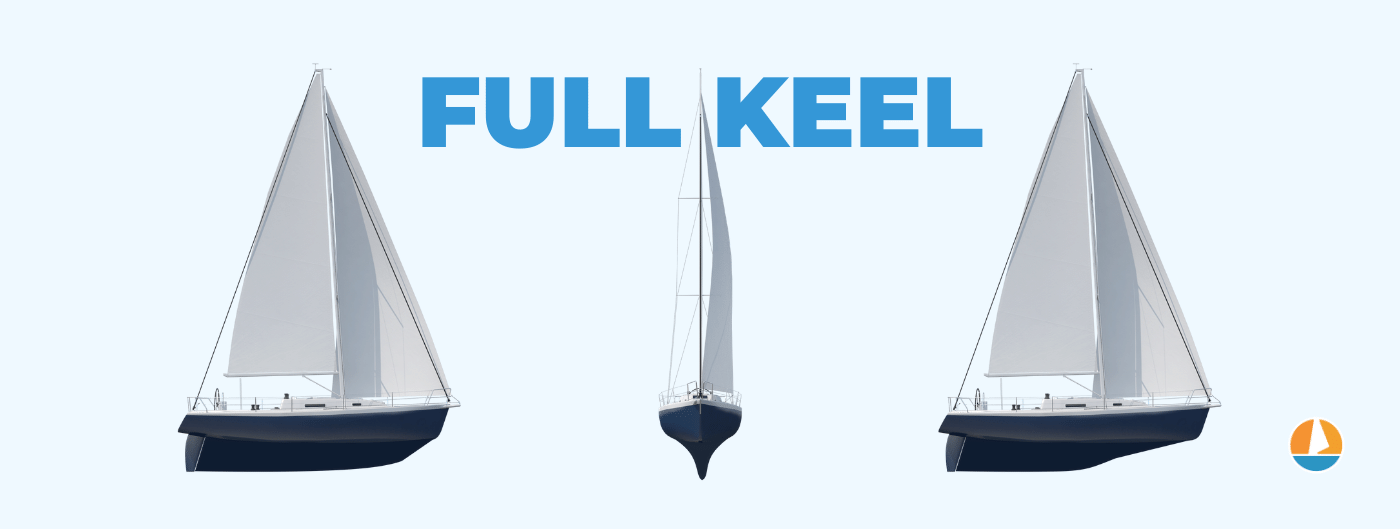

What is a full keel? A full keel runs from front to aft for at least 50% of the hull and is fully integrated into the hull. It has the largest wetted surface of any keel type, and it is also the heaviest. This results in directional stability and reduced heeling, providing the most comfortable ride, but also the slowest.

The wetted surface simply means the amount of water contact area. With such a large wetted surface, it decreases slippage to leeward the most of all keel types, while it counters heeling the most as well.

The full keel is the most comfortable and stable keel type available. However, comfort comes at a price. It delivers the worst performance due to this large wetted area. It is the slowest of the keel types, and it has the worst windward performance.

This makes full keels particularly great for longtime cruisers or liveaboards who prefer comfort over speed, but less ideal for daysailers who need to navigate in and out of slips regularly.

Since it runs for at least 50% of the hull, it doesn't need to run as deep as a fin keel, resulting in a more shoal draft.

Heavier keels result in increased displacement, so a full keel boat will need a larger sail area to compensate for its weight.

For a more detailed discussion on full keel advantages, I recommend reading William's excellent article 5 Surprising Advantages of a Full Keel Sailboat here.

Example sailboats with a full keel:

- Nicholson 22

- Island Packet 380

- Beneteau Oceanis 411 Clipper

- Beneteau First 50

- Jeanneau Sun Shine 38

- Dufour 455 Grand Large

There are a lot of great cruising boats with full keel designs , some of them considered classics.

Full Keel with skeg rudder

Full keels with a skeg rudder design have a protected rudder, thanks to putting a structural part of the keel directly in front of the rudder. This helps with fending off any hazards to the rudder, like floating pieces of rope, rocks, or garbage, and protects it in case of running aground. The skeg design ensures the rudder is nearly impossible to break off.

Fixed keel Good for cruising and liveaboards Faster than a regular full keel

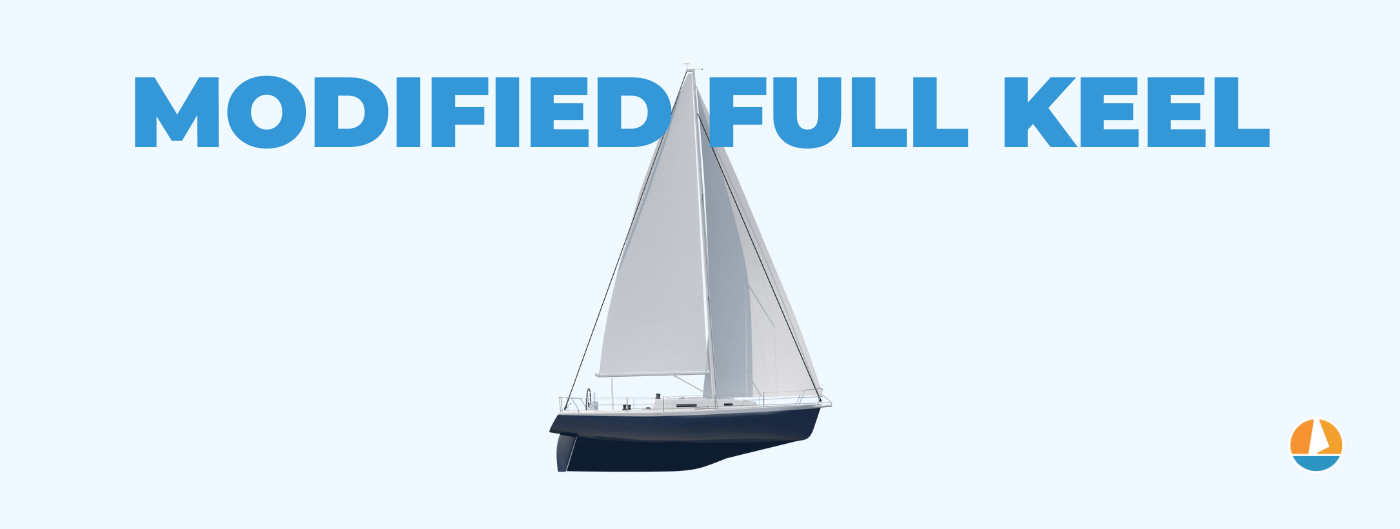

What is a modified full keel? A modified full keel is a full keel with a cutout at the front, reducing the wetted surface slightly, which increases performance without sacrificing too much comfort and stability. After the full keel, it has the best directional stability and the least amount of heel.

