The Worldwide Leader in Sailmaking

- Sail Care & Repair

- Sailing Gear

- Sail Finder

- Custom Sails

- One Design Sails

- Flying Sails

- New Sail Quote

- 3Di Technology

- Helix Technology

- Sail Design

- NPL RENEW Sustainable Sailcloth

- Sailcloth & Material Guide

- Polo Shirts

- Sweaters & Cardigans

- Sweatshirts & Hoodies

- Accessories

- Mid & Baselayers

- Deckwear & Footwear

- Luggage & Accessories

- Spring Summer '24

- Sailor Jackets

- NS x Slowear

- Sailor Jacket

- Sustainability

- North Sails Blog

- Sail Like A Girl

- Icon Sailor Jacket

- Our Locations

- North SUP Boards

- North Foils

- North Kiteboarding

- North Windsurfing

SAIL FINDER

SAILING GEAR

COLLECTIONS & COLLAB

WE ARE NORTH SAILS

ACTION SPORTS

Popular Search Terms

Collections

Sorry, no results for ""

NORTH SAILS

SAILCLOTH & MATERIAL GUIDE

For North Sails, building high quality sails has always meant using the best materials. Since inception, we have consistently delivered industry-changing advances and innovations in sailmaking technology, developing materials and processes to fit the needs of a wide range of boats and types of sailing.

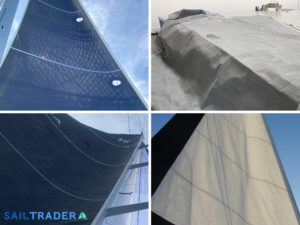

3Di MOLDED COMPOSITE SAILS

3Di is a unique, patented sailmaking technology that produces the world’s fastest and most reliable sails. 3Di sails mirror the balanced load bearing and shape holding of a rigid airfoil wing. They are constructed from spread filament tapes, contain no Mylar film, and are 3D molded into a one-piece, flexible composite sail structure.

LEARN MORE ABOUT 3Di

EXPLORE 3Di USE GROUPS

3di endurance, 3di downwind, north panel laminate.

North Panel Laminate (NPL) sailcloth is produced using the most advanced laminator in the world. Our machine was designed by North Sails material engineers and is purpose-built for laminating sailcloth. North Sails has been manufacturing exclusive cloth in our Sri Lanka facility since 2010.

LEARN MORE ABOUT NPL

EXPLORE NPL USE GROUPS

Npl downwind, north panel cloth.

North Sails has a long tradition of making dacron sails since the fiber was first introduced as a sailcloth in the 1950’s. Today we control every aspect of the cloth manufacturing processes – using our experience to ensure the highest quality products for both cruising and racing.

LEARN MORE ABOUT NPC

EXPLORE NPC USE GROUPS

Npc cross-cut, npc downwind.

EXPLORE SAIL TYPES

GET IN TOUCH

REQUEST A QUOTE

- Refresh page

The Ultimate Guide to Sail Types and Rigs (with Pictures)

What's that sail for? Generally, I don't know. So I've come up with a system. I'll explain you everything there is to know about sails and rigs in this article.

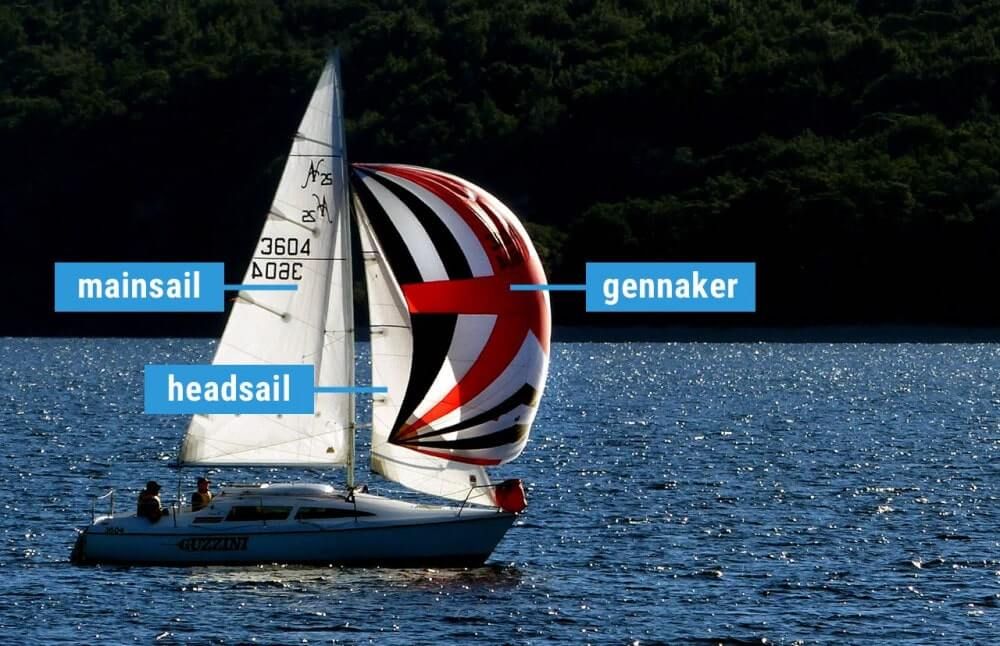

What are the different types of sails? Most sailboats have one mainsail and one headsail. Typically, the mainsail is a fore-and-aft bermuda rig (triangular shaped). A jib or genoa is used for the headsail. Most sailors use additional sails for different conditions: the spinnaker (a common downwind sail), gennaker, code zero (for upwind use), and stormsail.

Each sail has its own use. Want to go downwind fast? Use a spinnaker. But you can't just raise any sail and go for it. It's important to understand when (and how) to use each sail. Your rigging also impacts what sails you can use.

On this page:

Different sail types, the sail plan of a bermuda sloop, mainsail designs, headsail options, specialty sails, complete overview of sail uses, mast configurations and rig types.

This article is part 1 of my series on sails and rig types. Part 2 is all about the different types of rigging. If you want to learn to identify every boat you see quickly, make sure to read it. It really explains the different sail plans and types of rigging clearly.

Guide to Understanding Sail Rig Types (with Pictures)

First I'll give you a quick and dirty overview of sails in this list below. Then, I'll walk you through the details of each sail type, and the sail plan, which is the godfather of sail type selection so to speak.

Click here if you just want to scroll through a bunch of pictures .

Here's a list of different models of sails: (Don't worry if you don't yet understand some of the words, I'll explain all of them in a bit)

- Jib - triangular staysail

- Genoa - large jib that overlaps the mainsail

- Spinnaker - large balloon-shaped downwind sail for light airs

- Gennaker - crossover between a Genoa and Spinnaker

- Code Zero or Screecher - upwind spinnaker

- Drifter or reacher - a large, powerful, hanked on genoa, but made from lightweight fabric

- Windseeker - tall, narrow, high-clewed, and lightweight jib

- Trysail - smaller front-and-aft mainsail for heavy weather

- Storm jib - small jib for heavy weather

I have a big table below that explains the sail types and uses in detail .

I know, I know ... this list is kind of messy, so to understand each sail, let's place them in a system.

The first important distinction between sail types is the placement . The mainsail is placed aft of the mast, which simply means behind. The headsail is in front of the mast.

Generally, we have three sorts of sails on our boat:

- Mainsail: The large sail behind the mast which is attached to the mast and boom

- Headsail: The small sail in front of the mast, attached to the mast and forestay (ie. jib or genoa)

- Specialty sails: Any special utility sails, like spinnakers - large, balloon-shaped sails for downwind use

The second important distinction we need to make is the functionality . Specialty sails (just a name I came up with) each have different functionalities and are used for very specific conditions. So they're not always up, but most sailors carry one or more of these sails.

They are mostly attached in front of the headsail, or used as a headsail replacement.

