Sail Rigging Types: A Comprehensive Guide

by Emma Sullivan | Jul 22, 2023 | Sailboat Racing

Short answer sail rigging types:

Sail rigging types refer to the various configurations and arrangements of ropes, cables, and fittings used to support and control sails on a sailing vessel. Common types include the sloop, cutter, ketch, yawl, schooner, and catboat. Each type has different advantages and is suited for different sailing conditions and purposes.

Sail Rigging Types: A Comprehensive Guide for Exploring Different Options

Title: Sail Rigging Types: A Comprehensive Guide for Exploring Different Options

Introduction: Mastering the art of sail rigging is an essential skill for every sailor. It not only contributes to boat performance but also determines your ability to harness the wind effectively. With various types of sail rigging available, understanding their differences and knowing when to use them can be a game-changer on the water. In this comprehensive guide, we will explore different sail rigging options, providing you with professional insights and some witty anecdotes along the way.

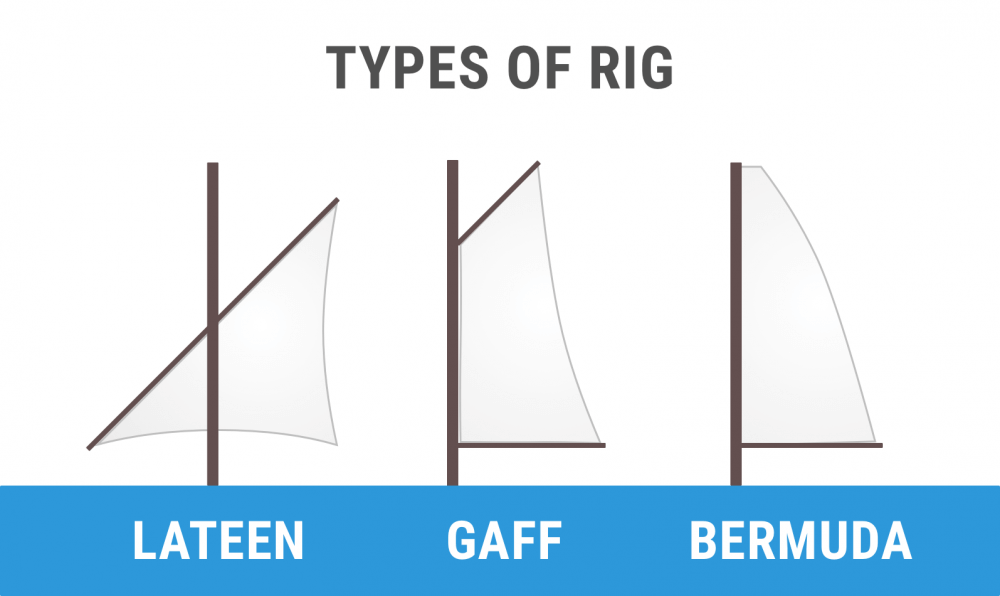

1. Bermuda Rig: Elegant and versatile, the Bermuda rig is undoubtedly the most common type found in modern sailing. Consisting of a single triangular mainsail and a jib in front, this arrangement allows sailors to easily control their sails while providing excellent maneuverability even in challenging conditions. Its origins can be traced back to the early 17th century, proving its timelessness as a reliable choice across various sailing disciplines.

2. Gaff Rig: For those seeking a classic look and craving nostalgia on the open seas, gaff rigs provide an impressive aesthetic appeal reminiscent of days gone by. Characterized by horizontal wooden poles (gaffs) supporting a four-sided mainsail, this traditional rig offers substantial power and good downwind performance. However, managing larger sails in heavier winds may demand more effort from the crew.

3. Cat Rig: Simplicity meets efficiency with cat rigs – perfect for solo or short-handed sailors who prefer straightforwardness without multiple lines cluttering their cockpit. This type comprises only one mast located near the bow carrying a large mainsail for optimum power-to-weight ratio. While cats excel at upwind sailing due to their balanced weight distribution, they might lack versatility compared to other rig types.

4. Ketch Rig: The sophisticated charm of ketch rigs has captured many sailors’ hearts throughout history. Featuring two masts – a taller main mast towards the front and a shorter mizzen mast towards the rear – ketch rigs offer versatility and fine-tuned sail options for diverse wind conditions. The presence of multiple sails enables better balance, making them ideal for long-distance cruising or upwind sailing when the going gets tough.

5. Schooner Rig: Sailors with a taste for grandeur will find themselves enchanted by the elegant schooner rig. Comprising of two or more masts, the fore-and-aft configuration differentiates it from its square-rigged counterparts. Schooners boast exceptional sail area flexibility and are often admired for their majestic appearance, ensuring an impressive sight among fellow seafarers. However, this elegance comes at the cost of additional complexity in sail management.

Conclusion: Choosing the right sail rigging type requires careful consideration of various factors such as your sailing style, boat size, intended use, and personal preferences. Each rigging type brings its unique set of advantages and limitations to the table, so finding the perfect fit might take some experimentation.

Remember: understanding how these different types influence your boat’s performance will not only enhance your sailing skills but also add excitement to each adventure on the water.

Happy smooth sailing with your newfound knowledge about sail rigging types!

Exploring the Pros and Cons of Sail Rigging Types: How to Choose the Right Setup for Your Needs

Title: Navigating the Seas of Sail Rigging: Weighing the Pros and Cons to Find Your Perfect Setup

Introduction: Setting sail on a mesmerizing voyage brings an unparalleled sense of freedom and exhilaration, but the success of your nautical adventure largely hinges on a crucial decision – choosing the right sail rigging setup. With a plethora of options available, it becomes vital to explore the pros and cons of sail rigging types in order to find the perfect fit for your specific needs. In this blog post, we will delve into the intricacies of various sail rigging types, providing you with detailed insights that will steer you towards making an informed choice.

Picture yourself standing at the helm while salty ocean breeze fills your lungs and gleaming waters extend as far as the eye can see. Now, imagine having complete control over how your vessel harnesses wind power to propel through these vast expanses. This is precisely where sail rigging comes into play – it ensures optimal utilization of wind energy through systematic arrangement and configuration of sails, masts, and supporting structures.

Anchoring Down: Understanding Key Sail Rigging Types

1. Bermuda Rig: Pros: – Efficiency: The Bermuda rig provides exceptional maneuverability due to its triangular shape which allows you to swiftly change course while maintaining stability. – Performance in varied conditions: Its versatility enables sailors to navigate efficiently across different wind speeds. – Ease of handling: The simplicity and user-friendly nature make it an ideal choice for both seasoned sailors and beginners alike.

Cons: – Limited sail area: Compared to other rigs like gaff or lug rigs, Bermuda rigs tend to have slightly smaller overall surface area which may impact speed in light winds. – Heightened stress on mast: The tall mast required by this type of rig increases bending forces when facing strong gusts or storms.

2. Gaff Rig: Pros: – Enhanced downwind performance: The large main gaff sail enables excellent downwind sailing, making it an ideal choice for cruisers seeking leisurely voyages. – Easy short-handed handling: With fewer sails to manage, the gaff rig is particularly advantageous for those who prefer solo or small crew sailing adventures. – Classic aesthetics: The timeless appeal of gaff rigs stands out from the crowd, inviting admiration from fellow sailors and onlookers alike.

Cons: – Limited upwind performance: Due to the relatively narrower sail area and lower aspect ratio compared to Bermuda rigs, gaff rigs may struggle when facing strong headwinds or sailing close to the wind. – Potential complexity in rigging: Setting up a proper gaff rig demands more time and meticulousness due to additional halyards and peak adjustments required.

3. Lug Rig: Pros: – Excellent adaptability: Lug rigs offer significant versatility as their sails can be easily set and adjusted according to varying wind conditions with minimal effort. – Broad range of applications: This type of rig is renowned for its robustness, making it a popular choice among dinghy sailors, coastal cruisers, and even historical vessels restoration enthusiasts. – Single-masted simplicity: Lug rigs often utilize a single mast arrangement that simplifies handling maneuvers, reducing any potential confusion during sailing operations.

Cons: – Suboptimal upwind performance: Similarly to gaff rigs, lug rigs may face limitations when attempting to sail efficiently upwind due to their narrower sail area. – Reduced speed potential: Despite providing stability in various conditions, lug rigs are generally not designed for maximizing speed over longer distances.

In your quest to find the perfect sail rigging setup tailored to your needs, understanding both the advantages and disadvantages associated with different types becomes paramount. From the nimble Bermuda rig ensuring swift course changes, through classic elegance offered by gaff rigging methods enabling relaxing jaunts on calm waters, to versatile lug setups favored by rugged adventurers – there exists a rigging choice that aligns with your sailing aspirations.

