Optimist Sailboat Build

Introduction: Optimist Sailboat Build

Building the Wood/Epoxy Optimist In 1947 a gentleman named Clark Mills designed a small sail boat for kids to learn to build and sail called the Optimist. This boat was designed to be built from 3 sheets of plywood, with basic woodworking abilities. As time progressed, builders began to modify the boats to gain speed advantages - as happens with all vehicles. In 1995 the International Optimist Association took the boat back to its roots and a set of dimensions were compiled to retain an exact shape of the boat, so as to remove design advantages from one boat to another. The Optimist is tightly controlled now with over 60 measurements and tolerances of the hull are generally +/- 5 mm. The tolerances do not allow the builder to exploit the possible variations of shape of the hull, but do allow a competent builder to construct a legal racing hull. Half Moon Bay Yacht Club has a summer youth sailing camp. Through the years we have trained many a young boy or girl to rig and sail the small boats available to us. Normally in an older Laser or Coronado 15. In 2011, the sailing program decided that the Optimist had a place in our sailing fleet to allow the younger kids (7-15) to rig, launch, sail and retrieve the boats themselves while under adult supervision. We set about looking at the building of wood/epoxy Optimist sailing boats. We quickly focused on making racing legal hulls so as to be competitive with other surrounding sailing clubs. This is where the accuracy and repeatability of the ShopBot CNC router at TechShop of Menlo Park www.techshop.ws became an invaluable tool in our fleet building. I made it at TechShop. Due to the close tolerances allowed, and the desire to have an almost identical fleet of boats, the ShopBot fit the bill to the letter. Once I redrew the plans into CAD drawings and transferred to cut files the different parts of the boats were identical. Each group of people that wanted to build a boat only had small amounts of fitting, beveling and gluing to accomplish, with very little use of dangerous equipment needed and quick progress to show for their efforts, so kids fit right into the task of building boats.

Attachments

The jig produced on the ShopBot retains the correct shape and supports the boat, while it is being built, to retain the exact design measurements. The plans for the boat can be found from many sources for free on the internet. Plans are available in many languages, as well. One such source is http://www.optiworld.org/Woodguide05.pdf Another guide to building an optimist is http://www.burcotboats.co.uk/howToBuild.pdf , as well as half a dozen other well written articles on the internet. But none provide CAD quality drawings or files to work with modern computer controlled machine tooling. Well, here they are: The jig as well as the major parts of the boat. The jig sides , mast step, rudder, dagger board , dagger board case ends and doubler pieces are made from 18mm or 3/4" ACX or marine grade plywood; (1219.2mm x 2438.4mm) 48" x 96".

Now to get started, the jig we have designed is the exact dimensions of a finished hull shape. Both ends of the jig have interlocking pieces to allow for inserting and removing as needed during the building of the boat. The cross members are standard 2" x 4" cut to 44" long and with a 3/4" dado 8" to each side of center to fit into the grooves of the forms. These should be cut so as to be flush with the top of the form and screwed into place to prevent movement. The bottom boards provide a stable platform for the jig to sit on. The jig should be placed on a flat surface for the build, as distortion to the jig will transfer to the boat being built. Save the scraps for blocking.

The file for the hull bottom, midship frame, dagger board case sides and corner braces are cut from one 4' x 8' sheet (1219.2mm x 2438.4mm) of 12mm Marine grade plywood If you save your larger scraps for doubling plates and gunwale rails, you will have very little waste. The first cuts should be for the 6mm deep dado at both ends of the hull to join the bow and transoms to. The second cut should be for the dagger board trunk cut out. The third cut should be the outline of all the pieces. In order to fit both sides of the dagger board trunk on one sheet, one side will have a joint to be epoxied together to match the other side.

The next setup should be for 6mm plywood. Again a 4' x 8' sheet will make both ends, both sides, mast thwart frame and again scraps can be used for doublers and clamping pads. You now have a boat cut and ready for a little fitting. Bevel the edges of the bottom to the approximate angles of 15 degrees with a block plane and you are ready to start your build. I would recommend a dry fit of all parts prior to mixing epoxy. This doesn't take long and may save you a lot of trouble with messy epoxy.

Center the bottom in the jig, stand on it to bow it and hold it down, and temporarily screw it to the 2" x 4" 's 130mm each side of center line to allow for gluing of the doublers without covering the screws, so they can be removed later. The holes will be filled in when the boat is removed from the jig with epoxy. Rip a 4' x 8' sheet of 4mm plywood into 1- 240mm strip and 2-80mm strips with a 45 degree beveled edge. This can be done on the ShopBot or a table saw. These are the doublers for the bottom to meet design minimum thickness while saving weight. Once these are epoxied into place and trimmed you are ready to install the sides, mid ship frame, bow and transom. The mid ship bulkhead can be used to position the strips in the correct place on the bottom of the hull. Once these are epoxied in position, placing some weights on top, until cured, works well. You will be covering the dagger board slot, but that can be easily cut out once the hull is removed from the jig and turned upside down for fitting the dagger board trunk and filling of screw holes.