The specialty sails can be divided into three different categories:

- downwind sails - like a spinnaker

- light air or reacher sails - like a code zero

- storm sails

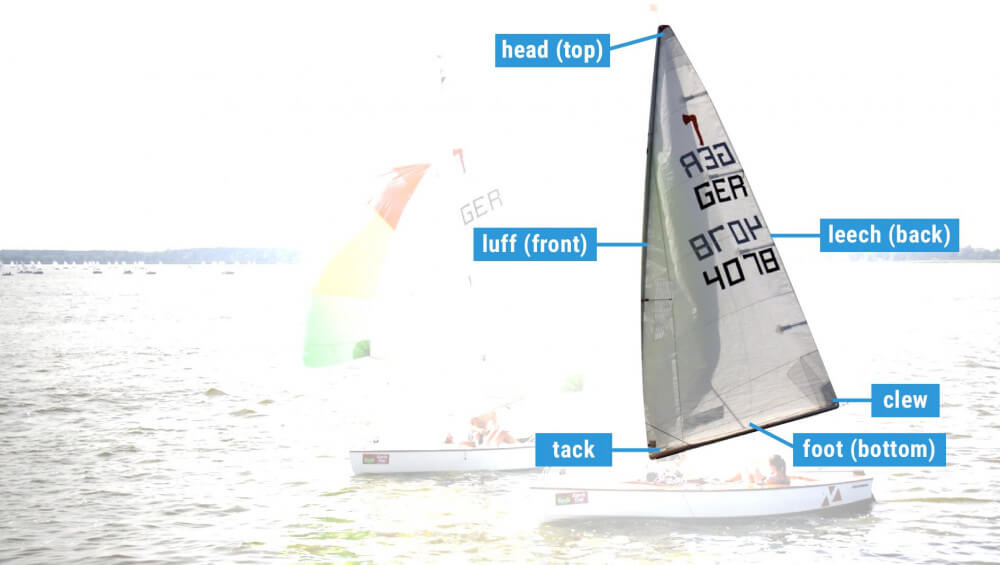

The parts of any sail

Whether large or small, each sail consists roughly of the same elements. For clarity's sake I've took an image of a sail from the world wide webs and added the different part names to it:

- Head: Top of the sail

- Tack: Lower front corner of the sail

- Foot: Bottom of the sail

- Luff: Forward edge of the sail

- Leech: Back edge of the sail

- Clew: Bottom back corner of the sail

So now we speak the same language, let's dive into the real nitty gritty.

Basic sail shapes

Roughly speaking, there are actually just two sail shapes, so that's easy enough. You get to choose from:

- square rigged sails

- fore-and-aft rigged sails

I would definitely recommend fore-and-aft rigged sails. Square shaped sails are pretty outdated. The fore-and-aft rig offers unbeatable maneuverability, so that's what most sailing yachts use nowadays.

Square sails were used on Viking longships and are good at sailing downwind. They run from side to side. However, they're pretty useless upwind.

A fore-and-aft sail runs from the front of the mast to the stern. Fore-and-aft literally means 'in front and behind'. Boats with fore-and-aft rigged sails are better at sailing upwind and maneuvering in general. This type of sail was first used on Arabic boats.

As a beginner sailor I confuse the type of sail with rigging all the time. But I should cut myself some slack, because the rigging and sails on a boat are very closely related. They are all part of the sail plan .

A sail plan is made up of:

- Mast configuration - refers to the number of masts and where they are placed

- Sail type - refers to the sail shape and functionality

- Rig type - refers to the way these sails are set up on your boat

There are dozens of sails and hundreds of possible configurations (or sail plans).

For example, depending on your mast configuration, you can have extra headsails (which then are called staysails).

The shape of the sails depends on the rigging, so they overlap a bit. To keep it simple I'll first go over the different sail types based on the most common rig. I'll go over the other rig types later in the article.

Bermuda Sloop: the most common rig

Most modern small and mid-sized sailboats have a Bermuda sloop configuration . The sloop is one-masted and has two sails, which are front-and-aft rigged. This type of rig is also called a Marconi Rig. The Bermuda rig uses a triangular sail, with just one side of the sail attached to the mast.

The mainsail is in use most of the time. It can be reefed down, making it smaller depending on the wind conditions. It can be reefed down completely, which is more common in heavy weather. (If you didn't know already: reefing is skipper terms for rolling or folding down a sail.)

In very strong winds (above 30 knots), most sailors only use the headsail or switch to a trysail.

The headsail powers your bow, the mainsail powers your stern (rear). By having two sails, you can steer by using only your sails (in theory - it requires experience). In any case, two sails gives you better handling than one, but is still easy to operate.

Let's get to the actual sails. The mainsail is attached behind the mast and to the boom, running to the stern. There are multiple designs, but they actually don't differ that much. So the following list is a bit boring. Feel free to skip it or quickly glance over it.

- Square Top racing mainsail - has a high performance profile thanks to the square top, optional reef points

- Racing mainsail - made for speed, optional reef points

- Cruising mainsail - low-maintenance, easy to use, made to last. Generally have one or multiple reef points.

- Full-Batten Cruising mainsail - cruising mainsail with better shape control. Eliminates flogging. Full-length battens means the sail is reinforced over the entire length. Generally have one or multiple reef points.

- High Roach mainsail - crossover between square top racing and cruising mainsail, used mostly on cats and multihulls. Generally have one or multiple reef points.

- Mast Furling mainsail - sails specially made to roll up inside the mast - very convenient but less control; of sail shape. Have no reef points

- Boom Furling mainsail - sails specially made to roll up inside the boom. Have no reef points.

The headsail is the front sail in a front-and-aft rig. The sail is fixed on a stay (rope, wire or rod) which runs forward to the deck or bowsprit. It's almost always triangular (Dutch fishermen are known to use rectangular headsail). A triangular headsail is also called a jib .

Headsails can be attached in two ways:

- using roller furlings - the sail rolls around the headstay

- hank on - fixed attachment

Types of jibs:

Typically a sloop carries a regular jib as its headsail. It can also use a genoa.

- A jib is a triangular staysail set in front of the mast. It's the same size as the fore-triangle.

- A genoa is a large jib that overlaps the mainsail.

What's the purpose of a jib sail? A jib is used to improve handling and to increase sail area on a sailboat. This helps to increase speed. The jib gives control over the bow (front) of the ship, making it easier to maneuver the ship. The mainsail gives control over the stern of the ship. The jib is the headsail (frontsail) on a front-and-aft rig.

The size of the jib is generally indicated by a number - J1, 2, 3, and so on. The number tells us the attachment point. The order of attachment points may differ per sailmaker, so sometimes J1 is the largest jib (on the longest stay) and sometimes it's the smallest (on the shortest stay). Typically the J1 jib is the largest - and the J3 jib the smallest.

Most jibs are roller furling jibs: this means they are attached to a stay and can be reefed down single-handedly. If you have a roller furling you can reef down the jib to all three positions and don't need to carry different sizes.

Originally called the 'overlapping jib', the leech of the genoa extends aft of the mast. This increases speed in light and moderate winds. A genoa is larger than the total size of the fore-triangle. How large exactly is indicated by a percentage.

- A number 1 genoa is typically 155% (it used to be 180%)

- A number 2 genoa is typically 125-140%

Genoas are typically made from 1.5US/oz polyester spinnaker cloth, or very light laminate.

This is where it gets pretty interesting. You can use all kinds of sails to increase speed, handling, and performance for different weather conditions.

Some rules of thumb:

- Large sails are typically good for downwind use, small sails are good for upwind use.

- Large sails are good for weak winds (light air), small sails are good for strong winds (storms).

Downwind sails

Thanks to the front-and-aft rig sailboats are easier to maneuver, but they catch less wind as well. Downwind sails are used to offset this by using a large sail surface, pulling a sailboat downwind. They can be hanked on when needed and are typically balloon shaped.

Here are the most common downwind sails:

- Big gennaker

- Small gennaker

A free-flying sail that fills up with air, giving it a balloon shape. Spinnakers are generally colorful, which is why they look like kites. This downwind sail has the largest sail area, and it's capable of moving a boat with very light wind. They are amazing to use on trade wind routes, where they can help you make quick progress.

Spinnakers require special rigging. You need a special pole and track on your mast. You attach the sail at three points: in the mast head using a halyard, on a pole, and on a sheet.

The spinnaker is symmetrical, meaning the luff is as long as its leech. It's designed for broad reaching.

Gennaker or cruising spinnaker

The Gennaker is a cross between the genoa and the spinnaker. It has less downwind performance than the spinnaker. It is a bit smaller, making it slower, but also easier to handle - while it remains very capable. The cruising spinnaker is designed for broad reaching.

The gennaker is a smaller, asymmetric spinnaker that's doesn't require a pole or track on the mast. Like the spinnaker, and unlike the genoa, the gennaker is set flying. Asymmetric means its luff is longer than its leech.

You can get big and small gennakers (roughly 75% and 50% the size of a true spinnaker).

Also called ...

- the cruising spinnaker

- cruising chute

- pole-less spinnaker

- SpinDrifter

... it's all the same sail.

Light air sails

There's a bit of overlap between the downwind sails and light air sails. Downwind sails can be used as light air sails, but not all light air sails can be used downwind.

Here are the most common light air sails:

- Spinnaker and gennaker

Drifter reacher

Code zero reacher.

A drifter (also called a reacher) is a lightweight, larger genoa for use in light winds. It's roughly 150-170% the size of a genoa. It's made from very lightweight laminated spinnaker fabric (1.5US/oz).

Thanks to the extra sail area the sail offers better downwind performance than a genoa. It's generally made from lightweight nylon. Thanks to it's genoa characteristics the sail is easier to use than a cruising spinnaker.

The code zero reacher is officially a type of spinnaker, but it looks a lot like a large genoa. And that's exactly what it is: a hybrid cross between the genoa and the asymmetrical spinnaker (gennaker). The code zero however is designed for close reaching, making it much flatter than the spinnaker. It's about twice the size of a non-overlapping jib.