Remember, choosing the right sail rigging type involves considering factors such as intended usage, personal preferences, and the geographical locations you plan to explore. By navigating through this comprehensive analysis of the pros and cons outlined above, you will confidently chart a course towards seamless control, superior performance, and unbridled satisfaction on every voyage.

Step-by-Step Guide: Understanding the Basics of Sail Rigging Types

Are you curious about sail rigging types? Maybe you’ve heard some terms like sloop and ketch, but aren’t quite sure what they mean. Don’t worry, we’ve got you covered! In this step-by-step guide, we will take you through the basics of sail rigging types, helping to demystify these terms and give you a clearer understanding of how different sailing vessels are set up.

Step 1: First Things First – What is Sail Rigging? Before diving into the different rigging types, it’s important to understand what sail rigging actually refers to. In simple terms, sail rigging encompasses all the components and systems that support and control the sails on a boat or ship. These include masts, booms, stays (cables or ropes), and various other hardware.

Step 2: Sloop Rig – The Most Common Type The sloop rig is undoubtedly the most common type of sailboat rig out there. It features a single mast located towards the bow (front) of the vessel with a mainsail attached to it. Additionally, there is usually a smaller headsail called a jib or genoa at the front of the boat. This arrangement provides versatility and ease of handling for sailors in varying wind conditions.

Step 3: Ketch Rig – Double The Fun If you’re looking for a bit more complexity in your sail rigging setup, then let’s talk about ketch rigs. Ketch rigs feature two masts – a taller mainmast towards the center of the boat and a shorter mizzenmast towards its stern (back). This configuration adds an extra dimension to sailing as it allows for more independent adjustments between sails on each mast. Ketch rigs are often favored by those embarking on long-distance cruising voyages due to their ability to balance sails effectively.

Step 4: Schooner Rig – A Majestic Sight For those with a penchant for classic sailing vessels, the schooner rig is sure to capture your imagination. The schooner rig typically consists of two or more masts, with the forward mast (the foremast) being shorter than or equal in height to the aft mast (the mainmast). Schooners were historically used as fast cargo vessels, and their elegant rigs earned them a reputation for speed. Today, schooners are favored by enthusiasts who appreciate their unique aesthetic appeal.

Step 5: Cutter Rig – Versatility at Its Finest The cutter rig may not be as commonly known as the sloop or ketch rigs, but it certainly has its advantages. This configuration features a single mast located towards the bow with multiple headsails attached to it. Typically, cutters have two headsails – a jib/forestaysail and a staysail. These additional sails give cutters greater flexibility to adapt to various wind conditions, making them ideal for both racing and cruising purposes.

Step 6: Cat Rig – Simplified Sailing Last but not least, we have the cat rig – a straightforward and minimalist sail setup that is common on smaller sailboats. The cat rig features a single mast positioned near the bow of the boat and only one mainsail attached directly to it. Due to its simplicity, this rigging type is often preferred by novice sailors or those seeking an easy-to-handle setup.

In conclusion, understanding sail rigging types can greatly enhance your sailing experience and help you make informed decisions when choosing a vessel for your adventures on the water. Whether you opt for the versatility of a sloop rig or yearn for the majestic sight of a schooner rig, each configuration offers its own set of benefits and appeals to different types of sailors. So go out there, discover which sail rigging type suits you best, and let your sails take you wherever your love for sailing desires!

Frequently Asked Questions about Sail Rigging Types: All You Need to Know

Sailing is an art that requires attention to detail, skill, and knowledge of various elements such as sail rigging types. As a sailor or someone interested in the world of sailing, it is essential to familiarize yourself with the frequently asked questions about sail rigging types. In this blog post, we aim to provide you with detailed professional insights while maintaining a witty and clever tone.

1. What are the different types of sail rigging?

When it comes to sail rigging, there are several types commonly used in sailing vessels. The most common ones include sloop rig, ketch rig, schooner rig, cutter rig, catboat rig, and yawl rig. Each type has its distinctive features and advantages depending on factors like boat size, wind conditions, and intended use.

2. What is the sloop rigging type?

The sloop rig is the most popular one among cruising yachts due to its simplicity and versatility. It consists of a single mast located towards the bow (front) of the boat with only one head-sail called a jib or genoa ahead of the mast. The mainsail is attached aft (back) of the mast.

Imagine a sleek and elegant vessel cutting through the waters effortlessly – that’s precisely what you get with a sloop rigged yacht!

3. What about ketch rigs?

Ketch rigs feature two masts: one mainmast taller than the other called the mizzen mast located aft of the mainmast. This configuration allows for better weight distribution and more flexibility in sail handling by dividing sails between two masts.

Picture yourself aboard an impressive vessel gliding across calm seas while enjoying full control over your sails – that’s what makes a ketch rigged yacht stand out!

4. How does schooner rigging work?

Schooner rigs boast two or more masts where all but one are shorter than or equal in height to the foremast, creating a distinct and captivating appearance. The larger area of sail provided by multiple masts allows for increased speed, making schooners highly sought-after in sailing races.

If you dream of commanding a magnificent vessel with multiple sails majestically billowing in the wind as you traverse the open ocean, consider investing in a schooner rigged yacht!

5. What sets cutter rigs apart?

Cutter rigs feature a single mast set slightly further back than the sloop rig, along with two or more headsails attached to the forestay. This configuration grants sailors greater flexibility to adjust their sails based on changing weather conditions.

Imagine yourself skillfully tacking your yacht against strong winds while effortlessly adjusting your foresail configurations – that’s precisely what cutter rigging offers!

6. How do catboat rigs function?

Catboat rigs are known for their simplicity and ease of handling. They typically have a single mast mounted forward with a single large mainsail without any accompanying headsails or jibs. This type of rig is perfect for leisurely cruising and is often favored by novice sailors due to its straightforward setup.

Picture yourself aboard an adorable catboat smoothly gliding across calm waters, appreciating the simplicity and charm it offers – that’s what makes catboats stand out from the crowd!

7. What about yawl rigs?

Yawl rigs resemble ketch rigs but possess a shorter mizzen mast positioned aft near the stern (rear) of the boat. The smaller mizzen mast improves balance and control during tricky maneuvers such as heaving-to or sailing downwind while preventing excessive weather helm.

Imagine yourself confidently navigating through rough seas while maintaining optimal control over your maneuvering options – that’s where yawl rigging truly shines!

By now, you should have gained a comprehensive understanding of various sail rigging types frequently encountered in the thrilling world of sailing. Remember to choose your sail rigging wisely based on your vessel size, intended use, and desired sailing experience. Bon voyage!

A Beginner’s Journey into Sail Rigging Types: Where to Start and What to Expect

Have you ever dreamt of embarking on an exciting sailing adventure, feeling the wind in your hair and the thrill of being one with the open sea? If so, then understanding sail rigging types is an essential first step towards turning that dream into a reality. In this beginner’s guide, we will take you through the fascinating world of sail rigging, providing you with valuable insights on where to start and what to expect.

First and foremost, let’s unravel the enigma behind sail rigging. So, what exactly is sail rigging? In simple terms, it refers to the arrangement and positioning of sails on a boat or ship. While this may sound straightforward, there are numerous types of rigs out there – each catering to specific sailing conditions and personal preferences. Fear not! We’ll navigate you through these options.

One commonly adopted type of rig is known as the sloop rig. This traditional setup features a single mast located near the bow (front) of the boat along with a main sail at its aft (rear) end. Additionally, there may be a jib or genoa placed forward of the mast for better control. The sloop rig offers excellent versatility and ease of handling for beginners due to its simplicity.

For those seeking more excitement and challenge on their sailing journey, consider exploring catamarans or trimarans – vessels featuring multiple hulls connected by crossbeams. These boats often employ a variant called the fractional sloop rig which adds exhilaration with increased speed potential while maintaining relative ease in managing sails.

Another popular option is the ketch rig – notable for its two masts: one taller main mast towards the boat’s centerline and another smaller mizzen mast positioned further aft. This arrangement provides greater flexibility when it comes to distributing sail area for different wind conditions while also offering redundancy should any one mast or sail be compromised.

If you’re yearning for a touch of history and aesthetics, delving into the world of schooners might just be what your heart desires. Schooners boast an elegant rig featuring multiple masts – two or more – with both fore-and-aft sails (sails that run parallel to the boat’s centerline) and square-rigged sails (sails perpendicular to the centerline). Though it may require a more skilled hand, sailing on a schooner can transport you to a bygone era with its majestic charm.

Now that we’ve covered some popular sail rigging types, let’s discuss where to start as a beginner. As appealing as it may be to dive straight into more advanced setups like schooners, it’s crucial to first gain familiarity and confidence with simpler rigs such as sloops. Take your time to understand the basics of sail controls, wind direction awareness, and safety precautions before progressing towards more complex rigs.

