Land Yacht build Plans

These detailed instructions will allow you to construct this land yacht in a few days. This is a great project for the do-it-yourself. The whole family can help in the construction and it will give everyone a feeling of ownership. And the best part: It’s very affordable to run!

The position of the rear wheels axles gives it a low center of gravity and very predictable cornering behavior. And as this land yacht has been integrally designed considering the sail tester results (click on “The Sail Tester” button above), it was calculated to have the best stability for beginners and family use.

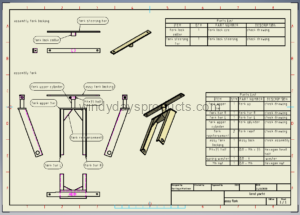

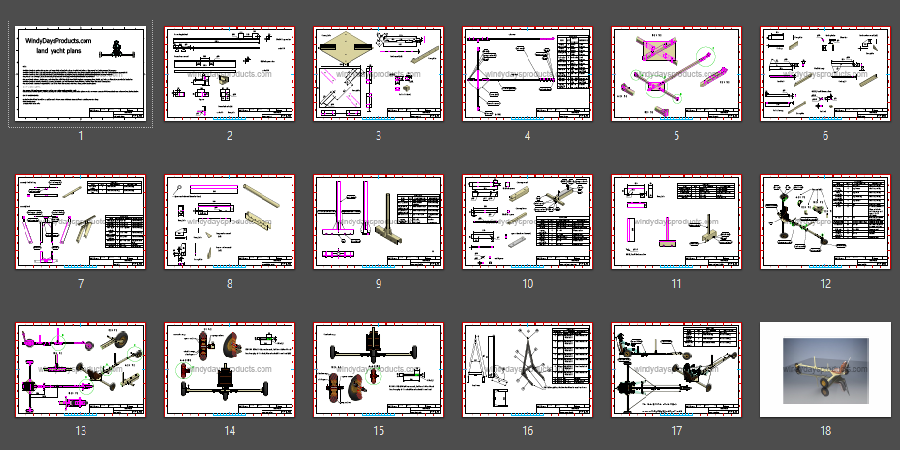

You can easily build this land yacht yourself with these comprehensive plans. I’ll give you the 3D CAD drawings and dimensions of every part that needs to be made, along with lists of materials, cutting lists and detailed building instructions. Everything you need to build your own landyacht. Plans and instructions are clear and are very easy to follow.

These plans are high quality C.A.D designs (Autodesk-INVENTOR). They have been formatted to be read using adobe reader. It’s a simple but effective land sailer to build with basic materials. I think you will really enjoy building and riding it as well.

I look forward to helping you with your project. So if for any reason during construction you have a question, just e-mail me.

Get the Landyacht Build Plans

GET the Land Yacht complete and detailed construction plans, instructions and lists of materials (.pdf)

Feel the speed, just 10 cm off the ground..

The manual include step-by-step progressive construction drawings with sub-assemblies, weldments, angles etc… Basically, you start at the beginning of the plans & work your way through step-by-step. Frame drawings show you how to start by making a tube base frame and then progressively build upon that starting point.

All materials are readily available worldwide. Tube notches are NOT needed to build the frame (they are all straight cuts). Lathe work is NOT needed for this project.

Introduction: Land Yacht

For our senior design project, we were tasked with designing, analyzing, and building a land yacht. A land yacht is basically a wind-powered cart that supports a single rider who trims the sail and steers the cart. Our design utilizes a three-wheeled chassis to supports the rider while he/she trims the sail with his hands while steering with his feet. This instructable is a guide to building the land yacht. Once built, it can be used on most terrains, including sand, dirt, grass, or concrete.

1 - A500 Hot Roll Pipe (1.25" x Sch 40 x 60")

1 - A500 Hot Roll Pipe (1.25" x Sch 40 x 48")

2 - A500/A513 Hot Rolled Mild Steel Rectangle Tube (1" x 1.5" x 24")

1 - 6061-T6 Aluminum Pipe (1.25" x Sch 40 x 72")

1 - 6061-T6 Aluminum Pipe (1.25" x Sch 40 x 84")

Mast Collar

1 - Aluminum Pipe (2.0" x Sch 40 x 24")

1 - A500 Hot Roll Pipe (2" x Sch 40 x 12")

Mast/Boom Connector

1 - Model 2T-7 Aluminum-Magnesium Tee (1.25")

1 - 6061-T6 Aluminum Pipe (1.25" x Sch 40 x 60")

1 - A36 Hot Rolled Mild Steel Round Bar (0.625" x 48")

1 - Tapered Head Tube

1 - Sunlite Threaded MX Fork

1 - Mild Steel Round Bar (0.625" x 24")

5 - Rigid Pulleys (1.5")

2 - Sealed Ball Bearings (0.625" shaft diameter x 1.375" housing diameter)

1 - 550 Cord (15')

1 - Uline Solid Rubber Wheel (10" OD)

2 - Uline Pneumatic Wheel (10" OD)

1 - Triangular Sail (5' x 10.5')

Step 1: Tools Required

Metal Band Saw

Miter Grinder

Drill Press

Bench Grinder

Tap and Die Set

Sewing machine

Step 2: Measuring/Cutting the Sail

The first part of this build is preparing the sail for the land yacht. Our land yacht utilizes a sail that has a 5-foot boom and a height of 10.5 feet. This sail height was determined to work with the size of the land yacht. Our team used a much larger sail from a sailboat that will need to be cut to the right dimensions. The first measurement should be 10.5 feet from the top of the sail. The next measurement is 5 feet, horizontally on the sail. You will notice, however, that after you have measured 10.5 feet from the top, there is not enough room to extend 5 feet horizontally on the boom. Therefore, you will need to measure the height of the sail to be more than 10.5 feet until you reach 5 feet in length for the boom. This was accomplished with a sail height of 11.5 feet. Once the measurements are finished, you can now cut the sail. Make a straight, horizontal cut along the foot (bottom) end of the sail.

Step 3: Folding the Edges of the Sail

In order to fit the mast and boom piping onto the sail, a sleeve will need to be created along the luff (height) and foot (bottom) sections of the sail. This sleeve should be measured at 3" in length. To measure, take one section of the sail and fold it over onto itself until you reach 3" in length. Then, mark this length in several sections to make it easier for yourself when sewing.

Step 4: Sewing the Sail

Once the sail dimensions have been marked and the sleeve has been marked, it is ready to be sewn. The sewing must be done utilizing a sewing machine. If you do not know how to use a sewing machine you can watch videos to understand the process. Taking the bottom section of the sail, fold it back onto itself until it lines up with the marks you created. These marks are your guide as you are sewing the sail. Complete this for the bottom section and the top section of the sail.

Step 5: Final Cuts/sews of the Sail

Remember that the sail height is currently at 11.5 feet. This needs to be taken down to 10.5 feet. Using scissors, cut off one foot of the top section of the sail. Make a horizontal cut. The top of this sail will now need to be sewn so that the sail threading does not unravel. Make a horizontal stitching at the top of the sail where it was cut. The clew end of the sail is currently open after making the sleeve. This end will need to be sewn shut. Fold the very end of the clew onto itself and sew this section closed. A 4" x 4" square will need to be cut and sewn at the tack end of the sail. This is in order for the mast-boom connector to fit.

Step 6: Rear Notching

Parts: Main tube (A500 Hot Roll Pipe) Tools: Angle grinder, cutting wheel.

- Using the rear tube as a guide for diameter, remove material from the end of the main tube as to fit the rear tube inside of the notch being created.

