Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← Install & Repair

Soundproof Your Inboard Engine And Generator

Advertisement

Save your voice and regain your floating peaceful refuge by adding soundproofing to your engine and generator.

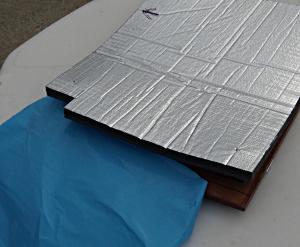

The best strategy to address noise is by containing it at the source, a good example being the insulation inside this engine cover.

Time spent on the water should be relaxing. But that can be difficult when you have to scream over engine or generator noise during conversations or are left lying awake at night listening to the melodious hum of an air conditioning unit. Installing soundproofing can make a huge difference in onboard noise reduction. Here's how to transform the hullabaloo of your boat into the peace and tranquility of a floating Zen garden.

The best way to combat noise is by containing it at the source — within an engine compartment, for example. Soundproofing is perfect for this application, and while not fireproof, it is typically fire-retardant up to around 225 F.

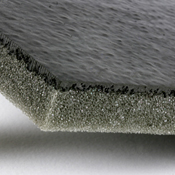

Installation of a good quality foam soundproofing barrier can reduce engine noise by 10 to 35 decibels (about 65%). Soundproofing material is available in a wide variety of forms, from sprays and paints to foil-backed foam panels. Foam panels are a popular choice and one that's very effective against airborne noise pollution.

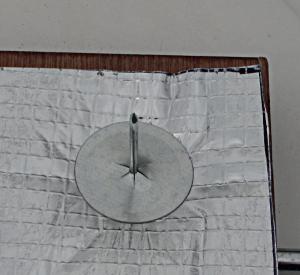

Soft sound shields, such as this one from GSI (stopthesound.com), provide both installation flexibility and significant noise reduction.

Self-adhesive panels are easy to install (just peel and stick), but you have to plan and position them exactly where you want them the first try as you typically can't reposition them without damaging the foam. Panels without adhesive backing require spray- or brush-on contact adhesives, which may allow a bit of last-minute repositioning, making them easier to work with in tight spaces.

Regardless of adhesives used, overhead panels require additional support from mechanical fasteners.

Regardless of the adhesives used, panels also require the use of mechanical fasteners (such as screws and fender washers) particularly for overhead horizontal installations.

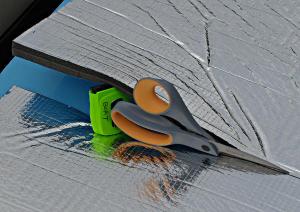

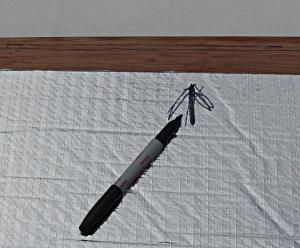

Soundproofing panels can be cut to shape with a box cutter or razor knife, however a serrated knife blade will provide a cleaner cut of the foam material itself. Thin sheets of soundproofing material can also be cut with a pair of good quality scissors. To ensure the best fit (and avoid cutting snafus) make cardboard templates first to check fit and for use as a cutting guide. Be sure to dry fit everything prior to applying adhesives or peeling self-adhesive panels.

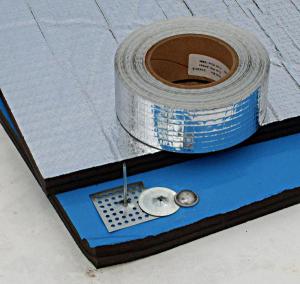

Use joining tape to seal and prevent sound "leaks" at panel joints.

When planning your installation, remember that sound flows like water, meaning you'll want to use Mylar seal or joining tape (typically provided by the manufacturer) to prevent "leaks" at panel joints. Cables and hoses penetrating the material should be sealed using tight-fitting rubber grommets, while access hatches should close snugly with a good, tight seal.

That said, any soundproofing installation must provide adequate ventilation for the engine. Required vents and air holes can be quieted using air baffles. It's not realistic to expect all noise to be eliminated once soundproofing is installed, but when done correctly, you should be able to carry on a conversation at normal volume levels. After all, who wants to yell when you are trying to relax?

Soundproofing Installation Tips

- Read all instructions for the soundproofing, adhesives, and mounting hardware prior to starting your project.

- Make templates to check fit prior to cutting panels. Be sure to allow for material thickness at corners.

- Ensure your installation provides adequate ventilation and keeps insulation material above bilge water levels. (Avoid exposure to any wet areas.)

- Provide a minimum clearance of 6 inches between soundproofing and engine or generator exhaust manifolds.

- Use sharp tools when cutting soundproofing, both to produce clean cuts and to avoid tearing of reflective foil. The foil or silver facing side should face upward when cutting.

- Handle soundproofing material carefully. Avoid folding the material back on itself, which can result in creasing.

- Seal all exposed edges, joints, and corners with Mylar seam tape to prevent water or other contaminants (such as fumes or oil) from entering and degrading the soundproofing material. Seam tape can also be used to provide chafe protection at wear points. You can purchase it at most marine stores.

- Don't rely on adhesives alone. Use fasteners and fender washers where appropriate (all overhead and vertical surfaces) to ensure backup in the event of adhesive failure.