The modified full keel is popular among (bluewater) cruisers, thanks to its increased handling and performance. Most modified full keels have a skeg rudder, ensuring it is well-protected.

The slightly reduced weight and wetted surface improve windward performance quite a lot, but it is still one of the most stable keel designs out there.

Example sailboats with a modified full keel:

- Hallberg-Rassy HR 40

- Dufour Arpege 30

- Beneteau Oceanis Clipper 281

- Jeanneau Sun Odyssey 37.2

Fixed keel Good for racing Fast

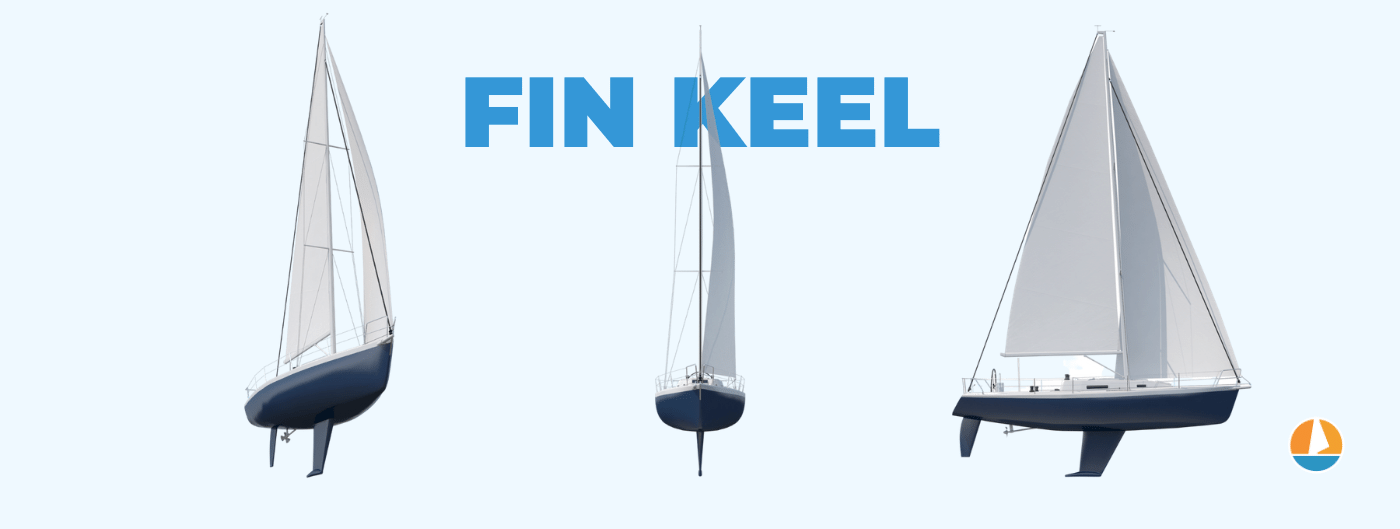

What is a fin keel? A fin keel is a long, weighted blade attached to the bottom of the hull. It is lighter, faster, and more maneuverable than a full keel, but also more vulnerable. The increased distance between ballast and sails provides a lever, reducing the need for a large wetted surface or additional ballast.

Fin keels are generally bolted onto the hull and run deeper and thinner than a full keel. They are also lighter. This helps increasing performance (a lot), making fin keels a lot faster in all situations.

There are some major disadvantages to fin keels, however. Fin keels are a lot less comfortable than full keels and allow for more heel and a less solid track, so less directional stability. Fin keels are also a lot more vulnerable than full keels. They can break off when running aground, or get damaged.

They are very popular among racers and perform better when maneuvering in tight spots, like getting in and out of slips.

Example sailboats with a fin keel:

- Catalina 30

- Jeanneau Sun Odyssey 36.2

Fin keel with skeg rudder

Fin keels with a skeg rudder use a small structural part in front of the rudder to protect it. This design is mostly integrated into the hull, making it less vulnerable, and a great compromise between speed and safety.

Fin keel with spade rudder

Fin keels with a spade rudder have a completely exposed rudder, and typically a fin that is simply bolted on. The keel isn't integrated into the hull, making it more vulnerable and less comfortable.