End Result: Rear tube fits snug into the main tube at a 90 degree angle ready for a strong weld.

Step 7: Front Notching

Parts: Main tube (A500 Hot Roll Pipe)

Tools: Horizontal/vertical metal cutting band saw, angle grinder, cutting wheel

- Using the horizontal/vertical metal cutting band saw, cut a 45 degree angle from the front of the main tube. Ensure this operation is done at a 90 degree offset from the rear notching.

- Notch the 45 degree cut to fit the head tube. This can be done with both the angle grinder and the cutting wheel.

End Result: The head tube fits into the notch ready for a strong weld.

Step 8: Rear Axle Threading

Parts: A36 Hot Rolled Mild Steel Round Bar (0.625" x 48")

Tools: Bench vice, vice grips, 5/8" Hex UNC threading die, cutting oil.

- Place the rear axle in the axle into the bench vice so that it is perpendicular to the ground. Ensure the vice is tightened enough so that the axle does not move or rotates while threading.

- Grip the 5/8" Hex UNC threading die TIGHTLY with the vice grips.

- Place the 5/8" Hex UNC threading die over the axle and begin to rotate while applying a large downward force. Apply a generous amount of cutting fluid. (Use a team member to ensure the die is perpendicular to the axle. Once the first few threads have begin to cut, the rest will follow the path that they have made. So any any mistake made in the beginning will not self correct and will ruin the axle)

- Continue to turn the die until two full inches have been completely threaded. Apply cutting oil often.After every 1/4 turn, counter rotate an 1/8 of a turn to brake the chips that have formed.

- Repeat for the other side of the axle.

End result: Rear axle threaded 2" on both sides fitting a 5/8" UNC nut.

NOTE: To protect the threads, place a nut on finished threads while storing or working on axle.

Step 9: Rear Axle Assmbly

Parts: A500 Hot Roll Pipe (rear tube), A36 Hot Rolled Mild Steel Round Bar (threaded axle), 2x Uline Pneumatic Wheel (rear wheel), 2x Sealed Ball Bearings (rear bearings)

Tools: 2x adjustable wrench.

- Using a file, remove an inch of this seam until rear axle bearing fits flush into rear tube.

- Insert threaded axle into to rear tube. There should be 3" of excess axle protruding from each end of the rear tube. (This is where the rear wheels and but will be)

- Insert rear bearings into the rear tube over the threaded axle. The bearings should be flush with the edge of the rear tube.

- Place wheels onto the rear axle. Ensure that the the side of the wheels with the bearings (the "long part" is facing inwards touching the rear tube.

End Result: Completed rear axle Assembly with all mentioned parts. Wheels spin freely and do not rattle.

Step 10: Rear Brace Members

Parts: 2x A500/A513 Hot Rolled Mild Steel Rectangle Tube (1" x 1.5" x 24")

Tools: Horizontal/vertical metal cutting band saw, angle grinder, cutting wheel.

- Cut 45 degree angle on both ends of the brace member using the Horizontal/vertical metal cutting band saw. The cuts should be made, as shown, in an orientation to connect the main and rear tube together.

- Using the angle grinder and cutting wheel, notch the brace member that that it cups the rear and main tube allowing for a strong weld to be made.

- Repeat with the second brace member.

End Result:Finished brace members cut and notched to fit into the main and rear tube for extra support.

Step 11: Head Tube Assembly

Parts: Tapered Head Tube, Sunlite Threaded MX Fork, Head Tube Bearing Stack.

Tools: Adjustable wrench.

- Using the instructions that came with the Head Tube Bearing Stack, assemble the first three components (bottom cup, bearing, and washer) onto the fork neck)

- Place the Tapered Head Tube on the fork neck ensuring that the head tube is seated into the bottom cup pf the bearing stack.

- Again using the included bearing stack instructions, place the bearing, top cup, and washer onto the fork. Ensure that the head tube is seated in the top cup. (the head tube should only be touching the top and bottom cup's and nothing else)

- Using the provided head tube nut. Tighten the the bearing stack/head tube assembly onto the threaded fork. The head tube should have no wobble and should be able to easily spin freely.

End Result: Front fork, head tube, and bearing stack all successfully assembled to complete the front end assembly.

Step 12: Welding the Chassis

Once the head tube has been assembled and the chassis is all ready, it is time to have everything welded. The mast holder can be slid through the 5' chassis pipe. It should be slid 1' back from the front and welded there. The rear of the chassis, where the 5' and 3.5' pipes meet perpendicular, can be welded together. The 2' support beams, as seen in previous pictures, can be welded. The head tube will need to be welded to the front of the chassis at a 45-degree angle. Lastly, the foot bar can then be welded to the top of the fork, seated perpendicular and parallel to the ground.

Step 13: Mount a Seat

The seat you choose can be up to you based on your size and comfort needs. For this particular project we chose a typical cheap folding metal chair.

Saw the legs off just below the actual seat portion so that all you have is the back of the chair, and the supports that lead down only as far as the seat. The hinges that allow the chair to fold should also remain included so the back can fold down.

Arrange the chair where you want it to sit on the chassis, centered on the long part of the chassis, above the rear axle and over the supports. Mark out 3-4 spots in a triangle or square shape on the chassis that would fit under the metal seat portion of the chair.

Drill holes through the seat and through the steel chassis. Select a bolt that's long enough to go through the chair and chassis, secure everything together with a washer and nut.

Step 14: Mast Assembly

Because the mast is too long and too expensive to ship at its full length of 13 feet, you'll have to put the two pieces together as tightly as possible.

We used an aluminum collar with a 2" inner diameter that was just big enough to hold the outer diameters of the two main mast pieces. Slide both mast pieces into the collar where they meet roughly in the middle. Drill through the aluminum and secure with nuts and bolts that will reach all the way through. One or two bolts per mast piece should do. Try to sand out any sharp edges to avoid cutting your sail.

Similarly for the boom, you will bolt in a t-shaped pipe (mast-boom connector) to one end of the aluminum pipe. Make sure not to push the boom all the way through the intersection. That remaining space in the t-pipe should have an inner diameter significantly larger than the outer diameter of the mast because it will need to be able to swing around.

Before you slide the sail on and put everything together, mark out where on the boom you want to place your Eye Bolts (the bolts with the loop on the end). Then drill through and secure them with a nut. Mark the same spots on your sail where your boom will sit, you will need to cut small holes so the loop end will stick out from under the boom. This is where you will thread your paracord rigging.

Recommendations

Water Contest

Woodworking Contest

Farm to Table Contest

DIY Boat Building Plans

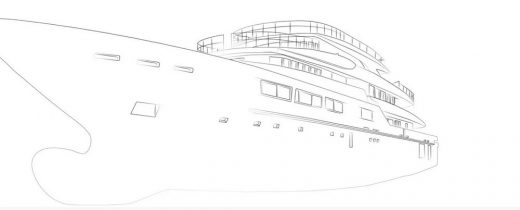

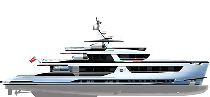

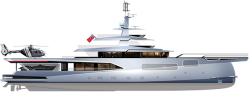

Yacht Plans & Blueprints

Download over 500 Boat Plans. Click on the link below.

-->click here<--.

Table of Contents

Overview of Yacht Plans & Blueprints

Yacht plans and blueprints are essential tools for anyone looking to build their own yacht . These detailed documents provide a roadmap for the construction process, outlining the necessary steps and specifications required to bring a yacht to life. Without a plan, building a yacht can be a daunting and overwhelming task. Yacht plans and blueprints provide the necessary guidance and structure to ensure a successful build.