- Apply adhesive for and install one panel at a time. Install the top panel first, which lets adjacent vertical panels provide support to the outer edges of the top panel.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Frank Lanier

Contributing Editor, BoatUS Magazine

Capt. Frank Lanier is a SAMS-accredited marine surveyor with over 40 years of experience in the marine and diving industries. He’s an author, public speaker, and multiple award-winning journalist whose articles on boat maintenance, repair, and seamanship appear regularly in numerous marine publications worldwide. Contact him via his YouTube channel “Everything Boats with Capt. Frank Lanier” or at captfklanier.com.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

The Best Guide to Soundproofing a Boat Engine Compartment

Sailing on a boat can be an exhilarating adventure. Nevertheless, loud engine noise and vibrations can spoil the enjoyment. Luckily, this guide presents methods to soundproof the boat engine compartment.

In this article, I’ll show you how to fix this problem. But before we proceed, it’s essential to identify the reasons for the uncanny noise from your boat’s engine so you can know what solution to apply.

Also, read these Handy Tips on How To Quiet Your Boat

Why Is My Boat’s Engine So Loud?

As an affiliate, I may collect a share of sales or other compensation from the links on this page.

If your boat’s engine is loud it may be due to a malfunctioning exhaust or a wrong propeller pitch. However, new boat engines can also be loud due to a lack of sound insulation.

New engines can be annoyingly loud. This in no way implies that the engine is defective. A new fiberglass boat has little to no sound insulation.

There’s also the issue of the propeller pitch. Installing the wrong propeller will affect the boat engine’s revolutions per minute (RPM). RPMs over 4,800 are bad for your engine.

A bad lubricant or gasoline identified by the engine sensors might also impact propeller pitch, causing the noise levels to rise. Listen to every sound, especially the one coming from your engine room, when sailing your boat.

Ensure you fix these problems before you resume sailing on your boat, as high noise levels are not suitable for your health, boat, and even aquatic life.

Soundproofing a Boat Engine Compartment – Step by Step

Here’s how to reduce noise in your boat’s engine compartment:

- Service your boat’s engine.

- Replace the engine propeller.

- Seal all openings except the vent.

- Isolate vibrating parts.

- Install a soundproof material in the engine’s compartment.

- Line the walls and ceiling of your boat’s engine room with soundproofing materials.

1. Service Your Boat’s Engine

This step is the first and most important. Before you go on sealing compartments, you must ensure the engine is in good condition. If the engine fails, there’ll be no boat ride after all. Get an expert to check the engine. Change lubricants if necessary.

2. Replace the Engine Propeller

If the wrong propeller is installed, you’ll have a lot of noise from your boat’s engine. The propeller is responsible for your boat’s revolutions per minute, affecting the noise. The simple solution is to replace the propeller with something more adequate.

3. Seal All Openings Except the Vent

Seal all areas that allow sound passage except the vent. You don’t seal the vent because, like every other system, the engine needs air to function properly. Using a soundproof material, seal the following places:

- Panel joints

- The spaces left by wire connections

- Pipes that lead outside

- The areas that lead from the engine room like the Lafayette

- Every single slight opening except the vent

4. Isolate Vibrating Parts

When two items collide or an object rattles, vibration occurs. Use light materials to separate solid objects that could collide in a boat engine compartment or use it to isolate concrete elements to reduce vibration. The light material allows the solid section to move while keeping the vibrations contained.

5. Install a Soundproof Material in the Engine’s Compartment

Sound absorption materials like foam-backed material and vinyl can help reduce noise inside a boat engine’s compartment. Insulating the engine compartment will reduce and absorb noise from the engine room. In addition, spread a waterproof carpet over the engine to reduce noise and keep water out.

6. Line the Walls and Ceiling of Your Boat’s Engine Room With Soundproofing Materials

You can use soundproofing materials such as 1-inch foam-backed cloth (foam spray) or perforated vinyl headliners to cover your boat’s walls and the ceiling of your boat’s engine compartment. Take a step further by covering the engine bay with these materials.

Adverse Effects of a Boat Engine’s Noise and Vibration

Constant exposure to engine noise and vibration can harm you and your boat. Some of these effects include:

- Boat squeaking

- Disruption of aquatic life

Let’s analyze these points below:

- Deafness: Noise is measured in decibels (dB). The human ear can tolerate sounds below 85dB. Sounds from 100dB and above can cause deafness. A loud boat engine produces sounds of up to 100dB. Constant exposure to sound at this level can damage your ear.

- Boat squeaking: Constant boat vibration can loosen fasteners and other weak sections of the boat. Those components will begin to squeak and make various unpleasant sounds. This can reduce the boat’s lifespan and even make a new boat appear old.

- Disruption of aquatic life: Boat Engine sounds affect the coral reef, stimulating erratic behavior in adult fish. Enraged adult fish can start attacking other younger harmless fish. This results in a higher rate of mortality in aquatic life.

How To Maintain Your Boat Engine and Prolong Its Lifespan

Boats are pretty expensive, so It’s pointless to spend money on a boat only to have the engine fail after a year or two. Here are five suggestions for extending the life of your boat engine.

- Warm up your boat regularly. Your boat’s engine can become cranky if you leave your boat for weeks or months without warmups. If you’re not taking the boat out, turn on the engine and let it rev for a few minutes now and then.

- Cruise more often. The longer you leave your boat’s engine idle, the weaker it gets. If you can afford it, cruising regularly keeps the boat’s engine alive and responsive.

- Keep fuel and oil fresh. Check your fuel and oil levels regularly.

- Regularly flush out salt water . Saltwater is bad for your boat’s engine. So you must always thoroughly flush immediately after sailing on salt water.

- Cover your boat. As simple as it sounds, it can be a burden. Always cover your boat when not in use. A boat cover will keep many unfavorable factors out of your engines, such as harsh weather and dust.

Cruising on your boat can be a delightful experience, but the noise and vibration from the engine compartment may spoil the fun.