Fin keel variant Good for cruising Less crossflow

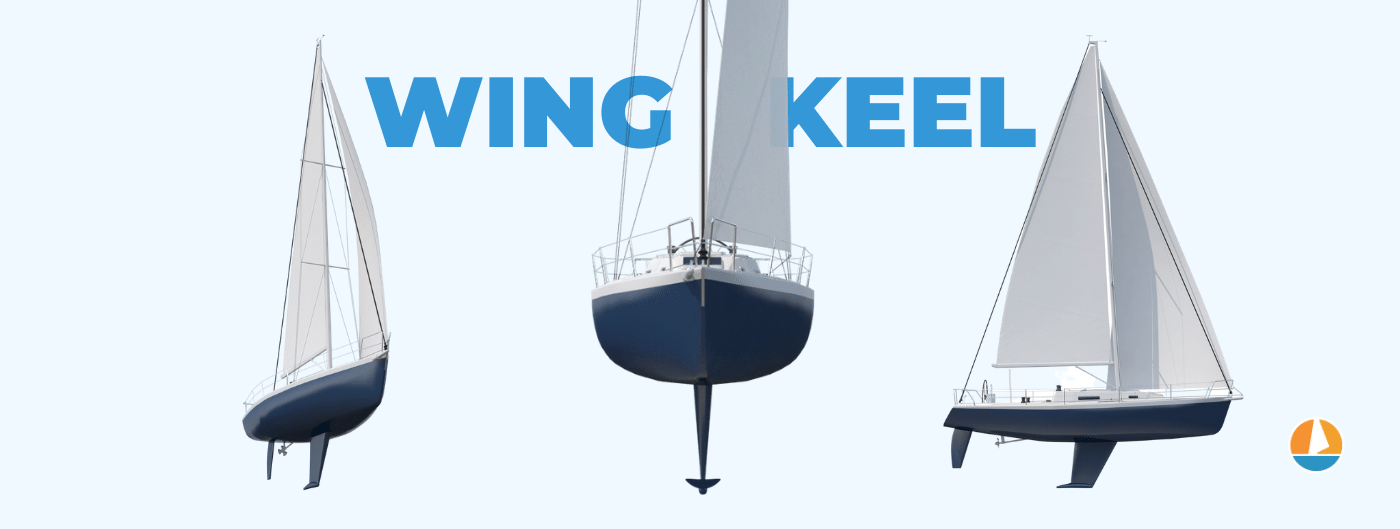

What is a wing keel? A wing keel is a fin keel with a horizontal foil at the tip, which is wing-shaped and generally weighted. Its shape reduces crossflow, improving directional stability, and its ballast decreases heel, resulting in a more comfortable ride. The addition of a wingtip allows for a shorter fin, reducing draft.

Wing keels are good for cruising since this design improves directional stability compared to a regular fin keel or a bulb keel.

We'll discuss the wing keel's advantages and disadvantages in more detail in this article.

Fin keel variant Good for cruising Stability

What is a bulb keel? A bulb keel is a high-aspect-ratio fin keel with additional ballast at the end, which generally has a bulb or teardrop shape. This ballast improves stability and utilizes the distance between force and counterforce as a lever. This design reduces the need for a deep fin, resulting in a shoal draft.

By placing the weight at the largest possible distance from the force on the sails, you need relatively little extra weight for the same reduction in heel, making bulb keels very effective for cruising.

This design reduces the wetted area while increasing the weight of the keel just slightly, which increases sailing comfort big time.

Example sailboats with a bulb keel:

- Bavaria B/One

- Beneteau First 24

Fixed keel Good for racing Can be beached

What is a bilge keel? A bilge keel is a twin keel which uses double fins, allowing the boat to be beached and rest on its keel upright. Bilge keels have double the wetted surface, which increases comfort and directional stability while decreasing heel. Modern bilge keels often provide decent windward performance, thanks to better design.

The bilge keel does sacrifice speed compared to the fin keel but doesn't necessarily offer worse performance overall. Older designs performed considerably worse than other keels and were especially slow.

Bilge keels have some major advantages over full keels and fin keels. The most important is that the boat can be beached, making it a popular design in tidal waters. Bilge keels are especially common along the British coastline, where fishermen keep their boats in tidal harbors.

Another major advantage is that the boat can be stored resting on its keels, making dry storage and maintenance a lot easier.

Of course, there are many more pros and cons to the bilge keel , which we go into here.

Example sailboats with a bilge keel:

- Dufour Dynamique 62

- Hunter Duette

- Patagonia Patago 39

- Macwester 27

Lifting keel Good for daysailers Versatile

What is a centerboard? A centerboard is a type of retractable keel that rests on a hinge and can be lowered through a slot in the hull. It folds out like a pocket knife and allows you to increase or reduce the draft of the boat. Centerboards are mostly used on small fishing boats.

The centerboard is a very versatile keel type, allowing you to have both a very shoal draft for inland waters, as well as steadying the boat and reducing heel for larger bodies of water, or even oceans.

I've sailed a Cornish Crabber with a centerboard for a week, and while we stayed inland, having the option to increase the keel depth really came in handy when crossing the IJsselmeer (a former sea in The Netherlands).

There's more to the center

Olaf Roethele

https://www.theyachtmarket.com/en/new-boats/cornish-crabbers/adventure-17/218/

My name is Olaf and I am the owner of a Cornish Crabber 17 Adventure boat.

I would like to ask you if you can imagine to install on this boat a Torqeedo 2.0 Pod motor? Therefore i guess a modification of the keel/skeg is necessary ?!

Best regards from Uruguay,

You completely missed the hybrid planing/water-ballast keel of the Macgregor range

Thanks a lot for this explanation

Roger Bannon

Very well written article which provides an excellent guide for us small wooden boat builders. Thanks.

