Solar power

Electric boats.

- electric boat

I drove a rare solar-electric yacht to test clean-sea propulsion, here’s how it went

While we at Electrek often tend to focus on electric vehicles taking over roads, it’s important to remember that our inevitable abandonment of fossil fuels stems to all modes of transportation, whether it’s by land, air, or even the sea . I recently had the opportunity to set sail on Sunwater Marine’s Ramblin’ Rose , a 40-foot sailing yacht powered by solar panels and electric propulsion. It’s one of the only vessels of its kind on the West Coast.

Sunwater Marine is a San Diego-based nautical transportation company with a keen focus on spreading the benefits of renewable energy and electric propulsion to sea dwellers.

It was founded by president James Richmond in 2020, amid the global pandemic. Richmond had a little more free time to search for a boat for blue water cruising to which he could add solar.

James has been sailing for over 50 years, and has nearly 40 years of experience in the renewable and energy-efficiency industry.

He soon found a 2015 Leopard 40 Catamaran and initially planned to simply add solar panels for an electric range and an energy-efficient water maker.

However, James soon discovered viable options for electric propulsion, and began researching the possibility of converting his new yacht to be be solar-electric.

The result is the Ramblin’ Rose , a catamaran that can haul 12 passengers and sleep up to nine. It also happens to be one of the only solar-electric yachts in the West Coast.

I got the chance to take the solar-electric yacht out of beautiful Coronado and test the technology out myself.

The Ramblin’ Rose solar-electric yacht

As previously mentioned, Sunwater Marine’s Ramblin’ Rose is centered around a Leopard 40 catamaran, built by Robertson & Caine in South Africa. Richmond then put an additional $100k into a renewable energy conversion, equipping the yacht with solar panels, and electric motors.

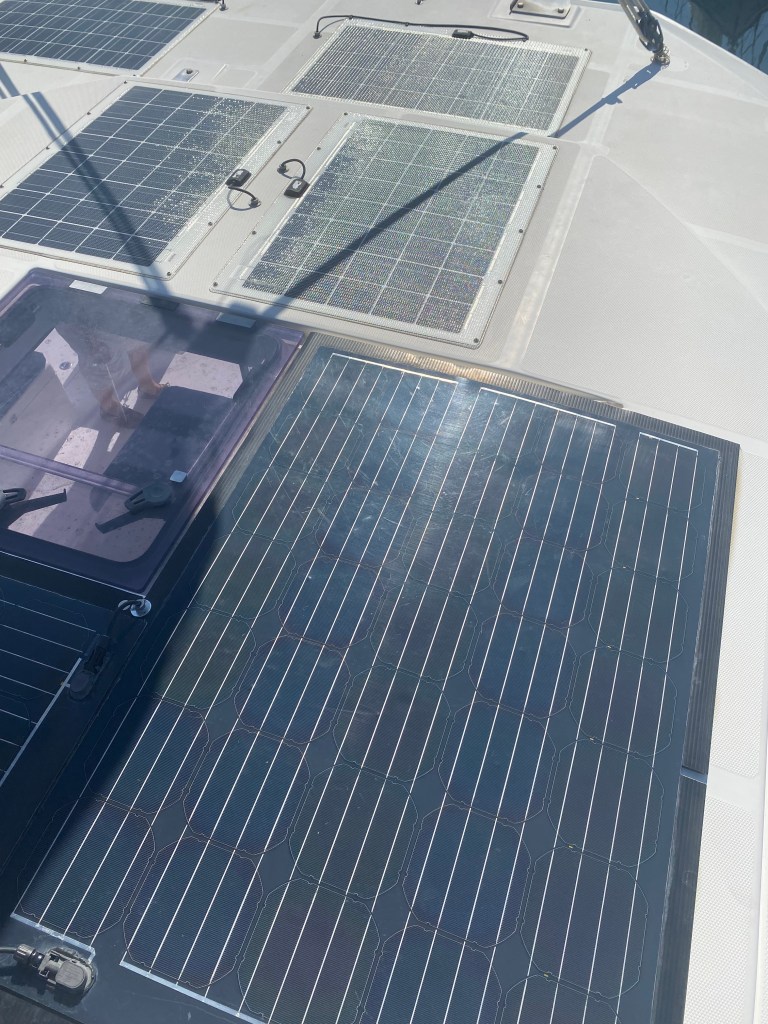

While the original catamaran came with some traditional solar panels, Richmond’s experience in renewable energy told him that would not suffice for his solar-electric yacht.

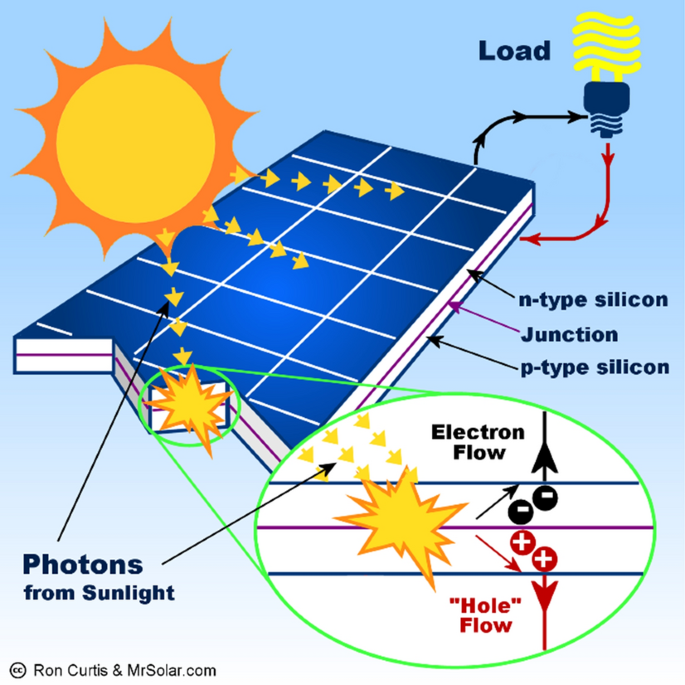

He added lighter and more flexible solar technology from Sunflare , the first company to successfully mass-produce thin, durable CIGS (copper indium gallium selenide) solar panels.

The Sunflare panels on the Ramblin’ Rose operate individually with their own bypass diode, so if one is shaded (by the sail for example), the rest still work.

Richmond also separated the solar panels into three separate zones, so if one side of the boat is shaded, the other two are still harnessing the sun’s power back into the boat’s batteries.

He also showed me how durable these advanced solar panels were, as I was able to walk around on top of them without worrying about breaking any glass or ruining them.

The panels help charge the electric yacht’s battery packs while out sailing and indicate to the captain when they are doing so.

Electric propulsion and battery packs

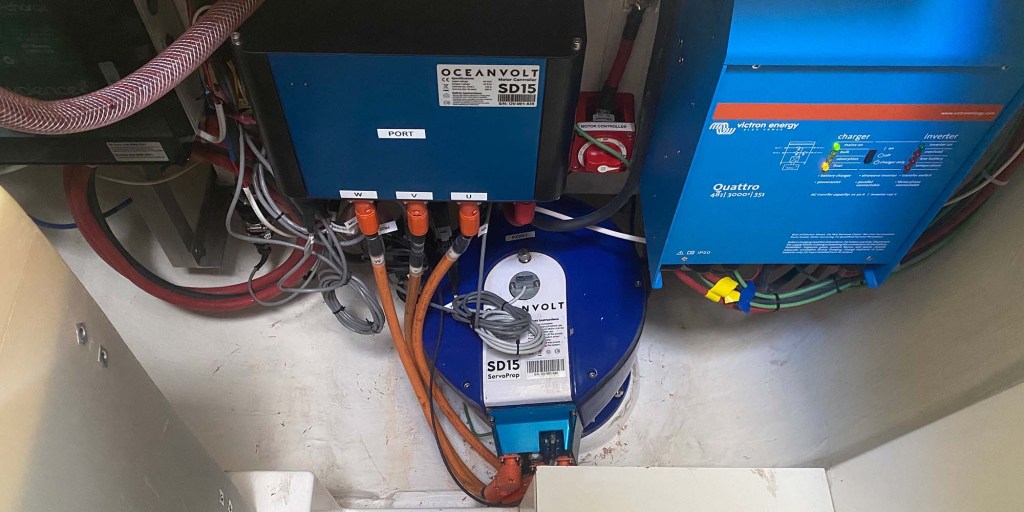

To help power this vessel in and out of the marina and on the sea, Sunwater Marine’s president researched electric propulsion systems around the world, and decided that OCEANVOLT was the best option.

The solar-electric yacht now features two OCEANVOLT 15 kW ServoProp sail drives , utilizing unique propeller blades that can change pitch to optimize efficiency and even regenerate power.

The software controlled variable system adjusts the pitch of each of the propeller blades automatically, so that the power generation and output are always optimal. This is much more efficient than traditional fixed propellers.

The electric propulsion is powered by a 48 volt system, meaning it’s safe to touch without electrical shock (an ideal situation for maritime fun).

Each electric motor on the yacht is powered by a bank of 12 Lithium Iron Phosphate (LFP) batteries on each side, 24 total. The batteries provide 21 kWh of power on each side of the vessel, 42 kWh in total.

Richmond explained that he positioned each battery pack eight inches off the bottom of the boat, too, so if any water were to come in, the batteries would still be OK. Furthermore, the captain showed me backup storage of eight additional batteries should anything go awry at sea.

The status of each and every battery is monitored 24/7 by a supervisory battery management system (BMS) that will shut the battery bank down, should any individual battery begin to malfunction. Fire is not something you want on a boat, despite being surrounded by water.

Additionally, the system was implemented to safely operate minimal electric functions under any conditions, so if the electric yacht were to tip over, there would still be power to send a distress signal.

Thoughts on the future of electric propulsion

After manning the helm of the the Ramblin’ Rose , there is a lot to be excited about for the future of electric propulsion at sea , especially on a gorgeous yacht.

The ride itself was eerily smooth and quiet compared to diesel motors, with zero vibration throughout the boat. If you didn’t look back and see the wake of the electric motors, you might not even notice the yacht was being propelled.

There is a lot of potential in electric propulsion, especially as it pertains to propellers than can remotely change their angle like the OCEANVOLT ServoProps. This makes reversing the electric yacht in particular, much easier for captains compared to fixed props built to push forward.

The ability to set sail and regenerate power from the propellers is also a huge perk and pairs nicely with the advanced solar panels. Plus, you always have shore power as a backup when you’re in a pinch.

From what I’ve seen, the biggest hurdle looking ahead will be battery capacity, and providing enough stored energy to power the electric propulsion systems on the yacht.

The solar panels do help a lot, but it’s a relatively slow process. Smaller, lighter battery options will be crucial for longer distances at higher speeds at sea someday. In the meantime however, we still have sun and wind to pick up the slack.

Currently, the range and top speed are still limited by this lack of surplus energy below deck. We didn’t take the Ramblin’ Rose above 7.5 knots (~8.6 mph) because we didn’t want to burn through all our battery life (that was also in respect to the charter setting sail after us that day).

The solar-electric yacht still has diesel motors onboard for emergencies, but Sunwater Marine’s founder agreed with me that we’d like to see a day when those motors are not needed at all. Unfortunately, the technology is not quite there yet.

Luckily, people like Richmond and Sunwater Marine are using their knowledge and resources (and personal funds) to figure this stuff out for the masses, while spreading the word about electric propulsion. It has become a genuinely viable option at sea, even if it is only in support of other forms of propulsion like sailing for now.

If you’re ever visiting the San Diego area, I highly recommend reaching out to Sunwater Marine and chartering the Ramblin’ Rose , or one of the other solar-electric yachts Captain Richmond is working on.

FTC: We use income earning auto affiliate links. More.