A windseeker is a small, free-flying staysail for super light air. It's tall and thin. It's freestanding, so it's not attached to the headstay. The tack attaches to a deck pad-eye. Use your spinnakers' halyard to raise it and tension the luff.

It's made from nylon or polyester spinnaker cloth (0.75 to 1.5US/oz).

It's designed to guide light air onto the lee side of the main sail, ensuring a more even, smooth flow of air.

Stormsails are stronger than regular sails, and are designed to handle winds of over 45 knots. You carry them to spare the mainsail. Sails

A storm jib is a small triangular staysail for use in heavy weather. If you participate in offshore racing you need a mandatory orange storm jib. It's part of ISAF's requirements.

A trysail is a storm replacement for the mainsail. It's small, triangular, and it uses a permanently attached pennant. This allows it to be set above the gooseneck. It's recommended to have a separate track on your mast for it - you don't want to fiddle around when you actually really need it to be raised ... now.

Why Use Different Sails At All?

You could just get the largest furling genoa and use it on all positions. So why would you actually use different types of sails?

The main answer to that is efficiency . Some situations require other characteristics.

Having a deeply reefed genoa isn't as efficient as having a small J3. The reef creates too much draft in the sail, which increases heeling. A reefed down mainsail in strong winds also increases heeling. So having dedicated (storm) sails is probably a good thing, especially if you're planning more demanding passages or crossings.

But it's not just strong winds, but also light winds that can cause problems. Heavy sails will just flap around like laundry in very light air. So you need more lightweight fabrics to get you moving.

What Are Sails Made Of?

The most used materials for sails nowadays are:

- Dacron - woven polyester

- woven nylon

- laminated fabrics - increasingly popular

Sails used to be made of linen. As you can imagine, this is terrible material on open seas. Sails were rotting due to UV and saltwater. In the 19th century linen was replaced by cotton.

It was only in the 20th century that sails were made from synthetic fibers, which were much stronger and durable. Up until the 1980s most sails were made from Dacron. Nowadays, laminates using yellow aramids, Black Technora, carbon fiber and Spectra yarns are more and more used.

Laminates are as strong as Dacron, but a lot lighter - which matters with sails weighing up to 100 kg (220 pounds).

By the way: we think that Viking sails were made from wool and leather, which is quite impressive if you ask me.

In this section of the article I give you a quick and dirty summary of different sail plans or rig types which will help you to identify boats quickly. But if you want to really understand it clearly, I really recommend you read part 2 of this series, which is all about different rig types.

You can't simply count the number of masts to identify rig type But you can identify any rig type if you know what to look for. We've created an entire system for recognizing rig types. Let us walk you through it. Read all about sail rig types

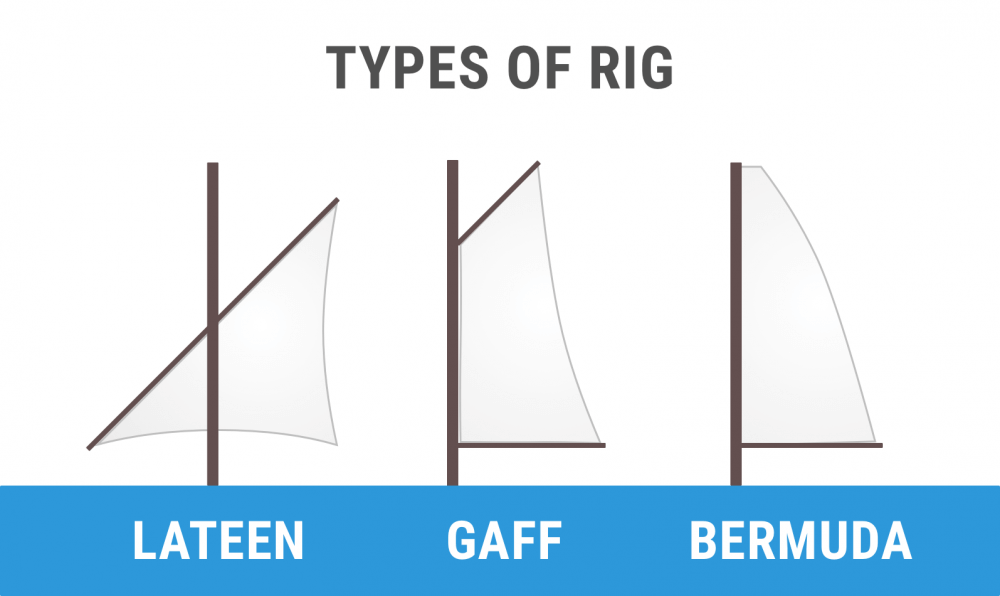

As I've said earlier, there are two major rig types: square rigged and fore-and-aft. We can divide the fore-and-aft rigs into three groups:

- Bermuda rig (we have talked about this one the whole time) - has a three-sided mainsail

- Gaff rig - has a four-sided mainsail, the head of the mainsail is guided by a gaff

- Lateen rig - has a three-sided mainsail on a long yard

There are roughly four types of boats:

- one masted boats - sloop, cutter

- two masted boats - ketch, schooner, brig

- three masted - barque

- fully rigged or ship rigged - tall ship

Everything with four masts is called a (tall) ship. I think it's outside the scope of this article, but I have written a comprehensive guide to rigging. I'll leave the three and four-masted rigs for now. If you want to know more, I encourage you to read part 2 of this series.

One-masted rigs

Boats with one mast can have either one sail, two sails, or three or more sails.

The 3 most common one-masted rigs are:

- Cat - one mast, one sail

- Sloop - one mast, two sails

- Cutter - one mast, three or more sails

1. Gaff Cat

2. Gaff Sloop

Two-masted rigs

Two-masted boats can have an extra mast in front or behind the main mast. Behind (aft of) the main mast is called a mizzen mast . In front of the main mast is called a foremast .

The 5 most common two-masted rigs are:

- Lugger - two masts (mizzen), with lugsail (cross between gaff rig and lateen rig) on both masts

- Yawl - two masts (mizzen), fore-and-aft rigged on both masts. Main mast much taller than mizzen. Mizzen without mainsail.

- Ketch - two masts (mizzen), fore-and-aft rigged on both masts. Main mast with only slightly smaller mizzen. Mizzen has mainsail.

- Schooner - two masts (foremast), generally gaff rig on both masts. Main mast with only slightly smaller foremast. Sometimes build with three masts, up to seven in the age of sail.

- Brig - two masts (foremast), partially square-rigged. Main mast carries small lateen rigged sail.

4. Schooner

5. Brigantine

This article is part 1 of a series about sails and rig types If you want to read on and learn to identify any sail plans and rig type, we've found a series of questions that will help you do that quickly. Read all about recognizing rig types

Related Questions

What is the difference between a gennaker & spinnaker? Typically, a gennaker is smaller than a spinnaker. Unlike a spinnaker, a gennaker isn't symmetric. It's asymmetric like a genoa. It is however rigged like a spinnaker; it's not attached to the forestay (like a jib or a genoa). It's a downwind sail, and a cross between the genoa and the spinnaker (hence the name).

What is a Yankee sail? A Yankee sail is a jib with a high-cut clew of about 3' above the boom. A higher-clewed jib is good for reaching and is better in high waves, preventing the waves crash into the jibs foot. Yankee jibs are mostly used on traditional sailboats.

How much does a sail weigh? Sails weigh anywhere between 4.5-155 lbs (2-70 kg). The reason is that weight goes up exponentially with size. Small boats carry smaller sails (100 sq. ft.) made from thinner cloth (3.5 oz). Large racing yachts can carry sails of up to 400 sq. ft., made from heavy fabric (14 oz), totaling at 155 lbs (70 kg).

What's the difference between a headsail and a staysail? The headsail is the most forward of the staysails. A boat can only have one headsail, but it can have multiple staysails. Every staysail is attached to a forward running stay. However, not every staysail is located at the bow. A stay can run from the mizzen mast to the main mast as well.

What is a mizzenmast? A mizzenmast is the mast aft of the main mast (behind; at the stern) in a two or three-masted sailing rig. The mizzenmast is shorter than the main mast. It may carry a mainsail, for example with a ketch or lugger. It sometimes doesn't carry a mainsail, for example with a yawl, allowing it to be much shorter.