Leave a comment

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

Professional BoatBuilder Magazine

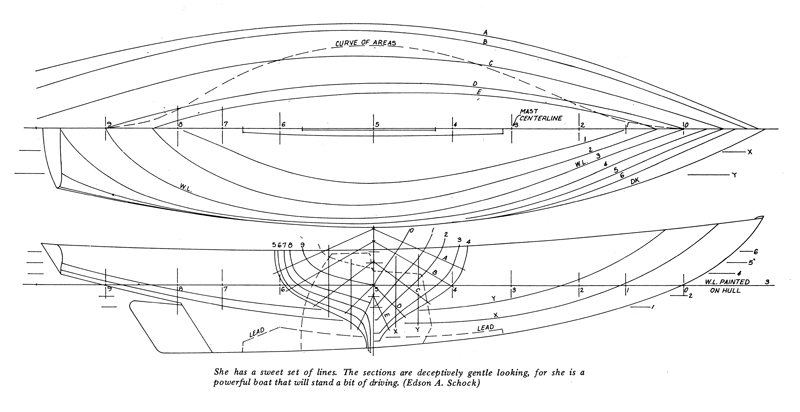

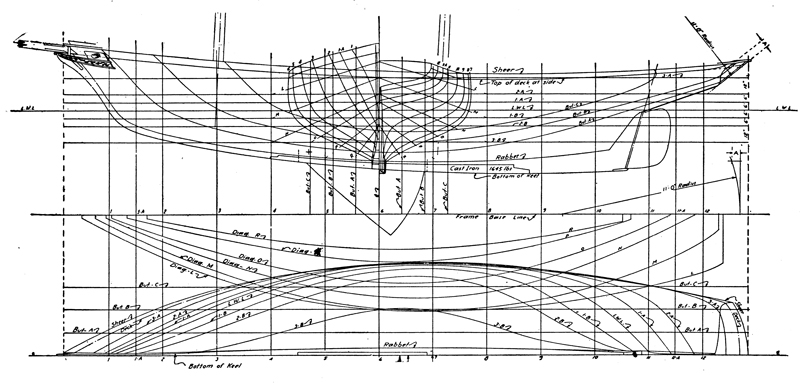

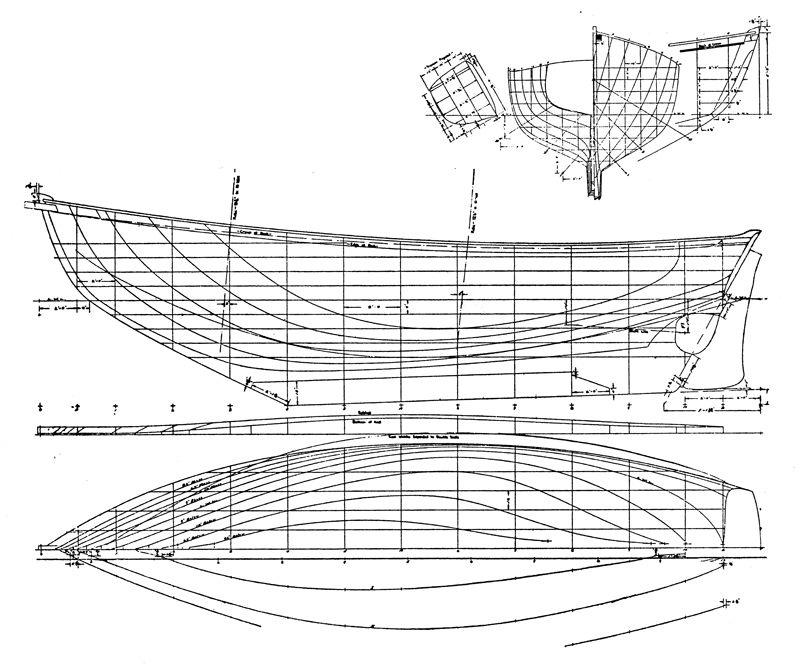

Notes on sailing-yacht hullforms, part 2.

By Jay Paris , Mar 22, 2022

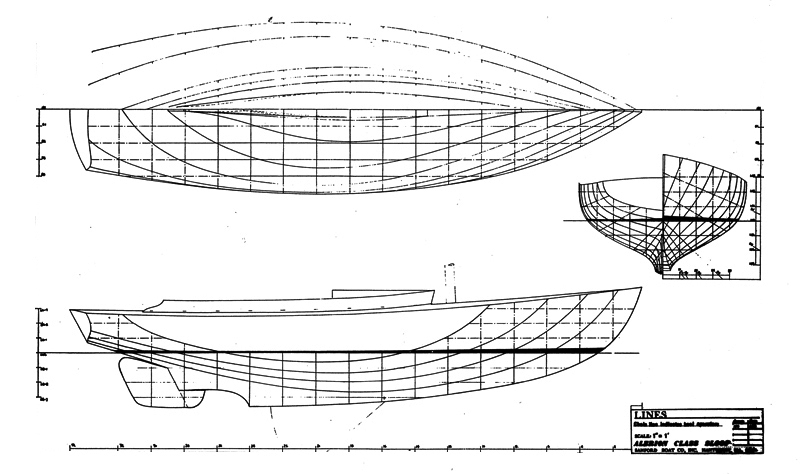

In “Notes on Sailing-Yacht Hullforms” ( Professional BoatBuilder No. 196, page 32) naval architect Jay Paris, citing drawings and photographs of his own designs as well as the lines of other designers, detailed some characteristics, attributes, and design methods used to develop monohull sailboat hullforms. Because of space constraints in the print magazine, we are publishing Paris’s additional notes and reference material on Proboat.com. In addition to his sections on fin-keel variants and parent hullforms, Paris includes a reference list of hullforms worthy of note for a number of reasons—aesthetics, excellence as examples of their type, historic significance, or design methodology. All but one of the hullforms in this Part 2 are round bottomed, and all the yachts cited, which were built during the past century, are wooden boat designs. The lengths for the hullforms in this article are length of hull (LOH) since length overall (LOA) includes extensions to the hull such as bowsprits and boomkins and length on deck (LOD) is often less than the hull due to bulwarks and reverse transoms. —Ed.

Twin-Keel and Retracting-Foil Variants

A variant of the fin-keel design is the twin-keel. Most common on coastal cruisers intended to take the ground when the tide is out, they reflect an empirical approach to their design. A few are serious offshore passagemakers, including the noteworthy Bluebird of Thorne .

This design is the combination of Robb’s talent and tank testing along with Lord Riverdale’s experience with his previous Bluebirds when he was R.A, Balfour. Bluebird of Thorne ’s keels canted outboard at 20°, and normal to her near circular midsection, were low aspect ratio, highly swept back asymmetrical foils that Robb implied were towed inboard and certainly were more sophisticated than those of almost all other twin keelers. Robb’s strong favorable opinions about this design concept have been frequently quoted in detail.

A more current fin-keel variation is the use of canting keels, with or without lift-generating sections, employed on offshore racers to shift the ballast bulb to weather to increase their righting moments.