Key Takeaways

- Yacht plans and blueprints are essential for yacht design and construction.

- There are different types of yacht plans and blueprints available, and it’s important to choose the right one for your needs.

- Reading and interpreting yacht plans and blueprints requires some knowledge and skill.

- Customizing yacht plans and blueprints can help you create a yacht that meets your specific requirements.

- Quality yacht plans and blueprints can be found online, but cost considerations should also be taken into account.

Understanding the Importance of Yacht Plans & Blueprints

Safety considerations are of utmost importance when it comes to yacht construction. Yacht plans and blueprints take into account various safety factors, such as stability, buoyancy, and structural integrity. By following these plans, builders can ensure that their yacht meets all necessary safety standards. Accuracy in measurements and specifications is another crucial aspect of yacht plans and blueprints. These documents provide precise measurements for each component of the yacht, ensuring that everything fits together seamlessly. This accuracy is essential for the overall functionality and performance of the yacht. Cost-effectiveness is yet another advantage of using yacht plans and blueprints. By having a detailed plan in place, builders can avoid costly mistakes and rework. The plans outline the necessary materials and quantities required for each stage of construction, allowing builders to budget effectively and minimize waste.

Types of Yacht Plans & Blueprints Available

There are three main types of yacht plans and blueprints available: stock plans, semi-custom plans, and custom plans. Stock plans are pre-designed plans that are readily available for purchase. These plans are created by professional yacht designers and offer a range of designs to choose from. Stock plans are a cost-effective option for those looking to build a yacht without the need for extensive customization. Semi-custom plans offer a middle ground between stock plans and custom plans. These plans allow for some level of customization, such as modifying the interior layout or adding specific features. Semi-custom plans provide a balance between affordability and personalization. Custom plans are tailored to the specific needs and preferences of the builder. These plans are created in collaboration with a yacht designer, taking into account the builder’s vision and requirements. Custom plans offer the highest level of personalization but can be more expensive and time-consuming to develop.

Factors to Consider When Choosing Yacht Plans & Blueprints

| Factors to Consider | Description |

|---|---|

| Size of the Yacht | Determines the number of people it can accommodate and the type of activities it can support. |

| Design and Style | Should match the intended use of the yacht and the owner’s personal preferences. |

| Materials Used | Affects the durability, maintenance, and cost of the yacht. |

| Cost | Should fit within the owner’s budget and include all necessary expenses such as construction, equipment, and maintenance. |

| Builder’s Reputation | Should have a proven track record of quality workmanship and customer satisfaction. |

| Availability of Plans and Blueprints | Should be easily accessible and provide detailed instructions for construction. |

| Legal Requirements | Should comply with local and international laws and regulations for safety, navigation, and environmental impact. |

When choosing yacht plans and blueprints, several factors need to be considered. The size and type of yacht are important considerations, as different designs and plans are suitable for different purposes. Whether you’re looking to build a small sailing yacht or a large motor yacht, selecting the right plan is crucial. The skill level of the builder is another factor to consider. Some plans may require advanced woodworking or metalworking skills, while others are more beginner-friendly. It’s important to choose a plan that aligns with your skill level to ensure a successful build. Budget is also a significant factor when selecting yacht plans and blueprints. Stock plans are generally more affordable, while custom plans can be more expensive due to the additional design work involved. It’s essential to establish a budget and find a plan that fits within your financial constraints.

How to Read and Interpret Yacht Plans & Blueprints

Reading and interpreting yacht plans and blueprints can seem daunting at first, but with some basic knowledge, it becomes much more manageable. Understanding symbols and abbreviations is crucial, as these are used throughout the plans to represent various components and materials. Familiarizing yourself with these symbols will help you navigate the plans effectively. Reading measurements and dimensions is another essential skill when working with yacht plans and blueprints. These measurements provide precise information about the size and placement of each component. It’s important to understand how these measurements are represented on the plans to ensure accurate construction. Interpreting sections and elevations is another aspect of reading yacht plans and blueprints. These drawings provide a detailed view of the yacht from different angles, allowing builders to visualize how everything fits together. Understanding these drawings will help you understand the overall structure and layout of the yacht.

The Role of Yacht Plans & Blueprints in Yacht Design

Yacht plans and blueprints play a crucial role in the yacht design process. They serve as a communication tool between the designer and the builder, ensuring that the builder understands the designer’s vision and requirements. Plans provide a visual representation of the yacht, allowing both parties to collaborate effectively. The importance of plans in the design process cannot be overstated. They provide a roadmap for the construction process, ensuring that all necessary steps are followed and that the final product meets the desired specifications. Plans also allow for adjustments and modifications to be made before construction begins, saving time and resources. Collaboration between the designer and builder is key when working with yacht plans and blueprints. The builder’s input and feedback are essential in ensuring that the plans meet their needs and preferences. This collaboration ensures that the final product is a true reflection of both the designer’s vision and the builder’s requirements.

Customizing Yacht Plans & Blueprints to Suit Your Needs

While stock plans offer a range of designs to choose from, sometimes builders may want to make modifications to suit their specific needs. Making modifications to existing plans is a common practice and allows builders to personalize their yacht without starting from scratch. Working with a designer to create a custom plan is another option for those looking for a truly unique yacht. Custom plans offer complete personalization, allowing builders to incorporate specific features or design elements that are not available in stock plans. This option requires collaboration with a yacht designer to bring your vision to life.

The Benefits of Using Yacht Plans & Blueprints for DIY Projects

Using yacht plans and blueprints for DIY projects offers several benefits. One of the most significant advantages is cost savings. By building your own yacht, you can save a significant amount of money compared to purchasing a pre-built yacht. Yacht plans and blueprints provide the necessary guidance to ensure a successful build, even for those with limited experience. Personalization is another benefit of using plans and blueprints for DIY projects. By building your own yacht, you have the freedom to customize every aspect of the design to suit your preferences. This level of personalization is not possible with pre-built yachts. The satisfaction of building your own yacht is also a significant benefit. The sense of accomplishment that comes from seeing your creation come to life is unparalleled. Building a yacht is a challenging but rewarding endeavor that allows you to create something truly unique.

Where to Find Quality Yacht Plans & Blueprints

Finding quality yacht plans and blueprints is essential for a successful build. There are several resources available for builders looking for plans. Online resources offer a wide range of options, including stock plans and custom designs. Many yacht design firms also offer plans for sale, providing professional designs and expertise. Boat shows and events are another great place to find quality yacht plans and blueprints. These events often feature displays from various designers and builders, allowing you to see different designs firsthand and speak directly with professionals in the industry.

Cost Considerations for Yacht Plans & Blueprints

The cost of yacht plans and blueprints can vary depending on several factors. Custom plans tend to be more expensive due to the additional design work involved. Stock plans are generally more affordable, but prices can vary depending on the complexity and size of the design. Budget-friendly options are available for those looking to minimize costs. Some designers offer discounted or budget-friendly plans that still provide high-quality designs at a more affordable price point. It’s important to research different options and compare prices to find a plan that fits within your budget.