Special thanks to the following people for letting me use their quality photos: Bill Abbott - True Spinnaker with pole - CC BY-SA 2.0 lotsemann - Volvo Ocean Race Alvimedica and the Code Zero versus SCA and the J1 - CC BY-SA 2.0 Lisa Bat - US Naval Academy Trysail and Storm Jib dry fit - CC BY-SA 2.0 Mike Powell - White gaff cat - CC BY-SA 2.0 Anne Burgess - Lugger The Reaper at Scottish Traditional Boat Festival

Hi, I stumbled upon your page and couldn’t help but notice some mistakes in your description of spinnakers and gennakers. First of all, in the main photo on top of this page the small yacht is sailing a spinnaker, not a gennaker. If you look closely you can see the spinnaker pole standing on the mast, visible between the main and headsail. Further down, the discription of the picture with the two German dinghies is incorrect. They are sailing spinnakers, on a spinnaker pole. In the farthest boat, you can see a small piece of the pole. If needed I can give you the details on the difference between gennakers and spinnakers correctly?

Hi Shawn, I am living in Utrecht I have an old gulf 32 and I am sailing in merkmeer I find your articles very helpful Thanks

Thank you for helping me under stand all the sails there names and what there functions were and how to use them. I am planning to build a trimaran 30’ what would be the best sails to have I plan to be coastal sailing with it. Thank you

Hey Comrade!

Well done with your master piece blogging. Just a small feedback. “The jib gives control over the bow of the ship, making it easier to maneuver the ship. The mainsail gives control over the stern of the ship.” Can you please first tell the different part of a sail boat earlier and then talk about bow and stern later in the paragraph. A reader has no clue on the newly introduced terms. It helps to keep laser focused and not forget main concepts.

Shawn, I am currently reading How to sail around the World” by Hal Roth. Yes, I want to sail around the world. His book is truly grounded in real world experience but like a lot of very knowledgable people discussing their area of expertise, Hal uses a lot of terms that I probably should have known but didn’t, until now. I am now off to read your second article. Thank You for this very enlightening article on Sail types and their uses.

Shawn Buckles

HI CVB, that’s a cool plan. Thanks, I really love to hear that. I’m happy that it was helpful to you and I hope you are of to a great start for your new adventure!

Hi GOWTHAM, thanks for the tip, I sometimes forget I haven’t specified the new term. I’ve added it to the article.

Nice article and video; however, you’re mixing up the spinnaker and the gennaker.

A started out with a question. What distinguishes a brig from a schooner? Which in turn led to follow-up questions: I know there are Bermuda rigs and Latin rig, are there more? Which in turn led to further questions, and further, and further… This site answers them all. Wonderful work. Thank you.

Great post and video! One thing was I was surprised how little you mentioned the Ketch here and not at all in the video or chart, and your sample image is a large ship with many sails. Some may think Ketch’s are uncommon, old fashioned or only for large boats. Actually Ketch’s are quite common for cruisers and live-aboards, especially since they often result in a center cockpit layout which makes for a very nice aft stateroom inside. These are almost exclusively the boats we are looking at, so I was surprised you glossed over them.

Love the article and am finding it quite informative.

While I know it may seem obvious to 99% of your readers, I wish you had defined the terms “upwind” and “downwind.” I’m in the 1% that isn’t sure which one means “with the wind” (or in the direction the wind is blowing) and which one means “against the wind” (or opposite to the way the wind is blowing.)

paul adriaan kleimeer

like in all fields of syntax and terminology the terms are colouual meaning local and then spead as the technology spread so an history lesson gives a floral bouque its colour and in the case of notical terms span culture and history adds an detail that bring reverence to the study simply more memorable.

Hi, I have a small yacht sail which was left in my lock-up over 30 years ago I basically know nothing about sails and wondered if you could spread any light as to the make and use of said sail. Someone said it was probably originally from a Wayfayer wooden yacht but wasn’t sure. Any info would be must appreciated and indeed if would be of any use to your followers? I can provide pics but don’t see how to include them at present

kind regards

Leave a comment

You may also like, 17 sailboat types explained: how to recognize them.

Ever wondered what type of sailboat you're looking at? Identifying sailboats isn't hard, you just have to know what to look for. In this article, I'll help you.

How Much Sailboats Cost On Average (380+ Prices Compared)

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

My Cruiser Life Magazine

Sailing Materials – What Are Sailboat Sails Made of?

Of all of the sailing materials found on the modern cruising or liveaboard sailboat, the sailing fabrics that make up the sails and lines may be some of the most space age. Sailing materials have advanced remarkably in the past 100 years, and the progress seems to keep speeding up.

There are still plenty of boats flying their trusty old Dacron sails, that’s for sure. But there are also more and more boats using advanced laminate sail fabrics. So let’s look at the differences and figure out which is right for your boat.

Table of Contents

Traditional canvas and “tanbark”, dacron sails, nylon sails, laminated sails and carbon fiber sailcloth, standard sail patterns, load-path sails, weave patterns in sailboat sail materials, the most crucial part of a sail design.

- Modern Sailboat Construction and Materials

Sail Materials FAQs

What are Sails Made Out Of?

Sail making material has actually changed dramatically in the last century. For example, the sails of the tall ships of yesteryear were made entirely of natural fibers, yet such a delicate thing is nearly impossible to find on a sailboat today.

But sails have progressed. What are sails made of? The most common material used today in Dacron, a synthetic fiber made of polyester. But progress doesn’t stop there. Today, sails are designed from the ground up in the loft, built fiber by fiber, for that specific application. Today’s racing sails and high-tech and truly marvels of modern engineering.

There are only four basic choices of fabric for sails.

- Natural fibers like cotton canvas, which are very rare now

- Synthetic modern fabric like polyester fiber Dacron, the most common sail material

- Lightweight fabrics like nylon, which is used for spinnakers and downwind sails

- High-tech composite fabrics called laminates, which are used on racing sailboats

Before the middle of the 20th century, sails were made of natural fibers (just like everything else on a boat). Cotton canvas was the material of choice but rotting was a major problem. Imagine what would happen to a cotton t-shirt left out in the sun and salt air 24/7/365.

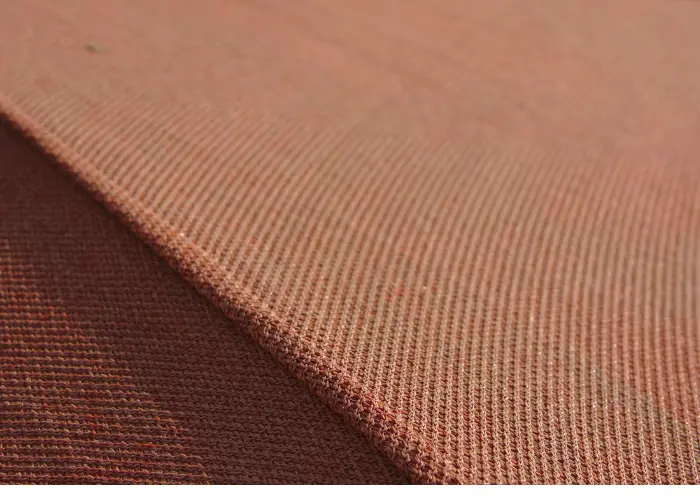

To help them last longer, cotton sails are tanned using tannins from tree bark. Tanbark sails, as these are called, have a reddish-brown color and are more resistant to rot, mold, and mildew.

The modern fabrics that replaced cotton have fixed most of the problems with rot, so real tanbark sails are basically a thing of the past. However, some modern sailcloth options are sold in a tanbark color for sailors who want that traditional look. True cotton sails are not an option for modern sailors. Even if you wanted to deal with the problems and expenses involved, finding a supplier for them would be next to impossible.

If anyone is still flying cotton sails out there, the only purpose would be for historical authenticity. Several museum ships around the world are maintained using original supplies and original materials. They have to source and sew their sails all from scratch.

Plastics changed nearly everything. Today, it’s nearly impossible to find a product that doesn’t contain some amount of plastic. Most types of sailboats are nearly all plastic when you look closely.

The canvas that most sailors associate with sailing is a woven acrylic cloth commonly referred to by its trade name, Sunbrella . It’s waterproof and extremely resistant to UV damage. It comes in a rainbow assortment of colors, although most boaters seem to prefer blue or green. Grey, tan, and red are also common, but you can find hundreds of options if you’re feeling creative. Sunbrella is used all over the boat–but not for sails.

The cloth used for sails is very similar, but it is woven heavier and more resistant to stretch. It is also most often referred to by its trade name–Dacron. Dacron is white in color 99-percent of the time. But it is also sold in tanbark, a reddish color that looks traditional.

Colored Dacron sailcloth is becoming more common, although it is still rare to see it on the water.

Dacron is the type of sail material you’ll see on nearly every sailboat you find. Dacron comes in various thicknesses or weights. The heavier the fabric, the stronger it is to take on heavy weather sailing. So a storm sail will be built out of heavy-weight fabric, whereas a 155-percent genoa made for light air will be made out of lightweight material.

The design and weight of the sail are matched for its purpose. Most boats are equipped with a set of sails that can do all conditions–but this nets you a “can do everything moderately well” sail. If you want light-air sails, the lighter fabric is then too thin to fly when the wind pipes up. If you want heavy-weather capability, the fabric will be too heavy to fill when the wind is light.