Parent Sailing-Yacht Hullforms and Evolution

Historically, designers have used specific earlier boats as the basis for follow-on designs, in some cases very closely but with changes in the overall size and proportions. For example, Nathanael Greene Herreshoff had noticeable success using his 26 ’ (7.92m) Alerion III NGH 718 of 1912 as the parent for designs as large as the 33.42 ’ (10.19m) Newport 29 of 1914 and the 43.25 ’ (13.18m) Fishers Island 31, designed by his son Sidney using NGH’s offsets.

The lines shown incorporate the cutaway deadwood aft with a balance portion of the rudder forward of the rudderstock as found in the Alerion copies by the Sanford Boat Company. Eliminating these features would restore the lines to the original NGH configuration.

Maynard Bray, in his book Aida , includes a photograph of Herreshoff’s offset booklet pages used in the mathematical expansion to create the 33.67 ’ (10.26m) Aida of 1926. The Buzzards Bay 25 of 1914 looks perhaps to be the least likely of being an Alerion derivative.

L.F. Herreshoff said the Buzzard’s Bay 25 was his favorite of his father’s designs.

Another famous parent hullform is the Pilot S&S 539, 32.92 ’ (10.03m) wooden stock class sloop of 1945. Olin Stephens wrote in Lines 2002 that the Pilot was “drawn in the Boston office by K. Aage Nielsen, who was, in theory, working under my supervision.” The later S&S 1727 fiberglass version from the New York office was lengthened to 36.07 ’ (10.99m).

Since there are not lines available in my references for the 1962 Pilot, this rendering by Al Mason gives a good sense of her hullform. Mason drew perspectives for many S&S designs.

The beautiful Anitra S&S 1358 48.42 ‘ (14.76m) yawl of 1958, the largest of the Pilot family, was the overall winner of the 1959 Fastnet Race.

In my own practice, The Paris Design P-32 (9.75m) Petrel is the parent of the later P-37, G-37, and OCC-47 designs.

While the P-32 hullform had many atypical features, a number of them were optimized for her longitudinally framed wood-foam-wood composite construction.

The P-32’s longitudinals are shown fitted into the molds setup at her stations. The clamps and longitudinals are laminated mahogany with the latter located on her waterlines ready for the double-diagonal planking to be glued and fastened. The temporary pine longitudinals in the underbody will be protected from any glue by duct tape prior to the first layer of planks being installed. The staples into the longitudinals are pulled as the second layer of planking is glued and stapled to the first. All permanent staples are Monel. The uppermost pine longitudinals are just above the tops of the bulwarks.

Those using state-of-the-art yacht design software often morph parents to the extent that their design “DNA” is no longer apparent.

Hullform evolution is similar but less slavishly derivative than the use of parent hullforms. The Viking ships of a thousand years ago are candidates for the most elegant hullforms of all time. The Scandinavian preference for double-enders has followed this fashion in some degree to modern times. Colin Archer’s Redningsskoite (rescue boats), which evolved from them, have inspired designers to this day. William Atkin’s 38 ’ (11.58m) ketch Ingrid , his highly refined granddaughter of this type, is considered to be one of his best designs.

Ingrid ’s fine lines with a wineglass midsection and 6 tons of outside and internal ballast contribute to the design’s good performance.

Knud Reimers’s Cohoe is a 1932, 32 ’ enlargement of his famous and beautiful 27 ’ (8.23m) Tumlare of 1927. These designs introduced lighter displacement and finer lines than earlier Scandinavian double-enders. Many consider the Tumlares to have the most beautiful hullforms of all time.

Knud Reimers, well-known for his Square-Meter boats, applied the same design philosophy to this double-ended cruiser. Reimers and I discussed his diagonals and contracted fairing approach during a week of sailing in the early 1970s.

A small Danish fishing boat type with very full sterns typical of the sound north of Copenhagen was the parent of the Spidsgatter classes of sailing yachts. Aage Nielsen, a Dane, was familiar with the type. Some of his smaller designs from 15 ’ to 26 ’ (4.57m to 7.92m) were referred to as Nielsenized Spidsgatters. Their full sterns were models for that of Holger Danske , his 42.5’ (12.95m) cruising ketch that won the 1980 Newport-to-Bermuda Race by a large margin.

One of Aage Nielsen’s favorite designs, Holger Danske , had a slippery hull, a low rating, and sailed like fury on a reach.

Over time, many working craft have served as models for sailing yachts. The danger, at times, has been designers ignoring the original function, loading, and the wind and sea conditions for which working craft were developed.

Design evolution can also be seen amongst ocean racers. Olin Stephens’s Stormy Weather came seven years after the famous Dorade of 1929, which had introduced the forms of his earlier inshore Six-Meter designs to the offshore world. These two sisters established a trend for blended-body ocean racers for some four decades.

Stormy Weather , slightly longer than Dorade , of similar displacement but with 22% more beam, was a favorite of her designer.

Sources From My Library

Starting before high school with the original five Uffa Fox books of 1934/1938, my office library has grown to almost a thousand books on sailing and sailing yachts with most containing technical material as well as numerous technical reports. I also have some 100 volumes addressing hydrodynamics, aerodynamics, and aerospace design containing material applicable to sailing yachts not addressed in yachting publications.

Lines drawings from my library that I consider worthy of note and reference but not embedded in the text are shown below with captions and sources. Note: Lines in the early five Uffa Fox books were redrawn by Fox.

Starling Burgess. Nina , 59’ Staysail Schooner, 1928.

Just one of Starling Burgess’s many beautiful sets of lines from the multi-talented aviation pioneer and yacht designer. Nina ’s blended body hullform was a very early example of the long waterline with short overhangs concept currently (2022) in vogue.

Howard I. Chapelle. Clipper-Bowed Centerboarder, 1936

Howard I. Chapelle was an eminent yacht designer and a historian who chronicled the designs of American working sailing craft. He chose a traditional clipper-bowed centerboarder to illustrate the steps in developing a lines drawing in his classic text on design of 1936.