When it comes to expectations, remember that learning sail rigging is not just about memorizing technicalities but also developing a deep connection with your vessel and nature itself. Sailing demands patience, adaptability, and an ability to read winds and waters intuitively. Embrace the challenges along your journey while keeping in mind that mistakes are part of the learning process – every experienced sailor has faced them at some point!

In conclusion, embarking on a beginner’s journey into sail rigging entails discovering various types of rigs suited for different purposes and preferences. Start by acquainting yourself with simpler setups like sloops before venturing into more intricate designs such as catamarans or historic schooners. Remember that progress takes time; focus on building foundational skills while embracing the joy and challenges sailing offers. So, hoist those sails high and set forth confidently into the vast ocean – adventure awaits!

Mastering Advanced Sail Rigging Techniques: Taking Your Sailing Experience to the Next Level

Are you ready to elevate your sailing skills and dive into the world of advanced sail rigging techniques? If you’re seeking to enhance your sailing experience with a touch of expertise, then look no further! In this blog post, we will explore the intricate realm of advanced sail rigging techniques that will undoubtedly take your passion for sailing to new heights. So grab a pen and paper, or bookmark this page, because you won’t want to miss out on these valuable insights.

Before we delve into the nitty-gritty details, let’s first understand what sail rigging entails. Sail rigging is the art of setting up and adjusting the sails on your boat in such a way that maximizes performance when catching those delightful winds. It involves an amalgamation of knowledge about different types of sails, their various components, and how they interact with each other in different wind conditions.

Now that we have established the importance of sail rigging let’s explore some advanced techniques that can set you apart from average sailors:

1. Fine-Tuning Your Mast Bend: The curve of your mast plays a crucial role in determining sail shape and overall performance. Knowing how to adjust this bend incrementally can optimize your boat’s speed and stability across varying wind strengths. By mastering mast bend adjustments using shroud tension or cunningham lines, you’ll harness every gust nature throws at you!

2. Perfecting Your Sail Twist: Achieving ideal twist in your sails can be a game-changer on the water. Adjusting the angle between the top and bottom sections of your sail enables controlled power distribution throughout its surface area. This technique allows you to maintain optimal balance while navigating unpredictable wind patterns, giving you an edge over other sailors struggling with less refined twists.

3. Utilizing Adjustable Tracks: Ever wished you could move your jib car forward or aft without hoisting it up the mast? Well, with adjustable tracks, you can! These clever inventions allow you to tweak your sail’s positioning effortlessly, adapting to various wind angles without compromising your boat’s balance. So say goodbye to inefficient sailing angles and hello to greater control!

4. Mastering Cunningham Controls: The cunningham is a powerful tool that regulates the tension along the luff of the sails. By skillfully manipulating this control line, you can flatten your sails during high winds or create depth for enhanced power in lighter breezes. Truly an advanced technique that adds finesse and versatility to your sailing repertoire.

5. Exploring New Sail Materials: Dacron may be tried and true, but have you ventured into the realm of exotic sail materials? With advancements in technology, innovative fabrics like carbon fiber or laminated materials offer superior strength-to-weight ratios and unbeatable performance gains. By experimenting with these new-age materials, you can unlock heightened speed potential while keeping your boat well-equipped for whatever Mother Nature throws at it.

Now that we’ve touched upon these advanced sail rigging techniques, remember that practice makes perfect! Experimentation and fine-tuning are vital components of mastering these skills. Don’t be afraid to reach out to experienced sailors or seek professional guidance in understanding these techniques better.

In conclusion, making strides from a proficient sailor to an extraordinary one involves exploring advanced sail rigging techniques meticulously. By adding these skills to your arsenal and implementing them effectively on the water, you’ll find yourself sailing circles around others who haven’t yet embraced these novel practices.

So gear up (pun intended), dive deep into masterful sail rigging methods – bending masts, twisting sails just right, utilizing adjustable tracks smartly – and let your newfound expertise take you on an exhilarating journey where average simply doesn’t exist!

Recent Posts

- Sailboat Gear and Equipment

- Sailboat Lifestyle

- Sailboat Maintenance

- Sailboat Racing

- Sailboat Tips and Tricks

- Sailboat Types

- Sailing Adventures

- Sailing Destinations

- Sailing Safety

- Sailing Techniques

The Ultimate Guide to Sail Types and Rigs (with Pictures)

What's that sail for? Generally, I don't know. So I've come up with a system. I'll explain you everything there is to know about sails and rigs in this article.

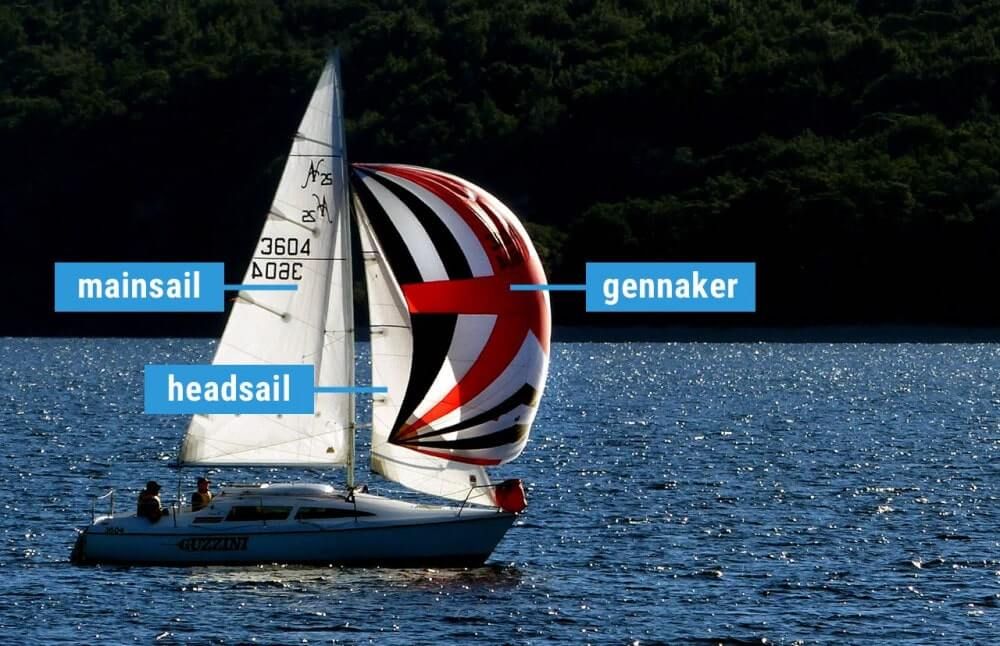

What are the different types of sails? Most sailboats have one mainsail and one headsail. Typically, the mainsail is a fore-and-aft bermuda rig (triangular shaped). A jib or genoa is used for the headsail. Most sailors use additional sails for different conditions: the spinnaker (a common downwind sail), gennaker, code zero (for upwind use), and stormsail.

Each sail has its own use. Want to go downwind fast? Use a spinnaker. But you can't just raise any sail and go for it. It's important to understand when (and how) to use each sail. Your rigging also impacts what sails you can use.

On this page:

Different sail types, the sail plan of a bermuda sloop, mainsail designs, headsail options, specialty sails, complete overview of sail uses, mast configurations and rig types.

This article is part 1 of my series on sails and rig types. Part 2 is all about the different types of rigging. If you want to learn to identify every boat you see quickly, make sure to read it. It really explains the different sail plans and types of rigging clearly.

Guide to Understanding Sail Rig Types (with Pictures)

First I'll give you a quick and dirty overview of sails in this list below. Then, I'll walk you through the details of each sail type, and the sail plan, which is the godfather of sail type selection so to speak.

Click here if you just want to scroll through a bunch of pictures .

Here's a list of different models of sails: (Don't worry if you don't yet understand some of the words, I'll explain all of them in a bit)

- Jib - triangular staysail

- Genoa - large jib that overlaps the mainsail

- Spinnaker - large balloon-shaped downwind sail for light airs

- Gennaker - crossover between a Genoa and Spinnaker

- Code Zero or Screecher - upwind spinnaker

- Drifter or reacher - a large, powerful, hanked on genoa, but made from lightweight fabric

- Windseeker - tall, narrow, high-clewed, and lightweight jib

- Trysail - smaller front-and-aft mainsail for heavy weather

- Storm jib - small jib for heavy weather

I have a big table below that explains the sail types and uses in detail .

I know, I know ... this list is kind of messy, so to understand each sail, let's place them in a system.

The first important distinction between sail types is the placement . The mainsail is placed aft of the mast, which simply means behind. The headsail is in front of the mast.