Take simple measures in sealing up your engine room and engine compartment to reduce the noise so you can enjoy your time on your boat.

Developing a maintenance culture will keep your boat’s engine in good condition and help prolong its lifespan.

Similar Posts

How To Soundproof Your Fence

5 Effective Tips To Soundproof A Metal Building

7 Proven Tips for a Soundproof Dog Crate That Really Work!

8 Best Tips to Get Rid of Cricket Noise at Night

How To Soundproof A Laundry Room the Right Way

How To Soundproof A Log Cabin

- Yachting Monthly

- Digital edition

Marine engine soundproofing

- April 16, 2014

Yachting Monthly guidelines for installing marine engine soundproofing

Duncan Kent’s full report on how to choose the best marine engine soundproofing for your yacht, can be read in the June 2014 issue of Yachting Monthly .

Guidelines on installing marine engine soundproofing: Foil/cloth and hard barrier soundproofing is best cut with a sharp modelling knife – but it’s easier and neater to cut the foam using a serrated blade. Thinner sheets cut well with good scissors.

Self-adhesive sheets are easy to peel and attach, but you must position it correctly first time. Plain-backed types require spray or brushed contact adhesives – the latter being more controllable in tight spaces. Mechanical fixings should be added to all horizontal upper surfaces.

Suppliers advise that all joints are covered using special joining tape to avoid ‘leakage’. Self-adhesive foil tape works excellently on foil-covered material, but white plastic tape from Vetus will peeled off easily.

Ideally, soundproofed bulkheads should totally encase the engine area, separate from any tanks, which can resonate - amplifying the sound. Engine noise can ‘flow’ along the bilges, so where possible bulkheads should continue down to the hull, leaving only limber holes for bilge water.

Remember to provide enough airflow for combustion. Open air holes will ruin the insulation, but a simple baffle will stop most of the noise escaping.

Finally, all cables and pipes should pass through snug-fitting rubber grommets, while any covers or side panels should fit snugly with a noise-tight seal.

- Backing Pads

- Bolts & Fixings

- Bonding Cable

- Bow Thruster Anodes

- Electro Eliminators

- Caterpillar

- Engine Anode Kits

- Volvo Penta

- Galvanic Isolation Blockers

- Ground Plates

- Manicooler Anodes

- Mooring Hanging Anodes

- Propeller Shaft Nut Anodes

- Outdrive Anodes

- Universal Pencil Anodes

- Boat Covers

- Boat Cleaning

- Damp Prevention

- Hand Cleaning

- Spillage Clean-Up

- Toilet Cleaning

- Water Cleaning

- Waterproofing

- Deck Coverings

- Fuel Treatments

- Gasket Material

- Oils, Greases & Lubricants

- Resins & Fillers

- Sail Protection

- Screen Wash

- Sealants & Adhesives

Fire Protection Sheets

Soundproofing adhesives & fixings, soundproofing damping barrier, soundproofing sheets.