Frederick A. Fenger. Diablesse , 38’ Wishbone Ketch, 1935

Frederick Fenger was an advocate of the dhow hullform with its unusual maximum draft near the bow. Diablesse ’s maximum draft was 23% of the waterline abaft the bow. Her forebody had V-shaped sections, hollow waterlines, and easy diagonals.

William Garden. Oceanus , 60’ Narrow Doubled-Ended Sloop, 1954

An example of a designer’s atypical boat for himself. An elegant, narrow sixty-footer (18.29m) intended for a crew of two, Garden and his wife. Interestingly, to quote an article in the January 1961 issue of Motor Boating : “ Oceanus was launched bottom up; there were considerable advantages in building her hull that way, and she was run into the water, parbuckled, and pumped out at insignificant cost and no risk compared with the tricky job of turning a hull of that size on shore.”

N.G. Herreshoff. Aida , 33.67’ Keel/Centerboard Yawl, 1926

Lines drawn by Doug Hylan from Original HMC 1002 Offsets. For the subtitle of his book, Maynard Bray wrote, “N.G. Herreshoff’s finest shallow-draft yawl.” Adding to the praise is the quote in the Preface that L. Francis Herreshoff called her “probably the finest boat of her size in the world.” In his book, Bray documents the evolution of Aida from Alerion through Pleasure NGH 907, the second of his shallow keel/centerboarders with low-aspect-ratio triangular foils.

L. Francis Herreshoff. Rozinante , 24’ Canoe Yawl (Ketch Rig), 1956

LFH’s graceful and leaner interpretation of the English canoe yawl was the only example of its type to be widely seen on American waters. Roger Taylor quoted LFH: “A canoe yawl can be about the safest that can be had since her design is based on those most seaworthy open boats ever known—whaleboats.”

George Holmes. Trent , 25’ Canoe Yawl, 1910

George Holmes, a designer and artist, was in the forefront of the English canoe yawl world. The term canoe yawl deserves explanation. It has nothing to do with the rig but rather with size, it being the same size or smaller than a ship’s yawl boat. The term canoe relates to it being either a day boat or coastal cruiser.

Robert Perry. Amati , 40’ High-Aspect-Ratio Fin-Keel, Spade-Rudder, Wood-Foam-Wood Composite, Fast Cruising Sloop, 1999

A significant departure from Perry’s early double-enders, this is one of his light-displacement sleds, for a couple with the emphasis on off-the-wind speed. His early designs were often double enders including the iconic Valiant with its full-ended cruiser stern. The term cruiser stern refers to the sterns on the cruiser class of warships prior to World War II.

Knud Riemers. Moose , 43.0’ 30-Square-Meter Sloop, 1934

Moose was the 1935 US 30-Square-Meter champion. Uffa Fox stated in 1936 that she was “probably the finest example of a 30-Square-Meter in the world.”

Sparkman & Stephens. Babe , 30.5’ Fractional Sloop, 1935

Babe , a favorite of Olin Stephens, was one of the 49 designs he illustrated and commented on in his book Lines. The modern S&S 30, purported to be an update of Babe and assigned a “1935” based design number 97-c2, has nothing in common with the original’s hullform.

Sparkman & Stephens. 1834 Intrepid , 64.25’ 12-Meter Sloop, 1967

Although conventional thinking states that deep draft is required for optimal windward performance, the heavily ballasted 12-Meters with minimal salient keel prove the exception. While articles about S&S designs often stated new from the board of OJS, it was not so during my time at the Madison Ave. office. Olin’s board did not have any room for drawings, so he would come into the main portion of the office to review a designer’s work and suggest changes, for example, to Mario Tarabocchia’s 12-Meter lines. I had the privilege of being involved in this process with the preliminary design of S&S 1770 Ta Aroa a New Zealand A Class racer. Olin had me start with a 5.5 meter’s lines, doubling their size, and proceeding under his guidance.

E.G. van de Stadt. Zeevalk , 41’ V-Bottom Plywood, Fin-Keel, Spade-Rudder, Fractional Sloop, 1949

This second design of E.G. van de Stadt’s and the first for Bruynzeel established his reputation as an innovative designer with a preference for fin-keel, spade-rudder configurations. This perspective or isometric illustrates Zeevalk ’s V-bottom hullform and the short-chord trim tab on the trailing edge of her fin keel.

Joel White. Dragonera , JW Design 49 74’ Fin-Keel Ketch, 1993

Joel White’s designs varied from traditional hullforms and construction in the fashion of Herreshoff and Nielsen to cold-molded fin keel types.

Jay Paris Designs:

No. 10 Aeromarine 50, 50 ’ Tall Mizzen Ketch 1968

No. 24 Lone Star, 54 ’ LOH Clipper Bow Ketch 1976

No. 27 Freedom 33, 33 ’ Cat Ketch for Gary Hoyt 1977

No. 33 P-32, 32 ’ Keel/Centerboard Sloop 1982

No. 40 P-45/Y-45, 45 ’ Ketch for YW/CW Contests 1988

No. 43 OCC/Sail, 43 ’ Sloop for Sail Article 1992 (An Ocean Cruising Club member survey design)

No. 48 P-37, Yawl for IBEX and METS Lectures 2007

No. 51 G-37, Keel/CB Yawl for a CCA Lecture 2014

No. 53 OCC-47, Keel/Centerboard Ketch 2018 (A rethink of the 1992 OCC member survey requirements)

Lines Drawings Reading List

In the following books, design examples illustrate the step-by-step creation of the lines reflecting the hullforms in fashion when the texts were written:

Chapelle, Howard I. Yacht Designing and Planning , 1936.

Clipper Bow 33.33 ’ DWL Shoal-Draft Centerboarder.

Kinney, Francis. Skene’s Elements of Yacht Design , 8th Ed., 1973.

Pipe Dream 25.42 ’ DWL Cruising Yacht.

Phillips-Birt, Douglas. Sailing Yacht Design , 3rd Ed., 1966 and 1976.

Full Keel 30 ’ DWL Fast Cruiser Including design using Diagonals.