Scooter Doll is a writer, designer and tech enthusiast born in Chicago and based on the West Coast. When he’s not offering the latest tech how tos or insights, he’s probably watching Chicago sports. Please send any tips or suggestions, or dog photos to him at [email protected]

Manage push notifications

Yachting World

- Digital Edition

The future of yachting: Smart technology for your next yacht

- Toby Hodges

- May 14, 2020

Could hydrogen-powered yachts be built from rocks or plants in the next decade? Toby Hodges investigates yachting’s eco future

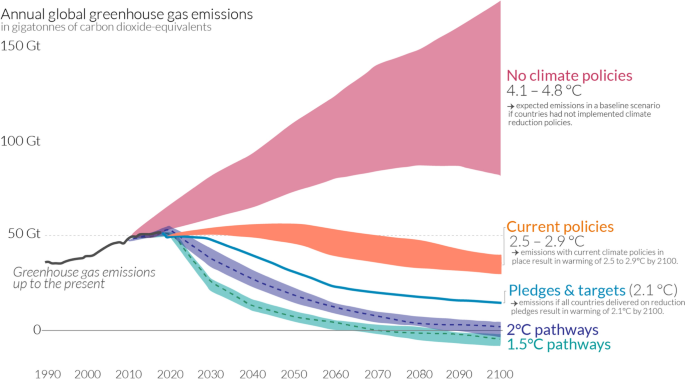

It’s becoming abundantly clear that to meet greenhouse gas emissions targets set out in the 2016 Paris Agreement, we’ll need to adopt some radical changes in all lifestyles. Thankfully sailing is, by its very nature, a green activity. In fact, if you wanted to live as carbon neutral a lifestyle as possible, move onto a yacht and go sailing! But for how much longer will we be able to buy glass reinforced plastic boats, powered by diesel engines ?

When you consider the energy, materials and waste in composite boatbuilding, it can paint an ugly picture. Ironically, the best way forward might be to revert back to building wooden yachts with hemp ropes and cotton sails, but that is perhaps not the most practical answer to supplying today’s global boating demands.

However, researching this feature has filled me with optimism. There are brilliant minds working in the marine industry and many fascinating solutions for alternative materials and power sources. So how might eco-tech change boatbuilding in the next ten years and what will your next yacht look like?

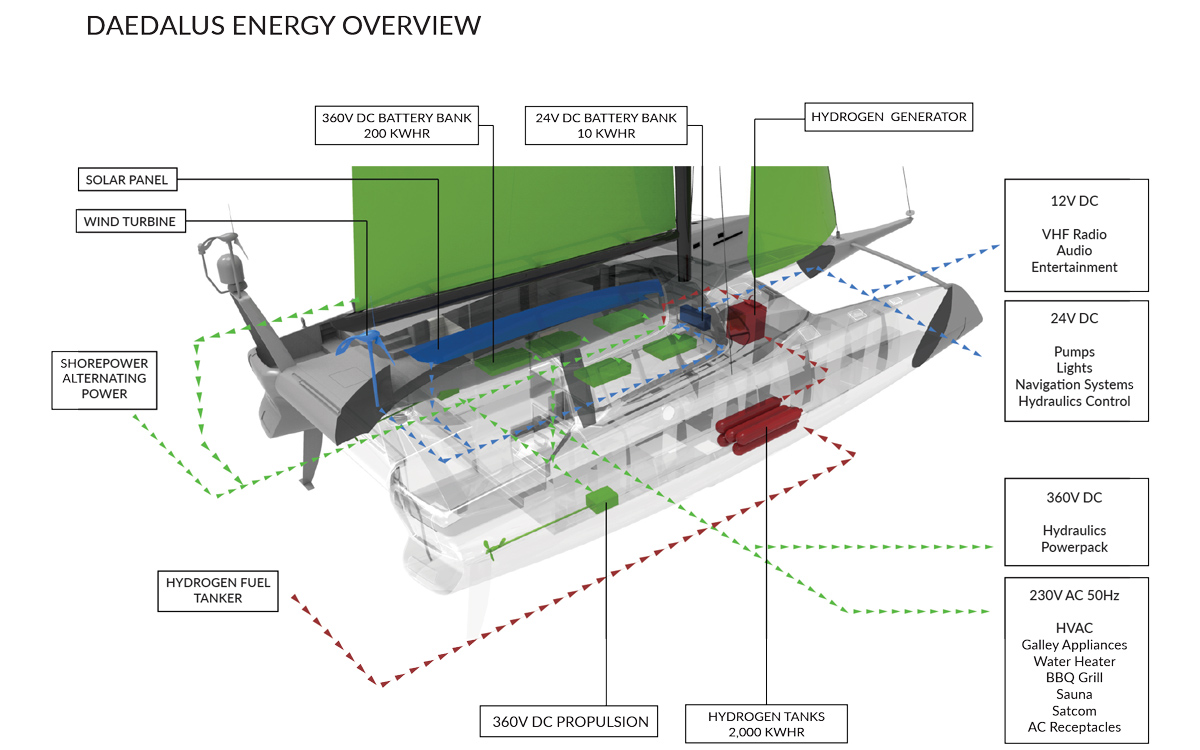

This hydrogen electric cat is midway through build at Daedalus in North Carolina

The simple solution

Technology will continue to make yachts ever simpler to operate. The ability to go daysailing easily will be critical for an increasingly time-poor generation, while powerboaters drawn to the eco credentials of sailing will seek an intuitive format, in yachts that are easy to rig, dock and manage.

Boatbuilders are progressively incorporating greener propulsion and sustainable power sources, and are turning to natural and recyclable materials. Whether they are regulated to do so or not, this is a logical step to take, especially if we, the buyers, demand a more ethical product.

In the next decade we’ll certainly see a marked increase in the use of 3D printing in boatbuilding. Already employed for custom parts, this technology could be used to build hulls and decks – printed structures with natural fibre skins surrounding them could eliminate the need for wasteful moulds.

Article continues below…

4 eco-friendly improvements to upgrade your yacht

1. Ditch the teak Teak is no longer universally popular. The price has gone up dramatically, supply is dwindling, and…

How hybrid sailing yachts finally became a feasible option

Every sailor is familiar with the wet cough of the diesel engine, and the acrid smell of its exhaust. For…

There are already bodies in place concentrating on the reduction of waste and energy use in boatbuilding, while promoting recycled and low-impact materials. 11th Hour Racing is doing commendable work here. The common boatbuilding technique of using hand laid-up polyester certainly looks increasingly endangered.

Search for speed

The most effective way to minimise your carbon footprint afloat is to sail, so there is a strong argument for choosing performance yachts , which can harness the wind more efficiently. Large yachts and catamarans have an advantage too as they provide the deck space to host numerous solar panels and the speed to incorporate regenerative propulsion.

During its research for the Outremer 4E project, and new 55, Grand Large Yachting found that the usage of a yacht accounts for a much higher carbon footprint than its build. If you are able to sail in five knots of wind, then you can sail 95% of time in the Mediterranean, it says (data from western Med June-September).

Outremer’s 4E prototype will be used by cruising guru Jimmy Cornell for his next circumnavigation

To achieve this performance requires minimising weight, but what are the best alternatives to using the traditional high strength-to-weight ratio synthetic fibres such as glass and carbon?

Basalt fibre has long shown promise and is being used by new French catamaran brand Windelo to build its hulls, with PET (recycled plastic bottles) cores. Basalt is transformed from volcanic rock (with minimal CO 2 emissions), so the fibres are particularly resistant to heat and are recyclable.

However, it is the fibres from plants that could offer the most potential for boatbuilding. Flax in particular, the plant from which linen is derived, looks like becoming one of the most effective alternatives for use in high-strength composite applications.

Natural promise: Linen fibres are derived from quick-growing flax plants

Boats from plants?

The flax-based products of Swiss company Bcomp have already been used effectively in motorsport bodywork and snow skis for their combination of stiffness and vibration damping.

Paul Riley, a composites expert now marketing Bcomp products for marine use, says that flax is lighter than glass fibres, with similar stiffness and significantly lower cost than carbon fibres, yet with up to 75% CO 2 savings. “I think we’ll see this coming into mainstream yachting in the next two to three years,” he says. “Manufacturers need to take a stand and switch to less environmentally impactful materials, which will also provide improved health and safety for their workers.”

Flax grows from seed to crop in eight weeks, rarely needs irrigation, and chemicals are not required. Thus far it has been used by German yard Greenboats, including on the 2016-built GreenBente 24, and superyacht builders Baltic Yachts. News that Gurit, global leader in composite material supply, will be the worldwide distributor for Bcomp, could lead to a broad adoption by marine manufacturers.

A Tesla Model S electric race car clothed in Bcomp flax composite bodywork

Visitors to the Düsseldorf Boat Show this year may have seen the potential of this fibre on the Greenboats stand. Its Judel/Vrolijk-designed Flax 27 daysailer became a test-bed for numerous natural and recycled materials. The hull is made from flax and bio resin with a PET core, the deck from cork.

Greenboats’ founder Friedrich Deimann told me how frustrated he became with using composite materials, especially coming from a wooden boatbuilding background. “It takes five times as much energy to produce glassfibre than linen fibre,” Deimann reports, showing me the plants from which he built his beautiful clear-coated daysailer.

Greenboats has been using Flax or Natural Fibre Composites (NFC) since 2010. And it minimises the use of moulds by using a stitch-and-glue technique to build panels. Deimann’s company shows what is possible, but he admits a lack of trained personnel and the costs of small-scale production are the current issues.

The Greenboats Flax 27 daysailer has a hull made of linen fibre and bio resin with a core of recycled plastic bottles

Another is resin control. “You can’t use hand lay-up with flax because it’s a natural material, and without compression the fibres can absorb a lot of resin,” says Deimann. “By vacuum-infusing the resin, you compress and control it.” Vacuum-infusing resin brings its own environmental issues because the plastic used in the bagging process creates a significant amount of landfill. Some boatbuilders have already found a clever solution here in reusable silicone bags.

But the resin itself still remains an issue for chemists to solve. Pure bio resins exist already, but for the high-performance epoxies required in boatbuilding the natural content might only be around 30%. Entropy resins, bio-epoxies used in marine, snow and surfboards for example, are manufactured by replacing petroleum-based carbon with renewable plant-based carbon – by-products from the agricultural industry.

Recyclable boats

Elsewhere, yards have been forging ahead with various technologies that offer a cleaner end of life potential. The hull of the mini 6.50 raceboat Arkema 3 was made from a recyclable thermoplastic composite using Elium acrylic resin, for example, which can be ground down and reused to manufacture new parts. And many RS dinghy hulls are made from rotomoulded and recyclable polyethylene.

Meanwhile, the benefits of using high-tech timber construction are clear for all to see thanks to Spirit Yachts . Its strip-planked technique makes for a very stiff, lightweight structure, with hulls made from largely renewable materials. Indeed, the beautiful new Spirit 111 flagship is being labelled as one of the most environmentally friendly superyachts ever.

Managing director Nigel Stuart has instigated a network of green initiatives at the Ipswich yard and in its yachts. The Spirit 111 includes energy-saving appliances throughout, including ultra-efficient hydraulics and genset, and a regenerative propulsion system for its Torqeedo electric drive.

And it is this latter element – power – that will surely be the primary focus for making cruising yachts greener in the coming decade.

Going electric

Torqeedo and Oceanvolt have led this drive so far, with Volvo Penta now ramping up its electromobility technology. And although Torqeedo has already delivered 100,000 electric drives, this represents only a small fraction of the market, according to CEO Dr Christoph Ballin.

“So far, only about 1.3% of marine propulsion systems are electric… we need to put the foot down and do more,” he states. Over the next decade, Ballin sees serial hybrid power as the optimum solution for yachts, systems that involve a large battery bank with a mix of solar and hydro power generation. This reduces the CO 2 footprint by around 90%, but with the safety net of a ‘diesel range extender’ – a compact generator, says Ballin.