Generally, we have three sorts of sails on our boat:

- Mainsail: The large sail behind the mast which is attached to the mast and boom

- Headsail: The small sail in front of the mast, attached to the mast and forestay (ie. jib or genoa)

- Specialty sails: Any special utility sails, like spinnakers - large, balloon-shaped sails for downwind use

The second important distinction we need to make is the functionality . Specialty sails (just a name I came up with) each have different functionalities and are used for very specific conditions. So they're not always up, but most sailors carry one or more of these sails.

They are mostly attached in front of the headsail, or used as a headsail replacement.

The specialty sails can be divided into three different categories:

- downwind sails - like a spinnaker

- light air or reacher sails - like a code zero

- storm sails

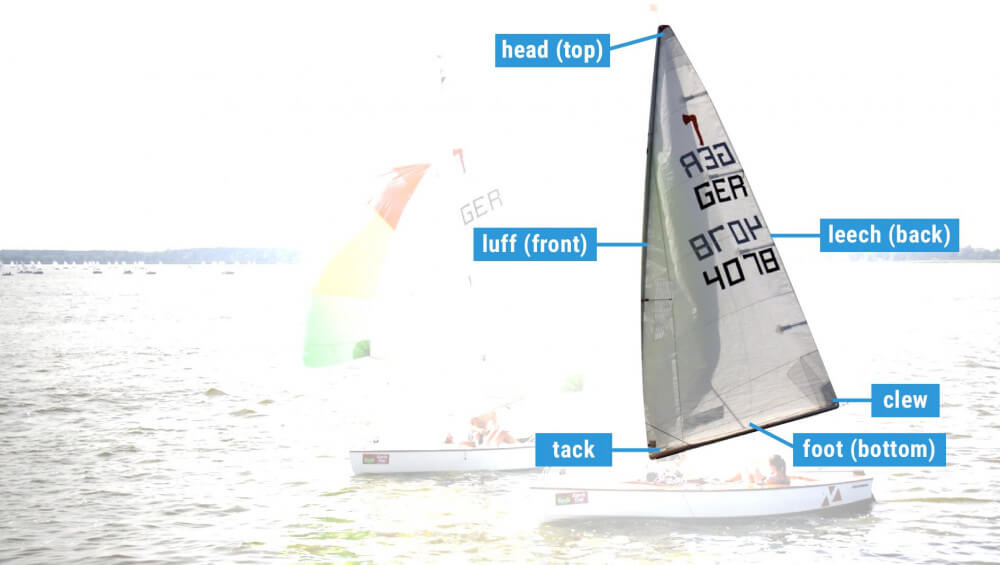

The parts of any sail

Whether large or small, each sail consists roughly of the same elements. For clarity's sake I've took an image of a sail from the world wide webs and added the different part names to it:

- Head: Top of the sail

- Tack: Lower front corner of the sail

- Foot: Bottom of the sail

- Luff: Forward edge of the sail

- Leech: Back edge of the sail

- Clew: Bottom back corner of the sail

So now we speak the same language, let's dive into the real nitty gritty.

Basic sail shapes

Roughly speaking, there are actually just two sail shapes, so that's easy enough. You get to choose from:

- square rigged sails

- fore-and-aft rigged sails

I would definitely recommend fore-and-aft rigged sails. Square shaped sails are pretty outdated. The fore-and-aft rig offers unbeatable maneuverability, so that's what most sailing yachts use nowadays.

Square sails were used on Viking longships and are good at sailing downwind. They run from side to side. However, they're pretty useless upwind.

A fore-and-aft sail runs from the front of the mast to the stern. Fore-and-aft literally means 'in front and behind'. Boats with fore-and-aft rigged sails are better at sailing upwind and maneuvering in general. This type of sail was first used on Arabic boats.

As a beginner sailor I confuse the type of sail with rigging all the time. But I should cut myself some slack, because the rigging and sails on a boat are very closely related. They are all part of the sail plan .

A sail plan is made up of:

- Mast configuration - refers to the number of masts and where they are placed

- Sail type - refers to the sail shape and functionality

- Rig type - refers to the way these sails are set up on your boat

There are dozens of sails and hundreds of possible configurations (or sail plans).

For example, depending on your mast configuration, you can have extra headsails (which then are called staysails).

The shape of the sails depends on the rigging, so they overlap a bit. To keep it simple I'll first go over the different sail types based on the most common rig. I'll go over the other rig types later in the article.

Bermuda Sloop: the most common rig

Most modern small and mid-sized sailboats have a Bermuda sloop configuration . The sloop is one-masted and has two sails, which are front-and-aft rigged. This type of rig is also called a Marconi Rig. The Bermuda rig uses a triangular sail, with just one side of the sail attached to the mast.

The mainsail is in use most of the time. It can be reefed down, making it smaller depending on the wind conditions. It can be reefed down completely, which is more common in heavy weather. (If you didn't know already: reefing is skipper terms for rolling or folding down a sail.)

In very strong winds (above 30 knots), most sailors only use the headsail or switch to a trysail.

The headsail powers your bow, the mainsail powers your stern (rear). By having two sails, you can steer by using only your sails (in theory - it requires experience). In any case, two sails gives you better handling than one, but is still easy to operate.

Let's get to the actual sails. The mainsail is attached behind the mast and to the boom, running to the stern. There are multiple designs, but they actually don't differ that much. So the following list is a bit boring. Feel free to skip it or quickly glance over it.

- Square Top racing mainsail - has a high performance profile thanks to the square top, optional reef points

- Racing mainsail - made for speed, optional reef points

- Cruising mainsail - low-maintenance, easy to use, made to last. Generally have one or multiple reef points.

- Full-Batten Cruising mainsail - cruising mainsail with better shape control. Eliminates flogging. Full-length battens means the sail is reinforced over the entire length. Generally have one or multiple reef points.

- High Roach mainsail - crossover between square top racing and cruising mainsail, used mostly on cats and multihulls. Generally have one or multiple reef points.

- Mast Furling mainsail - sails specially made to roll up inside the mast - very convenient but less control; of sail shape. Have no reef points

- Boom Furling mainsail - sails specially made to roll up inside the boom. Have no reef points.

The headsail is the front sail in a front-and-aft rig. The sail is fixed on a stay (rope, wire or rod) which runs forward to the deck or bowsprit. It's almost always triangular (Dutch fishermen are known to use rectangular headsail). A triangular headsail is also called a jib .

Headsails can be attached in two ways:

- using roller furlings - the sail rolls around the headstay

- hank on - fixed attachment

Types of jibs:

Typically a sloop carries a regular jib as its headsail. It can also use a genoa.

- A jib is a triangular staysail set in front of the mast. It's the same size as the fore-triangle.

- A genoa is a large jib that overlaps the mainsail.

What's the purpose of a jib sail? A jib is used to improve handling and to increase sail area on a sailboat. This helps to increase speed. The jib gives control over the bow (front) of the ship, making it easier to maneuver the ship. The mainsail gives control over the stern of the ship. The jib is the headsail (frontsail) on a front-and-aft rig.

The size of the jib is generally indicated by a number - J1, 2, 3, and so on. The number tells us the attachment point. The order of attachment points may differ per sailmaker, so sometimes J1 is the largest jib (on the longest stay) and sometimes it's the smallest (on the shortest stay). Typically the J1 jib is the largest - and the J3 jib the smallest.

Most jibs are roller furling jibs: this means they are attached to a stay and can be reefed down single-handedly. If you have a roller furling you can reef down the jib to all three positions and don't need to carry different sizes.

Originally called the 'overlapping jib', the leech of the genoa extends aft of the mast. This increases speed in light and moderate winds. A genoa is larger than the total size of the fore-triangle. How large exactly is indicated by a percentage.

- A number 1 genoa is typically 155% (it used to be 180%)

- A number 2 genoa is typically 125-140%

Genoas are typically made from 1.5US/oz polyester spinnaker cloth, or very light laminate.

This is where it gets pretty interesting. You can use all kinds of sails to increase speed, handling, and performance for different weather conditions.

Some rules of thumb:

- Large sails are typically good for downwind use, small sails are good for upwind use.

- Large sails are good for weak winds (light air), small sails are good for strong winds (storms).

Downwind sails

Thanks to the front-and-aft rig sailboats are easier to maneuver, but they catch less wind as well. Downwind sails are used to offset this by using a large sail surface, pulling a sailboat downwind. They can be hanked on when needed and are typically balloon shaped.

Here are the most common downwind sails:

- Big gennaker

- Small gennaker

A free-flying sail that fills up with air, giving it a balloon shape. Spinnakers are generally colorful, which is why they look like kites. This downwind sail has the largest sail area, and it's capable of moving a boat with very light wind. They are amazing to use on trade wind routes, where they can help you make quick progress.

Spinnakers require special rigging. You need a special pole and track on your mast. You attach the sail at three points: in the mast head using a halyard, on a pole, and on a sheet.

The spinnaker is symmetrical, meaning the luff is as long as its leech. It's designed for broad reaching.