Larsson, Lars and Rolf Eliasson. Principals of Yacht Design . 3rd/4th Eds., 2007 and 2014.

YD-40 39.5 ’ 2007 and YD-41 41 ’ 2014 Fin Keel Fast Cruising Yachts.

These books discuss various technical design details and parameters used by yacht designers:

Brewer, Ted. Ted Brewer Explains Sailboat Design , 1985.

Killing, Steve. Yacht Design Explained , 1998.

Perry, Robert H. Yacht Design According to Perry , 2008.

For a more theoretical explanation of the factors influencing sailing yacht design, I recommend:

Marchaj, C.A. Sailing Theory and Practice , 2nd Ed., 1982.

Marchaj, C.A. Seaworthiness: The Forgotten Factor , 1996.

Fossati, Fabio. Aero-Hydrodynamics and the Performance of Sailing Yachts , 2007.

Slooff, J.W. The Aero- and Hydrodynamics of Keel Yachts , 2015.

Bruce, Peter. Heavy Weather Sailing , 7th Ed., 2016.

About the Author: While attending Webb Institute Jay Paris worked two winters and one summer at Sparkman & Stephens. His graduate studies at MIT focused mostly on oceanography and research-vessel design. He also managed the MIT towing tank and operations of the yacht-testing program and participated in the international investigations into the 1979 Fastnet Race disaster. After MIT he was involved in the design of winches for the America’s Cup and high-end racing yachts, the design and construction of various sailboats, and the writing and editing of articles on sailing yachts for a number of different journals.

Read more Design , Drawing Board articles

- Amphfoil marries Air Props and Hydrofoils

In the wake of the Miami International Boat Show in February, longtime builder of quality cruising sailboats Shannon Boat Company of Bristol, Rhode Island, announced the rollout of the Amphfoil… Read more »

Departures: Carl Chamberlin

Passionate, competent, considerate, modest, and thoughtful is how designer and boatbuilder Carl Chamberlin is remembered by those who knew him. He died last November at age of 75 in Port… Read more »

SNAME Powerboat Symposium Is Back

The Society of Naval Architects and Marine Engineers (SNAME) Technical and Research Program, in cooperation with the Hampton Roads, Virginia Section of SNAME, will host the Sixth Annual Powerboat Symposium… Read more »

Recent Posts

- Rybovich Refit Revisited

- There was Only One Partner I’d Trust for the Refurb Project of my Life: AkzoNobel

- Citimarine Store Expands to a New State of the Art Location in Miami

- Find out how 3D printing can help your boatbuilding with MASSIVIT

- Companies (86)

- Construction (107)

- Design (162)

- Drawing Board (11)

- Education (25)

- Environment (16)

- Events (21)

- Materials (50)

- Obituary (18)

- People/Profiles (49)

- Products (16)

- Propulsion Systems (33)

- Racing (16)

- Repair (37)

- Rovings (319)

- Short Cuts (3)

- Sponsored Partner News (17)

- Systems (80)

- Task Sheet (1)

- Uncategorized (26)

- Wood to Glass (7)

ProBoat.com Archives

Yachting Monthly

- Digital edition

Boat handling: How to use your yacht’s hull shape to your advantage

- Toby Heppell

- October 8, 2021

Whether you have a long keel or twin keel rudders, there will be pros and cons when it comes to performance. Toby Heppell explores three boats' differences

Boat handling: how to use your yacht’s hull shape to your advantage

Ask any sailor to explain the differing characteristics of hull shapes and they will be full of opinions about the advantages and disadvantages of one boat or another.

But these views are usually clouded by past experience and bias.

To a degree the vast array of opinions on offer about any given design choice support the need for such a variety of hull shapes, keel choices, rudder types and so on.

Every yacht ever designed is right for someone out there in the world.

Given these deeply held biases, it can be difficult to get accurate representations of what the compromises and benefits that come from certain boat designs actually are.

Taking a data-driven approach to this question can be a very difficult task indeed, so naturally YM set out to do just that.

Raw data may seem dull, but understanding your boat’s numbers can improve your sailing and your boat handling

We set an objective to take three types of boat, broadly reflecting eras of design, and put them through their paces on the water in an attempt to find the idiosyncrasies inherent in each design and measure them.

Although far from a comprehensive overview of all design options available, the three representative styles we settled on were: a long keel with keel-hung rudder, a medium displacement fin keel and skeg, and a modern, wide hull with twin rudders.

We felt these gave a representation of the broad direction in design over the last 50 years, though there are many permutations of hull and keel that were not included.

In an ideal world, we’d have three boats built to the same length at the same time, by the same designer with only the differences listed above to speak of.

However, our proposal for commissioning, designing, building and sailing three brand new yachts for a comparative test was inexplicably shot down by senior management, so we did the next best thing and called up three owners, each with different style of boat to come to Lymington for the day.

We ended up with a Contessa 26, Rustler 37 and Jeanneau 389, and took our chances with the weather.

Boat handling: The three yachts:

Jeanneau Sun Odyssey 389

Credit: Graham Snook

High-volume hull with lift keel, twin rudders and sail drive

- Name: Windcatcher

- Owner: Flexisail.com

- Designer: Marc Lombard

- LOA: 11.75m/38ft 6in

- LWL: 10.40m/34ft 1in

- Beam: 3.76 m/12ft 4in

- Draught: 1.10m-2,25m/ 3ft 7in-7ft 4in

- Displ: 6,920kg/15,256 lbs

- Ballast: 1,769kg/3,900 lbs

- Sail area: 70 m2/754 sq ft

- SA/disp: 19.68

Medium displacement, fin keel and keg-hung rudder

- Name: Andrilott II

- Owner: Tim Stevenson

- Designer: Stephen Jones

- LOA: 11.28 m/37ft 0in

- LWL: 9.07m/29ft 9in

- Draught: 1.91m/6ft 3 in

- Disp: 8,845kg/19500 lbs

- Ballast: 3175kg/7000 lbs

- Sail area: 81 m2/ 871 sq ft

- SA/disp: 19.31

Contessa 26

Long keel with keel-hung rudder

- Name: Brizo

- Owner: George Smith

- Designer: David Sadler

- LOA: 7.77m/25ft 6in

- LWL: 6.10m/20ft 0in

- Beam: 2.29 m/7ft 6in

- Draught: 1.21m/4ft 0in

- Disp: 2,449kg/5,400 lbs

- Ballast: 1,043kg/2,300 lbs

- Sail area: 22m2/244 sq ft

- SA/disp: 12.15

How hull shape affects boat handling: methodology

Our aim was to try to make comparisons between the styles of boat without comparing the boats themselves.