Dacron is still the number one choice for most sailors because it’s widely available, easily repaired, reliable, and affordable.

More often than not, if you see a colorful sail, it is made of nylon. Nylon is another type of synthetic fiber, but it is woven thin into very soft and billowy fabrics. Many of us own nylon windbreakers or know of the ripstop nylon used in tents, umbreallas, or even parachutes.

When used for sailmaking, nylon is good for light wind sails. It’s not strong compared to Dacron but it is lightweight. That makes it good for catching the slightest puff of breeze. Spinnakers are made of nylon, and since they look and feel like parachutes, sailors often call them “chutes.”

Unlike Dacron, nylon is widely available in any color you could want. Spinnakers are usually creative expressions of the crew or made to match the boat. They often have many colors stitched together in colorful patterns, just like hot air balloons.

The hottest thing in sailing is laminated sailcloth. The word “laminate” refers to a combination of materials stacked together to make a composite structure. For example, our hulls are made of fiberglass laminates. Racing boats have sails that are often laminates made of high-tech fibers and fabrics that offer maximum performance, strength, and sail shape.

Laminate sails start with a Mylar sheet base layer. High-tech fibers are then laid out and glued to this base. Finally, a material called taffeta gives the sail some strength and resistance to chafing. With so many options of materials, all layered one on top of the other, the sail can be precisely the shape the designer intends. Laminated sails are usually black or grey in color, and are sometimes transparent.

Eight different sailing fabrics can be used in laminate sails.

- Carbon fiber sails

- Spectra or Dyneema (Aramid fibers)

Laminated cruising sails offer the best performance and sail shape, but they are extremely expensive and generally not for your average cruising boat. They tend to offer shorter service lives and are more prone to UV damage than Dacron sails.

These high-tech sails can be made in one of two ways. First, the laminate materials may be created in rolls, just like Darcon or any other woven fabric. The sail loft then takes the material and cuts the panels to make a sail. The sail can be cut crosscut, tri-radial, or bi-radial, just like any other.

Alternatively, some lofts are now creating the laminate fabric as they manufacture the sail. This allows them to orient the strongest fibers of the layup in the perfect place to take the load placed on it during sailing. These sails are called load-path sails. North Sails 3Di sails are an example of this super-cool technology.

Sail Material Design, Cut, and Weave

The sail manufacturing process is an involved one. Sails are sized for the boat and customized for the cruising conditions in sailing and the style of the sailor at the helm . As a result, there are seemingly endless choices if you want to replace your sails, from the materials used, the sail design and cut to use, the conditions you’ll be expecting, and your goals for your boat performance-wise.

Sails are unique in that they must have a specific shape to power the boat. A perfectly flat sail is ineffective. Instead, it should have a curve like an airplane’s wing. This curve, called the draft, must be built-in. Sailmakers cut each piece of the sail with this in mind, and then the completed sail can have as much or as little curve as necessary.

There are three main types of cut that a sail can have to accomplish this–crosscut, tri-radial, and bi-radial. Each type varies in complexity and cost to manufacture and provides a different amount of shape-holding potential throughout its service life.

Crosscut Sails

Most sails you find will have crosscut designs. These sails are cut in strips that run from forward to back at a slight angle. Once the entire sail has been stitched together, reinforcements are added at each corner.

Stretching is a natural part of a sail’s life as it is trimmed and filled with wind. A crosscut sail does not have any extra structure to help it resist stretching, so they are more prone to it than other cuts.

When a sail has been stretched so far that it loses sailing efficiency, it’s said to be “blown out.” When crosscut sails blow out it will be a gradual process as the panels stretch a little bit at a time.

Tri Radial Sails

Tri-radial cut sails have a distinctive look to them. The panels that make the sail are smaller triangles that radiate from each sail corner. Tri-radial sails are made of more panels than crosscut ones, so there is more potential for a knowledgable sailmaker to fine-tune the design. This can result in a more efficient sail shape.

The extra seams in the sail also reinforce the sail overall. This results in a sail that doesn’t stretch as much over time. But once it does go, it is likely to blow out and needs replacement quickly.

If you’d like to see a detailed look at how the pieces of a tri-radial sail fit together, check out this DIY video from Sailrite. Sailrite sells sew-your-own sail kits, with the parts cut from CAD-designed plans.

Biradial Sails

A bi-radial sail is just like a tri-radial, except that the panels that make the design come from only two corners–the head and the clew.

Load path sails are built piece by piece in the loft using composite laminates. Instead of starting with sheets of material, the loft starts with the raw materials that will make the completed sail. Then, it is glued together into the final shape, with strong fibers reinforcing its built-in shape.

Not all fabrics are woven together in the same way. Dacron can be woven in multiple ways, and your sailmaker must know how to combine the right weaves with how the fabric is cut for the sail. The weave is designed to provide strength in one direction and shape in another.

Quite often, the difference in price between two similar-looking pieces of Dacron comes down to the weave. This is because the weave gives the Dacron “tenacity.” High-tenacity Dacron fabrics are best for cruising sails because they stretch less and distribute the load evenly over the sail.

It’s also important to consider the weave of the material when choosing the cut of the sail. For example, a cloth that works for crosscut sails will not be best for a radial cut sail. In addition, some manufacturers weave the Dacron with high-tech fibers, like Dyneema, for extra strength.

The important thing to know is that the weave of the sail cloth fabric you chose must match the cut of the sail’s panels. In other words, you can’t use the fabric from a tri-radial sail to make a crosscut sail or vice versa.

Picking the Right Sailboat Sail Material

For the amateur sailor, sorting through the dizzying array of choices of sailboat sails material is daunting. The flashy racing sails and load path sails are tempting, but are they worth it?

The truth is, Dacron is still popular for a reason. If you’re lucky enough to be outfitting a $500,000 aluminum sailboat , buying the best of the best only makes sense. But most of us are on a budget when outfitting our boats.

What’s more, will you notice the difference between a high-tenacity high-end Dacron compared to a laminate? The answer is probably no on an older, heavy displacement cruising boat. But, on the other hand, on a high-performance catamaran or trimaran, it might be well worth the investment.

Here’s a video from renowned sail loft Precision Sails discussing the most important factors when choosing your next set of sails.

Modern Sailboat Construction and Materials

Our boats have progressed a lot since the wooden-hulled and canvas-sailed ships of the past. Revolutionary new materials mean boats and sails that resist water, pests, and UV damage. As a result, years are added to the life of parts, and maintenance costs are reduced in the process. And if there’s one thing that every boater can agree on, it’s that most time sailing and less time doing maintenance is good news.

Sails are a major investment. For the average boater, a set of new sails should last ten or more years. Unless you’re planning on circumnavigating or racing competitively, most people never have to replace a set of sails. If you are faced with the choice, be sure to consult with a knowledgable sail loft that is familiar with your boat and your goals for it.

What are the materials used in sailing?

Sailboat sails are usually made of Dacron, a synthetic fabric made of polyester. It is very heavy, resists tearing, is waterproof, and resistant to UV damage.

What is the best material for a sail?

Nearly all sails on cruising boats are made of Dacron, a trade-name for polyester fabric. Dacron is long-living and resistant to water, UV damage, and rot.

What material are sailboat sails made of?

The most common sail material is Dacron, a type of polyester fabric. Alternatively, racing boats or yachts may have laminate sails made of high-tech materials like Kevlar or carbon fibers.

Is boat sail material waterproof?

Yes, the materials used in sailmaking do not absorb water. Dacron is the most common material, and it is extremely water-resistant.

Matt has been boating around Florida for over 25 years in everything from small powerboats to large cruising catamarans. He currently lives aboard a 38-foot Cabo Rico sailboat with his wife Lucy and adventure dog Chelsea. Together, they cruise between winters in The Bahamas and summers in the Chesapeake Bay.

Leave a comment

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

- Best Marine Electronics & Technology

Sail Materials 101

- By Joe Cooper

- Updated: August 26, 2020

One of the largest expenditures a cruising sailor will ever face is upgrading the yacht’s power plant. Not the one under the companionway—the ones set off the mast. As a former sail consultant for Hood Sails, I know that when it comes to new sails, cost is a primary concern for many sailors. The cheapest sails, however, aren’t always the best value.

Sailmakers and sailcloth manufacturers understand the importance of knowing how the customer’s boat and sails will be used. In addition to price, other criteria sailors should consider are durability , over time or miles; ease of handling when flaking; in some instances, the sail’s weight (can the owner, if necessary, move it around on deck?); and, in the case of an overlapping headsail, its chafe resistance. And, of course, a new suit of sails should be able to withstand the occasional “Uh-oh” moment and have the ability to be regularly reefed and still retain proper shape, which is imperative.

If you’re in the market for a new sail, you need to understand the various options available, both in types of sail materials and in sail design, so you can pose the right questions to your sailmaker and understand their recommendations before purchasing.