Conclusion – Yacht Plans & Blueprints

In conclusion, yacht plans and blueprints are essential tools for anyone looking to build their own yacht. These detailed documents provide the necessary guidance and structure to ensure a successful build. Yacht plans and blueprints offer numerous benefits, including safety considerations, accuracy in measurements and specifications, and cost-effectiveness. When choosing yacht plans and blueprints, factors such as the size and type of yacht, skill level of the builder, and budget need to be considered. It’s important to understand how to read and interpret yacht plans and blueprints to ensure accurate construction. Yacht plans and blueprints play a crucial role in the yacht design process, facilitating collaboration between the designer and builder. Customizing yacht plans and blueprints allows builders to personalize their yacht to suit their specific needs. Using plans and blueprints for DIY projects offers cost savings, personalization, and the satisfaction of building your own yacht. Quality yacht plans and blueprints can be found online, through yacht design firms, or at boat shows and events. Cost considerations should also be taken into account when selecting plans, with budget-friendly options available. In conclusion, yacht plans and blueprints are invaluable resources for anyone embarking on a yacht-building project. They provide the necessary guidance, safety considerations, and personalization options to ensure a successful build. By utilizing these plans, builders can bring their vision to life while saving costs and experiencing the satisfaction of building their own yacht.

FAQs – Yacht Plans & Blueprints

What are yacht plans and blueprints.

Yacht plans and blueprints are detailed drawings and diagrams that provide a comprehensive guide for building a yacht. They include information on the yacht’s design, dimensions, materials, and construction techniques.

Who uses yacht plans and blueprints?

Yacht plans and blueprints are used by boat builders, yacht designers, and individuals who want to build their own yacht. They are also used by naval architects and engineers who are involved in the design and construction of yachts.

What information is included in yacht plans and blueprints?

Yacht plans and blueprints typically include information on the yacht’s hull design, deck layout, rigging, propulsion system, electrical system, plumbing system, and interior layout. They also include detailed drawings of each component and instructions on how to assemble them.

Where can I find yacht plans and blueprints?

Yacht plans and blueprints can be found online, in books, and through yacht design firms. Some yacht design firms offer custom plans and blueprints based on the client’s specific needs and preferences.

Do I need any special skills to use yacht plans and blueprints?

Building a yacht using plans and blueprints requires a certain level of skill and experience in boat building . It is recommended that individuals who want to build their own yacht have some prior experience in woodworking, fiberglassing, and other boat building techniques.

How long does it take to build a yacht using plans and blueprints?

The time it takes to build a yacht using plans and blueprints depends on the size and complexity of the yacht, as well as the builder’s skill level and available resources. It can take anywhere from several months to several years to complete a yacht build.

Written by DIY Boat Building Plans

Yacht Painting Tips

Yacht Polishing Tips

- 936-483-8600

- 1976 Go-Tag-Along

- Commercial Applications

- Cockpit Upgrade Package

3D Configurator

Contents of this page, browser requirements video introduction tutorial instruction manual proceed to configurator, proceed to 3d configurator, browser requirements, chrome (version 61 and higher) firefox (version 57 and higher) safari (version 11 and higher) edge (version 16 and higher), instruction manual - online 3d configurator, introduction how to access the configurator new user setup resetting a user password how to use the configurator starting a new design working on a design basic controls tabs, buttons and features exposing the floor plan adding items to the design select finishing options for the design viewing the design costs dealer account management share a design with someone else print the design in pdf, word or excel forecasting purchase vehicle delete design help center, introduction.

What is the Online 3D Configurator? The Land Yacht Motor Werks online configurator is an interactive ‘Build Your Own’ 3D modeling tool with the most realistic views on the market. The configurator allows users to design, configure and quote a customizable transportation solution for virtually any lifestyle or portable business venture. In a three-dimensional format that can be easily navigated, users can virtually explore an endless possible combination of configurations until they find the design that fits their needs. In addition to customizing the layout, color scheme and textures, there is the ability to view an itemized estimate of the buildout which can be printed or shared with others.

State-of-the-art functionality includes:

Fully interactive drag-and-drop interface for placing options browse available components through a collapsible menu structure rotate to view any angle choose items from a robust selection of customizable options move and rotate items sliced view of floorplan without walls for easy placement plus and a top down view with walls for spatial awareness customize finish details, which include: vehicle paint color seat upholstery colors cabinet and countertop colors itemized estimate save design for future use built-in calculator to see finance cost calculations create multiple designs and share with friends and family before making decisions, how to access the configurator.

The Land Yacht Motor Werks online configurator can be accessed from our website. There are multiple links from the website including a quick link at the top of the page and from the menu options. Along with access to the configurator, there is a Knowledge Base for answers to commonly asked questions and detailed instructions for using the configurator.

New User Setup

Access the Online Configurator login screen from the Land Yacht Motor Werks website and create an account to have full functionality of the site.

Click on the ‘New Customer? Click here to Register’ button.

Fill out the entire form, as each field is required for user account creation.

For passwords, follow the requirements below:

Passwords are required to be a minimum of 6 characters in length Passwords are required to have a number Passwords are required to have a special character, such as ! * @ _

Resetting a user password.

From the Online Configurator login screen, select ‘Forgot My Password’. A password reset link will be sent to your email address.

How to Use the Configurator

Once logged into the Online Configurator, you can start creating your new design or review previously saved designs.

Starting a new Design

To start a new design, click the menu button and select ‘create new design’, enter detailed information that will be used to help manage your design, design name: used to help differentiate between multiple designs select vehicle type: mercedes-benz sprinter 144 mercedes-benz sprinter 170 mercedes-benz sprinter 170 extended base vehicle price: used to help calculate total cost of the customization and calculate finance details utilizing the built-in finance calculator. zip/postal code: used for internal marketing awareness and analytics. (this information will not be referred or provided to a dealer without your permission) dealer account: the preferred mercedes-benz dealership that you will be working with., working on a design.

Before beginning your new Design, there are site functions that should be reviewed to fully understand tools and get the most out of the configurator capability. Please follow through with this instruction manual to get the best use of the configurator.

Note: Once started, a blank design will be provided for the Vehicle Type selected in the previous screen. ***The Vehicle Type cannot be changed once started. A new Design will need to be created.

Basic Controls:

Within the configurator, there are basically three different controls for movement of the scene and vehicle:

Left Click to drag the vehicle around the workspace: forward, backward, left or right Right Click to rotate the vehicle on a pivot point to get a better perspective for viewing from the top or side. Use scroll Button on your mouse to zoom in and out

If you don’t have a mouse or need to rotate the vehicle manually, you can click on the Mobile Controls button in the top right corner of the browser to pull up the navigation options.

Rotation Selection: Click on the arrow buttons to rotate as desired Scene Movement Selection: Click on the arrow buttons to rotate as desired Zoom In: Click to zoom in on the design Zoom Out: Click to zoom out of the design Focus: Click to bring the design back to the originals starting position

Tabs, buttons and features.

Navigation of the configurator revolves around the Product List, Cart and three tabs at the top of the Design screen. The design tabs allow users to toggle between the Design project, adjustments to the vehicle options and item specific tools.

Project Tools: Design Name ‘Save & Quit’ Button ‘New Scene’ Button Scene Tools: Options that pertain to the entire design Finish Options: Snapshot Notes Product Tools: Product Colors Information Focus: Bring vehicle to starting position Lock: Lock the selected item in place on the design Notes: To make personal notes about the selected item Rotate: To rotate the selected item in 90 Degrees Animate: (For future use) Delete: To remove selected item from the design

Exposing the floor plan.

To start placing items onto the design, the top and sides of the vehicle need to be sliced away. This is accomplished by clicking on the Scissors button in the top right corner of the design window.

Click once to remove the roof Click a second time to remove the walls and expose the floor plan Click again to add the roof and walls

Adding items to the design.

After exposing the floor plan, add items to the design by selecting a product category from the Product Menu on the left and then click on an item to have it automatically placed on the design.