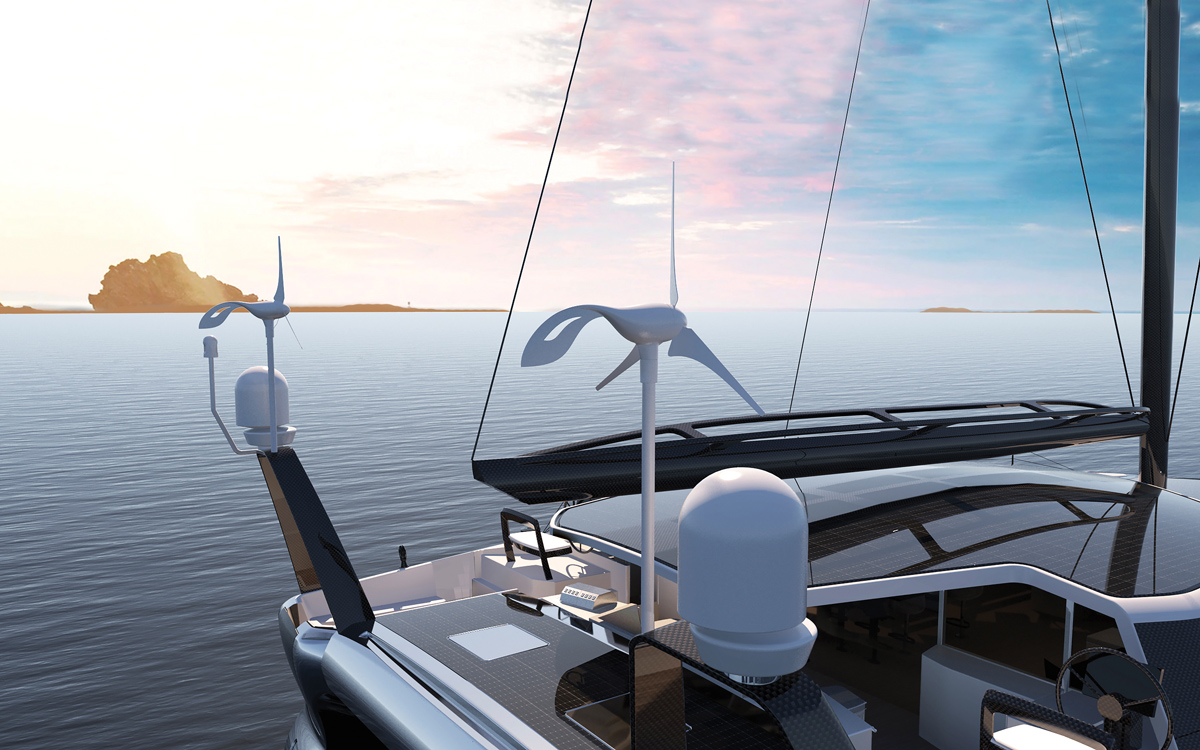

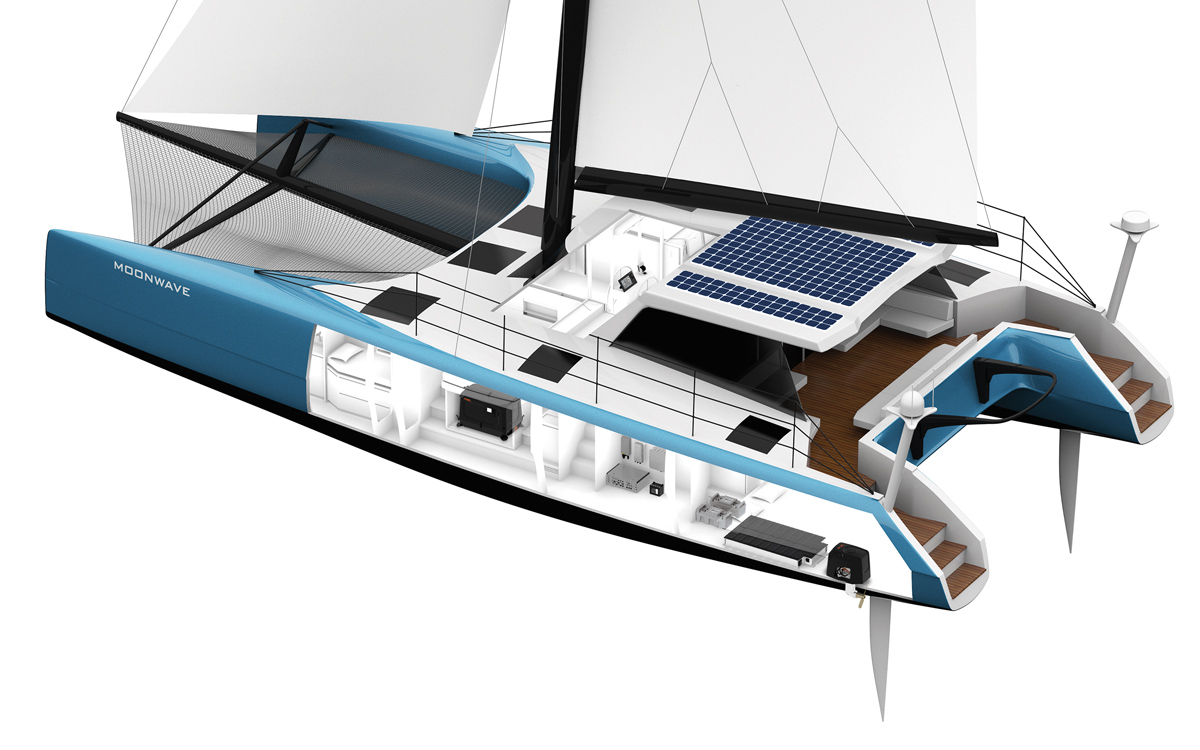

Moonwave is a Gunboat 60 recently refitted with the latest generation of Torqeedo’s Deep Blue electric drive system

Such a system caters for normal sailing and living requirements using only battery power. “The role of the generator is reduced from providing everyday energy for living on board (heating, cooking, washing, aircon) to emergency use, if you will. And the role of the combustion engine for driving the boat is completely eliminated.”

But what about hydrogeneration? Combined with enough solar panels, surely this will enable us to dispense with fossil fuels on board altogether? “I fully agree, hydrogeneration in terms of using the propeller to create power under sail is one thing that is here to stay,” Ballin believes.

ZF steerable saildrives are being integrated with Torqeedo systems for hydrogeneration

But it is dependent on the speed and size of the vessel. He points out that if you have a fast boat you can generate all the electricity you need while sailing: “We have a customer with Gunboat 60 which generates 10-15kW”.

Battery storage

“The limitation here,” points out Ballin, “is how much energy you can store in a battery, because of the energy density that batteries offer.” Torqeedo’s Deep Blue technology and use of BMW’s i3 high voltage lithium-ion batteries gives it an edge on competitors.

But is the reliance on lithium boat batteries as a ‘clean’ source of energy storage simply solving one problem by adding another? The questionable mining ethics surrounding the cobalt used in many lithium batteries has been widely reported and the question of battery recycling still remains unanswered.

Ballin foresees supply chains becoming more ethical from a human rights standpoint. He explains that BMW is now controlling the entire supply chain for its batteries, including sourcing the raw materials, to avoid inhumane working conditions.

This makes for another whole topic, as does the recycling issue, to which Ballin alludes to the potential for a second life for marine batteries in powerwalls and energy storage before they go into any recycling for cobalt extraction.

“We are in front of the largest mobility revolution since the introduction of combustion engines,” Ballin states. “We have to live with the fact that the stages in this transformation programme are all imperfect – and will be for more than ten years.”

Looking ahead, Ballin sees three key scenarios for what is possible for climate neutrality on boats: battery electric vehicles; hydrogen-power; and synthetic fuels. “The rule for sailors I think will be that wherever battery electric vehicles are feasible those are the preferred ways to go forward.

“If battery electric vehicles do not give you enough power, which is almost always the case for oceangoing vessels, then you can go to hydrogen for example… It will become mainstream to have a climate-neutral range extender.”

Hydrogen power

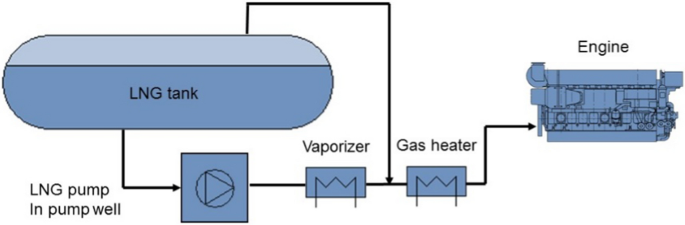

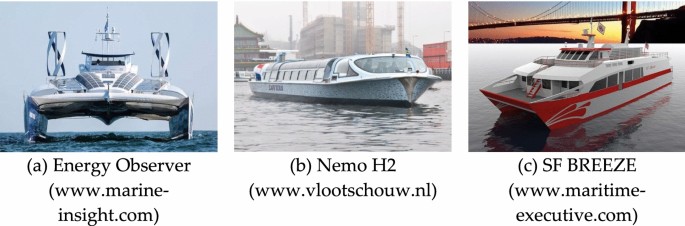

So could hydrogen be the holy grail of energy for yachts? Hydrogen fuel cells work by converting hydrogen (from seawater) to positive and negative electron charges. So far this process has been used as an energy source only by a few pioneering vessels, including Energy Observer , the first energy autonomous hydrogen boat to circumnavigate. And Race for Water , a solar and kite-powered multihull carrying a conservative amount of hydrogen (200kg) in 25 bottles, is currently three quarters of the way round the world.

Solo racing sailor Phil Sharp has been demonstrating a hydrogen fuel cell in place of a diesel engine to generate power aboard his Class 40 OceansLab . He believes larger scale commercial shipping and marine craft can adopt the technology to reduce their carbon emissions to zero.

For leisure yachts, however, hydrogen fuel cells are not yet economically feasible. Torqeedo’s Ballin explains the practical limitations: “The energy density of hydrogen per kg is a lot better than petrol or diesel, but the volumetric energy density is about 1/13th of diesel.” This means much larger fuel tanks are necessary – although these volumes can be reduced under pressure.

That helps to explain why hydrogen has been adopted by only a handful of (large) yachts thus far. A pioneer of the technology is Daedalus Yachts, which is midway through building the first hydrogen-powered superyacht. “Over the past two years we have conceived and developed not only a complete hydrogen electric marine propulsion system but also a clean energy micro grid with the only emissions being oxygen and pure water,” says Daedalus’s founder Michael Reardon.

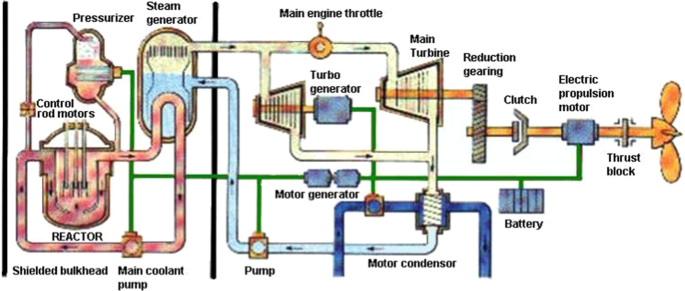

The overview of the Daedalus renewable energy and power system

The 88ft catamaran is being built to full commercial survey for world cruising for visionary Stephan Muff, who created the technology for Google Maps. The Daedalus electrolyser (which converts water to hydrogen) is the same as has been used in US spaceships and NATO submarines, so the North Carolina company is quietly confident it’s onto a reliable power source.

For the shorter term however, sailors should look to solar and battery technology, where we can assume continued improvements in efficiency and capacity for reduced costs. Building photovoltaic cells into biminis, decks, masts, and sails is already feasible.

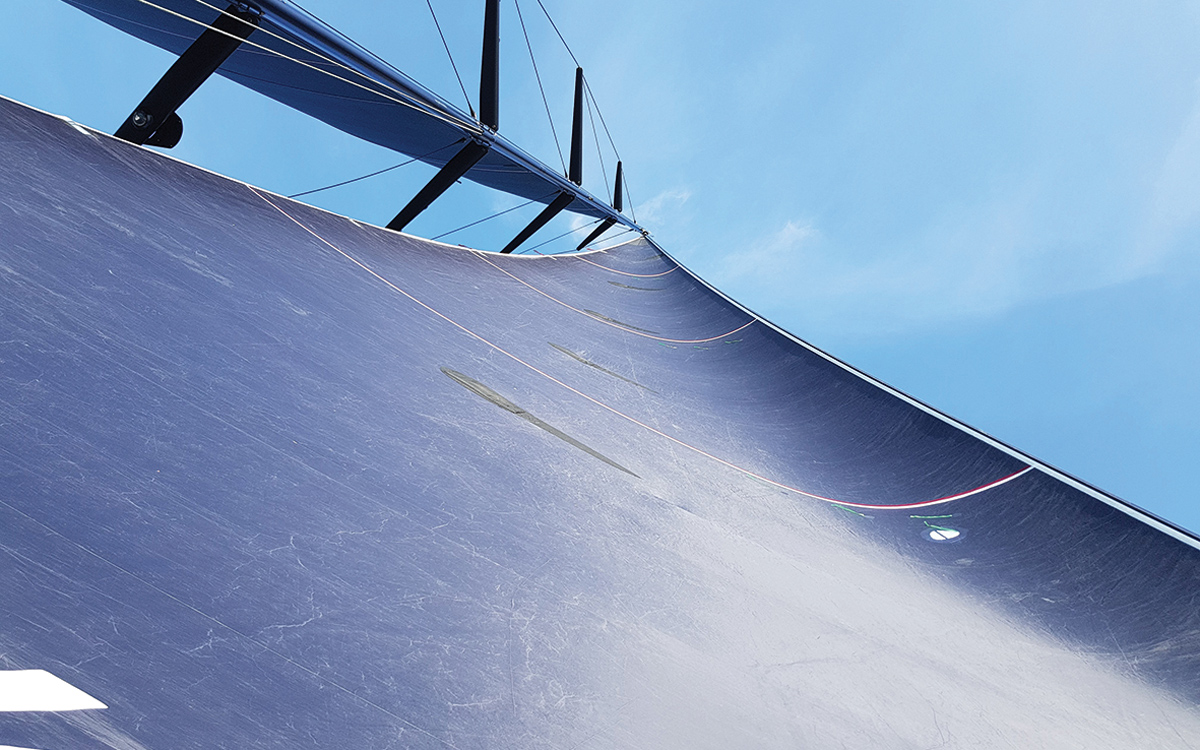

Using sail power alone whenever possible is an obvious objective. But it’s the sailcloth itself that is arguably the most disposable component, particularly aboard racing yachts. Laminate sails with a Mylar membrane can’t be recycled, so many used sails go to landfill, or are abandoned in sheds and shipping containers.