Our interest was not in finding out if a Contessa 26 outpoints a Jeanneau 389, rather trying to get to grips with the key characteristics of the different styles, what they delivered in data, and also to evaluate each style of hull with as unbiased a gaze as we could muster.

Sailing the boats against one another is always going to be difficult as the sail setup and rig has such an impact on performance.

Toby notes the Contessa 26’s data. Credit: Graham Snook

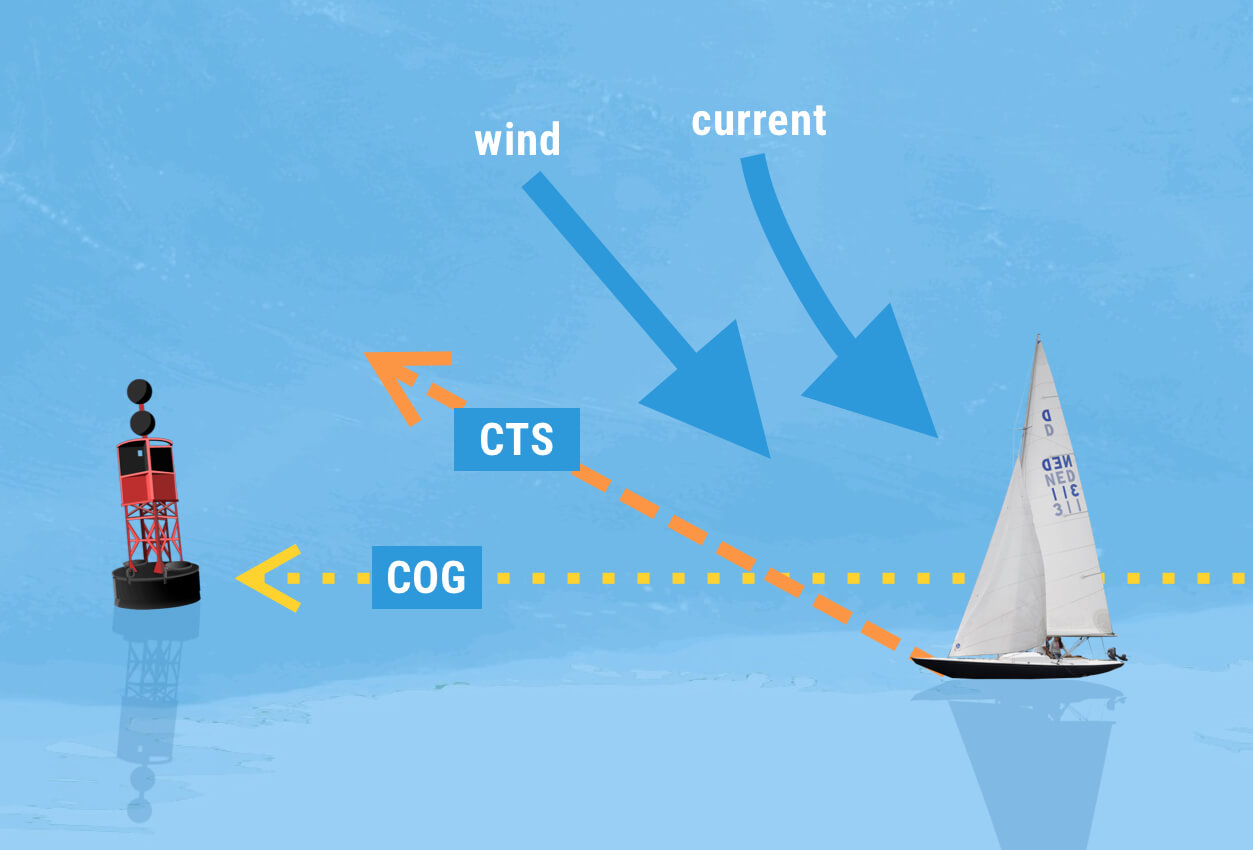

For the sailing portion of our test we chose to measure each boat’s apparent wind angle; apparent wind speed; compass heading; course over ground; and speed over ground, both up and downwind. We also set out to record heel and pitch, but in the light airs , these numbers weren’t that revealing.

This data should give an idea of how each boat was performing in the conditions and to see how close-winded each boat was and what their relative leeward drift might be.

For other factors we were more subjective and based it on how we felt each boat performed.

For the manoeuvring both in open sea and a busy marina , the data should be less subject to other forces and should give a better steer as to the differences inherent in the design choices of each boat.

How the boats sailed

On the day of our test, the NNW wind was light – in the high single to low double digits all day – and coupled with a flood tide, gave a very flat, wind-with-tide sea state.

Long, slow upwinds, and downwinds dominated by a significantly reduced apparent wind as the tide washed the boats toward our leeward mark were the order of the day.

YM editor, Theo Stocker, and I rotated through each boat noting the data, upwind and downwind , and trying to get a feel for the performance of each boat.

In light airs, good sail shape and minimal drag become more important than boat speed. Credit: Graham Snook

Clearly sacrificing so much waterline length to the other two boats, the Contessa 26 was always going to struggle in terms of outright pace.

Boat speeds were surprisingly close, however. Clearly in these conditions none of boats were reaching hull speed, so all the boats were being blown directly downwind at a relatively even speed.

Additionally in the light winds, the Contessa almost certainly benefitted from less wetted surface area than the other wider, heavier hulls.