Select an item from the Product List on the left Drag the item to the desired location Note: To assist with placement, sometimes it helps to rotate the scene around to get a different perspective view of the floorplan to ensure proper placement. Rotate the item if needed Lock an item in place to avoid accidental movement when working with other items Select additional items as needed until the desired configuration is complete

Select finishing options for the design.

After selecting all the items and confirming placement in the Design, proceed with customizing the finishing details, which includes paint, upholstery, cabinetry and countertop colors:

Click on the design outside of the van ensuring that you do not have an item selected Click on the Scene Tools tab Select the Finish Options tab Choose Your Finishes menu appears on left side of screen

Click on each Finish Option to select from the list of standard options to choose from:

Van Exterior color Seat Cushion color Cabinet colors Countertop colors

Viewing the design costs.

Once the items have been added to the design and the Finish Options have been selected, click on the Cart button in the top left corner to see a detail of the items selected.

At this point you have the option to review the selected items again and complete the design by clicking on the ‘More Details’ button or return to the design by clicking on the Products button on the top left corner of the site.

Click Exit to exit the design without saving Click Finish to save and exit the design Click on the X at the top right corner of the Materials List window to return to the Design

Dealer account management.

The online configurator allows Dealerships to create, view and manage designs that have been assigned to them. When accessing the configurator, a dealer will have the following options:

View designs by customer Search for designs by Design Name Filter by customer Share the design with someone else Print the design in PDF, Word or Excel Flag the design Forecast Finalize the purchase of the design with a supplied Purchase Order number Delete designs that are no longer relevant or valid

Share a design with someone else.

Click on the ‘Share this Design’ button to enter the email address of another person you would like to share the design with.

An option will appear to enter the email address of someone that you would like to share the design with.

After clicking the Share button, an email will be sent to the person with instructions on how to create a free account to access the design.

Print the design in PDF, Word or Excel

To print a copy of the design quote in PDF, Word or Excel format, click on the ‘Print Quote Configuration’ button

After clicking the ‘Print Quote Configuration’ button, an option to select the preferred format will appear.

Select the preferred format and a copy of the estimate will appear.

Forecasting

As part of the Dealer Account Management feature, the option to forecast a design has been incorporated to give better visibility and reporting of valid opportunities.

After clicking the ‘Forecast’ button, a dialog box will appear to enter the anticipated close date for the design.

The design will be updated to confirm that it has been forecasted.

Purchase Vehicle

To assist approved dealerships with converting design estimates to actual orders, the online configurator provides the ability to process an order electronically. This will automatically submit the order into the ERP system of Land Yacht Motor Werks and expedite the order process eliminating the need to reenter the data. For all electronic orders, a Purchase Order is required and a follow-up confirmation will made prior to any work commencing for a purchase made through the configurator.

After clicking the ‘Purchase Vehicle’ button, a confirmation window will appear.

Click the Acknowledgement box and enter a Purchase Order number to confirm the purchase of the design.

Delete Design

To delete a design and remove it from the online configurator, click on the ‘Delete Design’ button.

2023 © All Rights Reserved.

⛵Boat Mavens

Boating Lifestyle | Boats | Boat Shop

The Ultimate Guide to Planning and Building Your Own Boat

Welcome to the ultimate guide to planning and building your own boat . Whether you’re a seasoned boat builder or a beginner with a passion for the open water, this comprehensive guide will provide you with all the knowledge and insights you need to embark on your DIY boat building journey.

From the initial design phase to the final construction steps, we’ll walk you through the entire process, offering step-by-step instructions and expert tips along the way. With our guidance, you’ll be equipped to create your dream vessel and experience the satisfaction of cruising the waves in a boat you built with your own two hands.

Are you ready to dive into the exciting world of boat planning and building ? Let’s get started on this nautical adventure together!

Table of Contents

Key Takeaways:

- Planning and building your own boat is an achievable DIY project.

- This guide covers the entire boat building process , from initial design to final construction.

- Expert tips and insights will help you avoid common pitfalls and achieve professional-level results.

- Choosing the right materials is crucial for the success and longevity of your boat.

- Whether you’re a beginner or an experienced builder, this guide has something for everyone.

The Pleasures and Perils of Plywood

When it comes to boat building, plywood is a popular choice due to its versatility and affordability. Many boat builders opt for plywood boat construction as it offers a range of benefits. However, it’s essential to understand the potential drawbacks as well. In this section, we’ll explore the joys and challenges of building a boat with plywood.

The Advantages of Plywood Boat Building

Plywood boat construction comes with several advantages that make it an attractive option for boat builders. These include:

- Cost-effectiveness: Plywood is generally more affordable compared to other boat building materials such as fiberglass or aluminum, making it an excellent choice for those on a budget.

- Easy to work with: Plywood is lightweight and easy to handle, making it suitable for both professional and DIY boat builders.

- Versatile design options: Plywood can be easily cut and shaped, allowing for a wide variety of boat designs and customization options.

- Strength and durability: While plywood may not be as strong as some alternative materials, it still offers sufficient strength and durability when used correctly.

Tips for Successful Plywood Boat Construction

While plywood boat building offers numerous benefits, it’s essential to be aware of certain factors to ensure successful construction. Here are a few tips from experienced boat builders:

- Choose the right type of plywood: Marine-grade plywood is specifically designed for boat building, offering superior resistance to water and weather.

- Properly seal and protect the plywood: Applying a high-quality sealant and protective coatings is crucial to prevent water damage and increase the lifespan of the boat.

- Follow proper construction techniques: Plywood boats require specific construction techniques, such as edge sealing, scarf joints, and proper fastening, to ensure structural integrity.

- Regular maintenance is key: Like any boat, plywood boats require regular maintenance to prevent rot, delamination, and other issues caused by moisture exposure.

To better understand the benefits and challenges of plywood boat construction , let’s take a closer look at a comparison between plywood and other common boat building materials :

| Plywood | Fiberglass | Aluminum | Composites | |

|---|---|---|---|---|

| Cost | Affordable | Expensive | Expensive | Varies |

| Weight | Lightweight | Lightweight | Lightweight | Varies |

| Customization | High | Medium | Medium | High |

| Strength | Good | Very strong | Very strong | Varies |

| Maintenance | Regular | Minimal | Minimal | Varies |

This comparison highlights the unique attributes of plywood compared to other materials commonly used in boat construction. While each material has its advantages and disadvantages, plywood offers an appealing balance of affordability, versatility, and ease of use.

In the next section, we’ll delve into the process of designing your own boat , offering guidance and inspiration for those seeking a more custom approach to boat building.

Building Your Own Design

If you have a specific vision for your boat and want to embark on the exciting journey of custom boat building , this section is designed to provide you with valuable guidance. Whether you dream of a sleek and fast motorboat or a sturdy sailboat, designing your own boat allows you to bring your unique ideas and personal style to life.

Boat Design Process

The boat design process is a creative and analytical endeavor that involves translating your ideas into detailed plans. It begins with the conceptualization stage, where you brainstorm and sketch your boat’s layout, size, and overall design. From there, you’ll refine your ideas, taking into consideration factors such as functionality, aesthetics, and safety.

During the design process, it’s important to consider how you intend to use the boat. Factors such as the type of waters you’ll navigate, the number of passengers, and the purpose of the boat (fishing, cruising, racing, etc.) will influence the design. This section offers valuable insights from experienced boat designers and builders who share their expertise on boat design considerations .