- Trailer Accessories

- Antennas & Accessories

- Brackets & Hooks

- Cabin Heaters & Accessories

- Cup Holders

- Curtain Rods & Fittings

- Hatches & Portholes

- Latches, Locks & Stoppers

- Signs & Labels

- Table Legs & Bases

- Manual Wipers

- Screen Washing Kits

- Wiper Blades

- Wiper Motors

- Control Units

- Accessories

- Anchor Chain Connectors

- Anchor Chain Markers

- Bow Rollers

- Hawsehole Plates & Pipes

- Windlass Spares

- Barge Poles

- Bollards, Cleats, Eye Plates & Fairleads

- Canopy Fittings

- Cleaning & Protection

- Deck Fillers & Filler Caps

- Deck Plates

- Deck Plugs & Sockets

- Fenders & Accessories

- Fishing Rod Holders

- Flags, Poles & Wind Indicators

- Handles & Handrails

- Life Rings & Rescue Lights

- Mooring Equipment

- Radar Reflectors

- Scuppers & Drains

- Steps & Ladders

- Turnbuckles

- Waste Pump Out Deck Fittings

- Accumulator Tanks

- Calorifiers

- Valves & Fittings

- Deck Filler Keys

- Universal Deck Fillers

- Water Deck Fillers

- Water Deck Filler Caps

- Domestic Antifreeze

- Circulation Pumps

- Pressure Pumps

- Transfer Pumps

- Manual Pumps

- Immersion Heaters

- Push-Fit Plumbing Pipe & Fittings

- Taps & Showers

- Water Purifiers & Water Filters

- Water Tanks

- Connection Kits

- Inspection Lids

- Level Gauges

- Level Senders

- Water Treatments

- Flexible Shaft Couplings

- Flexible Shaft Coupling Earthing Connectors

- Flexible Shaft Coupling Spares & Accessories

- Gland Packing

- Packing Removal Tools

- Propeller Shafts

- Beneteau & Jeanneau Shaft Bearings

- Brass Shaft Bearings

- GRP Shaft Bearings

- Propeller Shaft Coupling Adaptors

- Solid Bobbin Shaft Couplings

- Solid Shaft Couplings

- Split Half Solid Shaft Couplings

- Propeller Shaft Seals

- Shaft Seal Repair Kits

- Remote Greasers & Cups

- Rope Cutters

- Alarms & Warning Devices

- Battery Boxes

- Battery Cable Terminals

- Battery Combiners

- Battery Connector Leads

- Battery Chargers

- Battery Isolator Switches

- Battery Monitors & Gauges

- Battery Split Chargers

- Battery Terminal Covers

- Isolation Transformers

- Panels & Controls

- Power Inverters

- Voltage Converters

- Cable Connectors & Accessories

- Fuses & Circuit Breakers

- Kettles and Coffee Machines

- Electronic Device Mounts & Accessories

- Accessory Plugs & Sockets

- DIN Plugs & Sockets

- Shore Power Plugs & Sockets

- Busbars / Power Distribution

- Covers & Insulation Disks

- Jump Start Power Connectors

- Power Bushings

- Relays & Solenoids

- Shore Power Connections

- Solar Panels & Accessories

- Switches & Switch Panels

- TVs & Accessories

- Voltage Converters & Inverters

- Windscreen Wiper Systems

- Adaptor & Drive Plates

- Alternators

- Crankcase Vent Systems

- Drive Belts

- Engine & Gearbox Oil

- Engine Flushing Valves

- Crankshaft Mounted Cooling Pumps

- Electric Circulation Pumps

- Engine Driven Circulation Pumps

- Pump Pulleys

- Flange Mounted Cooling Pumps

- Fuel Lift Pumps

- Pulley Driven Cooling Pumps

- Exhaust Outlets

- Expansion Tanks

- Flexible Engine Mounts

- Fuel, Air & Oil Filters

- Gearboxes, Spares & Accessories

- Glow & Spark Plugs

- Combined Heat Exchanger & Header Tanks

- Cooling Tubes - Tubestacks

- Engine Mounted Header Tanks

- Filler Necks

- Heat Exchanger Manifolds / Manicoolers

- Intercoolers

- Keel Cooled Manifolds / Manicoolers

- Nuts, Bolts & Washers

- Tubular Heat Exchangers

- Water Cooled Manifolds

- Oil Clean Up Products

- Oil Coolers & Accessories

- Outboard Motor Accessories

- Pressure Caps

- Starter Motors

- Beta Marine

- BMC, Leyland & Land Rover

- Johnson Evinrude (OMC)

- New Holland Genesis

- Thornycroft

- Volvo Penta Saildrives

- Volvo Penta Sterndrives

- Yanmar Saildrives

- Anti-Siphon Valves

- Check Valves

- Dry Exhaust Bellows

- Dry Exhaust Pipe

- Dry Exhaust Silencers & Accessories

- Cast Exhaust Outlets

- Exhaust Outlet Gaskets

- Multi-Choice Exhaust Flanges

- Multi-Choice Spray Heads

- Wet Exhaust Mixers

- Exhaust Lagging

- Exhaust Outlets & Flaps

- Exhaust Temperature Alarms

- Gas / Water Separators

- Heat Exchanger Filler Necks

- Heat Exchanger Nuts, Bolts & Washers

- Heat Exchanger O-Rings

- Manifold & Exhaust Outlet Gaskets

- Replacement Cooling Tubes (Tubestacks)