OneSails 4T Forte membranes are recyclable sails that use STR stripes, a high modulus fibre produced by compaction of polymer to create a flat ribbon

Polyester/Dacron sails are largely thermoplastic so can be melted and reformed (although typically coatings such as melamine render this highly problematic). However, other than turning them into bags and accessories, what are the options for sails with synthetic fibres, high modulus yarns, which are notoriously difficult to chop up and repurpose?

OneSails has been ahead of the game here with its 4T technology. It uses a recyclable base polymer and replaces the glues and resins with heat fusion. The result is a composite single structure sail, which uses a low-stretch technology to avoid Mylar or taffeta, for a completely recyclable sail. “This technology is the only genuine sailmaking system that offers the opportunity for sailors to recycle ‘end of life’ sails,” says OneSails UK’s John Parker.

North Sails’ 3Di products also avoid Mylar film and the company is working to recover raw material from used sails to turn it back into polyester fibres. North’s commercial director Tom Davis, who has overseen its cloth business for the last 20 years, sees two key areas of development with greener sails. Firstly with the raw materials: “I will be very surprised in the next few years if materials going into sails aren’t substantially bio-based.”

With its partner, Steelhead Composites, Daedalus has built the world’s only certified hydrogen containment vessel

And secondly, with what he terms the ‘back end’: “A very high percentage of the total acreage of sailcloth in all areas will be repurposed/recycled.” Again, he sees the quickest changes happening with polyester and reports that North is already using recycled PET films, which are chemically indistinguishable from oil-based film.

Davis has been impressed by the speed of the technology in these areas. “In the sailcloth/making business, we’re not big enough to be producing new yarn or filaments – that’s really a petrochemical level business. But we are the beneficiaries of the technologies those companies develop.”

So in the case of high modulus yarn products, North is working with a company that is producing a bio source for the monomers that become polymers and then become high performance yarn and fibre. “So instead of pumping oil out of the ground and converting it to plastic, they’re starting with trees and ending up with very high performance plastics,” Davis explains.

Positive thinking

It goes without saying that future yachts should be well insulated, durable and with very low energy loss and consumption. Battery banks and renewable regeneration will mean there’s little requirement for fossil fuels. Water filtration in and out of the boat is increasingly important. For those who spend long periods aboard, the growing energy efficiency of watermakers means there is simply no call to ship bottled water. Self-sufficiency rules.

The dissolving print your anchor leaves in the sand should be the only evidence a yacht ever leaves behind! I’m confident the next decade will bring a tidal wave of innovation in the marine sector. And with the right collective mindset, the future is indeed bright – it’s exciting and it’s green.

First published in the April 2020 edition of Yachting World.

- Israel-Gaza War

- War in Ukraine

- US Election

- US & Canada

- UK Politics

- N. Ireland Politics

- Scotland Politics

- Wales Politics

- Latin America

- Middle East

- In Pictures

- BBC InDepth

- Executive Lounge

- Technology of Business

- Women at the Helm

- Future of Business

- Science & Health

- Artificial Intelligence

- AI v the Mind

- Film & TV

- Art & Design

- Entertainment News

- Arts in Motion

- Destinations

- Australia and Pacific

- Caribbean & Bermuda

- Central America

- North America

- South America

- World’s Table

- Culture & Experiences

- The SpeciaList

- Natural Wonders

- Weather & Science

- Climate Solutions

- Sustainable Business

- Green Living

The revolutionary boat powered by the ocean

The Philippines’ traditional three-hulled boat is being redesigned, to draw its power not from fossil fuels, but from the energy of the waves.

We were standing in the pouring rain at Sabang Port, waiting for our turn to board a bangka (a traditional Filipino boat) that would take us to the entrance of the Puerto Princesa Underground River, which runs beneath a cave in Palawan, an island province on the western part of the Philippines. At last our bangka arrived, a trimaran with bamboo outriggers either side of its main hull.

The trimaran is a common sight on Philippine waters. The country pioneered this design in its early warships, then adopted it for its traditional sailboats and fishing boats. As an island nation, the Philippines relies on watercraft – boats, ferries and cargo ships – to transport people and goods across its more than 7,000 islands. But its fleet of cargo and passenger ships are one of the biggest contributors to the country’s greenhouse gas emissions. In 2012, transportation accounted for the second largest source of greenhouse gas emissions in the country’s energy sector , after heating and electricity.

Globally, 9% of all transport emissions came from international and coastal shipping in 2010 . That’s a small figure next to the 72% that came from road transport, but it puts shipping on a similar level to aviation, which made up 10.6% of transport emissions. And with the volume of world sea trade projected to grow at a rate of 3.8% a year to 2023 , emissions from the shipping industry are likely to increase too, unless the growth in sea traffic can be uncoupled from emissions.

A new design of ship in the Philippines is hoping to pose a low-carbon alternative to the country’s usual bangka, by working with the power of waves rather than against them. The ship is a hybrid model, using multiple internal combustion engines for initial propulsion but switching to wave energy while cruising in open waters.

This seacraft is the brainchild of Jonathan Salvador – a marine engineer and owner of shipbuilding company Metallica Marine Consultancy, Fabrication and Services – who was inspired by the conventional bangka’s design.

“The outrigger’s job is to provide stability so the bangka doesn’t tip sideways,” Salvador says. “But I also noticed that each time a wave hits the outrigger, the outrigger constantly reacts to the upward and downward movement of the wave. What if we can convert this reaction – this kinetic energy – into electrical energy?”

- The most powerful renewable energy

- The young people fighting Europe’s worst smog

- The spies catching fish pirates on the high seas

The way wave energy works will be familiar to anyone who has waded in sea waters. At times, the waves are strong enough to push you back to shore or tall enough to push you over. “Waves have a lot of momentum, and it’s that momentum you feel when you’re out in the water,” says Bryony DuPont, professor of mechanical engineering at Oregon State University. “Wave energy uses that momentum, sometimes as-is and you just need the motion of the waves, and sometimes we capture that momentum and force it through machinery that generates electricity.”

The hybrid trimaran has this machinery – a wave energy converter – in the form of hydraulic pumps integrated into its outriggers. As the pumps move through the waves, they harvest the momentum of these waves, converting their kinetic energy into electrical energy, which will then be fed into a generator that will supply electricity to the ship. The electricity then provides propulsion via a motor. The more waves the trimaran encounters, the more power it can produce from those waves.

Construction of the hybrid trimaran started in 2018 and was set for completion by early 2020, in a collaborative effort between the Metallica shipbuilding company and the Aklan State University. But a typhoon in 2019 delayed the project and community quarantines enforced this year due to the Covid-19 pandemic resulted in a skeletal workforce at best and brought the project to a standstill at worst. Despite these difficulties, the team is aiming to finish building the ship by the end of 2020, with a three-month sea trial scheduled for the first quarter of 2021. The vessel is expected to be capable of carring 100 passengers, four vans and 15 motorcycles.

The hybrid trimaran’s use of wave energy could be a significant step toward reducing the need for environmentally damaging fuels such as diesel in the Philippines. And with wave energy offsetting gasoline use, Salvador and his team aim to bring down the vessel’s carbon emissions by a third compared with the most modern large-scale shipping lines .

The wave energy converter would also benefit from the ship’s traditional trimaran design. “Wave energy requires motion of one part of the system relative to another,” says Rob Cavagnaro, a mechanical engineer at the Marine Sciences Laboratory of the Pacific Northwest National Laboratory in the US. “Having outriggers that can heave – or move up and down – relative to the central hull may be well-suited for this purpose.”

Moreover, waves are energy-dense; in other words, they can be ferociously powerful. At coastlines, waves can reach power densities of 60–70 kilowatts per metre in areas with deep waters . In the UK and the US, for example, the average wave power density is between 40 and 60 kW per metre . “If we can translate that energy into other useful forms, we can do a lot with very little,” DuPont says.

But converting the high-force, low-speed motion of waves in an efficient way can be a challenge. “There may be many sources of loss along the way, from friction in the hydraulic systems to heat in the electrical generator,” Cavagnaro says. The engineering challenge that remains is to minimise these losses.

Another hurdle would be designing a wave energy converter small enough for the ship’s dimensions. “Wave energy converters generally develop more power the larger they are, but if they’re so large that the waves can’t move them, then can’t effectively harvest momentum,” DuPont says.

Even so, a private company in Boracay, a popular tourist island in the country, has already expressed interest in operating the ship once it’s launched, says Rachel Habana, a senior scientist at the Philippine Council for Industry, Energy and Emerging Technology Research and Development, which oversaw the trimaran’s development. “We envision the future of public sea transport in the Philippines to be safe and green with less emissions, and we see the trimaran bringing that vision to life,” she says.

But as yet the hybrid trimaran is still a prototype. “Because we have new technology for the vessel, we need a technology verification step before we can go for full-scale commercialisation,” says Yasmin Tirol, project leader and campus director of Aklan State University’s College of Fisheries and Marine Sciences. “We already conducted some test modelling for the wave energy converter, but we have to look into its actual performance and optimise it.”

Cost is another issue. Funding for the project is at 76 million Philippine pesos (£1.2m; $1.5m), but Salvador estimates commercial-level costs to reach 250 million Philippine pesos (£4m; $5m) or more per ship. To keep expenses low, at least 80% of the trimaran’s parts are sourced locally, while the entire manufacturing and assembly process is done within the country. Staying local also opens up opportunities for improving the skills of the shipbuilding and ship engineering workforce in the Philippines, and allows smaller shipbuilders and the country’s large workforce of seafarers to participate.

Salvador refers to the current trimaran as a “series one” prototype, with plans for more ambitious series two and three versions that will use wave energy to help the engine create more power, or even fuel the vessel entirely. But this might be a difficult feat given the considerable power demands of large modern ships. “The power available in waves interacting with the ship may not be enough to meet the full energy needed for propulsion,” says Cavagnaro. “It would also depend on how large and long the waves are – the highest-energy waves are ones that would not be comfortable to move through.”

Wave energy powered vessels are a nascent technology, and it’s still to be seen which is the best way to draw power from the sea. For instance, the Autonaut, an unmanned surface vessel, uses foils to harvest wave energy for propulsion . Meanwhile, the most common design concept for wave-powered boats uses fins that move like dolphin kicks or a whale’s tail to propel the boat forward. All these have yet to go mainstream or be applied to larger seacraft.

But for any boat navigating the choppy waters between the islands of the Philippines, it is a tantalising prospect to turn that churning energy into forward motion. The hope is that this abundant, clean resource will become as widely used at sea as its more mature renewable energy counterpart: the wind.

“I think anyone who has surfed or swam in the ocean or been on a rocking boat has contemplated the immense power of ocean waves,” DuPont says. “It’s thrilling to see brilliant ideas stem from that spark of inspiration – from being connected to the ocean.”

The emissions from travel it took to report this story were 0kg CO2. The digital emissions from this story are an estimated 1.2g to 3.6g CO2 per page view. Find out more about how we calculated this figure here .

Join one million Future fans by liking us on Facebook , or follow us on Twitter or Instagram .

If you liked this story, sign up for the weekly bbc.com features newsletter , called “The Essential List”. A handpicked selection of stories from BBC Future , Culture , Worklife , and Travel , delivered to your inbox every Friday.