Key Considerations in Boat Design

When designing your own boat , there are several key considerations to keep in mind. These include:

- Intended use and purpose: Determine the primary use of your boat and the specific features required to support that use.

- Size and layout: Consider the desired size and layout to accommodate passengers, storage, and any special equipment needs.

- Materials and construction methods: Choose the appropriate materials and construction methods that align with your design goals and skill level.

- Aesthetics and style: Define the overall visual appeal and style of your boat to reflect your personal taste and preferences.

- Performance and stability: Strive for a design that delivers optimal performance, speed, and stability on the water.

- Safety and regulations: Ensure your design complies with safety standards and local regulations to guarantee a safe boating experience.

Designing your own boat is a rewarding and fulfilling endeavor that allows you to create a vessel perfectly tailored to your needs. By considering these key factors and drawing inspiration from experienced designers and builders, you’ll be well-equipped to embark on this exciting custom boat building journey.

| Key Benefits of Designing Your Own Boat | Challenges and Considerations |

|---|---|

Choosing the Right Materials

The choice of materials is crucial in boat building. The materials you select will determine the durability, performance, and overall quality of your boat. In this section, we will explore the different types of boat building materials and help you choose the best options for your project.

Wood has long been a popular choice for boat construction due to its aesthetic appeal and ease of working with. However, it requires regular maintenance and may be prone to rot and decay if not properly treated. Some common types of wood used in boat building include mahogany, teak, and cedar.

Fiberglass is a composite material made of a plastic resin reinforced with glass fibers. It is known for its strength, durability, and resistance to water. Fiberglass boats are low maintenance and can withstand harsh marine environments. They are also relatively lightweight, making them suitable for speed and performance.

Aluminum is a lightweight and corrosion-resistant material commonly used in boat construction. It offers excellent strength-to-weight ratio and requires minimal maintenance. Aluminum boats are durable and can handle rough conditions, making them popular for fishing and recreational purposes.

Composites, such as carbon fiber and Kevlar, are gaining popularity in boat building. These materials offer exceptional strength and stiffness while being lightweight. Composites are often used in high-performance boats, yachts, and racing vessels.

When choosing the right materials for your boat, consider factors such as the intended use of the boat, the desired lifespan, and your budget. It’s important to balance performance, durability, and cost to ensure the success of your boat building project.

| Material | Pros | Cons |

|---|---|---|

| Wood | Aesthetic appeal, ease of working with | Requires regular maintenance, prone to rot and decay |

| Fiberglass | Strength, durability, resistance to water | Relatively heavy, may require professional repairs |

| Aluminum | Lightweight, corrosion-resistant | Less aesthetic appeal, higher initial cost |

| Composites | Exceptional strength, stiffness, lightweight | Higher cost, specialized construction techniques |

By considering the advantages and disadvantages of each material, you can make an informed decision and choose the best materials for your boat construction project.

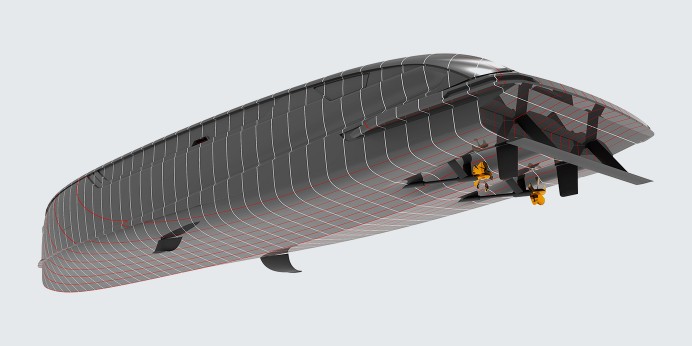

The Boat Building Process

Building a boat requires a systematic approach that involves several essential steps. Whether you’re embarking on a DIY boat construction project or assembling a pre-made kit, understanding the boat building process is crucial for ensuring a successful outcome. In this section, we’ll guide you through each step, from setting up the backbone to the final assembly of your boat.