- Replacement End Caps

- Inline Mufflers

- Pipe Repair Kits

- 180 Degree Bends

- Exhaust Elbow Connectors

- Exhaust Hose Reducers

- Rotating Hose Connections

- Straight Exhaust Lengths

- Waterlock Mufflers

- Wet Exhaust Hose

- Brass Fittings

- Bronze Fittings

- DZR Brass Fittings

- Non-Metallic Fittings

- Stainless Steel Fittings

- Blanking Caps

- Compression

- Fitting Kits

- Hose Connectors

- Pipe Manifolds

- Sender Adaptors

- Skin Fittings

- Gas Equipment

- Sealants & Thread Tape

- Strainers & Spares

- Valves & Spares

- Anti Theft Devices

- Copper & Nylon Tubing

- Diesel Deck Fillers

- Diesel Deck Filler Caps

- Petrol Deck Fillers

- Petrol Deck Filler Caps

- Filling Funnels

- Fuel Filters

- Fuel Filter Elements

- Fuel Filter Fittings

- Fuel Filter Spares & Accessories

- Fuel Polishing

- Fuel Primer Pumps

- Fuel Transfer Pumps

- Fuel Gauges

- Fuel Level Senders

- No Smell Fuel Filters & Elements

- Pipe Clips & Copper Saddles

- Fuel Clean Up Products

- Fuel Line Anti-Spill Devices

- Fuel Tank Fittings

- Jerry Cans & Portable Fuel Tanks

- Water Detection Alarms

- Cooker Spares

- Hobs & Sinks

- Electric Water Circulation Pumps

- Electric Water Pressure Pumps

- Electric Water Transfer Pumps

- Manual Water Pumps

- Fire Extinguishers

- Kettles and Coffee Makers

- Laundry Equipment

- Push Fit Plumbing Pipe & Fittings

- Refrigerators, Freezers & Cool Boxes

- Bulbs & Accessories

- Electrical Cables

- Ammeter Gauges

- Battery Condition Gauges

- Blank Gauges

- Clock Gauges

- Combination Gauges

- Compass Gauges

- Depth Sounders

- Fuel Level Gauges

- Hourmeter Gauges

- Inclinometer Gauges

- Oil Pressure Gauges

- Outboard Temperature Gauges

- Rudder Angle Gauges

- Speedometer Gauges

- Synchroniser Gauges

- Tachometer Gauges

- Trim Level Gauges

- Turbo & Vacuum Gauges

- Voltmeter Gauges

- Warning Gauges

- Waste Water Level Gauges

- Water Level Gauges

- Water Pressure Gauges

- Water Temperature Gauges

- Weather Gauges

- Gauge Voltage Converters

- Instrument Panels & Wiring Looms

- Depth Senders

- Fittings For Senders

- Oil Pressure Alarm Switches

- Oil Pressure Senders

- Pitot Speedometer Senders

- Resistance Exchangers

- Rudder Angle Senders

- Tachometer Senders

- Temperature Alarm Switches

- Temperature Senders

- Switch Panels

- Coolant & Heater Hose

- Deckwash Hose

- Ducting Hose

- Exhaust Hose

- Fresh Water Food Quality Plumbing Hose

- General Purpose Hose

- Hose & Pipe Repair Kits

- Clamp-Aid Hose Clips Guards

- Clipdrivers For Clips & Clamps

- Jubilee Hose Clips

- Jubilee High Torque Clips

- Jubilee Superclamps

- Hydraulic Oil Cooler Pipes

- Layflat Hose

- Sanitation & Waste Hose

- Hose Elbows

- Reducing Hose Elbows

- Reducing Straight Hose

- Specially Shaped Hose

- Straight Hose Lengths

- Steering Hose

- Water Intake Hose

- Edison Bulbs

- BA15s Bulbs

- BA15d Bulbs

- BAY15d Bulbs

- Festoon Bulbs

- Fluorescent & Halogen Tubes

- Right Angle Prefocus Bulbs (Golight Bulbs)

- Screw In Bulbs

- Sealed Beam Bulbs

- Wedge Base Bulbs

- Chart, Map & Reading Lights

- Deck Lights

- Floodlights

- Interior Lights

- Spares & Accessories

- Navigation Lights

- Pole Lights

- Rescue Lights

- Searchlights & Spotlights

- Underwater Lights

- Utility & Courtesy Lights

- Warning Lights

- Antifouling Paint

- Bilge & Locker Paint

- Blacking Paint

- Engine Paint

- Paint Brushes and Accessories

- Protective Coatings

- Rust Inhibitors

- Stove Paint

- Surface Preparation & Finishes

- Thinners, Degreasers & Strippers

- Topcoat / Flowcoat

- Topcoat Primers

- Underwater Primer

- Submersible Bilge Pumps

- Electric Motor Bilge Pumps

- Clutched Bilge Pumps

- Manual Bilge Pumps

- Bilge Pump Panels & Switches

- Bilge Water Level Alarms

- Bilge Pump Spares & Accessories

- Bilge Filters, Elements & Cleaners

- Strum Boxes

- Clutch Pumps

- Domestic Water Pumps

- Drill Pumps

- Crankshaft Mounted Engine Cooling Pumps

- Engine Pump Pulleys

- Flange Mounted Engine Cooling Pumps

- Pulley Driven Engine Cooling Pumps

- Impeller Pullers & Lubricant

- Livewell Pumps

- Macerator Pumps

- Sump and Oil Change Pumps

- Washdown Pumps

- Waste Pumps

- Beacons & Transponders

- Battery Isolators

- Bilge Pump Filters

- Circuit Breakers

- Deck Fillers with Labels Engraved

- Diesel, Fuel & Gas Shut Off Labels

- Electrical Cable

- Engine Mounts

- Fuel Fittings, Valves & Cocks

- Fuel Hose (ISO 7840)

- Fuel Tank Vents and Plugs

- Shore Power Cable

- Terminal Covers

- Ventilation

- Bungee Cords

- Emergency Ladders

- Fire & Smoke Alarms

- Hi-Vis Bags

- Kill Switches

- Life Jackets

- Buoyancy Aids

- Accessories & Spares

- Pet Buoyancy Aids

- Safety Plugs

- Searchlights

- No Smell Waste Filters & Elements

- Shower Sump Systems

- Plugs & Chains

- Toilet Spares

- Waste Water Tanks

- Extraction Pipes

- Odour Treatments

- Vacuum Valves

- Bow & Stern Thrusters

- 33C Fitting Control Cables

- 43C Fitting Control Cables

- Control Cable Fittings

- Industrial Control Cables (33C Fitting)

- UD617 Control Cables

- Dual Station Control Units

- Control Levers

- Helms & Bezels

- Outboard Engine Tie Bars

- Rudders, Glands & Tiller Arms

- Steering Wheels

- Actuators & Brackets

- Control Panels

- Clamshell Vents

- Dorade Boxes

- Extractor Fans

- Inline Blowers

- Mushroom Deck Vents

- Snail Cam Blowers

- Aqua Signal

- ASAP Electrical

- Faria Beede

- R&D Marine

- Engine Anodes

- Hull Anodes

- Propeller Shaft Anodes

Soundproofing

- Anchors & Accessories

- Calorifiers (Water Heaters) & Fittings

- Deck Fillers & Caps

- Water Tank Accessories

- Flexible Couplings

- Gland Packing & Removal Tools

- Propeller Shaft Bearings

- Propeller Shaft Couplings

- Batteries & Accessories

- Plugs & Sockets

- Power Distribution

- Engine Pumps

- Heat Exchangers & Exhaust Manifolds

- Engine Exhaust Outlets

- Tubes, Fittings & Hose Connectors

- Fillers & Filler Caps

- Filters, Elements & Spares

- Gauges & Senders

- Spill Prevention & Clean-Up

- Tanks & Accessories

- Cookers, Hobs & Sinks

- Gauges & Instruments

- Senders & Fittings

- Hose Clips, Clamps & Accessories

- Silicone Hose

- Bulbs & Tubes

- Interior Lights & Spares

- Navigation Lights & Spares

- Searchlights & Spares

- Bilge Pumps

- Engine Cooling Pumps

- Pump Spares

- Life Jackets & Buoyancy Aids

- Sink & Shower Waste Outlets

- Waste Water Tank Accessories

- Control Cables & Fittings

- Engine & Gearbox Controls & Spares

- Engine Stop Cables & Fittings

- Hydraulic Steering

- Mechanical Steering

- Trim Tabs & Accessories

Live Stock Figures

Free UK Delivery orders over £120 (inc vat) orders over £100 (ex vat)

Same Day Dispatch order by 3:30pm

Technical Help & Advice

Marine soundproofing and noise insulation sheets suitable for the engine room / engine bay or other sources of noise on board the boat.