Gennaker or cruising spinnaker

The Gennaker is a cross between the genoa and the spinnaker. It has less downwind performance than the spinnaker. It is a bit smaller, making it slower, but also easier to handle - while it remains very capable. The cruising spinnaker is designed for broad reaching.

The gennaker is a smaller, asymmetric spinnaker that's doesn't require a pole or track on the mast. Like the spinnaker, and unlike the genoa, the gennaker is set flying. Asymmetric means its luff is longer than its leech.

You can get big and small gennakers (roughly 75% and 50% the size of a true spinnaker).

Also called ...

- the cruising spinnaker

- cruising chute

- pole-less spinnaker

- SpinDrifter

... it's all the same sail.

Light air sails

There's a bit of overlap between the downwind sails and light air sails. Downwind sails can be used as light air sails, but not all light air sails can be used downwind.

Here are the most common light air sails:

- Spinnaker and gennaker

Drifter reacher

Code zero reacher.

A drifter (also called a reacher) is a lightweight, larger genoa for use in light winds. It's roughly 150-170% the size of a genoa. It's made from very lightweight laminated spinnaker fabric (1.5US/oz).

Thanks to the extra sail area the sail offers better downwind performance than a genoa. It's generally made from lightweight nylon. Thanks to it's genoa characteristics the sail is easier to use than a cruising spinnaker.

The code zero reacher is officially a type of spinnaker, but it looks a lot like a large genoa. And that's exactly what it is: a hybrid cross between the genoa and the asymmetrical spinnaker (gennaker). The code zero however is designed for close reaching, making it much flatter than the spinnaker. It's about twice the size of a non-overlapping jib.

A windseeker is a small, free-flying staysail for super light air. It's tall and thin. It's freestanding, so it's not attached to the headstay. The tack attaches to a deck pad-eye. Use your spinnakers' halyard to raise it and tension the luff.

It's made from nylon or polyester spinnaker cloth (0.75 to 1.5US/oz).

It's designed to guide light air onto the lee side of the main sail, ensuring a more even, smooth flow of air.

Stormsails are stronger than regular sails, and are designed to handle winds of over 45 knots. You carry them to spare the mainsail. Sails

A storm jib is a small triangular staysail for use in heavy weather. If you participate in offshore racing you need a mandatory orange storm jib. It's part of ISAF's requirements.

A trysail is a storm replacement for the mainsail. It's small, triangular, and it uses a permanently attached pennant. This allows it to be set above the gooseneck. It's recommended to have a separate track on your mast for it - you don't want to fiddle around when you actually really need it to be raised ... now.

Why Use Different Sails At All?

You could just get the largest furling genoa and use it on all positions. So why would you actually use different types of sails?

The main answer to that is efficiency . Some situations require other characteristics.

Having a deeply reefed genoa isn't as efficient as having a small J3. The reef creates too much draft in the sail, which increases heeling. A reefed down mainsail in strong winds also increases heeling. So having dedicated (storm) sails is probably a good thing, especially if you're planning more demanding passages or crossings.

But it's not just strong winds, but also light winds that can cause problems. Heavy sails will just flap around like laundry in very light air. So you need more lightweight fabrics to get you moving.

What Are Sails Made Of?

The most used materials for sails nowadays are:

- Dacron - woven polyester

- woven nylon

- laminated fabrics - increasingly popular

Sails used to be made of linen. As you can imagine, this is terrible material on open seas. Sails were rotting due to UV and saltwater. In the 19th century linen was replaced by cotton.

It was only in the 20th century that sails were made from synthetic fibers, which were much stronger and durable. Up until the 1980s most sails were made from Dacron. Nowadays, laminates using yellow aramids, Black Technora, carbon fiber and Spectra yarns are more and more used.

Laminates are as strong as Dacron, but a lot lighter - which matters with sails weighing up to 100 kg (220 pounds).

By the way: we think that Viking sails were made from wool and leather, which is quite impressive if you ask me.

In this section of the article I give you a quick and dirty summary of different sail plans or rig types which will help you to identify boats quickly. But if you want to really understand it clearly, I really recommend you read part 2 of this series, which is all about different rig types.

You can't simply count the number of masts to identify rig type But you can identify any rig type if you know what to look for. We've created an entire system for recognizing rig types. Let us walk you through it. Read all about sail rig types

As I've said earlier, there are two major rig types: square rigged and fore-and-aft. We can divide the fore-and-aft rigs into three groups:

- Bermuda rig (we have talked about this one the whole time) - has a three-sided mainsail

- Gaff rig - has a four-sided mainsail, the head of the mainsail is guided by a gaff

- Lateen rig - has a three-sided mainsail on a long yard

There are roughly four types of boats:

- one masted boats - sloop, cutter

- two masted boats - ketch, schooner, brig

- three masted - barque

- fully rigged or ship rigged - tall ship

Everything with four masts is called a (tall) ship. I think it's outside the scope of this article, but I have written a comprehensive guide to rigging. I'll leave the three and four-masted rigs for now. If you want to know more, I encourage you to read part 2 of this series.

One-masted rigs

Boats with one mast can have either one sail, two sails, or three or more sails.

The 3 most common one-masted rigs are:

- Cat - one mast, one sail

- Sloop - one mast, two sails

- Cutter - one mast, three or more sails

1. Gaff Cat

2. Gaff Sloop

Two-masted rigs

Two-masted boats can have an extra mast in front or behind the main mast. Behind (aft of) the main mast is called a mizzen mast . In front of the main mast is called a foremast .

The 5 most common two-masted rigs are:

- Lugger - two masts (mizzen), with lugsail (cross between gaff rig and lateen rig) on both masts

- Yawl - two masts (mizzen), fore-and-aft rigged on both masts. Main mast much taller than mizzen. Mizzen without mainsail.

- Ketch - two masts (mizzen), fore-and-aft rigged on both masts. Main mast with only slightly smaller mizzen. Mizzen has mainsail.

- Schooner - two masts (foremast), generally gaff rig on both masts. Main mast with only slightly smaller foremast. Sometimes build with three masts, up to seven in the age of sail.

- Brig - two masts (foremast), partially square-rigged. Main mast carries small lateen rigged sail.

4. Schooner

5. Brigantine

This article is part 1 of a series about sails and rig types If you want to read on and learn to identify any sail plans and rig type, we've found a series of questions that will help you do that quickly. Read all about recognizing rig types

Related Questions

What is the difference between a gennaker & spinnaker? Typically, a gennaker is smaller than a spinnaker. Unlike a spinnaker, a gennaker isn't symmetric. It's asymmetric like a genoa. It is however rigged like a spinnaker; it's not attached to the forestay (like a jib or a genoa). It's a downwind sail, and a cross between the genoa and the spinnaker (hence the name).

What is a Yankee sail? A Yankee sail is a jib with a high-cut clew of about 3' above the boom. A higher-clewed jib is good for reaching and is better in high waves, preventing the waves crash into the jibs foot. Yankee jibs are mostly used on traditional sailboats.

How much does a sail weigh? Sails weigh anywhere between 4.5-155 lbs (2-70 kg). The reason is that weight goes up exponentially with size. Small boats carry smaller sails (100 sq. ft.) made from thinner cloth (3.5 oz). Large racing yachts can carry sails of up to 400 sq. ft., made from heavy fabric (14 oz), totaling at 155 lbs (70 kg).

What's the difference between a headsail and a staysail? The headsail is the most forward of the staysails. A boat can only have one headsail, but it can have multiple staysails. Every staysail is attached to a forward running stay. However, not every staysail is located at the bow. A stay can run from the mizzen mast to the main mast as well.

What is a mizzenmast? A mizzenmast is the mast aft of the main mast (behind; at the stern) in a two or three-masted sailing rig. The mizzenmast is shorter than the main mast. It may carry a mainsail, for example with a ketch or lugger. It sometimes doesn't carry a mainsail, for example with a yawl, allowing it to be much shorter.

Special thanks to the following people for letting me use their quality photos: Bill Abbott - True Spinnaker with pole - CC BY-SA 2.0 lotsemann - Volvo Ocean Race Alvimedica and the Code Zero versus SCA and the J1 - CC BY-SA 2.0 Lisa Bat - US Naval Academy Trysail and Storm Jib dry fit - CC BY-SA 2.0 Mike Powell - White gaff cat - CC BY-SA 2.0 Anne Burgess - Lugger The Reaper at Scottish Traditional Boat Festival

Hi, I stumbled upon your page and couldn’t help but notice some mistakes in your description of spinnakers and gennakers. First of all, in the main photo on top of this page the small yacht is sailing a spinnaker, not a gennaker. If you look closely you can see the spinnaker pole standing on the mast, visible between the main and headsail. Further down, the discription of the picture with the two German dinghies is incorrect. They are sailing spinnakers, on a spinnaker pole. In the farthest boat, you can see a small piece of the pole. If needed I can give you the details on the difference between gennakers and spinnakers correctly?