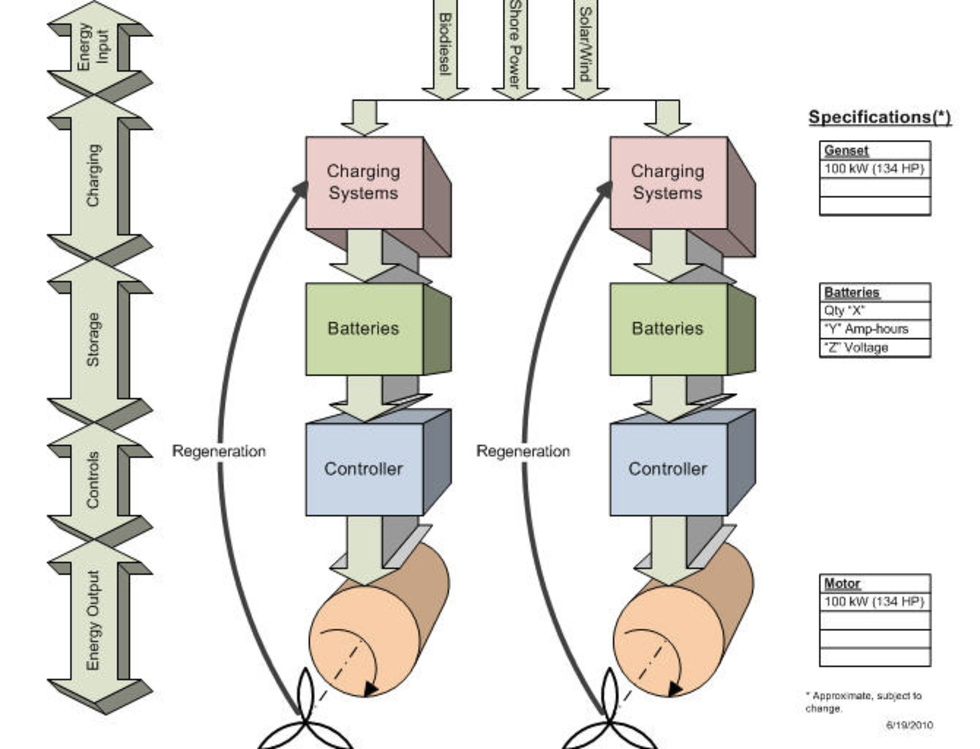

Regenerative Electric Propulsion

Imagine a sailing vessel meeting energy needs through regenerative power..

By combining technologies from the 19th and 21st centuries—skipping over the petroleum era—Matthew Turner will become a unique teaching tool that can inspire appreciation for past boat building designs while utilizing innovative technology solutions to construct a truly green sailing ship.

The basic regenerative electric propulsion concept is simple. Instead of diesel engines, the ship is propelled by AC electric motors directly connected to the propeller shafts and drawing energy from large battery banks. When the ship is sailing, the energy of the passing water causes the propellers to rotate, which, in turn, causes the electric motors to become generators that re-charge the batteries onboard. Significant electrical energy is created as sailing speeds increase.

New advances in propellers, electric propulsion/regeneration motors, battery technologies and electronic controllers make this possible and are available today.

Matthew Turner can, in fact, operate on a carbon-neutral basis. Energy to run our ship will come from regenerative power under sail, which can be fueled with bio-fuel, and dockside charging from solar panels and wind generators. The dockside solar will be facilitated by the US Army Corps of Engineers at their Bay Model facility, which has recently been outfitted with a rooftop solar array that generates 540 kW/h.

Day-to-day operations are designed to minimize energy and water use with a waste management system that will repurpose, recycle and reduce waste. By using LED lighting, induction cooking and low energy navigation and appliances, the Matthew Turner will use less than 50kWh per day. The vessel can produce enough clean energy in a day of sailing to sustain the vessel’s needs.

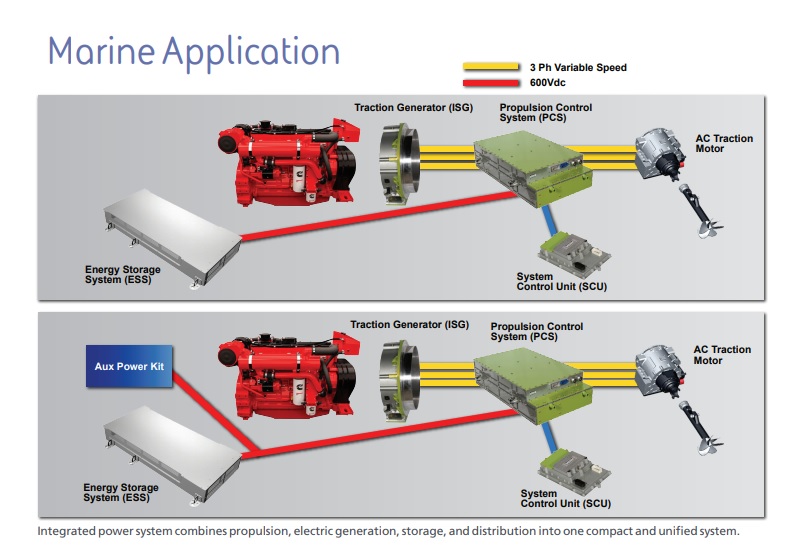

HybriGen Benefits:

- Power is delivered on-demand to support propulsion or auxiliary power, or both simultaneously

- Variable speed genset and lithium-ion battery banks eliminate under-loading of the engine and wasted fuel

- Reduced operating time of diesel generators also allows for reduced maintenance

- Electric traction motors and batteries allow for completely silent and emission-free cruising

- Flexible, tablet-based diagnostics and control system allows for powerful, yet easy-to-use system operations and monitoring

- Isolated propulsion system in each demihull provides complete redundancy

Read more about BAE’s HybriGen Power and Propulsion here

Yachting Monthly

- Digital edition

The true carbon cost of sailing – and why going electric could be less green than you think

- Theo Stocker

- February 7, 2024

New research reaches some surprising conclusions about which propulsion systems might actually have the lowest carbon footprint. Theo Stocker digs into the numbers

A white sail on a blue sea. What could be cleaner than that?’ Sailing nerds might recognise this quote from the all-time greatest sailing film, Wind . Or maybe that’s just me. Anyway, it’s easy to assume that drifting around with the breeze has little impact on the environment, let alone the global climate. But that assumption may be further from the truth than you think.

Certainly, the marine industry is tiny compared to other emitters of greenhouse gases, but it still registers on the scale. Recreational boats account for less than 0.1% of global greenhouse gas (GHG) emissions, specifically 0.7% of transportation carbon dioxide (CO₂) emissions in the United States and 0.4% of transportation CO₂ emissions in Europe.

Those numbers sound small, but then consider that there are estimated to be 50 million recreational craft globally, with as many as one million new boats being added to that number every year. New research has now been published by the International Council of Marine Industry Associations (ICOMIA) as they seek to plot a way forwards for the leisure marine industry.

The rather bleak headline is that if you want to move away from fossil fuel propulsion, you could easily generate a larger rather than smaller carbon footprint, whether you’re looking at biofuels, hydrogen, electric or hybrid propulsion systems.

The good news, however, is that the devil is in the detail. Make a few compromises to things like range and performance, conduct an honest appraisal of how you actually use your boat, and utilise new and emerging technologies, and you can reduce your boat’s carbon footprint, whether you’re buying a new boat or not.

John Kerry, with his granddaughter, signing the 2016 Paris Agreement on behalf of the US. Photo: Xinhua / Alamy Stock Photo

Paris climate agreement

The Paris Climate Agreement, a legally binding international treaty that seeks to limit global temperature increase to 1.5°C above pre-industrial levels, requires signatories to reduce global carbon emissions by 43% by 2030.

While the marine leisure industry might be a tiny proportion of global emissions, it is still a contributor. Given recent protests against superyachts and the perception of sailing and boating as an elite, luxury pastime, ICOMIA wanted to be able to work with regulators to reach policy decisions based on data rather than emotions, assumptions or ideologies.

Article continues below…

There was, however, a ‘vacuum of data’ and while regulators, companies and customers were all trying to take positive steps environmentally, there was very little cold, hard evidence guiding them, leaving potential for flawed choices and the potential dismissal of the best options for reducing the marine industry’s carbon footprint. To fill this void, they commissioned the most detailed research project ever undertaken on the subject in the marine industry.

The result of the project is the 550-page report Pathways to Propulsion Decarbonisation for the Recreational Marine Industry. So far, the report and its data has been shared with the European Commission Department of Growth, the US Dept of Energy and Governments in the United Kingdom, Spain and Sweden.

Infrastructure for new technologies to be adopted is an essential part of assessing their carbon footprint. Photo: Scharfsinn / Alamy Stock Photo

ICOMIA set out to create a robust and holistic analysis of the full environmental impact of all currently available propulsion technologies for recreational vessels under 24m (80ft).

It was to consider the full-life ‘cradle-to-grave’ impact of building, using and disposing of leisure craft. The report covers first-of-its-kind primary research study from Ricardo, a leading global engineering consulting firm. The resulting data took two years to compile and was subject to thorough peer reviews in an attempt to make this the most robust data possible.

ICOMIA’s aim was not to make a pronouncement on what technologies are green or not, but to provide benchmark data against which governments, boat builders, technology developers and you, the sailing public, can make informed choices.

The study covered nine types of vessel up to 24m, including inflatable tenders with small outboards, runabout day motor cruisers, fishing boats, pontoon boats (a large sector in the US), personal watercraft, sailing yachts, inland waterways craft, large displacement motorboats and performance motor yachts.

Steve Bruce, UK MD for ePropulsion, is sceptical about ICOMIA’s report. Photo: Scharfsinn / Alamy Stock

The study was broken down into six steps: exploring the decarbonisation options; conducting a Greenhouse Gas Life Cycle Assessment (LCA) to ISO 14044 and 14067 standards including the manufacture, use phase and end of life for energy converters and energy carriers; assessing the total cost of ownership of each system, including purchase, operation and maintenance; analysing the implications of life expectancy, maintenance, performance, safety and availability of each system; analysing the infrastructure implications, before ranking the suitability for each craft type and usage case.

The report is still pretty broad brush strokes, and there are plenty of caveats to the findings. How and where boats are used, what technology is installed, and the supply chains in each of those products have an impact, and ICOMIA says that it is keen that the data acts as a baseline for people to innovate around and find ways of cutting emissions in every part of a boat’s lifecycle.

Even so, some are sceptical about the report. Steve Bruce, Managing Director (UK) of electric engine manufacturer ePropulsion said, ‘I have to say I am extremely disappointed.

It would appear to me that the report has been written with a bias against electrification and has failed to consider several relevant factors, such as the ability to re-purpose and ultimately recycle batteries.

‘It also seems to be based on facts that do not appear to be in line with what we are being told by boat users in our daily conversations, so I would like to better understand precisely where the report writers have decided to select their data from and why.

‘The small amount of hours they suggest boats are used for does not correlate with the actual use profiles we are being asked to support.’

From a user point of view, electric propulsion has many benefits over combustion engines. Photo:

What the research doesn’t do

The report’s authors were keen to emphasise that they were not aiming to stymie certain solutions, but rather to identify the real-world use cases in which these systems are the best to choose, and to highlight where more development and investment is required.

They also noted that the research focuses on propulsion systems, while there are a whole host of other areas in which a pleasure vessel could reduce its carbon footprint, from building materials and manufacturing processes to supply chains, shipping, and disposal. Similarly, how a vessel is used will have a big impact.

ICOMIA CEO Joe Lynch explained, ‘This isn’t to tell people what to do but to help them make the best decision for their use case and allow industry to find solutions, by providing a set of data. It is a point in time study for most popular types of vessel currently in use. We hope to expand this out to more use cases and more emerging technologies, such as foiling, in due course, and aim to turn the work into a more usable life cycle analysis tool as a basis for solid decision making to help decarbonise the marine industry.’

The research did not interrogate the use of recycled goods, for example repurposed pre-used car batteries, or the re-engining of existing yachts, and nor did it pit one type of vessel against another.

It also didn’t give weight to local considerations, such as the need to reduce pollution or noise in ecologically sensitive environments, or increased user enjoyment or a reduction of maintenance.

‘This is a decarbonisation report rather than a usability report,’ said Lynch. ‘There are many other reasons to choose electric-based criteria such as noise, smell, cost, maintenance and so on,’ acknowledging the focus is very much on the global carbon emissions of a vessel’s lifecycle.

Electric cars have a very different set of parameters, meaning they are more able to offset the additional carbon emitted in their manufacture. Photo: Kenny Williamson / Alamy Stock Photo

Cars vs Boats

One of the big assumptions the report seeks to interrogate is that because electric cars, or ‘battery electric vehicles’ (BEV), are thought to be the most environmentally friendly solution for land-based transport, the same will apply on the water. The problem is that there are vast differences between cars and boats, according to the data.