The Quietlife soundproofing range consists of foam based soundproofing sheets and rockwool based soundproofing sheets. These also act as fire proof barriers, to add to their noise reducing capabilities. Foam based products, which include the Slimslab, Standard, 2 Quiet, Super and Quietlite ranges have a fire proof rating of BS476 (Part 6, 1998 and Part 7, 1971), whereas the FireBatt barriers, made from Rockwool, meet BS476 (Part 4, 1988) making them suitable for Class V vessels.

Here is a quick guide to our foam based soundproofing products to help you make the correct choice for your application:

Description

SlimslabStandard2 QuietSuperQuietlite

23mm32mm45mm58mm58mm

General purpose noise control, ideal for use where space is limited.Brilliant general purpose soundproofing - this is our most popular insulation!The best noise solution, has a twin barrier! For older engines and low frequencies.Excellent soundproofing for turbo charged engines and higher frequency sounds.Lightweight barrier and good performance - provides dramatic weight savings.

We also offer the Rockwool based Marine FireBatt 2000 range of sound proofing materials, which is Lloyds approved. We recommend this sheet is combined with a damping barrier for better noise insulation results.

Get offers in your inbox

Sign up for the latest offers, product news, technical advice and more.

By submitting your details you consent to our Privacy Notice .

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

01952 581340

Marine Insulation…

With 36 years of experience of producing acoustic materials for Soundproofing and Noise reduction, we have the perfect solution for your marine acoustic problems. Our marine insulation products are ideal for sound-proofing boat engine rooms and controlling noise and vibration problems. Acoustafoam’s Class O composite products offer the best possible acoustic result especially for engine room sound insulation due to the multi-layer combination.

Acoustafoam laminates are used in many industrial applications but mostly used for the marine industry engine room noise problem areas.

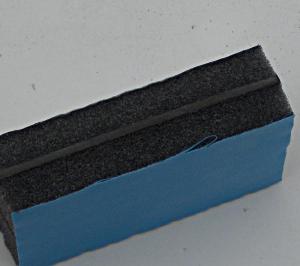

Acoustafoam Laminates have three layers in addition to a protective facing for cosmetic and practical functions:

The Absorption Layer

A thick layer of 25mm fire zero rated Class O foam which soaks up noise and stops it bouncing around the engine compartment.

The Transmission Layer

A high-density 5kg per square metre polymeric barrier that provides the highest possible mass for the job of transmission loss (stops noise from getting through to other areas of the boat at the application wall).

The Isolation Layer

This 6mm layer of foam has a crucial function, it acts like the gap in double glazing and stops the noise that hits the transmission layer being carried through to the bulkhead.

Acoustafoam Marine Laminates can be supplied with a range of facings. PU Films Black and White, Glass Fibre, Aluminium Coated Glass Fibre, Aluminium Foil, Fire Rated Fabrics or a range of Sprayed Fire Rated Paints.

Acoustafoam offers a standard variety of products for marine insulation applications. Sheets 990mm x 590mm x 32mm – 4 sheets per box with a self-adhesive backing. Installation is easy. Simply cut the material to shape, peel off the release paper and fix to the affected area. Use Acoustafoam jointing tape to seal butt joint edges.

Acoustafoam manufactures marine acoustic insulation made from Rockwool fire pro. RW2000 is a rock mineral wool slab engineered to provide A-rated fire protection aboard ships and offshore installations. This product is Lloyd Register of Shipping and MED certified A30 and A60 fire protection to steel decks and bulkheads. It can be used to provide fire protection, thermal insulation and sound reduction with the minimum of weight. The product is laminated with B67 foil coated glass Class O fire rated.

Material code: RW 2000. Description : Marine Rockwool Colour: Foil faced (B67) Sheet size: 1000mm x 600mm.Thickness: 25mm – 40mm – 75mm. Thermal conductivity: 0.033 w/mk at 10*c.

Acoustics: Marine Rockwool foil faced slabs can considerably reduce the level of environmental sound. Fire specification: RW 2000 is Lloyd’s Register of Shipping certified, and MED approved to provide A30 / A60 fire protection.

Applications: Fire protection, thermal insulation and acoustic treatment of marine and offshore installations. Finishes: The sheets can be supplied with a factory laminated reinforced foil facing. The foil is intended as a vapour barrier, and butt joints should be sealed with foil tape (b67/50mm/s.a.).

Fixing: Contact adhesive, Mechanical fasteners and Self-adhesive backing if required. Work on the site: Fit to clean, dry surface sheets of pre-cut shapes. All but joints cover with self-adhesive 50mm b67 foil tape. Sheets can be cut using a sharp knife. This product is also supplied with pre-cut shapes and edges material wrapped.

We’re Waiting To Help You

Therefore, get in touch with us today and let’s help your business acoustic solutions.

We are the founding company of the Acousta group. We specialise in the manufacturing of foam, rubber and plastic components for a wide variety of sectors. The components are processed from blocks, sheets and rolls of materials using our band saws, CNC machines and water jets to our customer’s specification.