Hi Shawn, I am living in Utrecht I have an old gulf 32 and I am sailing in merkmeer I find your articles very helpful Thanks

Thank you for helping me under stand all the sails there names and what there functions were and how to use them. I am planning to build a trimaran 30’ what would be the best sails to have I plan to be coastal sailing with it. Thank you

Hey Comrade!

Well done with your master piece blogging. Just a small feedback. “The jib gives control over the bow of the ship, making it easier to maneuver the ship. The mainsail gives control over the stern of the ship.” Can you please first tell the different part of a sail boat earlier and then talk about bow and stern later in the paragraph. A reader has no clue on the newly introduced terms. It helps to keep laser focused and not forget main concepts.

Shawn, I am currently reading How to sail around the World” by Hal Roth. Yes, I want to sail around the world. His book is truly grounded in real world experience but like a lot of very knowledgable people discussing their area of expertise, Hal uses a lot of terms that I probably should have known but didn’t, until now. I am now off to read your second article. Thank You for this very enlightening article on Sail types and their uses.

Shawn Buckles

HI CVB, that’s a cool plan. Thanks, I really love to hear that. I’m happy that it was helpful to you and I hope you are of to a great start for your new adventure!

Hi GOWTHAM, thanks for the tip, I sometimes forget I haven’t specified the new term. I’ve added it to the article.

Nice article and video; however, you’re mixing up the spinnaker and the gennaker.

A started out with a question. What distinguishes a brig from a schooner? Which in turn led to follow-up questions: I know there are Bermuda rigs and Latin rig, are there more? Which in turn led to further questions, and further, and further… This site answers them all. Wonderful work. Thank you.

Great post and video! One thing was I was surprised how little you mentioned the Ketch here and not at all in the video or chart, and your sample image is a large ship with many sails. Some may think Ketch’s are uncommon, old fashioned or only for large boats. Actually Ketch’s are quite common for cruisers and live-aboards, especially since they often result in a center cockpit layout which makes for a very nice aft stateroom inside. These are almost exclusively the boats we are looking at, so I was surprised you glossed over them.

Love the article and am finding it quite informative.

While I know it may seem obvious to 99% of your readers, I wish you had defined the terms “upwind” and “downwind.” I’m in the 1% that isn’t sure which one means “with the wind” (or in the direction the wind is blowing) and which one means “against the wind” (or opposite to the way the wind is blowing.)

paul adriaan kleimeer

like in all fields of syntax and terminology the terms are colouual meaning local and then spead as the technology spread so an history lesson gives a floral bouque its colour and in the case of notical terms span culture and history adds an detail that bring reverence to the study simply more memorable.

Hi, I have a small yacht sail which was left in my lock-up over 30 years ago I basically know nothing about sails and wondered if you could spread any light as to the make and use of said sail. Someone said it was probably originally from a Wayfayer wooden yacht but wasn’t sure. Any info would be must appreciated and indeed if would be of any use to your followers? I can provide pics but don’t see how to include them at present

kind regards

Leave a comment

You may also like, 17 sailboat types explained: how to recognize them.

Ever wondered what type of sailboat you're looking at? Identifying sailboats isn't hard, you just have to know what to look for. In this article, I'll help you.

How Much Sailboats Cost On Average (380+ Prices Compared)

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

No products in the cart.

Sailing Ellidah is supported by our readers. Buying through our links may earn us an affiliate commission at no extra cost to you.

The Standing Rigging On A Sailboat Explained

The standing rigging on a sailboat is a system of stainless steel wires that holds the mast upright and supports the spars.

In this guide, I’ll explain the basics of a sailboat’s hardware and rigging, how it works, and why it is a fundamental and vital part of the vessel. We’ll look at the different parts of the rig, where they are located, and their function.

We will also peek at a couple of different types of rigs and their variations to determine their differences. In the end, I will explain some additional terms and answer some practical questions I often get asked.

But first off, it is essential to understand what standing rigging is and its purpose on a sailboat.

The purpose of the standing rigging

Like I said in the beginning, the standing rigging on a sailboat is a system of stainless steel wires that holds the mast upright and supports the spars. When sailing, the rig helps transfer wind forces from the sails to the boat’s structure. This is critical for maintaining the stability and performance of the vessel.

The rig can also consist of other materials, such as synthetic lines or steel rods, yet its purpose is the same. But more on that later.

Since the rig supports the mast, you’ll need to ensure that it is always in appropriate condition before taking your boat out to sea. Let me give you an example from a recent experience.

Dismasting horrors

I had a company inspect the entire rig on my sailboat while preparing for an Atlantic crossing. The rigger didn’t find any issues, but I decided to replace the rig anyway because of its unknown age. I wanted to do the job myself so I could learn how it is done correctly.

Not long after, we left Gibraltar and sailed through rough weather for eight days before arriving in Las Palmas. We were safe and sound and didn’t experience any issues. Unfortunately, several other boats arriving before us had suffered rig failures. They lost their masts and sails—a sorrowful sight but also a reminder of how vital the rigging is on a sailboat.

The most common types of rigging on a sailboat

The most commonly used rig type on modern sailing boats is the fore-and-aft Bermuda Sloop rig with one mast and just one headsail. Closely follows the Cutter rig and the Ketch rig. They all have a relatively simple rigging layout. Still, there are several variations and differences in how they are set up.

A sloop has a single mast, and the Ketch has one main mast and an additional shorter mizzen mast further aft. A Cutter rig is similar to the Bermuda Sloop with an additional cutter forestay, allowing it to fly two overlapping headsails.

You can learn more about the differences and the different types of sails they use in this guide. For now, we’ll focus on the Bermuda rig.

The difference between standing rigging and running rigging

Sometimes things can get confusing as some of our nautical terms are used for multiple items depending on the context. Let me clarify just briefly:

The rig or rigging on a sailboat is a common term for two parts:

- The standing rigging consists of wires supporting the mast on a sailboat and reinforcing the spars from the force of the sails when sailing.

- The running rigging consists of the halyards, sheets, and lines we use to hoist, lower, operate, and control the sails on a sailboat.

Check out my guide on running rigging here !

The difference between a fractional and a masthead rig

A Bermuda rig is split into two groups. The Masthead rig and the Fractional rig.

The Masthead rig has a forestay running from the bow to the top of the mast, and the spreaders point 90 degrees to the sides. A boat with a masthead rig typically carries a bigger overlapping headsail ( Genoa) and a smaller mainsail. Very typical on the Sloop, Ketch, and Cutter rigs.

A Fractional rig has forestays running from the bow to 1/4 – 1/8 from the top of the mast, and the spreaders are swept backward. A boat with a fractional rig also has the mast farther forward than a masthead rig, a bigger mainsail, and a smaller headsail, usually a Jib. Very typical on more performance-oriented sailboats.

There are exceptions in regards to the type of headsail, though. Many performance cruisers use a Genoa instead of a Jib , making the difference smaller.

Some people also fit an inner forestay, or a babystay, to allow flying a smaller staysail.

Explaining the parts and hardware of the standing rigging

The rigging on a sailing vessel relies on stays and shrouds in addition to many hardware parts to secure the mast properly. And we also have nautical terms for each of them. Since a system relies on every aspect of it to be in equally good condition, we want to familiarize ourselves with each part and understand its function.

Forestay and Backstay

The forestay is a wire that runs from the bow to the top of the mast. Some boats, like the Cutter rig, can have several additional inner forestays in different configurations.

The backstay is the wire that runs from the back of the boat to the top of the mast. Backstays have a tensioner, often hydraulic, to increase the tension when sailing upwind. Some rigs, like the Cutter, have running backstays and sometimes checkstays or runners, to support the rig.

The primary purpose of the forestay and backstay is to prevent the mast from moving fore and aft. The tensioner on the backstay also allows us to trim and tune the rig to get a better shape of the sails.

The shrouds are the wires or lines used on modern sailboats and yachts to support the mast from sideways motion.

There are usually four shrouds on each side of the vessel. They are connected to the side of the mast and run down to turnbuckles attached through toggles to the chainplates bolted on the deck.

- Cap shrouds run from the top of the mast to the deck, passing through the tips of the upper spreaders.

- Intermediate shrouds run from the lower part of the mast to the deck, passing through the lower set of spreaders.

- Lower shrouds are connected to the mast under the first spreader and run down to the deck – one fore and one aft on each side of the boat.

This configuration is called continuous rigging. We won’t go into the discontinuous rigging used on bigger boats in this guide, but if you are interested, you can read more about it here .

Shroud materials

Shrouds are usually made of 1 x 19 stainless steel wire. These wires are strong and relatively easy to install but are prone to stretch and corrosion to a certain degree. Another option is using stainless steel rods.

Rod rigging

Rod rigging has a stretch coefficient lower than wire but is more expensive and can be intricate to install. Alternatively, synthetic rigging is becoming more popular as it weighs less than wire and rods.

Synthetic rigging

Fibers like Dyneema and other aramids are lightweight and provide ultra-high tensile strength. However, they are expensive and much more vulnerable to chafing and UV damage than other options. In my opinion, they are best suited for racing and regatta-oriented sailboats.

Wire rigging

I recommend sticking to the classic 316-graded stainless steel wire rigging for cruising sailboats. It is also the most reasonable of the options. If you find yourself in trouble far from home, you are more likely to find replacement wire than another complex rigging type.

Relevant terms on sailboat rigging and hardware

The spreaders are the fins or wings that space the shrouds away from the mast. Most sailboats have at least one set, but some also have two or three. Once a vessel has more than three pairs of spreaders, we are probably talking about a big sailing yacht.

A turnbuckle is the fitting that connects the shrouds to the toggle and chainplate on the deck. These are adjustable, allowing you to tension the rig.

A chainplate is a metal plate bolted to a strong point on the deck or side of the hull. It is usually reinforced with a backing plate underneath to withstand the tension from the shrouds.

The term mast head should be distinct from the term masthead rigging. Out of context, the mast head is the top of the mast.

A toggle is a hardware fitting to connect the turnbuckles on the shrouds and the chainplate.

How tight should the standing rigging be?

It is essential to periodically check the tension of the standing rigging and make adjustments to ensure it is appropriately set. If the rig is too loose, it allows the mast to sway excessively, making the boat perform poorly.

You also risk applying a snatch load during a tack or a gybe which can damage the rig. On the other hand, if the standing rigging is too tight, it can strain the rig and the hull and lead to structural failure.

The standing rigging should be tightened enough to prevent the mast from bending sideways under any point of sail. If you can move the mast by pulling the cap shrouds by hand, the rigging is too loose and should be tensioned. Once the cap shrouds are tightened, follow up with the intermediates and finish with the lower shrouds. It is critical to tension the rig evenly on both sides.

The next you want to do is to take the boat out for a trip. Ensure that the mast isn’t bending over to the leeward side when you are sailing. A little movement in the leeward shrouds is normal, but they shouldn’t swing around. If the mast bends to the leeward side under load, the windward shrouds need to be tightened. Check the shrouds while sailing on both starboard and port tack.

Once the mast is in a column at any point of sail, your rigging should be tight and ready for action.

If you feel uncomfortable adjusting your rig, get a professional rigger to inspect and reset it.

How often should the standing rigging be replaced on a sailboat?

I asked the rigger who produced my new rig for Ellidah about how long I could expect my new rig to last, and he replied with the following:

The standing rigging should be replaced after 10 – 15 years, depending on how hard and often the boat has sailed. If it is well maintained and the vessel has sailed conservatively, it will probably last more than 20 years. However, corrosion or cracked strands indicate that the rig or parts are due for replacement regardless of age.

If you plan on doing extended offshore sailing and don’t know the age of your rig, I recommend replacing it even if it looks fine. This can be done without removing the mast from the boat while it is still in the water.

How much does it cost to replace the standing rigging?

The cost of replacing the standing rigging will vary greatly depending on the size of your boat and the location you get the job done. For my 41 feet sloop, I did most of the installation myself and paid approximately $4700 for the entire rig replacement.

Can Dyneema be used for standing rigging?

Dyneema is a durable synthetic fiber that can be used for standing rigging. Its low weight, and high tensile strength makes it especially popular amongst racers. Many cruisers also carry Dyneema onboard as spare parts for failing rigging.

How long does dyneema standing rigging last?

Dyneema rigging can outlast wire rigging if it doesn’t chafe on anything sharp. There are reports of Dyneema rigging lasting as long as 15 years, but manufacturers like Colligo claim their PVC shrink-wrapped lines should last 8 to 10 years. You can read more here .

Final words

Congratulations! By now, you should have a much better understanding of standing rigging on a sailboat. We’ve covered its purpose and its importance for performance and safety. While many types of rigs and variations exist, the hardware and concepts are often similar. Now it’s time to put your newfound knowledge into practice and set sail!

Or, if you’re not ready just yet, I recommend heading over to my following guide to learn more about running rigging on a sailboat.

Sharing is caring!

Skipper, Electrician and ROV Pilot

Robin is the founder and owner of Sailing Ellidah and has been living on his sailboat since 2019. He is currently on a journey to sail around the world and is passionate about writing his story and helpful content to inspire others who share his interest in sailing.

Very well written. Common sense layout with just enough photos and sketches. I enjoyed reading this article.

Thank you for the kind words.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

- Boat Rigging: Setting Sail for Success

In the world of sailing, boat rigging plays a crucial role in ensuring the safety, efficiency, and performance of your vessel. From standing rigging to sail rigging types, it's essential to understand the intricacies of rigging a yacht to embark on smooth sailing adventures. In this comprehensive guide, we'll dive into the nuances of boat rigging, helping you navigate the open waters with confidence.

Boat Rigging Basics

Before we delve into the details, let's start with the fundamentals of boat rigging. Understanding the key components and their functions is essential for any sailor, whether you're a novice or a seasoned pro.

Standing Rigging

Standing rigging refers to the fixed support structure of a boat's mast, including wires, cables, and rods. It plays a critical role in maintaining the mast's vertical position and overall stability.

Sail Rigging Types

Sail rigging is not a one-size-fits-all concept, but rather a diverse world with various types and configurations to suit different sailing needs. Understanding these rigging types is essential for any sailor looking to optimize their boat's performance and safety.

Ship Riggings

Ship riggings have played a pivotal role in shaping the history of seafaring and maritime exploration. These complex systems of ropes, wires, and sails have been integral to the functionality and success of various vessels throughout the ages.Explore the significance of ship riggings, their evolution, and their influence on modern-day boat rigging.

Materials Matter

The choice of materials for your boat rigging is a decision that can't be taken lightly. Two popular options, Dyneema and Kevlar, offer distinct advantages.

Dyneema Rigging

Dyneema rigging represents a breakthrough in the world of sailboat rigging. This cutting-edge material, known for its remarkable strength and low stretch properties, has revolutionized the way sailors experience the open water. Often referred to as the ultimate innovation in the world of sailing, Dyneema rigging offers a myriad of advantages:

- Exceptional Strength: Dyneema rigging boasts remarkable strength-to-weight ratio, making it incredibly robust and reliable even in demanding conditions.

- Low Stretch: Dyneema has minimal stretch, which translates to improved sail control and responsiveness, ensuring better performance.

- Lightweight: It's significantly lighter than traditional rigging materials like steel, reducing the overall weight of your vessel and enhancing speed and maneuverability.

- Low Maintenance: Dyneema rigging requires minimal maintenance, offering sailors peace of mind and more time on the water.

- Resistance to Corrosion: Unlike metal rigging, Dyneema is not susceptible to corrosion, ensuring a longer lifespan and durability.

- UV Resistance: Dyneema is highly resistant to UV rays, making it ideal for prolonged exposure to sunlight.

- Easy Handling: Its flexibility and ease of handling simplify rigging installation and adjustments.

- Enhanced Safety: Dyneema's strength and reliability contribute to safer sailing experiences, reducing the risk of rigging failure.

- Versatility: It's suitable for a wide range of applications, from standing rigging to halyards, making it a versatile choice for sailors.

- Eco-Friendly: Dyneema is an environmentally friendly option as it doesn't release harmful substances into the water, contributing to a cleaner marine ecosystem.

Dyneema vs. Kevlar

Weigh the pros and cons of Dyneema and Kevlar to determine which suits your sailing needs best:

Dyneema Rigging:

- Exceptional Strength: Dyneema boasts impressive strength, making it highly reliable for rigging purposes.

- Low Stretch: It has minimal stretch, enhancing sail control and overall performance.

- Lightweight: Dyneema is significantly lighter than traditional materials, reducing the vessel's weight.

- Low Maintenance: Requires minimal upkeep, saving time and effort.

- Corrosion Resistance: Dyneema is not susceptible to corrosion, ensuring durability.

- UV Resistance: It's highly resistant to UV rays, making it suitable for extended exposure to sunlight.

- Safety: Dyneema's strength and reliability contribute to safer sailing experiences.

- Versatility: Suitable for various rigging applications, from standing rigging to halyards.

- Cost: Dyneema can be more expensive than some traditional materials, initially.

- Abrasion Resistance: It may be less resistant to abrasion compared to Kevlar.

Kevlar Rigging:

- Excellent Abrasion Resistance: Kevlar is highly resistant to wear and tear, ensuring longevity.

- High Tensile Strength: It offers impressive tensile strength, making it suitable for demanding applications.

- Stiffness: Kevlar is stiffer than Dyneema, which can be advantageous for some rigging configurations.

- Heavy: Kevlar is heavier than Dyneema, potentially impacting vessel performance.

- Low UV Resistance: It is less resistant to UV radiation, which can affect its durability over time.

- Higher Stretch: Kevlar tends to stretch more than Dyneema, which can impact sail control.

- Prone to Corrosion: Unlike Dyneema, Kevlar can be susceptible to corrosion.

- Cost: It can be expensive, and the initial investment may be higher than other materials.

Choosing between Dyneema and Kevlar depends on your specific sailing needs and priorities. Dyneema is favored for its strength, low stretch, and light weight, while Kevlar excels in abrasion resistance and tensile strength. Consider these factors when making your rigging material selection.

Stainless Steel Yacht Rigging

When it comes to yacht rigging, durability is paramount, and stainless steel rigging wires stand out as a top choice. Their robust nature, coupled with an unmistakable touch of elegance, makes them an ideal option for discerning sailors. Stainless steel yacht rigging is highly resistant to corrosion, even in the harsh marine environment. This resistance not only ensures a longer lifespan but also reduces maintenance efforts, allowing you to spend more time on the water. Additionally, the sleek appearance of stainless steel adds a touch of sophistication to your vessel. Whether you're cruising the open seas or participating in regattas, stainless steel yacht rigging combines style and substance to offer a premium sailing experience.

Spectra Standing Rigging

Spectra standing rigging is a game-changer for sailors seeking top-tier performance and durability. This advanced material, known for its incredible strength and low stretch properties, has revolutionized the way we approach standing rigging. Spectra rigging offers advantages that are hard to beat – it enhances the stability and safety of your vessel while providing exceptional responsiveness. The minimal stretch ensures precise sail control, making it the go-to choice for those who demand the utmost from their rigging. If you're looking to take your sailing experience to the next level, Spectra standing rigging is a choice that can't be ignored.

Read our top notch articles on topics such as sailing, sailing tips and destinations in our Magazine.

Rigging a Yacht: A Step-By-Step Guide

Now that you've grasped the basics and material options, let's dive into the practical aspect of rigging a yacht. Follow these steps to ensure a smooth and safe sailing experience.

Planning and Preparation

Rigging a yacht is a meticulous process that requires careful planning and thorough preparation. Before embarking on your sailing adventure, it's crucial to ensure that every aspect of your yacht's rigging is in top-notch condition. The advantages of this step-by-step guide are manifold. It guarantees the safety of both the vessel and its passengers, reduces the risk of mid-sail complications, and ultimately enhances your overall sailing experience. By meticulously inspecting your rigging and addressing any issues during the planning and preparation phase, you can set sail with confidence, knowing that your yacht is ready to navigate the open waters seamlessly.

Inspecting Your Rigging

Rigging a yacht is a meticulous process that demands careful attention to detail. One crucial aspect is inspecting your rigging. This step ensures the safety and efficiency of your sailing adventure. Regular inspections , even before you set sail, can identify potential issues and help prevent mishaps on the water . Inspecting your rigging is not only a safety measure but also a way to guarantee that your yacht performs at its best, allowing you to enjoy smooth and stress-free sailing experiences.

Rigging Replacement

When it comes to maintaining your yacht's rigging, the necessity of rigging replacement cannot be overstated. Whether due to wear and tear or a desire to upgrade to modern materials, knowing when and how to replace your rigging is crucial.

Specialized Rigs for Small Sailboats

For small sailboat enthusiasts , specialized rigs can enhance your sailing experience. Explore the options available for these nimble vessels.

Ship Rigging Terms

Sailboat rigging comes with its unique terminology. Get acquainted with the essential terms:

- Mast: The vertical spar or structure that supports sails and rigging.

- Boom: A horizontal spar that extends from the mast to support the bottom of a sail.

- Shroud: Rigging wires that support the mast from the sides.

- Stay: Rigging wires that support the mast from the front or back.

- Halyard: Lines used to raise and lower sails.

- Sheet: Lines used to control the angle of the sails with respect to the wind.

- Jib: A triangular foresail set in front of the mast.

- Tack: The lower forward corner of a sail.

- Clew: The lower after corner of a sail.

- Topping Lift: A line that supports the boom when the sail is not in use.

Understanding these ship rigging terms is essential for efficient and safe sailing, allowing you to communicate effectively with your crew and navigate the open waters with confidence.

Sailboat Stays and Shrouds

Sailboat rigging comprises various components, and among the most critical are sailboat stays and shrouds. Stays are the fixed support cables or wires that keep the mast upright, while shrouds add lateral support, preventing the mast from swaying. These components work together to maintain the mast's stability and ensure safe and efficient sailing. The proper tension and alignment of stays and shrouds are crucial for the overall performance and safety of a sailboat. Regular inspections and maintenance of these rigging elements are essential to prevent wear and tear, making sure they remain reliable on your sailing adventures. Understanding the role of sailboat stays and shrouds is fundamental for any sailor, whether you're navigating coastal waters or crossing the open sea.

In conclusion, boat rigging is a multifaceted subject that greatly influences your sailing experience. Understanding the fundamentals, material choices, and the process of rigging a yacht is essential for a successful voyage.

So what are you waiting for? Take a look at our range of charter boats and head to some of our favourite

sailing destinations .

The global authority in superyachting

- NEWSLETTERS

- Yachts Home

- The Superyacht Directory

- Yacht Reports

- Brokerage News

- The largest yachts in the world

- The Register

- Yacht Advice

- Yacht Design

- 12m to 24m yachts

- Monaco Yacht Show

- Builder Directory

- Designer Directory

- Interior Design Directory

- Naval Architect Directory

- Yachts for sale home

- Motor yachts

- Sailing yachts

- Explorer yachts

- Classic yachts

- Sale Broker Directory

- Charter Home

- Yachts for Charter

- Charter Destinations

- Charter Broker Directory

- Destinations Home

- Mediterranean

- South Pacific

- Rest of the World

- Boat Life Home

- Owners' Experiences

- Interiors Suppliers

- Owners' Club

- Captains' Club

- BOAT Showcase

- Boat Presents

- Events Home

- World Superyacht Awards

- Superyacht Design Festival

- Design and Innovation Awards

- Young Designer of the Year Award

- Artistry and Craft Awards

- Explorer Yachts Summit

- Ocean Talks

- The Ocean Awards

- BOAT Connect

- Between the bays

- Golf Invitational

- Boat Pro Home

- Pricing Plan

- Superyacht Insight

- Product Features

- Premium Content

- Testimonials

- Global Order Book

- Tenders & Equipment

.jpg/r%5Bwidth%5D=320/c01b08f0-3198-11ec-b3da-5dc06521023f-Black%20Pearl%20-%20Tom%20Van%20Oossanen%20(3).webp)

The definitive guide to sailing yacht rigging

Related articles, superyacht directory.

Do you know your Bermudan rig from your DynaRig or wingsails? And which is best? BOAT explains it all...

Take a look at a modern racing yacht from above, beating to windward and heeled to the breeze, and you can see at a glance why Bermudan rigs have stood the test of time. With its fore and aft sails bladed into efficient aerodynamic shapes, a modern yacht can slice close to the wind and be driven hard. Such a sight would have been outlandish a century ago. Then, a typical trading barquentine could set 18 sails to catch light airs, but it needed a large crew to battle with canvas far out on the yards. In a modern miracle as incredible in its way as flight, today’s racing yachts can sail faster than the speed of the wind – in some cases several times faster.

A mainsail set on a single spar is an age-old concept but only in the 19th century was it adapted as the Bermudan or Marconi rig. A one-piece mainsail set on a mast without a gaff, hoisted with one halyard and controlled by one sheet, was simpler and more efficient. This revolution became the power train of pleasure yachting and racing.

But perhaps the time is coming for a re-evaluation of simpler rigs requiring fewer crew – alternatives with lower loads operated by automated systems. In an era of reduced carbon consumption, could more radical sailplans even herald a revival in sail power?

The evergreen Bermudan rig

The Bermudan rig is the all-rounder, able to perform well at all angles of sail. It is efficient upwind, while downwind the sail area can be significantly boosted with a big gennaker or spinnaker. For good reasons, it is the first choice for nearly every modern sailing yacht up to around 60 to 65 metres for cruising and regatta racing alike. At larger sizes, however, things start to become trickier, and the trade-offs get interesting.

Over the last decade, sail handling technology has steadily advanced to allow sloop rigs to grow larger and larger. “But with that comes a highly loaded rig, many tonnes of compression from tension in the rigging, and you have to build structure in the boat to accept that,” explains Paul MacDonald, founder and superyacht sales manager of Southern Spars.