For a start, propelling a boat over a set distance takes roughly 10 times more energy than it takes to move a car. Then you’ve got the fact that most cars are used much more regularly and for longer periods than cruising boats.

This means that of a car’s total lifetime carbon footprint, less than 20% of it is in its manufacture, with almost 80% in its usage – energy supply, exhaust emissions and maintenance – and a bit in its end-of-life disposal. For a boat, the research shows that while some yachts are heavily used, many lie idle for great chunks of time, and they arrived at an average annual usage of a sailing boat’s engine of just 24 hours a year, based on data from engine manufacturer service records and data from the US Environmental Protection Agency.

For the various kinds of motorboats, this increases to between 35 to 48 hours a year. Only a commercially operated rental jet ski had an average use case of over 100 hours a year.

Proportionately, as much as 50% of a boat’s lifetime emissions come from its manufacture, 10% from scrappage and 40% from its usage (and even less when it comes to sailing boats). This gives you a much shorter lever with which to balance out carbon already emitted with a reduction of carbon in usage.

Small dinghies are now frequently powered by electric motors. Photo: Benjamin Sellier

Supply chain carbon

The research analysed the carbon contribution, or global warming potential (GWP), of each stage in the supply chain and lifecycle of each propulsion system, for each of the vessels being considered.

It assumed a like-for-like comparison of energy storage and range, rather than the ‘optimised’ systems referred to later. While these vessels would not be usable in the real world, it made it possible to compare the carbon footprint of equivalent processes within the supply chain.

In the figures given, an inflatable dinghy using an electric outboard can eliminate around 40% of its total GWP from its usage emissions (energy, tank to wake) alone, compared to the petrol-driven baseline. However, this has to offset an almost three-fold increase in its raw materials (propulsion) carbon footprint and a manufacturing footprint that is around two-and-a-half times higher.

Using sustainable marine fuel caused a far bigger increase in the craft’s total footprint, in which the energy well-to-tank actually doubled the craft’s footprint.

For sailing yachts, there is a proportion of the vessels’ total GWP that is attributed to the hull and structure’s raw materials that is several times higher than that of any of the propulsion systems’ raw materials, including electric, though manufacturing impacts are significant.

Mineral extraction and the processes involved are a large part of batteries’ carbon footprint

By far the worst option for a sailing boat was hydrogen, where the well-to-tank impact of the fuel accounted for 40% of the vessel’s total GWP, giving a hydrogen-propelled vessel a carbon footprint twice the size of a fossil fuel-propelled boat.

Both electric and hybrid systems’ GWP were 50% higher than the baseline, with much of this coming from raw materials, manufacture, and surprisingly, maintenance, given electric systems’ almost maintenance-free usage, due to the necessary replacement of the batteries (estimated life span of 12.5 to 15 years).

Even sustainable marine fuel had a higher total impact by about 12% before use-case optimisation, due to a higher energy well-to-tank impact.

Darren Vaux, President of ICOMIA, says, ‘There is a lot of carbon in the supply chain of the batteries, and because there is such low utilisation of hours, it’s very hard to offset. Sailing craft life is long, so the batteries have to be replaced during the course of its life because they don’t have the same longevity.

‘The fascinating thing is that electric motors’ torque profile, lack of noise and all of that are absolutely ideally suited for marine. The challenge is the energy storage, both in terms of the energy density, and also the life of the batteries and the carbon embodied in them from most battery manufacturers.

‘Where manufacturers who operate in a country where they have a high green-energy mix, and a supply chain for manufacture in a factory with a very low carbon footprint, then there’s a competitive advantage to say, “I’ve got a battery that has a very low carbon footprint,” and that will address some of the carbon issue. The energy density of batteries is still significantly lower, but this may be satisfactory in some cases.’

Fitting any kind of alternative propulsion to runabout day boats like this RIB requires a significant compromise.

Realistic comparisons

The five power systems weighed up were all systems that use existing technologies currently available commercially. These were: conventional petrol or diesel internal combustion engines (ICE) as a baseline; sustainable fuels used as drop-in alternatives for fossil fuels in ICEs; hybrid fuel (fossil/sustainable) and electric systems; battery electric drives, and hydrogen ICE or fuel cells.

In order to calculate the life cycle assessment of vessels equipped with the various alternative propulsion systems, it was unrealistic to substitute in systems that provided like-for-like power and range.

As Patrick Hemp, ICOMIA technical consultant explained, ‘We get a lot of questions around the bottom-up approach and why H2 ICE and Battery Electric needed to be optimised. The main reason Ricardo had to do this was because the current baseline speed/range is simply not possible with Hydrogen ICE or Battery Electric (too much weight and volume) and hence, a downsizing was required.’

Fitting any kind of alternative propulsion to runabout day boats like this RIB requires a significant compromise

Runabout motorboat

As an example, a small runaround motorboat may have a typical range of 14 hours and 166 miles. To give the same range in a single duty cycle (one tankful or battery charge) with hydrogen propulsion, fuel storage would need to be around 430% larger than the ICE system and would be 350% heavier, giving the boat a displacement 56% greater.

With electric propulsion, the volume of the batteries for this range would be 360% larger and 820% heavier, with a vessel displacement 133% heavier.

In the calculations, the researchers decided to optimise the power system so that it could still fulfill the way most people use the boat, but with a propulsion system as close to the mass, volume and performance of the existing system as possible.

When aiming to achieve a range of 3 hours and 35 miles for the same small motorboat – a reduction of around 80% – a hydrogen system that was 61% larger and 13% heavier with a displacement increase of just 6% was achievable. For electric power for the same range reduction, the system was 23% larger, while being 81% heavier, with a displacement increase of 16%.

A sailing yacht has a huge fuel-free range if sailed, but most cruisers rely on auxiliary propulsion to keep making progress when conditions don’t suit. Photo: Richard Langdon

Sailing vessel

The calculation for a sailing boat used a baseline of a boat running on diesel, though the HVO fuel figures are identical. With a 21kW / 28hp engine and 70L fuel tank, the boat has a range of 24.5 hours and 147 miles, and there is no increase to mass, volume or displacement for either diesel or HVO.

Change to a hybrid electric drive system running a 21kW / 28hp ICE engine, with a 21kW electric drive. The fuel tank can be reduced slightly to 59L for the same range, but the system volume increases by 69% and would be 137% heavier, increasing the boat’s displacement by 6%.

For an electric or hydrogen system, the systems were specified to a range of 4 hours / 24 miles at an equivalent 6 knots, a reduction in range of around 84%.

The electric system, with a 21kW motor needed a battery capacity of 49kW, which resulted in a system that was actually 18% smaller than the baseline, though it was 61% heavier, and resulted in an additional 3% displacement.

Hybrid Marine specialises in diesel-electric parallel hybrid systems built around new Beta and Yanmar engines

The hydrogen-powered boat, with 21kW engine, had high-pressure fuel tanks to hold 3.7kg of hydrogen. This system was 49% larger than a standard engine and tank, and was 12% heavier, adding just 1% to the boat’s displacement.

Alternative propulsion systems were optimised in this way to enable realistic life cycle assessment comparisons to be made. Looking at the data then, sailors are free to make choices about whether they would be more happy to accept compromises to range, performance, the amount of space on board, and displacement, as well as cost.

Unsurprisingly, the report found alternatives are more expensive than the status quo, albeit within an enormous range. Electric systems as specified in the optimised use cases were 40% to 250% more expensive, 85% to 200% more for hydrogen, 25% to 115% more for hybrid, and 5% to 45% more for using sustainable drop-in marine fuel alternatives.

Large numbers of yachts remained unused or very lightly used, leading to just 24 engine hours a year on average

How much do boats get used?

While ‘battery electric on-road automotive vehicles’ (BEV) reduce CO₂ emissions by between 50% and 70% relative to conventional fossil fuel engines over their lifetime, the initial CO₂ created during the production of an electrical vehicle (EV) can be at least 50% more than a conventional ICE vehicle due to raw materials and the energy intensive process of creating the battery.

This means it takes an electric car 100,000 to 150,000km (62,000 to 93,000 miles) to get the break-even point where it is starting to have a positive impact on carbon emissions, which might take 3-5 years of fairly heavy use.

This also takes into consideration the fact that drivers’ range expectations have, on average, been reduced, so that one battery charge on your car will take you about 60% of the distance your old diesel or petrol car would have done. The cost, size and weight of the batteries would be prohibitive for a like-for-like range, and the environmental cost – mostly attributed to the batteries – would also be even higher.

For boats, those with very high use cases, and where small batteries with limited range can be specified, such as ferries and other commercial vessels, some of the new technologies really do add up in a similar way to cars. But the average leisure cruising yacht (though not, for example, a liveaboard cruiser), has just 24 hours of engine use a year, over its 45-year life span, according to the data.

Diesel engines remain the lowest impact propulsion to manufacture and install, but the emissions from the supply and use of them needs to be reduced

If this seems crazily low, marine surveyor Ben Sutcliffe Davies explained, ‘When I go to survey a vessel, I’m often amazed at how few hours have been put on the engines. It’s rare to find a yacht that’s done much over 50 hours in a year.’

Certainly, many boats will be used far more than the assumptions in this report, but there are also many boats that sit sadly idle, used for a handful of days or hours over the summer. The ‘use case’ of any boat is one of the key deciding factors in what propulsion technology will be the greenest option, and it’s worth remember that this report aims to look at the majority average rather than outliers.

In order to get to the ‘break even’ point on an average GRP cruising yacht, where the new propulsion system’s reduced usage emissions have compensated for its increased manufacturing emissions, you will need to do 60 hours of electric motoring a year (compared to 24 hours average), every year for its 45-year life span.

To get to a point where you have cut your emissions by 50% – the benchmark in the automotive industry – you will need to increase your usage by 600% above the average, or 168 hours of motoring a year on your electric engine. The figures are almost identical for a hybrid system.

Liveaboard and long-term cruisers clearly have a much higher use case, giving them longer to offset carbon with alternative technologies. Photo: Crew Eastern Stream

For a hydrogen system, which has a manufacturing footprint slightly lower than that of battery systems, the break even point comes sooner, with a modest 52% usage increase (36.5 hours), but with a slightly higher carbon footprint in use, a 50% reduction in emissions compared to a diesel engine will take a whopping 192 hours of motoring a year.

Surprising findings

Once the use cases and optimised propulsion systems have been taken into account, for many recreational sailing yachts that match the assumed use case, opting for electric propulsion in a new yacht or converting a used boat to hydrogen, hybrid or electric propulsion will be worse for the environment than sticking with a fossil fuel internal combustion engine (ICE).

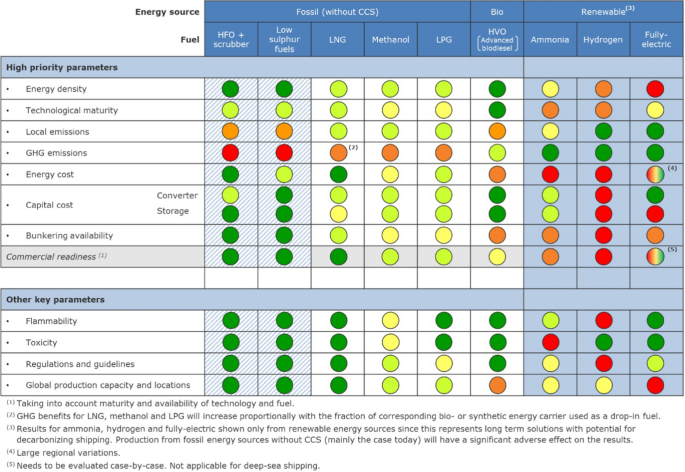

For most vessels and average use cases, the best way of reducing environmental impact for the time being is to retain conventional ICE engines, but switch to sustainable synthetic or biofuels such as hydrotreated vegetable oil (HVO) or e-petrol, the report claimed.

Doing this in a sailing yacht will, over the vessel’s 45-year lifespan with an average annual usage of 24 hours, reduce the vessel’s global warming potential by around 35%, compared to using fossil fuels in an ICE engine. The same benefit applies to both new boats and the numerically more significant existing fleet of boats already in use. Switching to electric or hybrid propulsion may in fact increase the vessel’s global warming potential by over 35%.

If you can find somewhere to buy HVO biofuel, this will be simplest way to immediately cut your carbon

Of the nine vessel types analysed, electrification was only the greenest option for a commercially operated personal water craft used for 156 hours per year over a 12.5 year lifespan. The highest impact of going electric was for a displacement motorboat, used for 48 hours a year over 45 years, where the global warming potential went up by over 80%.