Subscribe To Our Newsletter

Sign up to receive email updates on new products, announcements, useful articles & much more…

Visit our Popular Forums

- Monohull Sailboats

- Multihull Sailboats

- Powered Boats

- General Sailing

- Antares Yachts

- Fountaine Pajot

- Lagoon Catamarans

Cruising Business

- Boat Classifieds

- General Classifieds

- Crew Positions

- Commercial Posts

- Vendor Spotlight

Life Aboard a Boat

- Provisioning: Food & Drink

- Families, Kids, & Pets Afloat

- Recreation, Entertainment, & Fun

- Boat Ownership & Making a Living

- Liveaboard's Forum

Seamanship, Navigation & Boat Handling

- Seamanship & Boat Handling

- Training, Licensing, & Certification

- Health, Safety, & Related Gear

- Rules of the Road, Regulations, & Red Tape

Engineering & Systems

- Const. / Maint. / Refit

- Product / Service Reviews

- Electronics: Comms / AV

- Electrical: Batts / Gen / Solar

- Lithium Power Systems

- Engines & Propulsion

- Propellers & Drive Systems

- Plumbing / Fixtures

- Deck Hdw: Rigging / Sails

- Aux. Equipment & Dinghy

- Anchoring & Mooring

Photo Categories

- Member Galleries

- Life Onboard

- Sailing in the Wind

- Power Boats

- Cruising Destinations

- Maint. & Boat Building

- Marine Life

- Scuba Diving & Divers

- General Photos

Recent Photos

Listing Categories

- African Cats

- view more »

- Crew Wanted

- Crew Available

- Enhance Your Account

- Meet the Mods

- Meet the Advisors

- Signup for The Daily Cruiser Email

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IMAGES

VIDEO

COMMENTS

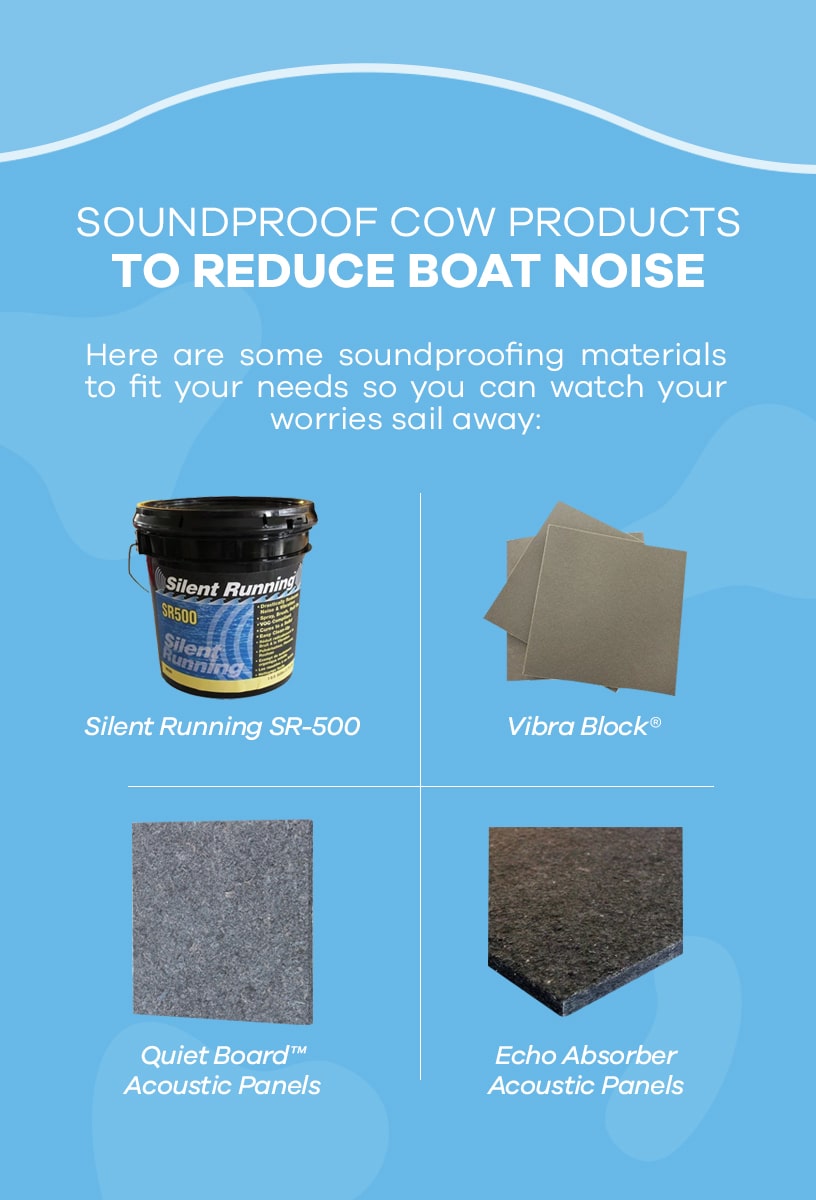

Let us help. 206-632-4462. Email. Silence the noise & create a peaceful trip! Fisheries Supply offers marine sound insulation, soundproofing foam & engine compartment insulation for all boats.

Clean the Surface - Remove any old insulation to expose the metal (or fiberglass). Then, use denatured alcohol to clean off any rust or dirt. Add Sound Deadener - Completely cover the boat engine compartment with Damplifier Pro™. Add the Insulation - Your second layer is Heat Wave Pro™ or Mega Block™, to add insulation and sound absorption.

The best way to combat noise is by containing it at the source — within an engine compartment, for example. Soundproofing is perfect for this application, and while not fireproof, it is typically fire-retardant up to around 225 F. Installation of a good quality foam soundproofing barrier can reduce engine noise by 10 to 35 decibels (about 65%).