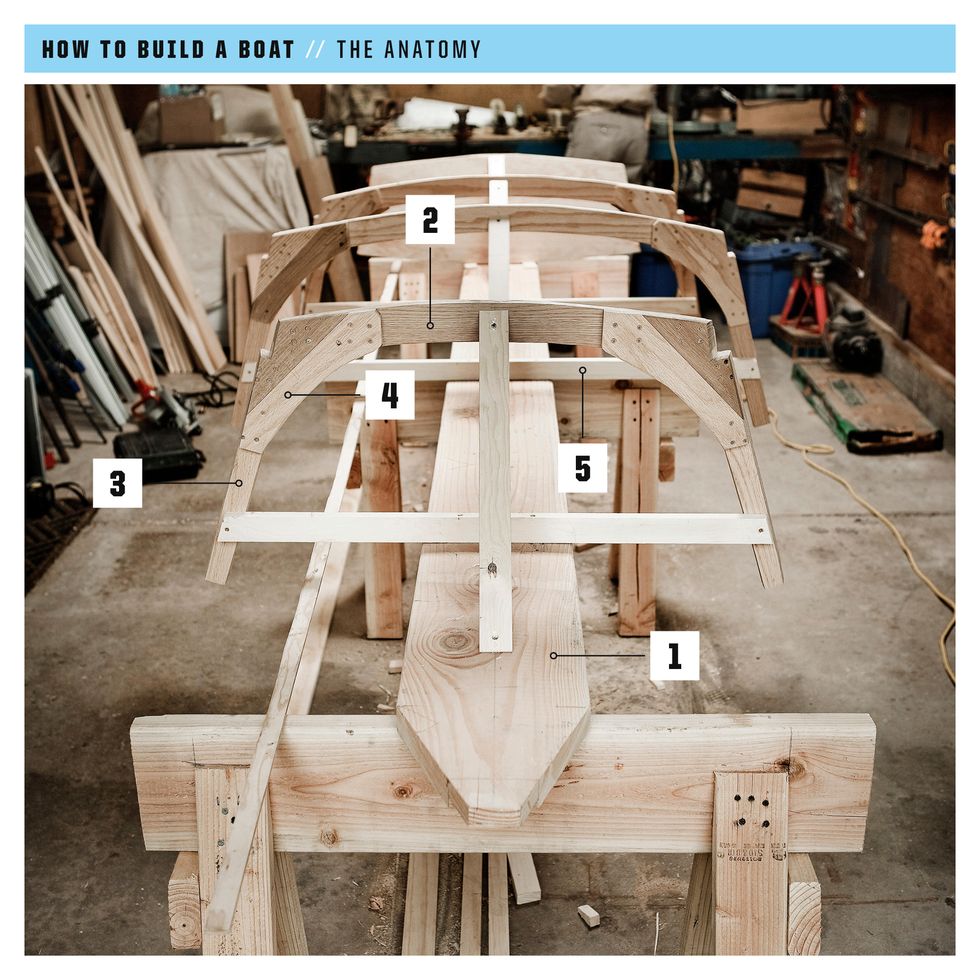

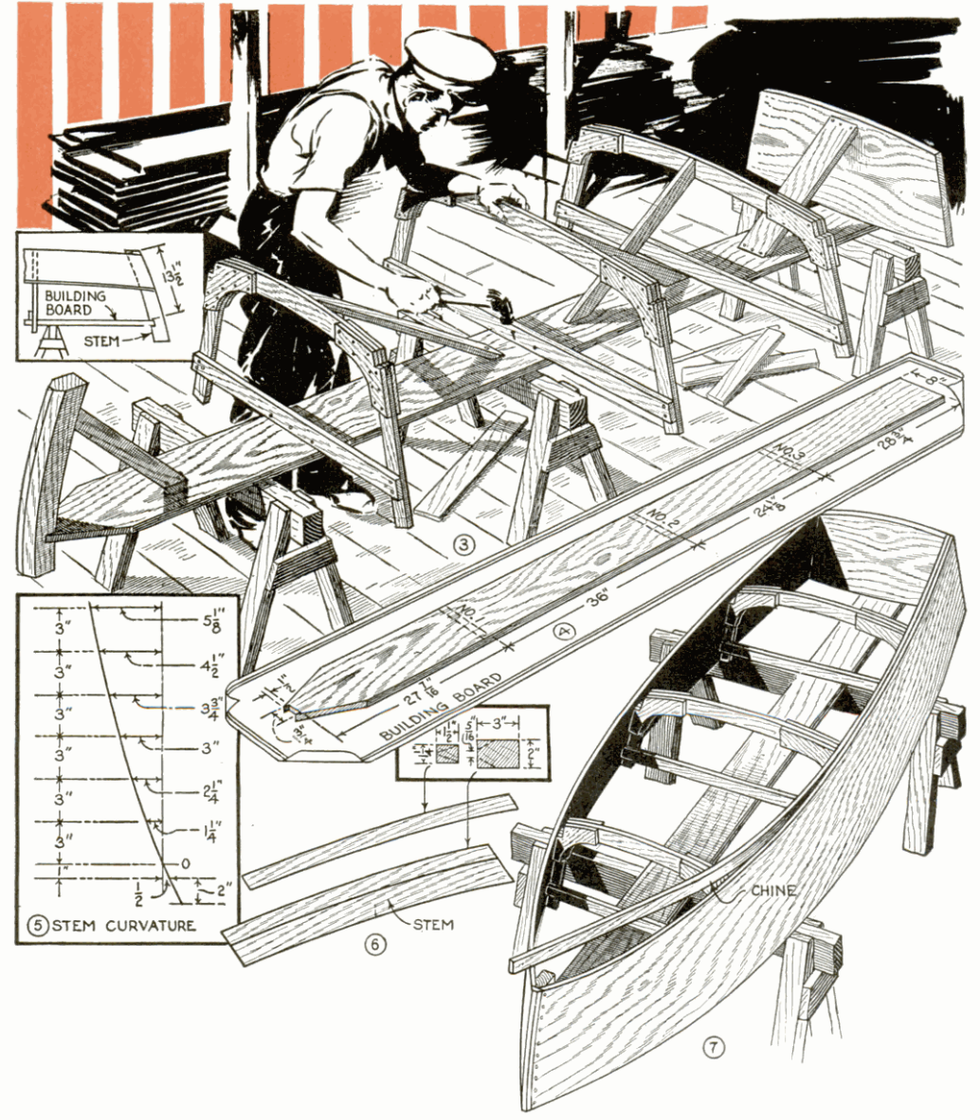

1. Setting up the Backbone and Framing

The first step in boat construction is setting up the backbone, which includes installing the keel, stem, and sternpost. These components create the structural framework of the boat. Once the backbone is in place, you’ll proceed to frame the boat, adding the ribs or frames that provide shape and support. This stage requires accuracy and attention to detail to ensure a properly aligned and sturdy frame.

2. Planking

After the framing is complete, it’s time to attach the planks to the boat’s frame. Planking can be done using various methods, such as using plywood or traditional wooden planks. Each plank is carefully fitted and fastened to the frame, creating the outer skin of the boat. This process requires precision to achieve watertight seams and a smooth finish.

3. Fiberglassing

To strengthen and protect the hull, many boat builders choose to fiberglass the boat’s exterior. Fiberglass provides additional durability, water resistance, and improves the overall structural integrity of the boat. This step involves applying layers of fiberglass cloth and resin to the hull, followed by sanding and finishing to create a smooth surface.

4. Interior and Exterior Finishing

Once the hull is complete, attention turns to the interior and exterior finishing of the boat. This includes installing bulkheads, cabinetry, flooring, and other interior components. On the exterior, you’ll apply paint or varnish to protect the boat from the elements and enhance its appearance. Finishing touches such as adding hardware, windows, and electrical systems complete the boat assembly process.

| Step | Description |

|---|---|

| 1 | Setting up the Backbone and Framing |

| 2 | Planking |

| 3 | Fiberglassing |

| 4 | Interior and Exterior Finishing |

As you progress through each step of the boat building process , it’s important to follow best practices and consult reliable resources for guidance. Experienced boat builders can provide valuable insights and advice based on their years of experience. By executing each step with care and precision, you’ll be one step closer to completing your very own boat.

Tips and Techniques

Enhance your boat building skills with these valuable tips and techniques. Whether you’re a beginner or an experienced boat builder, these insights from professional boat builders will help you improve your craftsmanship and achieve professional-level results in your DIY boat construction project.

Tool Maintenance

Proper tool maintenance is essential for efficient and precise boat building. Keep your tools clean, sharp, and properly stored to ensure optimal performance. Regularly inspect and replace any worn-out or damaged tools to avoid compromising the quality of your construction.

Paint Finishes

Choosing the right paint and applying it correctly is crucial for a beautiful and durable finish on your boat. Consider factors such as durability, UV resistance, and compatibility with the boat’s material. Follow proper surface preparation techniques, including sanding and priming, to achieve a smooth and flawless paint finish.

Scarphing Plywood

Scarphing plywood is a technique used to join two pieces of plywood together to create longer panels without compromising strength. Properly scarphed joints are crucial in boat building to ensure structural integrity. Learn the correct angle and length ratios for scarphing plywood and practice the technique to achieve strong and seamless connections.

Fiberglassing

Fiberglassing is a common technique used to reinforce and protect boat structures. Learn the proper techniques for applying fiberglass cloth and epoxy resin, including wetting out, rolling out air bubbles, and achieving a smooth finish. Understanding the fiberglassing process will help you create strong and durable components for your boat.

You may also like: Hobie Itrek 9 Ultralight Review

Recommended Boat Building Techniques

| Technique | Description |

|---|---|

| Plywood Scarphing | A technique for joining plywood sheets to create longer panels without compromising strength. |

| Fairing | The process of shaping and smoothing a boat’s hull to achieve optimal hydrodynamics. |

| Epoxy Filleting | Using thickened epoxy to create structural fillets for bonding joints and reinforcing corners. |

| Steam Bending | A technique used to bend wood using steam to make complex shapes for boat components. |

| Vacuum Bagging | A method of applying pressure to composite laminates for improved bonding and consolidation. |

| Wire Splicing | A technique for connecting and securing wires in a boat’s electrical system. |

By implementing these boat building tips and techniques into your project, you’ll enhance your skills and ensure the successful completion of your DIY boat construction . Remember to always prioritize safety, attention to detail, and the use of high-quality materials to create a boat that is both structurally sound and visually impressive.

In conclusion, this ultimate guide to planning and building your own boat provides a comprehensive resource for anyone interested in DIY boat construction. The guide covers the entire process, from initial design considerations to final construction techniques, offering valuable insights and recommendations from experienced boat builders.

Whether you’re a novice exploring the world of boat building or an experienced builder looking to enhance your skills, this guide equips you with the knowledge and confidence to embark on your own boat building journey. By following the step-by-step instructions and incorporating the expert tips shared in this guide, you’ll be well on your way to bringing your dream boat to life.

Throughout the guide, we have touched on important topics such as the pleasures and perils of using plywood, the benefits of designing your own boat, the selection of the right materials, and the various stages involved in the boat building process. With this comprehensive coverage, you’ll be empowered to make informed decisions and tackle each step of the construction with confidence.

Whether you’re interested in building a small rowboat for calm lake excursions or a larger cruising yacht for adventurous voyages, this guide serves as a valuable resource for all types of boat building projects. We hope that the information presented here has inspired you to embark on your own boat building journey and that you find great joy and satisfaction in the process.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

COMMENTS

I'll give you the 3D CAD drawings and dimensions of every part that needs to be made, along with lists of materials, cutting lists and detailed building instructions. Everything you need to build your own landyacht. Plans and instructions are clear and are very easy to follow. These plans are high quality C.A.D designs (Autodesk-INVENTOR).

Hey guys, Here's a short video of some pictures and video clips of the land yacht I built for a school project. I based my design on the Blokart, I used 304...

The first part of this build is preparing the sail for the land yacht. Our land yacht utilizes a sail that has a 5-foot boom and a height of 10.5 feet. This sail height was determined to work with the size of the land yacht. Our team used a much larger sail from a sailboat that will need to be cut to the right dimensions.

Yacht plans and blueprints are essential tools for anyone looking to build their own yacht. These detailed documents provide a roadmap for the construction process, outlining the necessary steps and specifications required to bring a yacht to life. Without a plan, building a yacht can be a daunting and overwhelming task.

The Land Yacht Motor Werks online configurator is an interactive 'Build Your Own' 3D modeling tool with the most realistic views on the market. The configurator allows users to design, configure and quote a customizable transportation solution for virtually any lifestyle or portable business venture. ...

Planning. Draw what your land yacht will look like. Devise some criteria such as. o The vehicle should travel in a straight line and a distance of at least 20cm when placed in front of a working hairdryer. o The vehicle should have a working sail. o The vehicle should have either a fixed axle or a fixed wheel. You decide!

Planning and building your own boat is an achievable DIY project. This guide covers the entire boat building process, from initial design to final construction. Expert tips and insights will help you avoid common pitfalls and achieve professional-level results. Choosing the right materials is crucial for the success and longevity of your boat.

A Land Yacht. Blast from the Past by H. Ashley, The Rudder, v.15, 1904, p. 675. We love our old magazines so here is a little treasure from the dusty old pages. A Land Yacht. At the time of the great French war a British frigate that was on blockade duty off the coast near Quieberon, stood too far in to reconnoitre, and being caught by a calm ...

Boat Plans, Patterns and Supplies For the Amateur Boat Builder! Every year, thousands of amateurs much like yourself build their own boats the proven Glen-L way. Many builders save 50% or more over the price of a factory-built boat. It's easier than you might think, and it can be a rewarding experience.

Design your own Wider 32, a versatile and eco-friendly yacht, with our online configurator. Choose colors, materials, options and accessories.

Merle Wood & Associates have seen the construction (including those now in progress) of more than 60 yachts ranging from 100 feet to more than 500 feet in length. Because of this, we are globally recognized by our piers and clients as leaders in new yacht construction. 1-954-525-5111.

The Superyacht Construction Team - Key Players. The process of building a yacht will involve a great number of decisions, so having the support of a knowledgeable and experienced team is imperative. The owner may wish to engage a respected yacht broker to build the team, knowing that they spend a significant amount of time liaising with key ...

Read more. Dynamiq is a smart superyacht builder meeting the needs of intelligent buyers for next-generation yachts: efficient, easy to order and effortless to customize. Our fast-displacement yachts are designed in Monaco and engineered in the Netherlands, ensuring exclusive contemporary styling and comfort, with long-range capabilities.

Design Your Own Yacht. When designing your own yacht, you have a few options, from commissioning a custom new build yacht construction project through to refitting an existing yacht. When deciding which route to take, it's helpful to know some of the pros and cons of each approach. Option 1: The deluxe, no-holds-barred, fully custom yacht.

Build yourimagination. Build your. imagination. As a process, having your own yacht built comes close to having your own house built. You have an idea, you talk to an architect, you discuss the intended use, possibilities, materials and budgets. Except that when its done, you can take your boat all over the world.

Yacht interior design. Knowing the hull type, we can take your wishes and put them in a preliminary design. This will be a rough outline of the general arrangement (interior layout), a sail plan, a lateral view of the underwater hull and a deck plan. Together with you and the architect we can tweak this plan into a final design.

Choose a Design Plan: The first step in building a yacht is choosing a design plan that works best for your needs. Consider the size, shape, features, and overall aesthetic you want your yacht to have. Research different types of yachts and decide which is right for you. 2.

1.Understanding Your Preferences. First, take the time to understand what you like and want in a boat. Think specifically about how you plan on using the yacht. When you have a crystal clear vision of what your yacht will need, you're less likely to get hung up with unimportant details. You won't be swayed by a barbecue and sun lounges when ...

Your Custom Yacht Realised. The process of building a custom yacht is exciting yet challenging. The road from concept to creation can be a long one that involves considerable research and planning. TJB Super Yachts' team of experts is on hand to guide you, acting as a liaison between designers, shipyards, and architects throughout the full ...

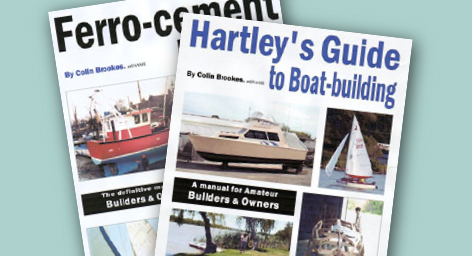

Boat plans. Hartley Boats has the widest range of boat plans for sail boats, power boats, catamarans and trimarans, dinghys and small craft, canoes and kayaks, surfboards and surf skis, vintage power boats, self steering capabilities and trailers. Established in 1938, more than 100,000 boats have now been built by enthusiasts from our plans.

The next step was to clamp thin strips of wood, called battens, to the frame to stand in for the planks, so I could measure and mark all those angles. Then, I took the parts off the board and ...

Mr. Vance spilled scores of details about his life in his coming-of-age memoir. We've collected the highlights. By Shawn McCreesh Follow the latest news from the Republican National Convention ...

Working from a kit also helps. 'Having all the pieces pre-cut gave me a great kickstart,' he says. Price: £1,768. Kit includes all plywood parts for the boat. Total cost will be around five times this price, for all the additional timber, glues, paint, fixings, sails and rope. Cape Henry 21.

A Northern Colorado prairie rattlesnake den, make that a "mega-den," is causing quite the buzz. Researchers say the den on undisclosed private land is home to as many as 2,000 rattlesnakes ...

Monaco Grand Prix 2024. "Building a yacht requires extensive and detailed. knowledge of what to build, where to build it, how to. build it and how much it will cost. Our expert project. managers have overseen the construction of. many of the world's premier superyachts." Laurent Brady. Technical Manager.

Speaking of tight spaces, you might also need to downsize what you own if you plan on living full-time in a houseboat. "On average, houseboats offer approximately 600 square feet of indoor and ...

Senator J.D. Vance of Ohio, accepting his party's nomination for vice president, denounced "Wall Street barons" and illegal immigration as the convention's previous unity message shifted ...

A Gen Z data scientist recommends building your own AI project to get hands-on experience to talk about in your interviews. Menu icon A vertical stack of three evenly spaced horizontal lines.

How they got there, top scorers, pedigree, key players and the coach - all you need to know about UEFA EURO 2024 winners Spain. La Roja were in excellent form in Germany, winning all seven games ...