Since the 1950s, the default material for cruising sails has been Dacron sailcloth. But as boats got larger and more performance oriented—and their sails became highly loaded— sailmakers and cloth manufacturers developed and used fabrics that could better retain their shape. Today, sailors have essentially two material options, Dacron or laminates, the latter of which are built using a variety of specialized fibers.

In the United States and abroad, four major suppliers of sailcloth—Dimension Polyant, Bainbridge International, Challenge Sailcloth, and Contender Sailcloth—provide sailmakers with Dacron and laminate cloths and related materials to build strong, state-of-the-art headsails and mainsails.

Reliable, Affordable Dacron Sailcloth

Dacron sails are made from polyester fiber, which exhibits two primary sets of engineering properties: either high or low tenacity. The strengths of these fibers include their initial recovery from stretch; the break load for their size; resistance to chafe, exposure to ultraviolet light, and flex; reasonable cost; and minimal shrinkage when heated. High-tenacity fiber is superior for sails in every category, but it costs more, which is why there’s a wide discrepancy in price between low-tenacity Dacron sailcloth and its high-quality counterpart.

Obviously, high-tenacity Dacron makes better cruising sails. The cost difference between a “value” cloth and a “premium” one, both from the same supplier, can be significant, close to 100 percent for some 8-ounce Dacron sail fabric that I’ve seen ($7 per yard versus nearly $15 per yard). Today, however, most sailcloth manufactured for the U.S. market is high-tenacity.

Dacron sailcloth that’s suitable for use in a crosscut sail is by far the most widely produced. Crosscut construction is easily the simplest way for a sailmaker to build any sail. It essentially involves stitching together horizontal panels of cloth that are stacked from the foot to the head.

Cloth for this style of construction is commonly called fill-oriented . The “fill” is the fiber that runs across the roll of cloth and, in the case of crosscut sails, is the thicker and less crimped direction. ( Crimp refers to the S-curves caused by the weaving process.) When producing this cloth, the fill is pre-tensioned in the weaving process, and each strand of yarn is kept relatively short, since the width of a roll of cloth measures, at most, 6 feet. On the other hand, the warp—the thread that’s woven through the fill—might measure a couple of hundred feet in length.

Crosscut construction wastes very little cloth and is the fastest way to fabricate a sail; the seams between panels also offer many opportunities to design shape in the sail. The vast majority of modern boats use Dacron sails.

Recently, Challenge Sailcloth developed a Dacron product for use in radial-panel layout. North Sails also has its own version of Dacron, called Radian. In both materials, the warp, or long yarns, are or should be thicker than the fill.

Radial polyester fabric provides sailmakers with the opportunity to design and build triradial sails in woven material. Why is this important? The simple answer is that Dacron is the most durable fabric in absolute terms and that the radial-construction option can accommodate the higher loads placed upon larger or more performance-oriented sails. Sailmakers orient the sail’s panels to derive the shape of the sail and retain it over time. The radial corners are intended to minimize the so-called bias load —the 45-degree axis diagonally across the roll. The point to remember is that if you’re in the market for a sail, remember that the sailcloth in a triradial sail and the sailcloth in a crosscut sail are woven differently and aren’t interchangeable. Discuss the pros and cons of each with your sailmaker before placing an order.

Understanding Laminate Sail Materials

Laminated sails were first introduced in the early 1970s. The Australian 12-Meter Southern Cross tried using Kevlar fibers laminated to film and built as a crosscut sail before the 1974 America’s Cup. These early attempts at laminated sails proved to be unreliable—they were prone to break without notice—and were never used in competition. However, sailmakers realized the potential, and since then, building sails using several versions of laminated fabric has become the default fabrication method for racing and high-performance sails. The goal is a stretch-resistant, shape-holding, lighter sail that’s still affordable.

With laminate sails, there are many more components to the cloth, and sailmakers market their products under different names, which can be confusing. But reduced to the basics, the elements of laminated sailcloth are not unlike the components in the layup of a fiberglass boat; these include fibers, an adhesive, and a core.

Currently, there are eight different fibers used in sailmaking: carbon fiber, Spectra/Dyneema, Twaron, Technora, Kevlar, Vectran, polyester, and Pentax (which is basically “Dacron on steroids”). Only three of these—Dacron, Vectran, and Spectra—can be readily woven into a viable sail fabric. The remaining fibers are incorporated into a fabric in two basic ways; more on this in a moment.

Mylar film, the sheet form of polyester, is at the core of laminate sails. The film acts as a base to which everything else is glued to form the finished product. In addition, there is a specialized fabric called taffeta that’s used to provide chafe protection to the Mylar, as Mylar alone isn’t particularly durable and doesn’t respond well to chafe or sunlight. Taffeta, a woven polyester fabric consisting of small-diameter fibers, is glued onto the Mylar film—sometimes on one side, sometimes on both, depending on the sail’s intended use.

Finally, there’s a layer called the scrim . This is a combination of fibers—made entirely of Spectra, a Spectra/carbon blend, or consisting of other materials—driven by the sail’s intended use. The fibers in a scrim are assembled in combinations of angles in relation to each other and with different degrees of separations between the fibers. The scrim is designed to support the various secondary loads at work on a sail.

Historically, laminated sails of any construction method were usually replaced when the fibers delaminated from the film or the film itself broke down. Better glues and application methods, and the introduction of taffeta, largely addressed these two problems. Today, it’s virtually unheard of for a sail to fail because the fiber collapsed.

Two fundamental ways exist to make the laminate sail fabric. In one, the entire fabric is manufactured by a cloth company and arrives at the loft as a roll, known as roll goods . In building sails with roll goods, the laminated cloth is cut into panels that are then sewn together in one of three patterns: triradial, biradial, or crosscut. From the consumer’s perspective, panel configuration, for the most part, is a low priority, although there may be a small price difference among them. Your sailmaker can provide more information.

Load-Path Sails

Prior to the late 1980s and the introduction of North’s 3DL sails—so-called molded sails —sailmakers and cloth manufacturers were working on their own versions of what has become known as load-path or string sails , which is the other way of making a laminate fabric. Essentially, continuous fibers are glued down on a Mylar film in computer-generated paths engineered to handle the loads placed on the sail. Load-path construction eliminates the break in the fibers present in a sail fabricated from roll goods, where at each seam the fibers terminate and start again in the next panel.

CAD stands for computer-aided design, and CAM stands for computer-aided manufacturing; the shape of a load path sail is designed using the CAD elements of a CAD/CAM system. There are two stages to the sail-design process: aerodynamic shaping and engineering. After the sail is both designed and engineered, the basic sail skin, or Mylar, is crosscut; then each panel is glued to its mate using high-strength glue. With the film spread flat on a floor, the fibers are overlaid onto the Mylar sheet. Different sailmakers use proprietary techniques to unite the glue, the fiber, and the film as a working sail.

The one exception to this flat-floor method is North’s 3DL product, in its various versions. At North, the Mylar film is still cut and glued together, but it’s then laid onto the mold, a huge articulating machine that’s programmed to assume the same shape as the finished sail. The fibers and the rest of the components are laid onto the film on the mold using computer-controlled tooling. The whole sail is then pressurized and heated in much the same way as a hull or spar is produced in an autoclave.

These load-path sails thus combine making the sail with making the fabric , as both occur at the same time. Once the complete skin or membrane is cooked, it’s removed from the mold, and then the rest of the sail’s components—batten pockets, luff tape, numbers and lettering, headboard, and so on—are incorporated into a finished product.

Placing an Order for New Sails

Sailors have many things to consider when contemplating the purchase of new sails, especially laminated ones, but there are a few things to remember.

Generally speaking, in terms of durability, most sailmakers assume that three to five years is a reasonable life span for laminated sails, though many have clients who’ve gotten many more years of service. Incredibly, the threshold for many high-performance racing laminates is measured in hours.

For the most part, load-path sails feel smoother. In the assembly of the many panels of the sail made from roll goods—a practice in which the pieces are glued together by hand, which is an acquired, imperfect skill—the finished product can feel bumpy, and the seams often don’t lie flat when the sail is flying. These issues are minimized with load-path sails.

Pricewise, load-path sails are generally more expensive but retain their original shape longer. Their performance is better right out of the bag. And load-path sails are considerably lighter than laminate sails built with other methods.

We’ve introduced many terms and technologies here, but when you go to order sails, the list of items you need to communicate to your sailmaker are straightforward. Be clear about how you actually use your boat—how much, if ever, you race or head offshore; how often you sail in heavy weather; how long you intend on keeping the boat; the true-wind conditions of your most frequent cruising grounds. And of course, be crystal clear about your budget.

Sailmakers are, at heart, sailors themselves, and they love shooting the breeze about boats and sailing. Find one you trust. The ever-evolving technology in sailcloth and construction is fascinating, but at the end of the day, as with most transactions, buying sails is about forging relationships.