Line your engine compartment to reduce noise levels. This flexible composite combines the sound-absorbing properties of open-cell polyurethane foam and the noise barrier capabilities of high-density PVC vinyl sheeting.The 3/32" flexible vinyl sheet is fused between two layers of foam—an exterior ("decoupler") layer and an interior ("absorber") layer.

Soundown 28/AC-AL Noise Reduction Installation Kit - NACAL. $54.99. Silent Running Spray Kit - SR1000SK. $167.99. Soundown Yachtsman's Jr. Noise Reduction Kit - NFBK05. $139.99. Soundown 2" x 15' Noise Reduction Mylar Installation Tape - NPST5. $12.62. Soundown Noise Reduction Polyester Foil Seam Tape - NPST36.

Sound absorption materials like foam-backed material and vinyl can help reduce noise inside a boat engine's compartment. Insulating the engine compartment will reduce and absorb noise from the engine room. In addition, spread a waterproof carpet over the engine to reduce noise and keep water out. 6.

Duncan Kent's full report on how to choose the best marine engine soundproofing for your yacht, can be read in the June 2014 issue of Yachting Monthly. Guidelines on installing marine engine soundproofing: Foil/cloth and hard barrier soundproofing is best cut with a sharp modelling knife - but it's easier and neater to cut the foam using.

Soundproofing Sheets. Marine soundproofing and noise insulation sheets suitable for the engine room / engine bay or other sources of noise on board the boat. The Quietlife soundproofing range consists of foam based soundproofing sheets and rockwool based soundproofing sheets. These also act as fire proof barriers, to add to their noise reducing ...

Our marine insulation products are ideal for sound-proofing boat engine rooms and controlling noise and vibration problems. Acoustafoam's Class O composite products offer the best possible acoustic result especially for engine room sound insulation due to the multi-layer combination. ... It can be used to provide fire protection, thermal ...

Wooden Hand Roller. Large Compartment (36 sq ft) Damplifier Pro - 36.5 Sq Ft (22 sheets, 12" x 20" each, 2mm thick) Mega Block - 36 Sq Ft (9 sheets, 24" x 24" each, 1/2" thick) Foil Insulation Tape - 1 roll (2" x 150') Wooden Hand Roller. Install Guide. Step 1: Damplifier Pro on the Fiberglass Doghouse. Clean the doghouse with denatured alcohol.

Need insulation for your boat engine cover? Well we got you covered, follow along with Eric as he installs one of our Boat Engine Compartment Insulation Kits...

Engine noise can 'flow' along the bilges, so where possible bulkheads should continue down to the hull, leaving only limber holes for bilge water. Remember to provide enough airflow for combustion. Open air holes will ruin the insulation, but a simple baffle will stop most of the noise escaping.

Step 3: Cut the new insulation to fit the spaces appropriately. The adhesive on the foam is delivered with a peel-off layer. It's useful to measure the foam carefully and then 'dry-fit' it once or twice to ensure a good fit. Then peel off the protective layer and stick it on. Here's a photo of the back of my engine compartment, after I ...

Company Info. Soundproofing America 1859 Lindbergh Street Suite 200 Charlotte, NC 28208 Call us at 1-800-823-6817

Last spring I needed to replace and upgrade the Sound Insulation / Sound Proofing on my boat after upgrading and installing a new engine in the boat. The engine compartment and panels had to be modified with the port side of the engine compartment needing to be moved out 1.5 inches and a new front panel made and Sound Insulation / Sound ...

2010. Boat Model. Limited S. Boat Length. 24. May 5, 2015. #18. I ordered 20 feet of bulb seal and used about 18. To line the entire engine compartment and hatch you need about 17 linear feet, 1 linear foot at McMaster Carr is 4 square feet as I recall.

How to Soundproof the Boat Engine and Products to Use. The best way to tackle boat noise is to focus on soundproofing the engine compartment. When soundproofing an inboard motor compartment, install a quality foam barrier to lose more than 30 dB of noise. Also, you will want to seal panel joints with a soundproofing sealant or tape to keep sound from leaking and ensure panels fit tightly together.

Quietpad has been developed for marine sound proofing but is a versatile product suitable for a range of demanding applications. It is a multilayer soundproofing system consisting of Class 0 foam, Quietstone barrier matt and aluminium facing. There is an optional self adhesive backing if required. Marine engine rooms create large amounts of low ...

Please try another query, or turn off the store toggle to view available products. Acoustical Foam. Insulation Hangers, Kit includes 10 hanging pins with washers and caps. Noise Reduction Seam Tape. Products. Articles. ON. Pickup Today at Raleigh change my store. Engine Sound Insulation Engine Sound Insulation.

Insulation is rated by its R-Value. The higher the R-Value, the more resistant to warm or cool air transfer it has. Here are MPBS, we recognize every job is different, which is why we offer free estimates and recommendations for each job. For a FREE estimate or for more information, please contact 208.882.4716 ext. 1330.

Rauch Insulation, LLC is a residential insulation contracting business based in Moscow, ID - serving the greater Latah County and the L/C Valley region. we specialize in conditioning residential living space by focusing on all aspects of the building envelope; ventilation, moisture, temperature, and noise transfer. Call today for a free estimate on new and remodeled homes.

Insulation Installer. We're on the lookout for motivated individuals who are dedicated to giving their best effort. Our commitment is to provide top-notch service as professionals in our field. At the core of our business, we aim to attract and keep individuals who share our passion for building a business grounded in values such as integrity ...