If your vessel, its systems, their manufacture, and your usage don’t match the averages used in this report, then the life-cycle assessment might reach different conclusions, particularly if your usage is higher than average, but it’s worth considering the lifespan emissions when making these decisions.

How we choose to build, propel, and dispose of boats could be limited if their climate impact isn’t addressed

Conclusions

The research concluded that renewable diesel fuel, specifically hydrotreated vegetable oil (HVO) ICEs can provide the largest global warming potential (GWP) reductions compared to existing ICE propulsion, but only if the fuel is produced using waste feedstocks so that it’s not taking resource away from global food production, and gives the marine industry the greatest chance of decarbonising by as much as 90% by 2035 without compromising a vessel’s range or performance.

That’s all very well, and marinas with existing fuel supply infrastructure should be able to adapt easily, but it would require a huge increase in the supply of HVO in order to facilitate that change, and that capacity just isn’t there at the moment. As the report notes, ‘There is considerable uncertainty over the availability of these fuels through to 2035, and caution must be taken to guarantee that e-fuels are produced using low-carbon electricity sources and biofuels are produced with low GWP feedstocks.’

It also concludes that because electric-only systems ‘may have a higher GHG contribution from raw materials and manufacturing than conventional propulsion systems’, vessels that have low-usage cases are unlikely to ‘yield a reduction in greenhouse gases’ over their lifespans. Boats that are in frequent and prolonged use may be more likely to reach the break-even point, while hydrogen and hybrid systems may, in some cases, be the greenest option.

ICOMIA is now working on making a full life-cycle assessment tool available to the industry so that boats and use cases can be examined on a case by case basis. The report is a snapshot of the LCA for each type of boat, and a series of assumptions made about its usage.

ICOMIA President Darren Vaux, explains, ‘These use cases should cover the majority of the market, but there will be outliers that don’t fit these use cases. We are trying to move the dial on meeting the Paris Agreement for decarbonisation of the marine industry. At the moment, the only thing that will get us there is drop-in HVO fuels.

‘We need to focus policy-makers’ minds,’ Vaux continues. ‘We’re building infrastructure for electric vehicles, but we also need an infrastructure for the supply of sustainable fuels. We also want to challenge innovation, to encourage the industry to use the data-set as a challenge, with a clear focus on what the supply chain carbon impacts are.

‘Our data-set is the majority case, but that leaves room for boat builders to find ways around it, to say, “We’re better than that.”’

Enjoyed reading this?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

Watch CBS News

Take a tour of the Energy Observer, a sailboat running on 100% renewable energy

By Alecia Reid

April 12, 2024 / 6:11 PM EDT / CBS New York

NEW YORK -- A sailboat running on 100% renewable energy has made its way around the world for the last seven years and is now in New York City until Earth Day.

CBS New York's Alecia Reid got a tour of the vessel.

The Energy Observer is a decommissioned racing catamaran, now refitted with solar panels covering the entire vessel, in addition to innovative technology. It's a step towards a greener, more sustainable, low-carbon future.

"What we're trying to show to people is that a mix of renewable energies is the best option," boat swain George Conty said.

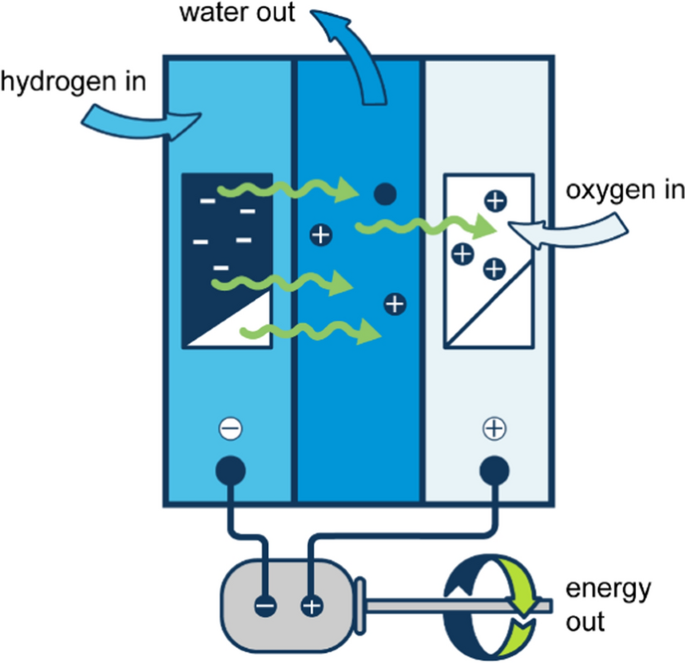

The floating lab is the first self-sufficient, zero-emission vessel. The crew of five uses renewable energy and hydrogen technology to power the boat as they sail around the world. The initial energy comes from the sun and wind.

"The excess, we store it in batteries. Then when the batteries are full and we still have some sun, instead of just losing this energy that arrives on the boat, we produce hydrogen to continue storing this energy in the form of gas," on-board system engineer Luc Bourserie said.

Engineers are constantly testing the technology to ensure it works. The hope is that any part of the prototype can be used as an inspiration to others searching for ecological sustainability.

"We have proof that the technology works," said Beatrice Cordiano, on-board scientist and climate energy expert. "The concept is quite simple, you just have to deploy a lot of renewable energy capacity."

It's definitely tight quarters living on the boat year-round, but the crew has a decent-sized kitchen that they make good use of.

"And sometimes we don't, and make salads. We adapt," Bourserie said.

People interested in touring the Observer can win a chance at the Earth Day Festival in Union Square on April 14. The vessel will remain in New York City until April 22 before heading to the Summer Olympics in Paris.

Alecia Reid is an award-winning, Emmy-nominated reporter for CBS News New York. She is a sustainability and social justice advocate; passionate about giving a voice to people who may not otherwise be able to tell their stories.

Featured Local Savings

More from cbs news.

Video shows NYPD officers punching Brooklyn shelter worker

Watch: NYC Schools Chancellor David Banks on "The Point"

NYPD looking for man who took knife from Brooklyn subway shooting scene

Up to $50,000 per homeowner now available in NYS Flood Program

Advertisement

Sustainable energy propulsion system for sea transport to achieve United Nations sustainable development goals: a review

- Open access

- Published: 06 April 2023

- Volume 4 , article number 20 , ( 2023 )

Cite this article

You have full access to this open access article

- Zhi Yung Tay 1 &

- Dimitrios Konovessis 2

8165 Accesses

14 Citations

2 Altmetric

Explore all metrics

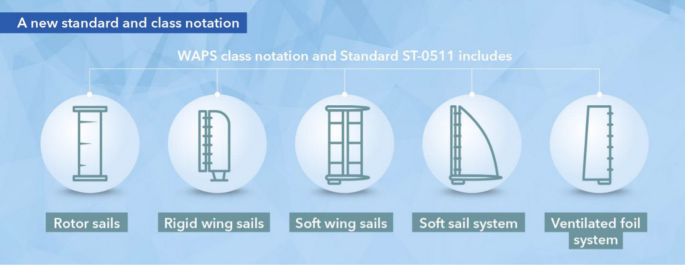

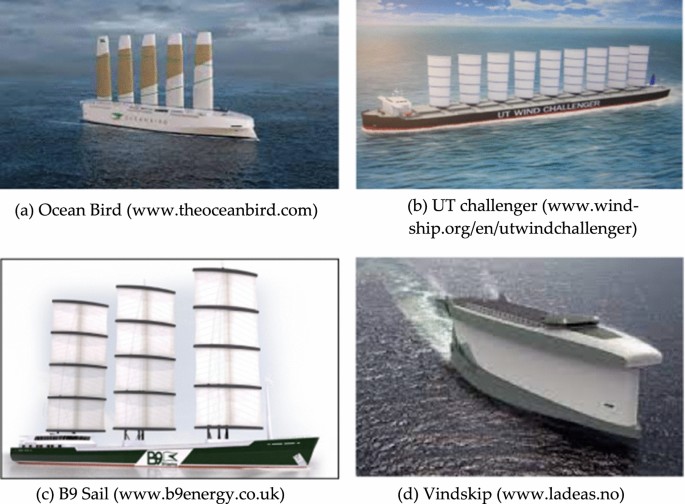

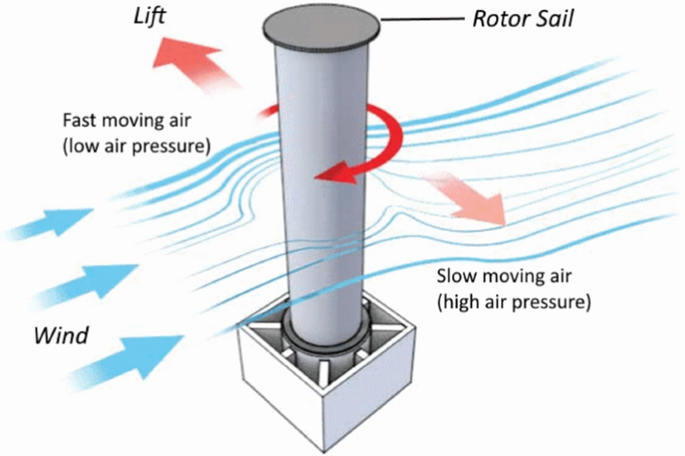

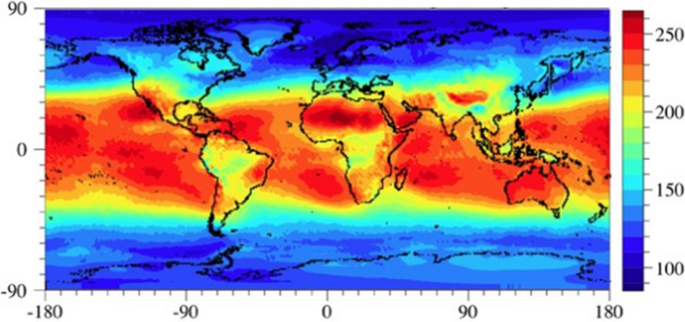

The cost of renewable energy technologies such as wind and solar is falling significantly over the decade and this can have a large influence on the efforts to reach sustainability. With the shipping industry contributing to a whopping 3.3% in global CO 2 emissions, the International Maritime Organization has adopted short-term measures to reduce the carbon intensity of all ships by 50% by 2050. One of the means to achieve this ambitious target is the utilisation of propulsion systems powered by sustainable energy. This review paper summarises the current state of the adoption of renewable energy and alternative fuels used for ship propulsion. Special focus is given to the means of these alternative energies in achieving the United Nations Sustainable Development Goals, in particular Goal 7 (Affordable and Clean Energy), Goal 9 (Industry, Innovation and Infrastructure) and Goal 13 (Climate Action). A state-of-the-art for various ships powered by renewable energy and alternative fuels is investigated and their technologies for mitigating carbon emissions are described. The cost for each technology found in the literature is summarised and the pros and cons of each technology are studied.

Similar content being viewed by others

Putting the Pieces Together for Sustainable Shipping

Energy Transition in Maritime Transport: Solutions and Costs

Energy Efficiency and Management Onboard Ships

Avoid common mistakes on your manuscript.