Joe Cooper is a former sailmaker who’s sailed and raced boats ranging from dinghies to America’s Cup contenders. Currently a sailing coach and consultant, he lives in Middletown, Rhode Island.

Sailmaker Resources

Doyle Sailmakers

North Sails

Quantum Sail-Design Group

UK Sailmakers

Ullman Sails International

- More: Gear , How To , sailing gear , sails & rigging , sails and rigging , seamanship , systems

- More How To

3 Clutch Sails For Peak Performance

It’s Time to Rethink Your Ditch Kit

8 Ways to Prevent Seasickness

How To De-Winterize Your Diesel Engine

Bitter End Expands Watersports Program

Sailboat Review: Tartan 455

Miracle in a Bowl

Cole Brauer Completes the Global Solo Challenge

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

What Are Sailboat Sails Made Of | Fabrics & Inspection Tips

When I was recently looking for new sails, I wondered what Fabric Are Sailboat Sails Made Of? So, I did some research and testing to find it out.

So, What Fabric Are Sailboat Sails Made Of? Sails are made from a wide variety of fabrics, from natural fibers, such as flax, hemp, and cotton in various forms of sails canvas to synthetic fibers such as polyester, nylon, aramids, laminate and carbon fibers.

Modern sails are crafted from innovative materials to withstand the adverse weather conditions they face on the water and to last much longer compared to the sails in older boats. Let’s discuss this topic in more details.

What Fabric Are Sails Made of?

Modern sails are mainly made of the following materials:

Polyester fiber is the most common sailcloth used around the world, it is often known by its trade name Dacron. Dacron’s properties include great resiliency, high UV, fatigue, and abrasion resistance.

With excellent flex strength Dacron is one of the most affordable sailcloth in the market. Polyester fibers are more waterproof than traditional choices because it has four layers of protection.

Flex strength is the ability of a cloth to regain its strength after being folded back and forth.

Widely used for spinnakers, it is lightweight material, with high strength, excellent abrasion resistance, and flexibility, it also shows good UV resistance.

However, it has a low modulus, allowing too much stretch for upwind sails.

Nylon is a rugged material, however, it is very susceptible to damage when exposed to chlorine and other chemicals. So, bear in mind, if you have nylon sails, never use chlorine-based bleaches when washing and cleaning.

This type of fiber is predominantly used for racing sails and can also be used in laminated cruising sails.

Its properties include high strength, higher strength-to-weight ratio than steel, and a greater modulus than Mylar and Dacron.

It loses its strength with flexing, folding, and flogging, and does not resist UV light well.

Spectra sails are usually used on spinnakers and on high-performance sailboats where the sails are replaced frequently.

Spectra’s properties include excellent UV resistance, superior breaking strength, excellent low stretch, and high flex strength.

However, over time Spectra is very much prone to permanent elongation under a sustained load which causes its shape to change.

This is also the main reason why Spectra is usually used for spinnakers on high-performance sailboats.

On par with to Spectra, Dyneema is exceptionally strong fiber produced by Dutch firm DSM.

Dyneema is more widely available in a variety of sizes and is growing rapidly in popularity.

Dyneema’s properties include a high strength-to-weight ratio with outstanding low stretch and abrasion and excellent UV resistance qualities.

This is a polyester film which is at the center of laminate sails. The film acts as a base to which everything else is glued to.

Its properties include excellent tensile strength, great dimensional stability, and transparency. Mylar is used extensively in racing sails.

Carbon Fiber

Carbon fiber is the best performing fiber used by the sailmaking industry today. It is a high modulus fiber made from carbon, it is virtually unaffected by UV exposure with exceptional low stretch.

Carbon fiber sails are extremely durable and flexible, however, the only disadvantage to carbon fiber is degradation from flexing. I have seen fiber comparison charts rating carbon and kevlar virtually the same score for flex. So, it is not that bad after all. They are much costlier.

Laminate Sails

These fabrics are made of layers of film, taffeta and scrim glued and laminated together under extremely high temperatures, as a result, a light, strong membrane sail fabric is created.

Laminate fabric combines technical efficiency, durability and easy handling.

Its properties include excellent tear strength and excellent wrap stretch performance. Laminate fabric is high in UV ray resistance.

The main attribute of laminate cloth is its ability to retain their shape which makes the sailboats fast. Laminates are generally lighter than woven sails and have a higher modulus.

Laminate sails are significantly more expensive than other type sails. But they last for a very long time.

How Long Does A New Sail Last?

Majority of the wear happens at the start of the journey when the sails are unfolded and pull up and likewise at the end of the journey rather than in open water where your boat may sail for hundreds of miles.

This process is so personalized and different from one sailor to another and even from one journey to another that it makes is very hard to give a lifespan in terms of the number of years or sailed miles.

One thing is certain though, the wellbeing of your sail is not affected much by mileage directly, the two most essential factors in aging of the sails are flogging/flapping and UV exposure.

Besides, flogging/flapping can quickly break down all types of sailcloth. UV light deteriorates the stitching and the sailcloth itself so, it is very crucial to cover your sail if it is not being used.

Additionally, the well being of your sails are depending on some more factors that are listed below:

- What type of fiber/cloth is the sail made of

- How the sails are used and

- In what weather conditions have the sails been used

- Amount of care it has received, etc.

As your sails age over time, they stretch in high load sections and obviously, it causes the shape to change.

With that steering will become hard and even it will affect your speed.

Before the sails are stretched out of the shape, it is a good to idea to replace them, as this will make a significant difference to the way your vessel sails.

How To Inspect Your Existing Sails

In this section, I will discuss my general guidelines on how to inspect the sails’ structural strength and overall well-being.

To start out, the sails need to be spread in a wide area to make inspecting effective for you.

At least you should be able to work from edge to edge to edge cause a lot of time the damage is to be found in the leech, inboard batten pocket ends and spreader patches.

So, once the sail is spread properly go over all the seams and the edges. And you will be looking for rips in the stitches, making sure all edges are in good shape.

Make sure you have colored masking tape or just blue house tape to mark along when you spot any issue during the inspection.

Here are some areas that you might want to look closely when inspecting your sails:

- Check all the seams all around: Polyester treats are weakened over time so, be sure to check the seam of the sail carefully.

- Inspect all the edges (support tape)

- Inspect luffs edges thoroughly

- Inspect sail window: Polish and clean them but if they are in bad shape replacing them will be a good idea.

- Look out for Holes and Rips: Holes and rips are not uncommon even for new sails. Holes and rips could be fixed by stitching patches on the damaged area.

- Check Sails slides, Grommets and Shackles: They may be broken and may need to be replaced

- Inspecting batten pockets and tell tails: batten pockets are known for being problem areas from abrasion, old elastic, or even mission or broken battens.

- Inspect the Spreader Patch: especially on a Genoa, a spreader can do a significant amount of damage to the sail so, make sure you check it properly and the spreader is in a good shape.

- Inspecting Leechline Cleats and Velcro: Leechline is tensioned and fastened down with velcro sometimes, or cleats. So, run through and be sure they are in good shape.

- Assess the Corner Rings: Rings that are secured with webbing at the corners of the sails should be inspected thoroughly. Look for frays in the webbing and the stitching on the webbing.

- Check the sail numbers and logo if you have one.

- Inspect the headboard: They are seldom a problem, but still, we want to inspect them completely to make sure they are in good shape.

A great tool that I like a lot is the speedy stitcher, it is a super handy tool. It can stitch the seams or webbing without you have to bring down the sail. You can do it on the spot.

Click here to check Speedy Stitcher on Amazon.

Best Practices For Buying A New Sail

Good sails ensure speed, sailing efficiency and safety on your vessel. When your sails are in great shape, your boat heels less, reduces the tendency to round up into the wind in storms and making steering and controlling the boat more pleasurable.

Please consider the following tips before buying a new sail:

- Before you look for a sailmaker you need to inspect your sails completely and find out if your sail is repairable. Follow the steps here above for a full inspection.

- If your sails are beyond the repair and you choose to go with new sails then first you need to decide what type of fabric, and fabric thread count you want your sails to be made of.

- Once you made your choice, it is advisable to find local sailmaker. Choosing local sailmakers will save you loads of time and money. As many sailmakers want to take their own measurement.

- One additional benefit of choosing a local sailmaker is that you can expect the sailmaker to do a “test drive” under sail, in different conditions. However, be ready to pay for sailmaker’s time.

- Once you have the contact details of the sailmaker(s) in your area you approach them and ask them for quotes. Choose the best sailmaker possible, please note that the cheapest quote may not always be the best choice.

- Also, this is the time that you want to let them know what type of boat is the sail for and the type of sail you wish for, the measurement, etc.

- Communicate how many mainsail reefs you need, as this affects the cost, versatility and also safety. If you are day sailing, one reef is sufficient, for coastal and offshore sailing two are needed, etc.

- It is recommended to consider battens: communicate with sailmaker the quantity, type and location of battens on the sail.