The plans show two temporary braces. These can be made from any scrap plywood and are used to hold the proper shape of the sides while doing the assembly and glue up. Once the gunwale rails are installed these will be removed and discarded. The bow and transom fit into the dado at the front and rear of the hull bottom panel. The sides wrap around the outsides. A couple small blocks of wood screwed onto the jig at the bow and stern help in keeping the sides in position while clamps are applied. A small slot cut into the two forward jig pieces to allow a small bar clamp of your choice works well to hold the two sides together tightly. Once you are comfortable with the fit of all the parts your ready to mix epoxy. Wet out each side with unthickened epoxy. Then add a small layer of thickened epoxy and assemble with the temporary braces and mid ship brace installed. Next is the mast deck and thwart. Fit and epoxy in place. Some of the scraps of 18mm can be used for the doubler in these areas. You can install the bow and transom doubler before or after this step.

Gunwale rails and rub rails are next. You can use layers of plywood or fancy colorful woods if you plan to use a clear finish to show off your work. Build up the layers until you get to the final thickness required, per the plans. Rip 1 for each side of boat starting with a 45mm wide piece stepping down 5mm for each 10mm of thickness. Cut out pockets for and install the corner blocks next. Form and shape the rails to the required shape and thickness and you are ready to remove the boat from the Jig. We used a hand planer for the rough shape and finished with a belt sander. It will now hold its shape and dimensions. The jig can be used as a cradle to support the boat as you work on it either upside down or right side up.

Once the boat is removed from the jig, it can be turned over and all joints filled with thickened epoxy. Install the dagger board trunk through the hull and epoxy in place. We choose to put our club logo and hull # on the sides of the dagger board trunk. Once again the ShopBot makes this a blank canvas for your artistry. Below one of the boys is rounding the edges before the dagger board trunk is installed. Shape the bottom of the dagger board trunk to conform to the hull bottom from the outside once it is cured in place. Install the doubler pieces on the inside to help support the dagger board trunk. We installed a few wood dowels into the midship frame to add strength as well. Sand, epoxy and finish the exterior of the hull as desired, with either paint or a clear finish. On the inside of the hull fillet the joints with thickened epoxy. Install the flotation attachment pads, and main sheet block pad. Sand, epoxy and finish the interior of the boat as desired and the hull portion of your sail boat is ready for hardware installation. We chose white enamel for the insides for a cleaner look. You will also find the plans from one of the internet sites below. Download these and print copies to have available as you work.

To build a race legal hull requires a measurement by a certified Optimist qualified measure person. Plan on 4 hours or more for this process. The PDF file is the list of measurements for the hull. The tolerances are close, but with the use of the CNC controlled cutting you should have a race legal hull that your kids can be fully involved in the building of. The dagger board piece and rudder that was cut will need to be shaped and profiled. Again we used a plane for the rough shape, followed by the belt sander. Hardware kits are available online as well as sails, spars, FRP rudders and dagger boards at very reasonable prices. One such site is : http://www.mauriprosailing.com/Optiparts-Optimist/Optiparts-Optimist.htm?gclid=CKHtt7O1t64CFQ9-hwodHBRhrA

Sail Plan The sail can be home-made, as well, but with mass production the prices just are hard to beat. Again the spars can be made from PVC pipe, Wood or Aluminum tubing, but most can be purchased for a cheaper price than your time and investment. You probably won't need the hottest racing level gear until you see if your kids are in for it. Then watch out if they catch the bug! You will be one proud parent to have started them out on such a great and rewarding life of sailing. http://www.mauriprosailing.com/Optiparts-Optimist/Optiparts-Optimist.htm?gclid=CKHtt7O1t64CFQ9-hwodHBRhrA

Finalist in the ShopBot Challenge

Participated in the Make It Real Challenge

Recommendations

Books and Bookshelves Contest

Fix It Contest

All Things Pi Contest

Wooden Optimist

Building the Clark Mills Plywood Optimist Pram

- Clark Mills

- Plans: Rudder 1954

Original Clearwater Plans

- Optimist Sail Plan

- Opti Stories

- Optimist Videos

- Virginia Beach Project

- Copenhagen Project

Optimist Club Racer

Clark Mills designed the original Optimist Pram in 1947 . His intention was to offer a simple boat that children could use to learn to sail and build themselves. It was the biggest hull Clark Mills could make from two 4 ft by 8 ft sheets of plywood. We chose to name our version of the Optimist the “Club Racer” to reflect the original idea behind the design. The Club Racer is the same as the epoxy/wood version of the Optimist as described by the IODA standards to within 99%, however, it is much easier to build and will be stronger and last longer.

In 2009 we were approached by a group of local volunteers who were starting a youth sailing club. Part of their idea was to have the young sailors build their own boats. We agreed to help them with the boat building portion. The Optimist was the natural choice as they wanted to compete against other clubs. We provide after-sales support via our forum where you will get all the help you need while you build. The building notes are very detailed making this a project that first time builders can undertake without fear! Now your sailing club can involve your youngest sailors in a project where they build the craft on which they will learn to sail. Then they go on to race against one another on the world’s most recognized sailing craft. The Optimist is sailed in over 120 countries and it is one of only two yachts approved by the International Sailing Federation exclusively for sailors under 16. The Optimist is the biggest youth racing class in the world.

NOTE: There are no plans for the Club Racer, only a kit which includes detailed building notes.

Optimist Club Racer – Complete Kit

- $ 1,155.29

- Add to cart

Optimist Club Racer Opti_CR-CNC Kit

- $ 1,068.00

Optimist Basket Mold Kit

- $ 710.00

Study Plans

Kit building notes, basket mold assembly.

The best technical support: we will help you succeed! All our plans and kits come with full technical support.

Also on our site, you will find hundreds of pages of tutorials, plans updates, a forum to share ideas about our boats, and thousands of pictures of completed boats, and many of the building steps done by builders like you.

All of the supplies required to build our boats are available at BoatBuilderCentral.com. Epoxy resins, fiberglass, marine plywood, foam, paint, and hardware will be delivered right to your door!

Privacy Overview

Optimist Buying Guide

By tom coleman.

The Optimist; at first glance a simple little kids boat…right? The more you get to know this “simple” little kids’ boat, the more you realize it’s not so simple. But little Jimmy starts sailing class in a month and you’re told to provide a fully rigged Optimist for his use. Where do you start? What do you really need and what’s it all gonna cost? Tom “Optiguytom” Coleman, long associated with junior sailing, is considered internationally as an Optimist guru, especially when it comes to getting kids started in racing. In this article he helps parents get started into the world of the Optimist, unraveling the mysteries of understanding, choosing and purchasing an Optimist sailboat.

Optimist Basics

The Opti, or Optimist Dinghy, is relatively unchanged from the first prams designed and built by visionary Clark Mills in Clearwater, FL, 65 years ago. Testament to Mills’ genius, the Opti remains the largest and fastest growing sailboat class in the world, a phenomenon as THE definitive teaching boat for hundreds of thousands of children the world over.

The Opti is not for everyone. It was designed for children. Optis are sailed by kids as young as five* years old and can be officially raced by kids up to age fifteen. Although it’s possible for a parent to sail an Optimist alone or with a small child, realistically adult sized sailors just don’t fit well. That’s part of the magic behind why they work so perfectly for kids.

Mills originally designed the Opti to be garage-built out of $50 worth of materials… hence the “one sheet of plywood” nearly 4’x8’ size. Little did Clark know that one day two Optis could easily slide into the back of a Suburban or mini-van, or that Mom and a teen could lift it onto the car top, or that the spars (mast, boom, and sprit) could be shipped UPS or flown as baggage.

Why Buy Them Their Own Boat?

Many learn-to-sail programs provide Optis for participants, but some have gotten so popular that you will need to supply your own boat. Check with the program and solicit their recommendation on procuring a suitable Optimist. As a rule, Optis hold their value extremely well, making the overall investment quite reasonable. While a brand new, ready to race Optimist will start at less than $3,000, completely rigged Optis suitable for beginners can be had for less than $1,000. Another reason to buy your child their own Opti is the pride of ownership that comes from taking care of their own vessel. It’s a great way to build responsibility and help get them invested in this life-long activity.

What Will They Need to Start?

When we say Optimist, or Opti, we are talking about a complete, ready to sail package. Although there are many possible accessories and upgrades, this is what your child must have:

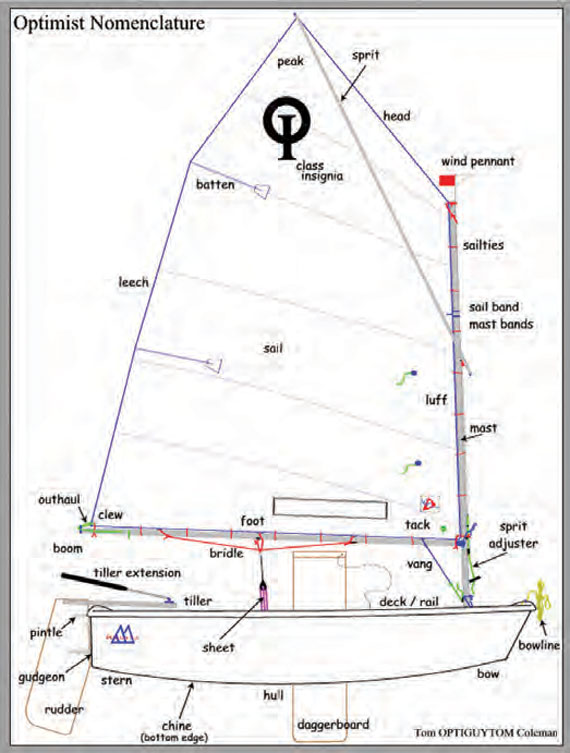

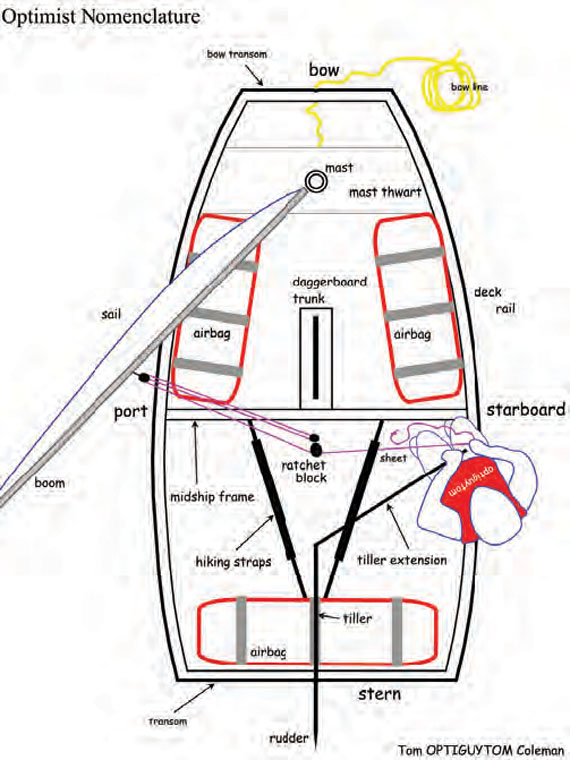

Hull – it’s the shell or body of the boat, the vessel itself. The vast majority are built of fiberglass. It includes the deck which runs around the top edge and is for sitting on, not standing. The hull also includes the mast thwart, daggerboard trunk and midship frame. These are all permanently attached during manufacture. Every hull has important parts attached mechanically (with screws), or secured by other means. These include hiking straps, ratchet block, dagger board bungee, three flotation bags, mainsheet, mast step (should be adjustable), and bow line.

Blades – sometimes called foils. They are the rudder (with tiller and extension) and the daggerboard.

Sail – usually white, made of Dacron.

Rig – often called spar set; these are the mast, boom, and sprit; the poles that support the sail. The rig includes the lines (ropes) and blocks (pulleys) that control the sail.

Accessories

Bailers – need two in the boat at all times, flimsy plastic bottles don’t work and are NOT safe.

Blade Bag – protects and stores the daggerboard and rudder, makes for easier carrying.

Life jacket – must be USCG Approved and appropriate size.

Whistle – secured to life jacket with a short lanyard.

Bow bumper – protects not only your investment but those of others.

Dolly – for dockside transport, launching, sometimes storage. Some programs require them.

Covers – depending on how boat will be stored a top or bottom cover may be a good investment.

Praddle – one handed paddle. Regular canoe or telescopic paddles DO NOT WORK!

New, Used, Chartered?

New complete Opti packages start at around $2700 while used Optis range from $500 on up depending on age, condition, and accessories. A third option is called a “chartered” or “event” Optimist. Think of these as demos, typically used at a few regattas by good sailors. Often these come with brand new spars and sail, carry new boat warranties, and sell for $200 – 300 below retail.

Club, Intermediate, Advanced, Premium Racer?

Those are names of various Opti packages differentiated by the equipment each comes with. Beginning sailors should be most interested in the “Club” or “Club Racer” version. Besides being the most economical, it’s designed for their level; a little heavier duty with less parts to loose or break. The Intermediate will have some upgrades mainly of interest to racing. The Advanced (read more expensive), are aimed at delivering a product suited exclusively toward competitive sailing and bear no advantage to those starting out. It’s important to know that the hull is really the same in each package and can be upgraded as the sailor progresses with the purchase of different spars, blades, and sails.

Where to Buy

Local Sailing Programs

Check the bulletin boards at local yacht clubs and community sailing centers and you’re likely to find at least a couple of formerly sailed Optis available. Ask around, during weekend and after school Opti classes (yes, most have already started), and you may uncover some unadvertised bargains.

Friendly Neighborhood Dealer

Shopping new or used Optis at your local dealership is perhaps the easiest way to obtain the right boat for your child. Typical small boat sales staff, as a rule, are local sailors and have insight on the surrounding programs and what each expects. You’ll find them to be very knowledgeable, highly enthusiastic, but not pushy.

The best deals can be found at the many spring open houses, boat swaps, or Opti auctions. You’ll be able to compare $600 fixer-uppers and $1,000 bargains (privately owned, taken in on commission) to used, chartered and brand new Optis, all at one location. The dealer can fix you up with necessary accessories, including roof racks to transport the newest addition to your family.

Online shopping can produce some real bargains, but has its limitations. eBay and Craig’s List occasionally have listings, but the drawback of buying sight unseen or traveling a long distance to see only one boat may not prove prudent. A recent search produced only one Opti on ebay and five scattered from New Jersey to Rhode Island.

JSALIS.org has a page of used Optis and equipment for sale as does the Opti Class at usoda.org.

Yes, but is it “Class legal”?

Class legal means that the hull, spars, sail and blades (and some accessories) meet certain rigid requirements pertaining to materials, measurements and construction. These requirements keep the Optimist safe for your child while ensuring that every Opti is virtually the same and one doesn’t have a significant advantage over another on the race course. Your Opti may be class legal if it has a sticker with a unique ISAF number or if very old, an IYRU number. The best guarantee is if you have the measurement papers issued by USODA (United States Optimist Dinghy Association) that came with the boat.

…and is it Necessary?

It’s only necessary if those holding the race say it is. Within your program it shouldn’t matter and most green fleet regattas (for beginners) are only concerned that it is safe and a reasonable facsimile. As your child progresses and begins to do more racing (regionally, nationally and even internationally), having a class legal Optimist is an “Opti-must”.

* It’s generally agreed that most kids are not developmentally ready for formal sailing instruction until 8 years of age.

Tom “OPTIGUYTOM” Coleman has been associated with the Optimist Class as a coach and instructor trainer for over a decade. He was Marketing Manager for McLaughlin Boat Works for nearly fifteen years. In 2004 he was chosen by the US Olympic Committee as Developmental Coach of the Year for Sailing. You’ll find him running the Green Fleet at many top Optimist regattas.

You can reach Tom for clinics and regatta coaching at Optiguytom@yahoo.com .

Share this:

Previous article, next article, one thought on “optimist buying guide”.

- Pingback: #7015 Opti Sailing Dinghy - Chesapeake Bay Maritime Museum

Leave a Reply Cancel reply

You must be logged in to post a comment.

Oar / Paddle

Optimist dinghy template plans.

If you are considering building a wood-epoxi Optimist dinghy, you will definitely need our Optimist Dinghy Template Plans.

The Optimist Dinghy Template Plans contain the descriptions, materials and dimensions of each and every part, all drawn to scale, needed to build the boat. The plans of the auxiliary jig and temporary frames are also included.

The plans are accompanied by a 28-page instructions booklet, with advice on materials and techniques, and a precise sequence of procedures for building the wood-epoxy Optimist dinghy to the official IODA regulations. A measurement checklist is also included.

These plans were developed from an accurate mathematical model of the Optimist hull, which corrects the numerous errors and inconsistencies found in the official IODA plans.

The plans are issued in the form of electronic documents sent to your email address - no shipping costs nor need to wait for the post. They include 14 sheets of professional quality drawings, 5 of them in A3 format and 9 in A4 format, in metric units. You can use these plans to have the parts CNC-routed or laser-cut at your location, or to cut the parts yourself.

Free email support is provided during the build process.

Design Specifications

Send your enquiries to:

ACCESS TO EXPERIENCE

Subscribe today.

Publishing dynamic editorial content on boat design construction, and repair for more than 40 years.

1 YEAR SUBSCRIPTION (6 ISSUES)

Print $39.95, digital $28.00, print+digital $42.95, from plans & kits, flats river skiff 12, 16' 0" prospector, echo bay dory skiff, from the community, catspaw dinghy (joel white).

This Joel White and N.G.

1940 Nunes Bros San Francisco Bear Boat

23' sloop Huck Finn is Bear #17, long a part of the renowned Bear class on San Francisco Bay.

1947 Quincy Adams 17 -Price reduction to $9,000. Make offer.

Mahogany planked on oiled oak frames. Spruce spars and stainless rigging.

Truant Fantail Gaffer

Constructed by the Northwest School of Wooden Boat Building to an Ed Louchard design, "Belle' rec

- - Kit build logs for subjects built from 1901 - Present Day

- Remember me Not recommended on shared computers

Forgot your password?

International Optimist Dinghy by Jason Builder - FINISHED - BlueJacket Shipcrafters - 1" = 1'

- Optimist Dinghy

- BlueJacket Shipcrafters

By Jason Builder August 20, 2022 in - Kit build logs for subjects built from 1901 - Present Day

- Reply to this topic

- Start new topic

Recommended Posts

Jason builder.

Ahoy Fellow Model Ship Builders!!

Just purchased and received the Optimist kit from Bluejacket. I bought this as a model to build with my daughters, which I am looking forward to and I hope they enjoy it as well! Both of them sailed on Opti's so they have a connection to the boat. This is the first model I have built by BlueJacket and the kit has made a good first impression. The contents are well packaged contents, and as this is intended as a beginners first ship model, the kit includes a nice full size print drawing (not pictured) , glues, paints, pin-vise with drill bits, pliers, tweezers, razor knife, and all components needed for the build. Just opened up the box and I'm hoping to get started over the weekend.

- Roger Pellett and yvesvidal

Completed Model Links:

Optimist Sailboat model by BlueJacket

3D printed model of a Disney Motor Launch

Billing Boats FD10 Arnanes

Krick Alexandra

Amati Golden Yacht Ship in a Bottle

My hobby website: www.argobuilder.com

Link to comment

Share on other sites.

Here's all the components unpacked. I'm going to have a cheery ole time building this simple fun model.

- Roger Pellett

Nice project. Our Community Sailing Association uses Optimists for sailing lessons here in the Duluth, MN/ Superior,WI harbor. I personally have never tried to fit myself into one but they look like they would be fun to sail.

Groetjes Everyone!

Well it's a rainy day today so, perfect time to work with the kiddo's on this project.

- Ryland Craze and ccoyle

We started by separating the parts and assembling the hull mold frame.

Then we assembled the hull mold frame:

Got to do some math and geometry laying out the bulkhead locations on the hull floor:

My daughter liked nailing the hull bottom down to the mold with pins.

Then we glued together the transoms

- Roger Pellett , mtaylor and Ryland Craze

We took a little break and then got to gluing up the hull! First we glued the aft transom in place, then we glued down the floor stringers using the temporary positioning transoms. Had one of the temporary positioning transoms in the wrong spot, 1st mistake of the build! Woe is me! More on this stringer positioning business later.

Here are the stingers glued down. We had a spacer in the wrong location so the stringers are a bit too close together towards the front of the dingy.

In this next photo you can see a newly installed bulkhead towards the fore, this supports the mast thwart. It comes with notches in the bottom that fit perfectly with the stringers (if your stringers are in the right place!) This is how we found out our stringers weren't in exactly the right spot. I trimmed the bulkhead so that it would fit the existing location of our stringers. Unless you were building it, you wouldn't notice what I'm writing about. Main point is, make sure the temporary stringer spacers are in the right spot earlier in the build. At the end of the day it will not be noticeable on ours.

Next, we glued in the chines along the bottom of each side. These are cut to length from 1/16 x 1/8" stock. We cut them carefully to length and they fit nicely. Trim them to fit properly in the pockets in the fore and aft transoms. 1st picture below shows the fore end of the chine strip, trimmed to fit into the pocket in the fore transom. Dry fit everything, then glue it in. Note: using quick set medium weight superglue (which came in the kit) for gluing up all wooden parts. If you're new to this you will quickly learn about how best to use this glue, sometimes called CA, as it will stick to you as easily as to the wood and the lightweight and medium weight versions "wick" very well into joints; one can hold the pieces to be glued together together and apply the glue to the joint and it will wick into the joint well and bond it. Careful with your fingers and wear gloves if you're concerned.

Chines glued in:

- Ryland Craze , Roger Pellett , king derelict and 1 other

What a fun morning we had! With the chine stringers glued in place, we set the temporary form/bulkheads in place to prepare for gluing on the hull sides. In the first photo below one can again see the error of my ways regarding stringer spacing. The bulkhead closer to me when I took the picture is the temporary form. The bulkhead in the background is the one that will eventually support the mast thwart. The two narrow stringers running along the hull bottom are supposed to run through well fit notches in both those bulkheads, note that I had to cut the notches away into larger openings that fit the actual location of the stringers.

With the forms in place, we chamfered them and trimmed/chamfered the chines and bottom to prepare for attachment of the sides. Below photo is of the bottom and the chines carved, sanded and ready for the hull sides.

Hull sides glued in place!

- yvesvidal , ccoyle , king derelict and 3 others

Mike Collier

Looks like you are doing a great job. I like the looks of that kit, may buy one myself. I just bought the Red Baron from Bluejacket.

- Ryland Craze and mtaylor

Your build is looking good!

We owned one of these years ago and taught the kids how to sail with it. I may have to build a few as gifts!

Thanks for the encouragement! Here's the latest progress:

Mast Step Thwart and gunwhales installed. I cut the gunwhales to length first, then carved the ends to fit the corner gussets, then soaked them in hot water, then pre-formed them by forming them into a curved shape using pins and I cork board until they dried in a curve, then glued them into position.

- Ryland Craze and yvesvidal

- yvesvidal , longshanks , ccoyle and 1 other

Well I'm cruising along on this project, both because it's fun, and because I just ordered the Billing Boats Oseborg Viking Ship kit. 1st coat of white paint is drying on the hull. The kit comes with matte white for the hull, but I think I am going to finish it with gloss white. I remember the opti's at the lake being more shiny than matte. I will also be finishing it with varnishing spars rather than aluminum painted spars (even though my kids sailing school boats did have aluminum spars....so I guess I'm just finishing this thing the way I want it to look).

I sanded the foil shape into the rudder and also sanded down the tiller and tiller extension. In this photo I am using the plans to ensure the tiller is glued to the rubber at the correct location and angle (I decided to glue the tiller to the rudder , not to pin it).

Using the pin vise and drill bit (included in the kit! and the pin vise is nicer than the old one I had, so I am happy about that) to drill the mounting hole for the tiller extension:

Using pins to suspend the tiller and extension for varnishing:

I cut the boom and attached the boom jaws, sprit, and mast to length, sanded them and now varnishing them. The ends of these spars will be painted gloss white, and it is that tip end that I have in the jaws of the bench vise:

As long as I was varnishing, I built up the display stand (sanded all sides, chamfered all exposed edges with sandpaper) and applied 1st coat varnish:

That's all for now folks. Have a great day!

- Ryland Craze , yvesvidal , aechmea and 1 other

Little bit o work on the sprit tonight. The ends of the sprit on opti's are pin shaped for rigging. I shaped the pins by turning the sprit down at the ends on my mini lathe. I wrapped the sprit in paper to protect it from denting in the 3 jaw chuck, which worked well. Happy with results. This job could be done by carving down the end with a razor or by sanding it down with a file, but I like playing with tools so used my little lathe. Some photo's are below. I didn't even use the tool rest, I used a file and just held it up the the spar end to get the pin shape I wanted.

Hi Everyone!!

Made some progress this evening on the rudder and pintles and gudgeons. I built up the rudder and tiller including a functioning/pivoting tiller extension and a tiller extension clip mounted on top of the tiller. In a deviation from the stock kit I made up brass pintles and gudgeons using brass brads and small brass tubing. Other than that, just painting and sanding the hull and spars.

Good Evening,

Painting and sanding and painting and sanding the hull. I am pleased with the gloss white vs matte white that came with the kit. Also finished painting and varnishing the spars tonight, along with attaching/installing the eyebolts and cleats. Eyebolts were installed by drilling a hole in the spars with the pin vise and then carefully gluing the trimmed eyebolts into the holes.

- yvesvidal and Seventynet

I used mahogany (not from kit) for the rub rail.

- yvesvidal , ccoyle , DanB and 1 other

Beautiful little hull.

Nicely done!

Builds in progress - Hayling Hoy

Builds completed - Naval Cutter Cheerful - by Syren Ship Model Company - Cape Cod Catboat - by Bluejacket - Gokstad - by Dusek - Ship's Boat - by Dusek - Brazzera - by MarisStella

Were Optimists always fiberglass or were the early ones wooden?

Thank you all for the encouraging comments!

The Optimist was designed by Clark Mills in Clearwater Florida in 1947 and was originally designed as an easy to build wooden boat. The initial optimists were wooden. Over 150,000 optimists have been built!

Closing in on the completion of this fun little model. Last night I made the sail.

-Traced and cut out the sail with a scalpel. I left additional material for a 3/16" hem as can be seen in the photo.

-Ironed the hems flat

-Stitched all the hems on a sewing machine

-Cut out strips of sail fabric for batten pockets, and stitched on the batten pockets

-Ironed the sail again

-Cut and installed the battens

- yvesvidal and VTHokiEE

Argh! I traced out the upper edge of the sail above, along the sprit, not along the top of the sail on the drawing, so my sail is the wrong shape. Will have to make another one. Silver lining....I get more practice on the sewing machine.

Someday I will learn the measure twice , cut once lesson, but it wasn't today.

Hi All, here is the 2nd sail, correct size. Optimist decal applied to both sides. Note bolt-rope stitched into the hems.

Making inflatable float-bags using my mini lathe. One could also easily carve these shapes with a knife, so if you are considering making this model.....you do not need a lathe, you can use a knife for this.

- yvesvidal and Aero

I drilled and used the sewing needle from the kit for the mast-head wind indicator pole. Snipped off

the top of the needle with a steel wire cutter.

Their is a nice brass ring that secures the foot of the mast, here it is installed at the floor of the hull:

Here is the mainsheet block assembly. I drilled out the little cast blocks and installed them into the wooden block that mounts to the floor. Then I rigged the mainsheet prior to gluing this assembly down.

Rigged up the rest of the running and standing rigging per the kit, and installed the floatation cells. This was a very fun model to build and the mistakes I made taught me once again to pay attention more even when I think something is "easy". The kids enjoyed it as well and when it was done, my daughter said "where's the bailing bucket?!"...... all the opti's in the sailing school had bailing buckets and she had a clear memory of that. So before I can call the model complete I will make a bailing bucket. I'll 3D print it. stay tuned. Here's where the model is at now.

- yvesvidal , Michiel Frirz , Prowler901 and 3 others

Sorry for all the pictures at 90deg, not sure how to rotate pictures on the forum.....

MrBlueJacket

11 hours ago, Jason Builder said: Sorry for all the pictures at 90deg, not sure how to rotate pictures on the forum.....

I had that problem, too. Just re-size the pictures down a bit.

Thanks for the tip Mr. BlueJacket, just resized and re-inserted a number of the photos above and the orientation is now correct.....makes it much easier to look at the picture. This was a very fun model to build and the result is a fine, accurate, model of an opti.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

× Pasted as rich text. Paste as plain text instead

Only 75 emoji are allowed.

× Your link has been automatically embedded. Display as a link instead

× Your previous content has been restored. Clear editor

× You cannot paste images directly. Upload or insert images from URL.

- Insert image from URL

- Submit Reply

Recently Browsing 0 members

- No registered users viewing this page.

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild 237 South Lincoln Street Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful links.

- Articles Database

- NRG Home Page

- NRG Online Store

- Important: Our Guidelines

- Terms of Use

- Buildlog Index

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

Our Emblem ®

Nautical Research Guild ® and the NRG logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,999,236 & No. 6,999,237, registered March 14, 2023)

- Existing user? Sign In

- Latest Posts

- All unread content since my last vist

- Unread topics I have posted in

- Create New...

IMAGES

VIDEO

COMMENTS

Optimist Sailboat Build: Building the Wood/Epoxy Optimist In 1947 a gentleman named Clark Mills designed a small sail boat for kids to learn to build and sail called the Optimist. This boat was designed to be built from 3 sheets of plywood, with basic woodworking abi…

Hi guys, i just decided to share my plans, www.boatyourself.com to download plans in 3d and cutting plans...This optimist is based on international optimist ...

This web page is dedicated to building an Optimist plywood pram to the specifications of the original Optimist Pram designed in 1947. We are using a set of plans redrawn by CABBS - Cleveland Amateur Boat Builders and available for $24.00. These wonderful little boats will never measure to the strict International Optimist Design.

In order to take part in Optimist races you will have to join IOCA UK for £25 per year, and make sure the boat is insured, about £27 per year, and don’t forget to keep the annual buoyancy test up to date. The total for paperwork then is £98. So we now have a tidy new boat, called Skylark, that is measured and on the weight limit, all that ...

Clark Mills designed the original Optimist Pram in 1947. His intention was to offer a simple boat that children could use to learn to sail and build themselves. It was the biggest hull Clark Mills could make from two 4 ft by 8 ft sheets of plywood. We chose to name our version of the Optimist the “Club Racer” to reflect the original idea ...

Optimist dinghies waiting to a wind. The Optimist is a small, single-handed sailing dinghy intended for use by young people up to the age of 15. The Optimist is one of the two most popular sailing dinghies in the world, with over 150,000 boats officially registered with the class and many more built but never registered.

In this article he helps parents get started into the world of the Optimist, unraveling the mysteries of understanding, choosing and purchasing an Optimist sailboat. Optimist Basics. The Opti, or Optimist Dinghy, is relatively unchanged from the first prams designed and built by visionary Clark Mills in Clearwater, FL, 65 years ago.

The Optimist Dinghy Template Plans contain the descriptions, materials and dimensions of each and every part, all drawn to scale, needed to build the boat. The plans of the auxiliary jig and temporary frames are also included. The plans are accompanied by a 28-page instructions booklet, with advice on materials and techniques, and a precise ...

The Optimist was designed by Clark Mills in Clearwater Florida in 1947 and was originally designed as an easy to build wooden boat. The initial optimists were wooden. Over 150,000 optimists have been built!

material for an Optimist. We use only the best Optiparts equipment in every boat we build. All Optiparts fittings have been tested repeatedly, and have held up in the worst environments for over 30 years. Since our founding, we have been proud to work with Harken® manufacturing. Over the years, this partnership has brought unique Optimist