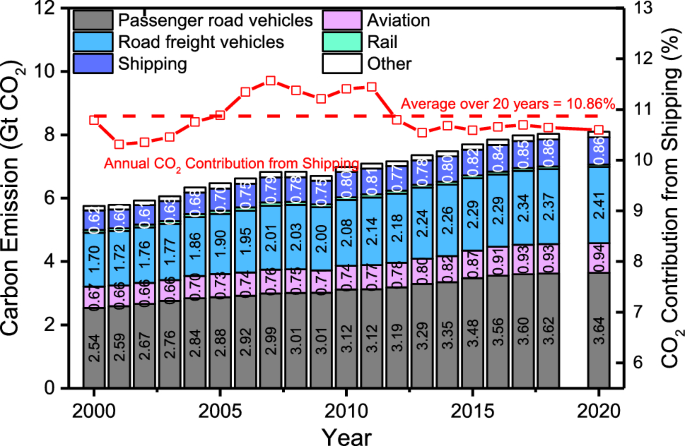

1 CO 2 emission trends

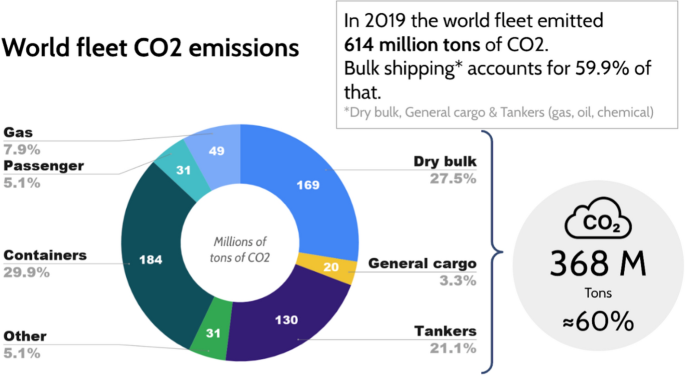

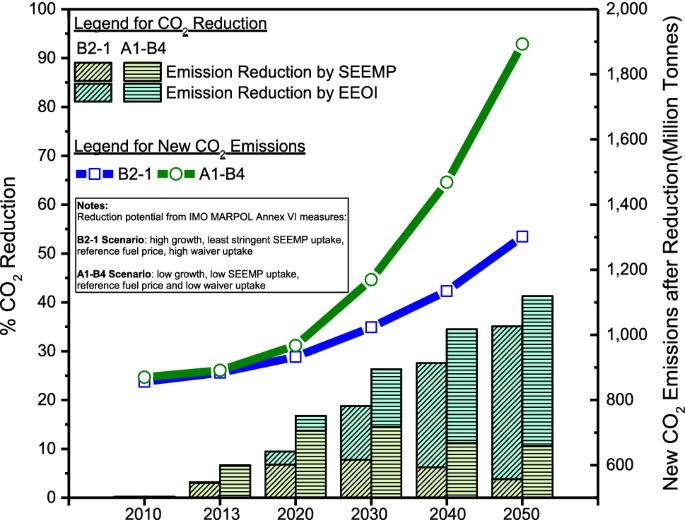

1.12 billion metric tons of carbon dioxide (CO 2 ) were released by ocean-going vessels in 2007 [ 1 ]. This value was equivalent to the annual greenhouse gas (GHG) emissions from over 205 million cars [ 1 ]. In addition, international shipping contributed to around 3.3% of global annual CO 2 emissions calculated in the third greenhouse study by the International Maritime Organisation (IMO) [ 2 ]. Since global trade is constantly growing, IMO also predicted that the emissions from international shipping could grow between 50 and 250% by 2050 [ 3 ].

Based on the data found on IEA’s website that track the CO 2 emissions from international shipping [ 4 ], the emission reduction was not on track with the IMO’s goal. The emission rate from the shipping fleet alone was about 800 million metric tonnes of CO 2 in 2019, 794 million metric tonnes in 2020 and increased to 833 million metric tonnes in 2021 [ 5 ]. This trend was not consistent with the goals set by the IMO and thus alternative energy sources have to be sought to support and work towards the goal of cutting CO 2 emissions by 50% by 2050 [ 2 ].

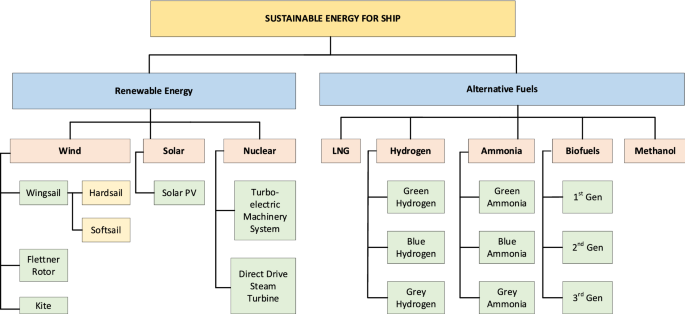

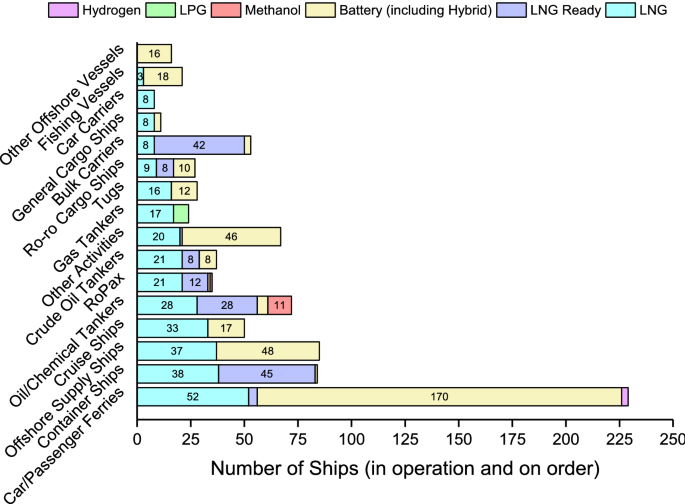

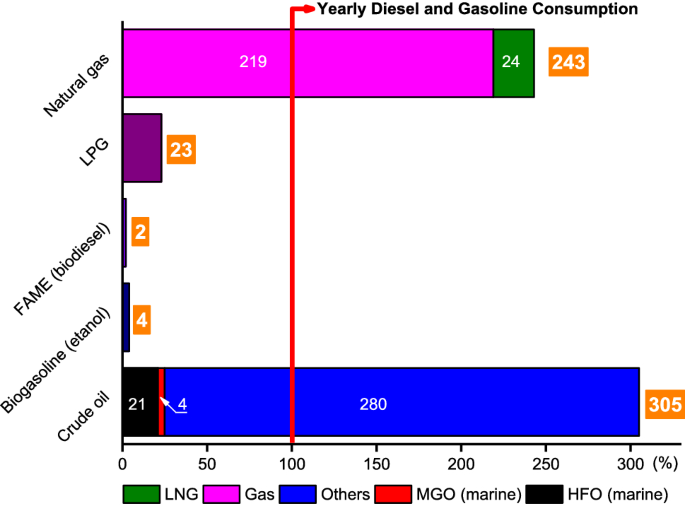

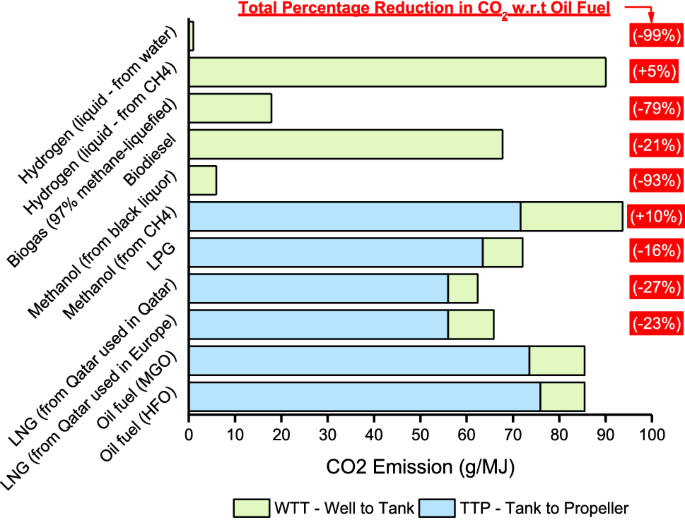

The maritime industry contributes to over 90% of shipping all around the world [ 6 ]. With an estimated emission of around 1,056 million tonnes of CO 2 in 2018, the maritime industry itself was responsible for 2.89% of global GHG emissions [ 7 ]. However, with the onset of new renewable technologies and alternative fuels, the emissions from the maritime industry are expected to be cut down significantly. The industrial revolution for ship propulsion led to innovative technologies such as steamships and the introduction of coal, followed by new generation ships powered by oil. The 4 th industrial revolution for ship propulsion will see the use of clean energy in the evolution and growth of the shipping industry. Currently, thanks to the mission set by IMO, ships using heavy fuel oil (HFO) that produce GHG such as Sulphur Oxides (SO x ) and Nitrogen Oxides (NO x ) were required to reduce their sulphur content to 0.5% or less in 2020 [ 8 ]. Furthermore, stricter measures were put in place in Emission Control Areas (ECA) such as the North Sea and the coast of the United States, designated under the MARPOL Annex V1 [ 9 ]. Technology has also evolved, and shipping companies are considering various methods to achieve the intended zero emissions in their ships, such as using electric propulsion ships loaded with batteries, and next-generation marine fuels such as hydrogen, ammonia and biofuel. Furthermore, the use of wind and solar power is also being considered as a hybrid propulsion system integrated with conventional diesel-powered vessels to reduce fuel consumption and carbon emissions.

According to a report by International Energy Agency [ 10 ], the current policy framework estimates that low- and zero-carbon fuels are projected to make up roughly 2% of total energy consumption in international shipping in 2030 and 5% in 2050 [ 10 ]. This falls severely short of the 15% in 2030 and 83% in 2050 set in the Net Zero Scenario [ 10 ]. To reduce emissions, other renewable energy technologies need to be implemented such as the technology of using ammonia as the fuel source for international shipping, which is the main low-carbon fuel that is projected to reduce emissions in the Net Zero Emissions Scenario [ 10 ]. The various initiatives to decarbonise the shipping industry in alignment with the UN SDGs are provided in the next section.

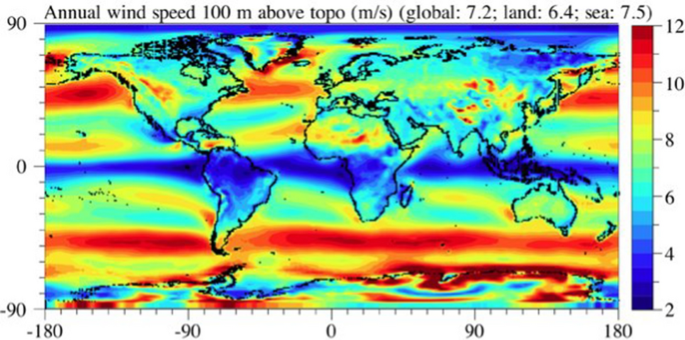

2 Sea transportation and United Nations Sustainable Development Goals

The shipping industry and research community have been actively seeking means to reduce GHG emissions since the initial strategy for the reduction of GHG emissions from ships was adopted by IMO in 2018. Various methodologies and technologies were proposed such as via the installation of exhaust gas cleaning systems [ 11 , 12 ] (EGCS, also known as scrubbers), slow steaming [ 13 , 14 ], achieving fuel efficiency using big data and machine learning systems [ 15 , 16 , 17 , 18 , 19 , 20 , 21 , 22 ], optimization of ship engineering design [ 23 , 24 , 25 ], innovative ship design to reduce ship resistance [ 26 , 27 ] and many more. Numerous state-of-the-art reviews on the utilisation of alternative fuel (AF) and renewable energy (RE) in the maritime industry in achieving the climate target have been covered, e.g., in [ 28 , 29 , 30 ]. Law et al . [ 31 ] made a comparison of AF for shipping in terms of lifecycle energy and cost and reviewed 22 potential pathways toward decarbonisation of the shipping sector. Wang et al . [ 32 ] summarised the low and zero-carbon fuel technologies of marine engines and proposed the future development of low and zero-carbon ships. A techno-economic assessment of alternative marine fuels for inland shipping was presented by Percic et al. [ 33 ], Korberg et al. [ 34 ] and Fam et al. [ 34 ] where the Percic et al . [ 33 ] article highlighted that methanol as the most economical AF. The usage of AF and technologies for short-sea shipping were also covered in [ 35 , 36 ]. The current state of ship propulsion and alternative options from the aspects of costs, infrastructure, regulations etc. in achieving decarbonisation by 2050 were highlighted in [ 37 ]. A comprehensive review of the means to decarbonise the shipping industry via assessment of fuels, efficiency measures and policies was highlighted in [ 38 , 39 ]. The articles suggested that LNG must be combined with various efficiency measures to meet the 50% climate target whereas wind assistance presents a strong potential to reduce fuel consumption.

While numerous review articles touched on the utilization of RE and AF in the maritime industry from the techno-economical, fuel efficiencies, policies etc. points of view, this review article is motivated by the role the maritime industry could play in achieving the United Nations (UN) Sustainable Development Goals (SDGs) to eradicate poverty and achieve sustainable development by 2030 via the use of RE and AF. Set up in 2015 and adopted by the UN Member State, the UN SGDs are a collection of 17 interlinked global goals designed to be a “shared blueprint for peace and prosperity for people and the planet, now and into the future” [ 40 ]. The IMO as part of the UN family is actively working towards the 2030 Agenda for Sustainable Development and the associated SDGs. The IMO has committed to reducing GHG from international shipping by at least 50% by 2050 compared to the 2008 level, with a vision to phase GHG out entirely in this century. Recognizing the fact that around 90% of traded goods are carried by sea transportation [ 41 ], there is no doubt that the 2030 Agenda for Sustainable Development could only be achieved with sustainable sea transportation.