- Finally, ask your sailmaker to include all hardware and labor charges in the quote.

Related Questions:

Are Sailboat Sails Waterproof And Mold Proof?

So, Are Sailboat Sails Waterproof and mold proof? Depending on the material the sails have been made with, almost all of the modern sailboat sails are resistant to water, and mold to a certain extent.

Modern sails are designed to withstand the adverse sea conditions they face and last much longer compared to the cotton sails on the older boats.

I am the owner of sailoradvice. I live in Birmingham, UK and love to sail with my wife and three boys throughout the year.

Recent Posts

How To Sail From The Great Lakes To The Ocean

It’s a feat in and of itself to sail to the Great Lakes. Now you want to take it one step further and reach the ocean, notably, the Atlantic Ocean. How do you chart a sailing course to get to the...

Can You Sail from the Great Lakes to the Gulf of Mexico by Boat?

You have years of boating experience and consider yourself quite an accomplished sailor. Lately, you’ve been interested in challenging yourself and traveling greater distances than ever before. If...

- Sail Making Material: A Comprehensive Guide

by Emma Sullivan | Aug 23, 2023 | Sailing Adventures

Sail making material

Sail making materials, typically used for constructing sails, include Dacron (polyester), Mylar (polyester film), and laminated fabrics such as Dyneema and Aramids. These materials possess durability, strength, and resistance to UV radiation, making them ideal choices in sail manufacturing.

1) Exploring the World of Sail Making Material

When it comes to sail making, the importance of using the right materials cannot be emphasized enough. The materials used in sail making have evolved over time, with advancements in technology and a deeper understanding of aerodynamics playing a significant role in this process. In this blog post, we will take you on a journey through the world of sail making material, exploring its various types and their unique characteristics.

One of the most commonly used materials for sails is dacron. Dacron is a synthetic fabric known for its durability and versatility. It is often favored by sailors due to its resistance to UV rays and its ability to hold shape even during extreme weather conditions. Additionally, dacron has excellent tear strength, allowing sails made from it to withstand heavy winds without succumbing to damage.

Another popular material used in sail making is laminated polyester film. This material offers a high level of performance and is ideal for racing sails. Laminated polyester film has low stretch properties which enhance the stability of the sail, allowing it to maintain its intended shape and deliver optimal performance on the water.

For those looking for lighter weight options, carbon fiber is an excellent choice. Carbon fiber sails are known for their exceptional strength-to-weight ratio, providing sailors with an advantage in terms of speed and performance. The stiffness of carbon fiber allows for better control over sail shape adjustments while sailing at higher speeds.

Kevlar is another material that has gained popularity among competitive sailors. This aramid fiber boasts incredible strength and impact resistance while remaining remarkably lightweight. Its high tensile strength allows Kevlar sails to withstand intense wind pressure without losing their form or structure.

An alternative option that has garnered attention recently is woven Dyneema fabric. Dyneema is renowned for being one of the strongest fibers available while still maintaining remarkable flexibility and lightness. Sails made from woven Dyneema offer superior durability combined with outstanding shape retention abilities, resulting in enhanced overall performance.

In recent years, sail makers have also begun utilizing natural materials such as hemp in sail construction. Hemp fibers offer an eco-friendly alternative for those who prioritize sustainability without compromising the strength and durability required for sailing.

As technology continues to advance, we can expect even more innovative sail making materials to emerge. From cutting-edge synthetic fabrics to sustainable options, the world of sail making materials truly offers a vast array of choices for sailors of all types.

In conclusion, understanding the different types of materials available for sail making is crucial in order to make informed choices that will ultimately impact the performance, durability, and speed of your sails. Whether you opt for traditional dacron or explore new-age alternatives like carbon fiber or Kevlar, each material has its own set of strengths and advantages. By taking into account factors such as weather conditions, desired performance characteristics, and personal preferences, you can select the perfect material that will enhance your sailing experience and propel you towards victory on the water!

2) How to Choose the Right Sail Making Material for Your Project

Title: Choosing the Perfect Material for Sail Making – A Confluence of Art and Science

Introduction: Welcome aboard, sailing enthusiasts! Crafting a sail is an exquisite art that blends aesthetic finesse with scientific precision. Just as each vessel possesses its own unique character, finding the right sail making material to complement your project requires careful consideration. In this blog post, we will navigate through the process of selecting the perfect material for your sails, exploring a plethora of factors ranging from performance to durability. So hoist your imaginary anchor and let’s embark on this voyage of knowledge.

1) The Anatomy of Sails: Before delving into material selection, understanding the fundamental composition of a sail is paramount. A traditional sail comprises three layers: the woven fabric or membrane, bonding agents (if applicable), and various reinforcements such as yarns or tapes. It is this fusion that establishes both its structural integrity and ability to harness wind power effectively.

2) Performance-Oriented Materials: When aiming for peak performance on the open seas, optimal material selection becomes crucial. High-performance fibers like carbon or aramid (Kevlar®) are highly sought after in competitive sailing circles. Carbon fiber sails excel in their exceptional stiffness-to-weight ratio, enabling them to maintain shape even under intense loads. Conversely, aramid fibers bring remarkable strength while ensuring reduced weight for enhanced speed.

3) Cruising Comfort and Durability: If you envision leisurely cruises rather than fierce regattas, durability and comfort are essential considerations when choosing sail materials. Contemplating options like Dacron or polyester fabrics proves wise since they offer excellent resistance against UV degradation and mildew formation. These materials not only ensure longevity but also deliver smooth handling characteristics vital for stress-free cruising experiences.

4) Hybrid Solutions – Striking a Balance: The quest for a compromise between performance-oriented materials and cruiser favorites has led to impressive hybrid constructions within the realm of modern sail making. Hybrid sails often combine different materials strategically, embracing the strengths of each component. For instance, a combination of carbon and polyester fabrics harmonizes heightened performance with increased durability, meeting the needs of both sailing enthusiasts and competitive racers alike.

5) Environmental Considerations: As our collective consciousness gravitates towards sustainability, it is essential to explore eco-friendly options for sail materials. Ethical manufacturers now produce biodegradable laminates that offer environmentally conscious sailors peace of mind without compromising on performance and durability. Opting for these innovative alternatives showcases your commitment to preserving our beloved oceans.

Conclusion: Selecting the ideal sail making material may appear daunting at first glance, but fear not! By understanding your sailing goals, whether it be chasing podium finishes or cruising serenely across endless horizons, finding equilibrium between performance, comfort, durability, and environmental friendliness becomes attainable. Remember, the material you choose will not only propel your vessel but also infuse it with character unique to your vision as a sailor. So hoist those sails high and let them become an embodiment of excellence!

Fair winds and following seas!

3) A Step-by-Step Guide to Working with Sail Making Materials

Introduction:

Sail making is a time-honored craft that requires attention to detail and precise craftsmanship. Whether you are a seasoned sailor or an aspiring sail maker, understanding the materials involved in sail production is crucial. In this step-by-step guide, we will delve into the world of sail making materials, discussing their properties and offering practical tips for working with them. So, grab your sewing kit and let’s set sail on this creative journey!

Choosing the Right Sail Fabric:

The first step in any sail-making project is selecting the appropriate fabric. Sail fabrics come in various types such as Dacron, laminates, and nylon, each with its unique characteristics.

Dacron: Dacron is a popular choice due to its durability and affordability. It provides excellent resistance against UV rays and retains its shape even under high loads. When working with Dacron sails, make sure to choose the correct weight (measured in ounces per square yard) depending on your boat’s size and intended use.

Laminates: Laminated sails offer enhanced performance through advanced technology. These fabrics consist of layers of film sandwiched between polyester or other fibers. They are known for their superior strength-to-weight ratio but can be slightly more expensive than Dacron. When working with laminates, follow specific manufacturer recommendations regarding cutting techniques to avoid compromising their structural integrity.

Nylon: Nylon sails excel in light air conditions due to their excellent flexibility and stretch characteristics. However, they are less resistant against UV rays compared to Dacron or laminates. When using nylon fabrics for sail making projects, ensure proper reinforcement at areas prone to high loads such as corners or reef points.

Preparing Your Workspace:

Before diving into your sail-making endeavor, it’s essential to set up a suitable workspace equipped with all necessary tools and materials.

1) Cleanliness is Key: Clear any clutter from your workspace to ensure an organized environment conducive to creativity and precision. This will minimize the risk of misplacing or damaging crucial materials during the process.

2) Adequate Lighting: Good lighting is essential for accurate measurements and precise stitching. Position your workstation near a window or use adjustable task lighting to eliminate shadows and enhance visibility.

3) Tools of the Trade: Gather all the necessary tools, including a sturdy cutting surface, fabric shears, measuring tape, marking chalk or pencil, sewing machine with a heavy-duty needle, thread, and appropriate reinforcement materials like webbing or sailcloth patches.

The Cutting Process: